Rolling and spreading type roof greening structure and greening method thereof

A technology of roof greening and roll-laying, which is applied in botany equipment and methods, container cultivation, gardening, etc., can solve the problems of complex construction process and large space occupation, and achieve simple construction steps, large space occupation, storage and transportation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

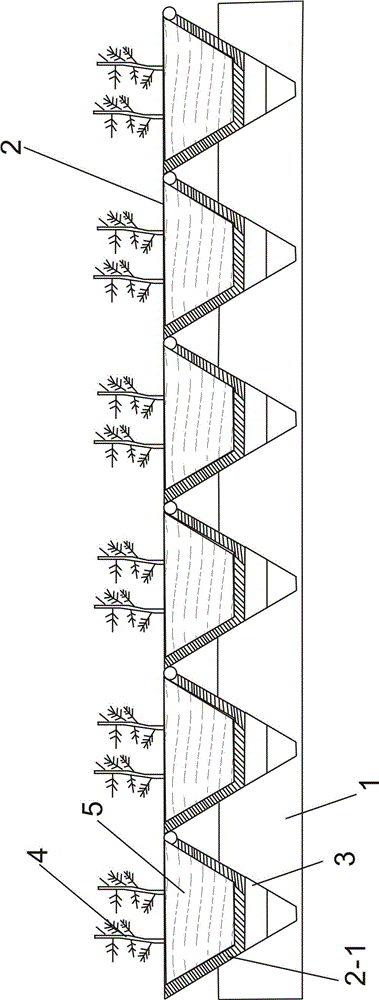

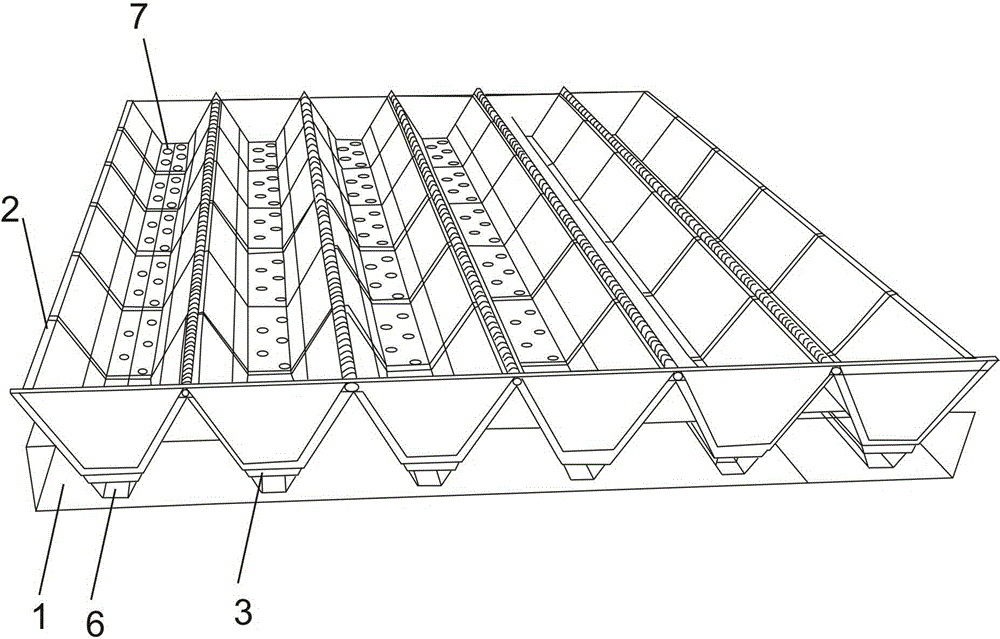

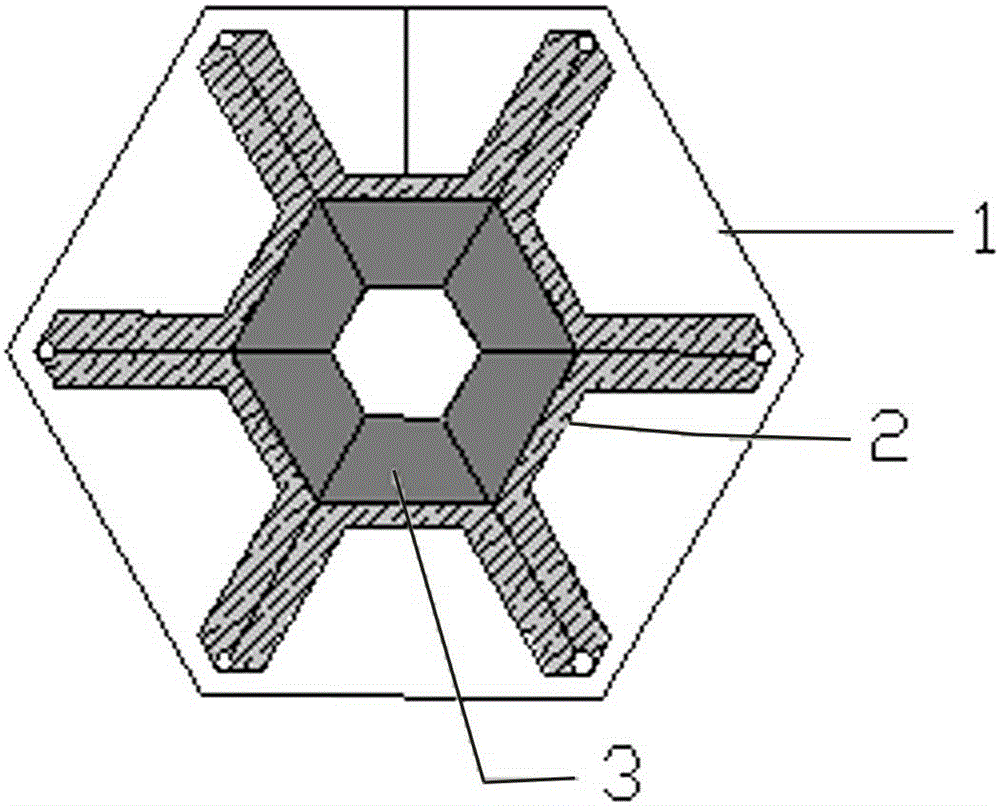

[0039] Such as figure 1 , figure 2 and image 3 As shown, a rolling green roof structure,

[0040] It includes a support base plate 1 that can be rolled and laid, a planting base groove 2 and a spacer plate 3;

[0041] The support base plate 1 is composed of five base plate units 1-1 and connection units 1-2 respectively located on both sides of the whole body composed of five base plate units 1-1, each base plate unit 1-1 and each connection unit 1- 2 is a long strip, the cross section of the base plate unit 1-1 is an isosceles trapezoid, the cross section of the connecting unit 1-2 is a right angle trapezoid, and the cross section of the two connecting units 1-2 is spliced with the base plate The cross-sections of the units 1-1 are consistent, each base unit 1-1 and the connection unit 1-2 are connected to each other to form a foldable whole, and the five base units 1-1 and the two connection units 1-2 forming a plurality of vacant slots 6;

[0042] The planting foun...

Embodiment 2

[0050] A method for greening a roof by using the above-mentioned rolling roof greening structure, the method comprising the following steps:

[0051] 1) Roof site treatment: according to the drainage situation, the green structure shall be reasonably arranged, leveled and waterproofed with polyvinyl chloride membrane;

[0052] 2) Expand the rolling roof greening structure as a whole into layers, and divide it into supporting base plate 1, planting base groove 2, and spacer plate 3;

[0053] 3) Expand the supporting base plate 1 and lay it on the roof site treated in step 1;

[0054] 4) Between each base unit 1-1 supporting the base plate 1, a spacer board 3 is laid in the vacant groove 6 between the base plate unit 1-1 and the connection unit 1-2;

[0055] 5) Place the planting foundation groove 2 on the supporting base plate 1, place each base groove unit 2-1 of the planting base plate 2 on the spacer plate 3 of each vacant groove 6 of the supporting base plate 1, and make t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com