Tensioning device and method for applying prestressing force on high bending moment prestressed concrete electric pole

A tensioning device and prestressing technology, which is applied in the processing of building materials, construction, building construction, etc., can solve problems such as safety accidents, production safety accidents, steel plate ring deformation, etc., to ensure construction quality, facilitate assembly and construction, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

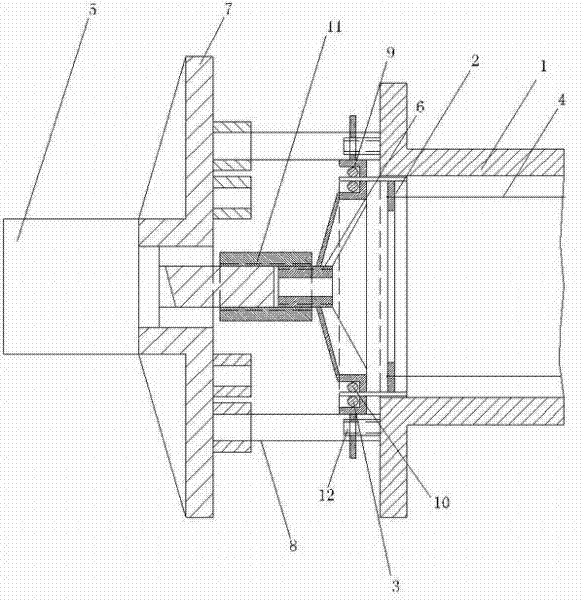

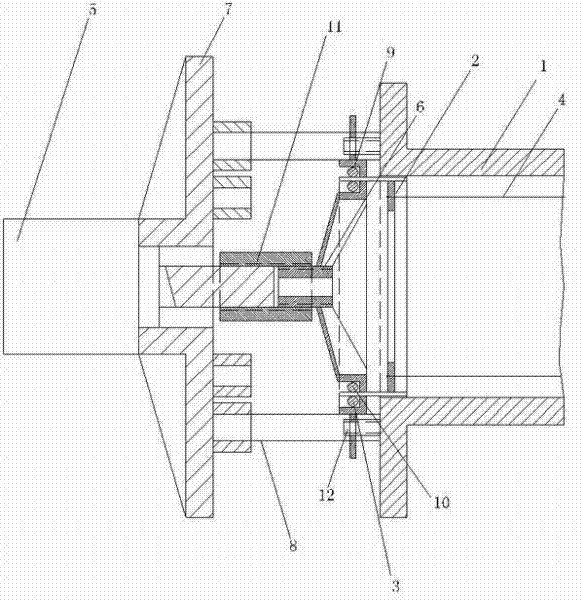

[0021] see figure 1 , the present invention includes a hollow steel mold 1 with an open end and a flange plate on the outside of the port, a steel ring 2, an outer arc rib 3 fixed on the outer wall of the steel ring 2, a steel bar 4 anchored on the steel ring 2, Jack 5, tension claw 6, support frame 7, fixed plate 9 inner arc rib 10 and tension nut, steel plate ring 2 and steel bar 4 are arranged inside steel mold 1 and steel plate ring 2 is fixed with outer arc rib 3 and protrudes To the outside of the steel mold 1, the support frame 7 is set on the jack 5, and the middle part of the support frame 7 is provided with a through hole for the pull shaft of the jack 5 to pass through, and the pull shaft of the jack 5 passes through the through hole of the support frame 7 and extends to the support On the other end of the frame 7, the tension claw 6 is connected to the pull shaft of the jack 5 through a tension nut 11 threaded, and the support frame 7 withstands the flange plate of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com