Shear wall construction process based on fully prefabricated floor slab

A construction technique and shear wall technology, applied in formwork/formwork/work frame, joints of formwork/formwork/work frame, walls, etc., can solve transportation and installation troubles, high construction cost, and large manpower consumption Material resources and other issues, to achieve the effect of convenient assembly and construction, reduce construction cost, and reduce difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

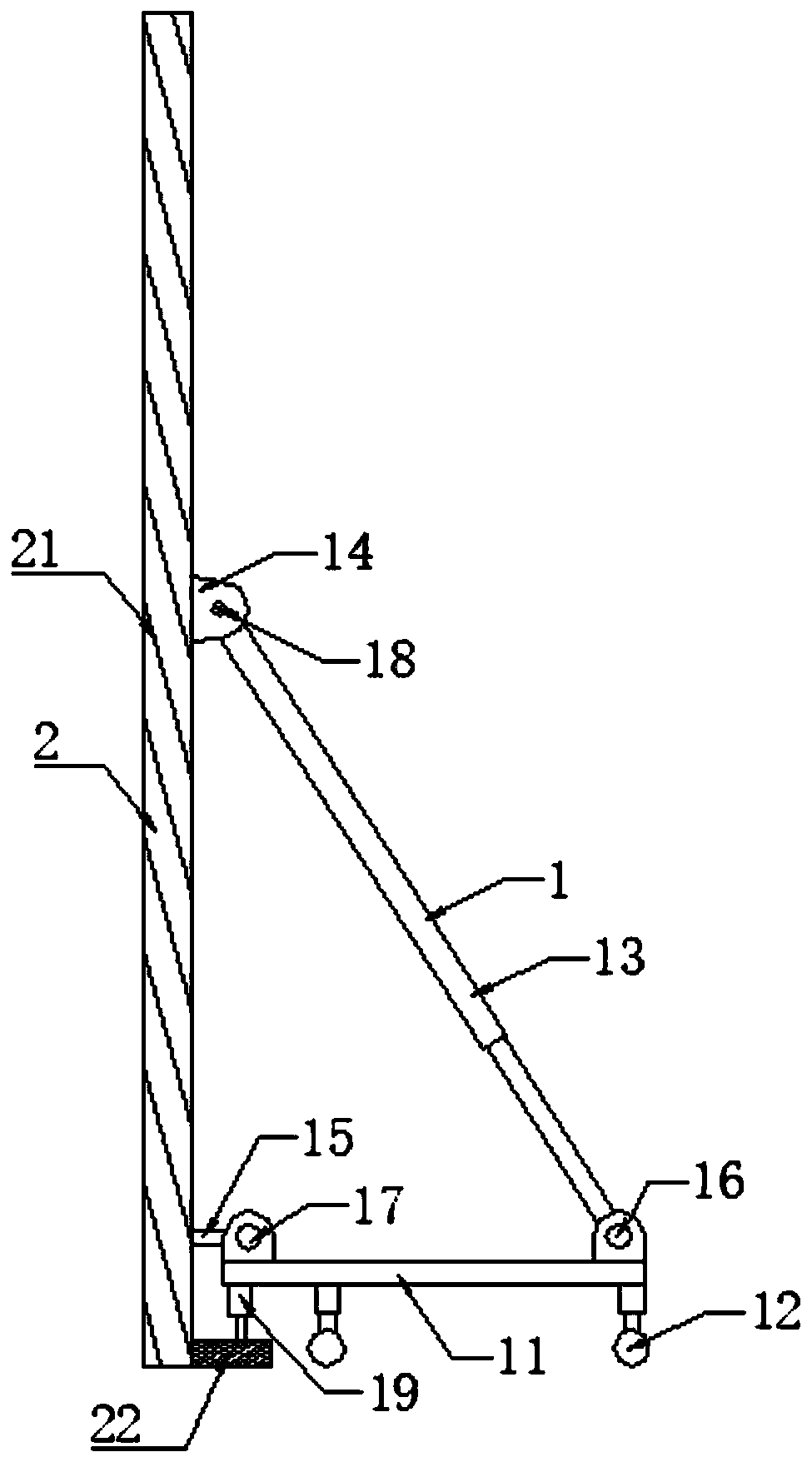

