Prestressing force stiffened structure for concrete faced rockfill dam and construction method thereof

A face rockfill dam and prestressing technology, applied in dams, barrages, water conservancy projects, etc., can solve the problems of interlocking effect, difficult connection of reinforced structures, high cost, and reduce engineering costs, simple structure, and enhanced interlocking. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

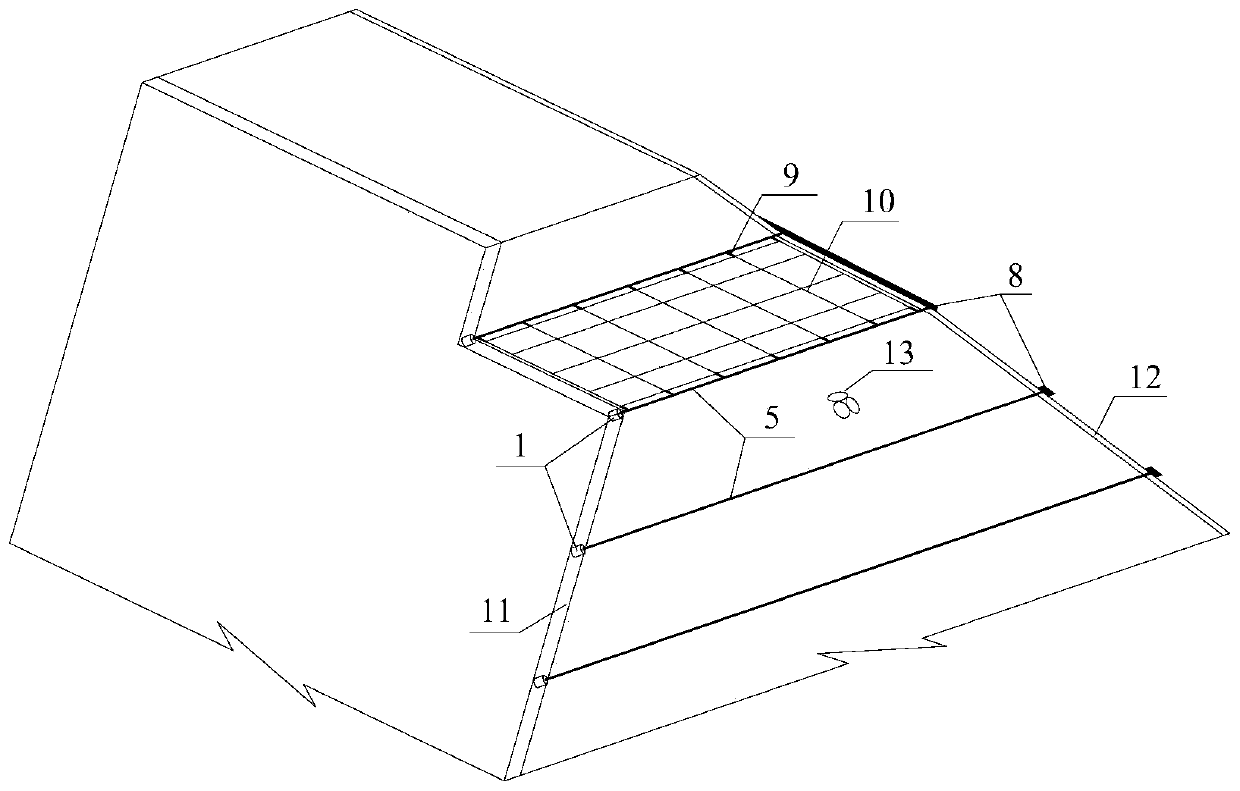

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

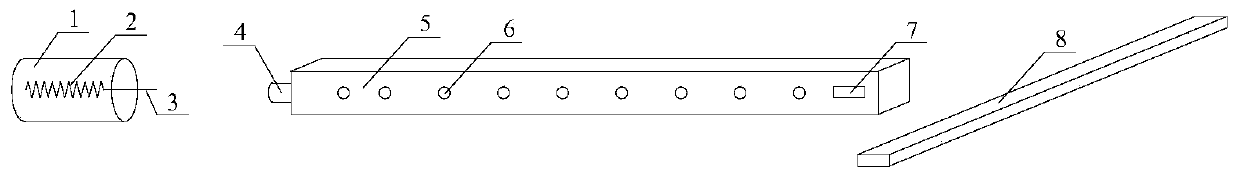

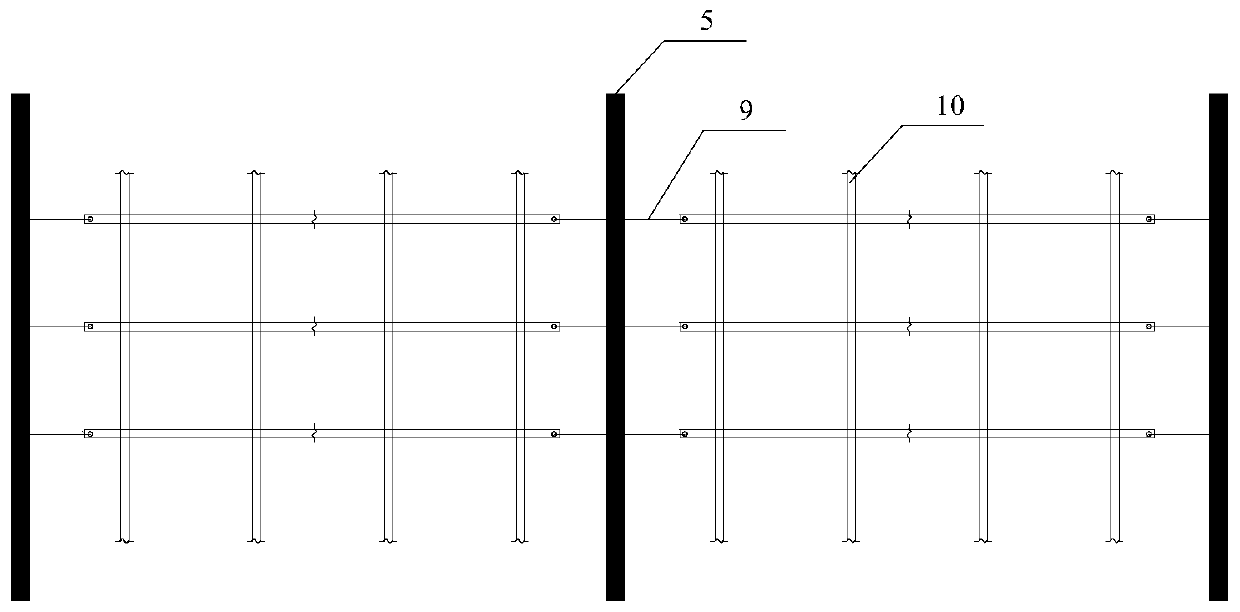

[0029] The prestressed reinforced structure of the face rockfill dam of the present invention is as Figure 1-4 As shown, it includes a spring tube 1, a reinforced beam 5, a retaining beam 8, a geogrid 10 (specifically, a steel-plastic geogrid), and a binding wire 9. The sleeve 4 is on the reinforced beam 5 , the retaining beam 8 is embedded in the reinforced beam 5 , and the binding wire 9 binds the geogrid 10 on the reinforced beam 5 .

[0030] Such as figure 1 As shown, the spring tube 1 is hollow, the shell is metal, and a spring 2 is arranged inside. One end of the spring 2 is fixedly connected to the tube wall, and the other end is fixedly connected to the ribbed steel bar 3 (for example, threaded steel bar), and the ribbed steel bar 3 protrudes from the tube wall. There are threaded buckles at the end. The diameter of the spring tube 1 may be 100mm-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com