Prefabricated energy dissipation and shock absorption filled wallboard

An infill wall and prefabricated technology, applied in the direction of walls, shockproof, building components, etc., can solve the problems of reduced lateral stiffness, reduced seismic damage, inconvenient installation of doors or windows, etc., to achieve the effect of easy installation and easy assembly and construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

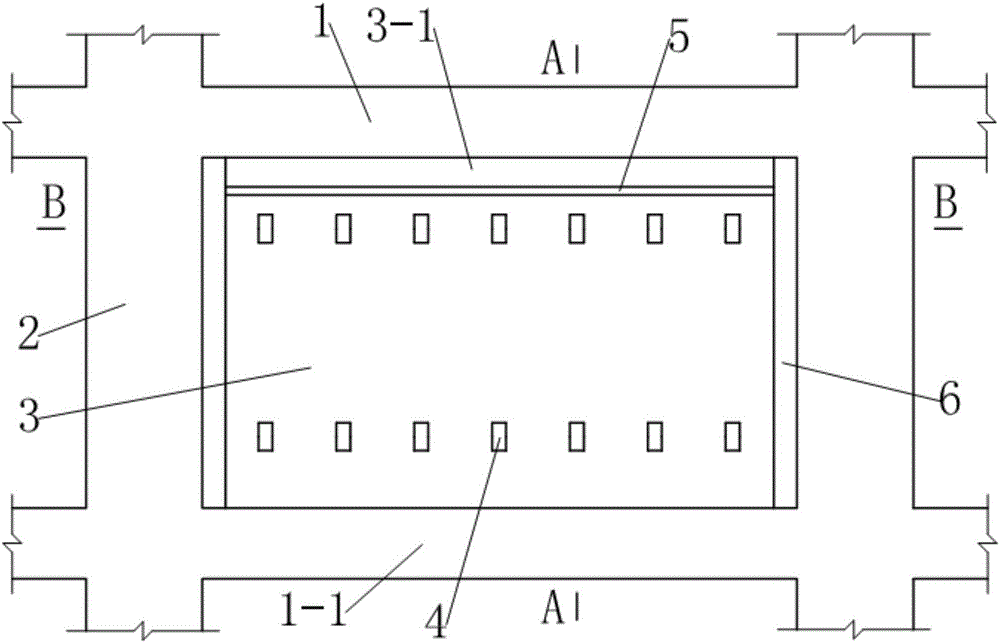

[0021] This example is a concrete frame with a span of 4200mm and a floor height of 3300mm. The cross-sectional size of the frame column is 500mm×500mm, and the cross-sectional size of the frame beam is 300mm×500mm; the concrete strength grade is C30; Design Code" (GB50010-2010) and "Code for Seismic Design of Buildings" (GB50011-2010).

[0022] see Figure 1~3 , the energy-dissipating and shock-absorbing filling wallboard in this example has a masonry that is filled in the space enclosed by the upper frame beam 1, the lower frame beam 1-1 and the frame columns 2 on both sides; The shock-absorbing concrete slabs 3 respectively fixed on the upper frame beam 1 and the lower frame beam 1-1 and the flexible waterproof filler polystyrene in the structural joints 6 between the shock-absorbing concrete slab 3 and the frame columns 2 on both sides Ethylene foam composition;

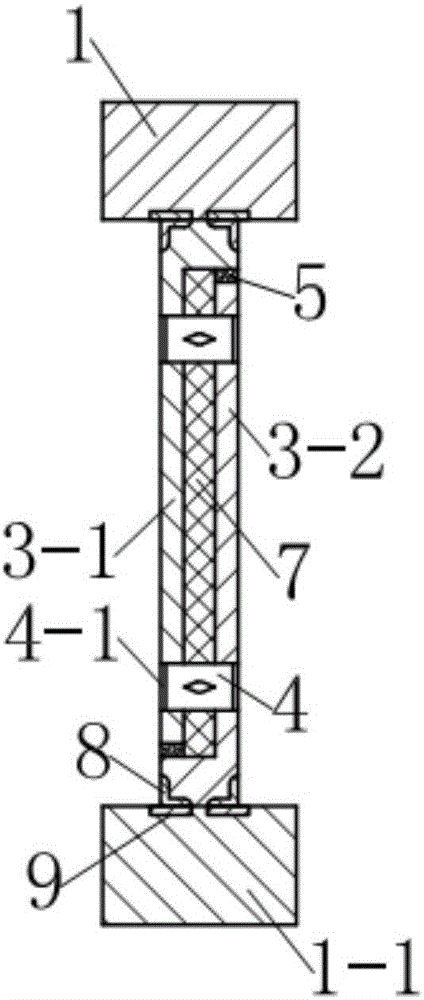

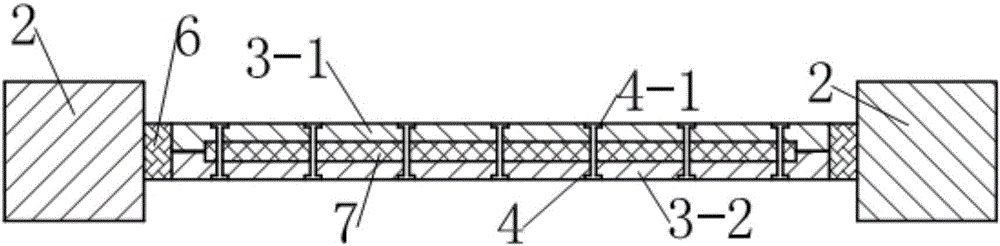

[0023] see figure 2 and image 3 , the shock-absorbing concrete slab 3 includes a vertical section of the ...

example 2

[0027] see Figure 4 and 5 , the energy-dissipating riveting member 4 described in this example is three rows of steel rods vertically passing through the insulation layer 7, and the number of each row is 7 pieces. The middle part of the steel rods is provided with an annular groove, and the bottom of the groove is arc-shaped; The two ends of the steel rod are respectively riveted to the outer surfaces of the two panels through steel plates 4-1. The implementation method of this example except the above is the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com