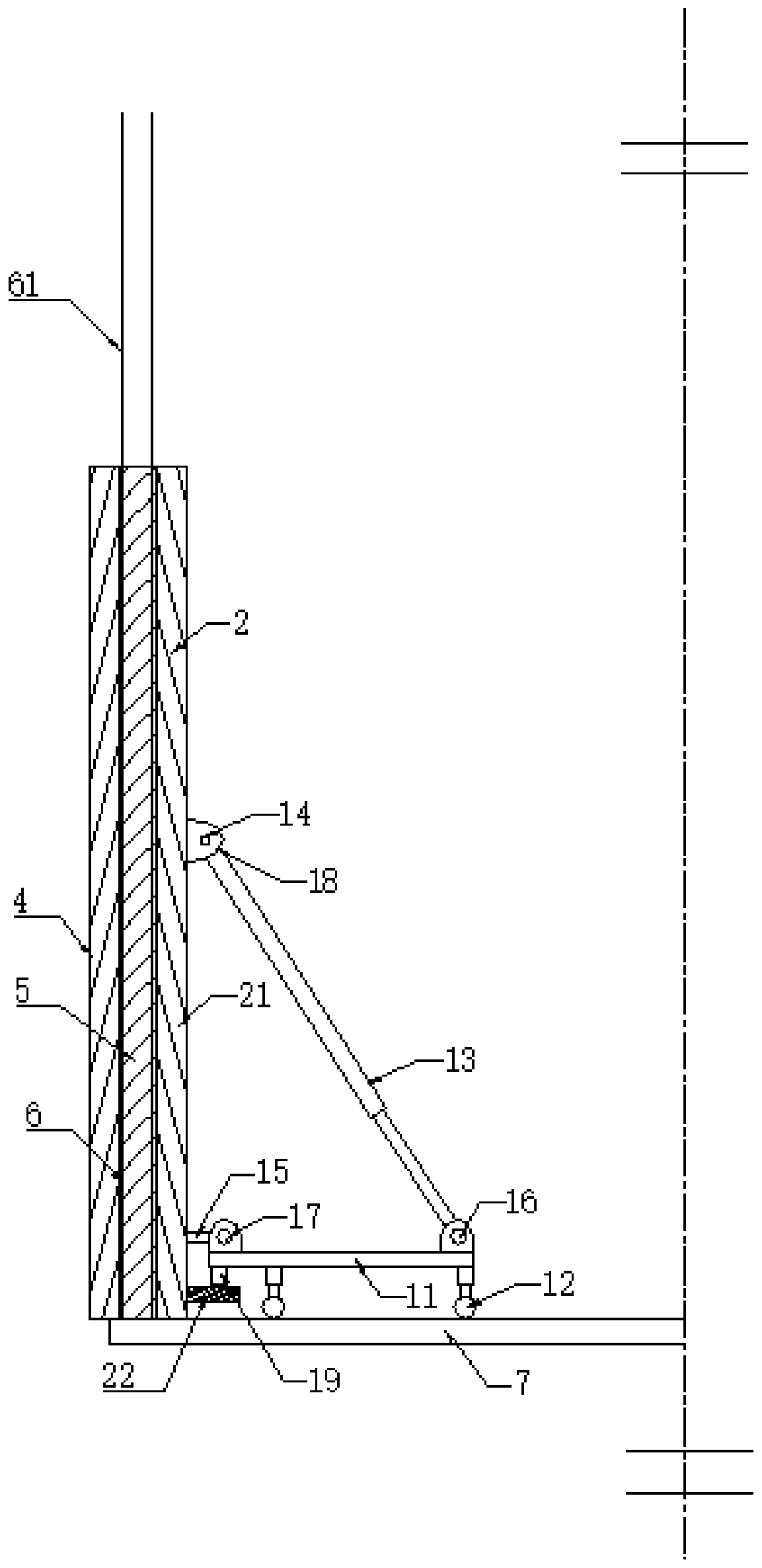

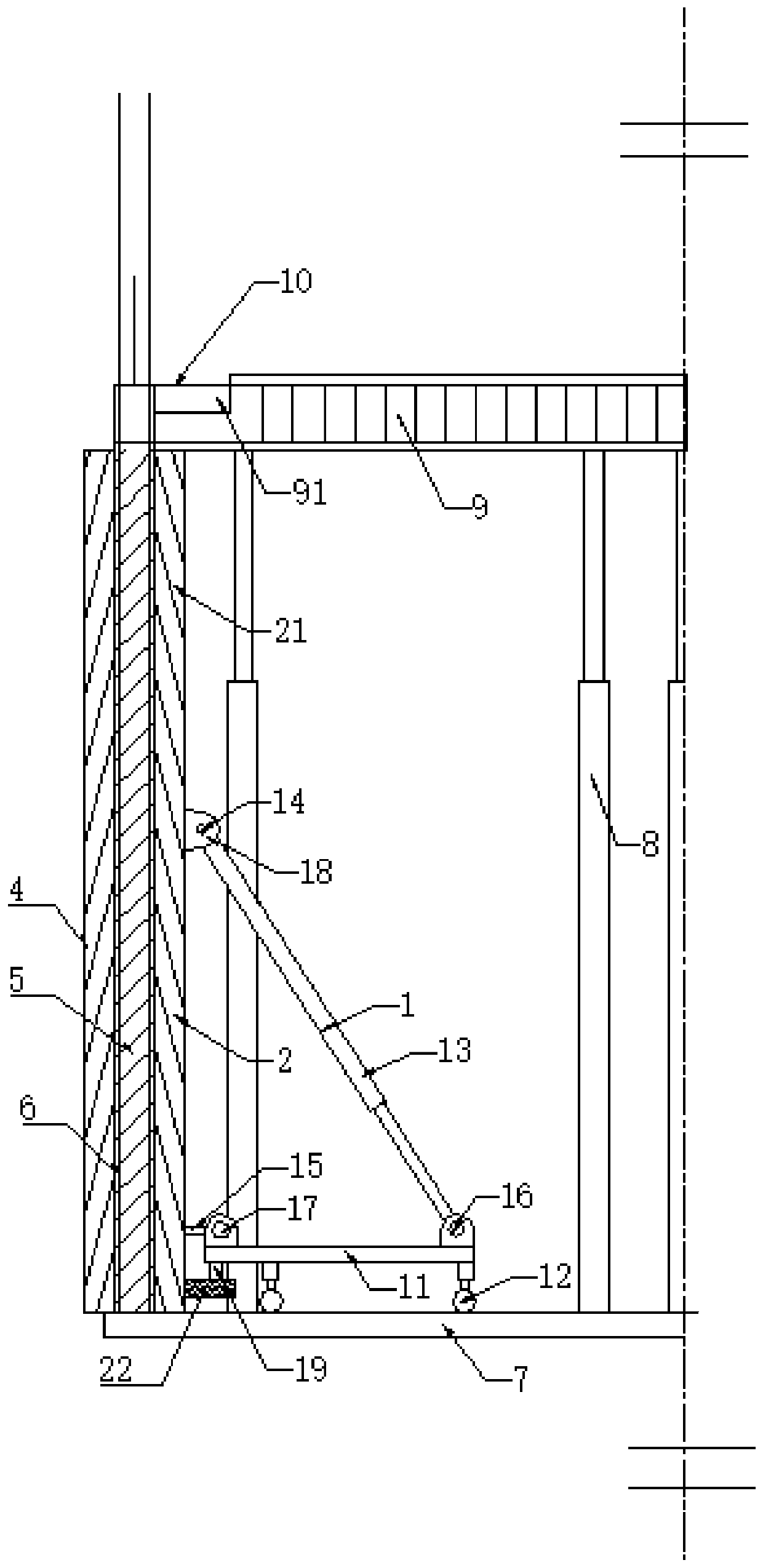

[0039] Such as Figures 1 to 7 As shown, a shear wall construction process based on a fully prefabricated floor includes the following steps:

[0040] (1) After the construction of the standard layer 7 is completed, the shear wall reinforcement 6 of the bottom layer is bound, and the upper end of the shear wall reinforcement 6 is reserved with a connecting reinforcement 61, and the height of the upper end of the connecting reinforcement 61 exceeds the preset elevation of the upper floor slab ;

[0041] (2) Install the shear wall inner formwork 2 and the shear wall outer formwork 4 respectively on both sides of the shear wall reinforcement 6, and the shear wall inner formwork 2 and the shear wall outer formwork 4 are all set as slices Type shear wall formwork;

[0042] (3) Concrete is poured to described shear wall reinforcing bar 6, treats that concrete maintenance is finished, promptly finishes the described shear wall 5 construction of bottom (state as figure 2 shown); ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com