Energy dissipation and shock absorption assembly type infilled wallboard structure

A technology of filling wall and slab structure, applied in the direction of wall, earthquake resistance, building components, etc., can solve the problems of reducing the seismic response of the structure, inconvenient for on-site construction, inconvenient for quick repair, etc., to prevent damage, strong energy consumption, The effect of high tensile yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

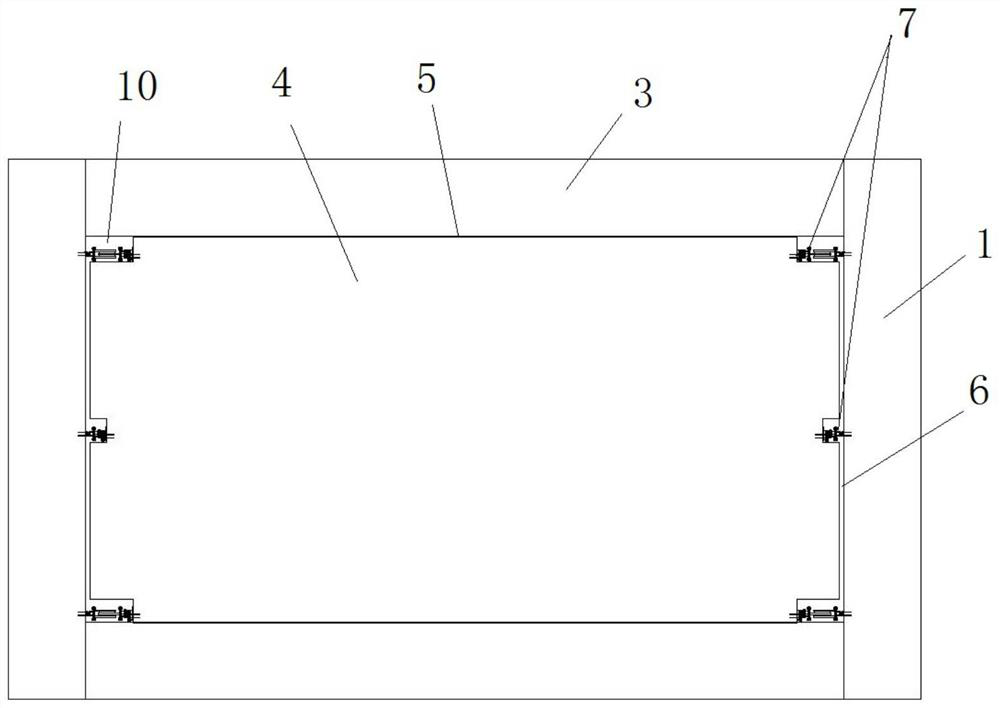

[0032] Such as Figure 1-8 As shown, it includes a frame composed of frame columns 1 and frame beams 3 and a wall panel structure inside the frame. In this embodiment, the frame is a concrete frame with a span of 5400mm and a floor height of 3000mm. The cross-sectional dimensions of the left and right frame columns are both 500mm×500mm, and the cross-sectional dimensions of the top and bottom beams are both 300mm×500mm. The design strength of the concrete The grade is C30. The reinforcement of beams and columns is determined according to "Code for Design of Concrete Structures" (GB50010-2010) and "Code for Seismic Design of Buildings" (GB50011-2010).

[0033] A damping layer 5 is installed between the wall panel 4 and the frame beam 3; a flexible filler 6 is filled between the wall panel 4 and the frame column 1;

[0034] The flexible filler 6 is a PU foaming agent.

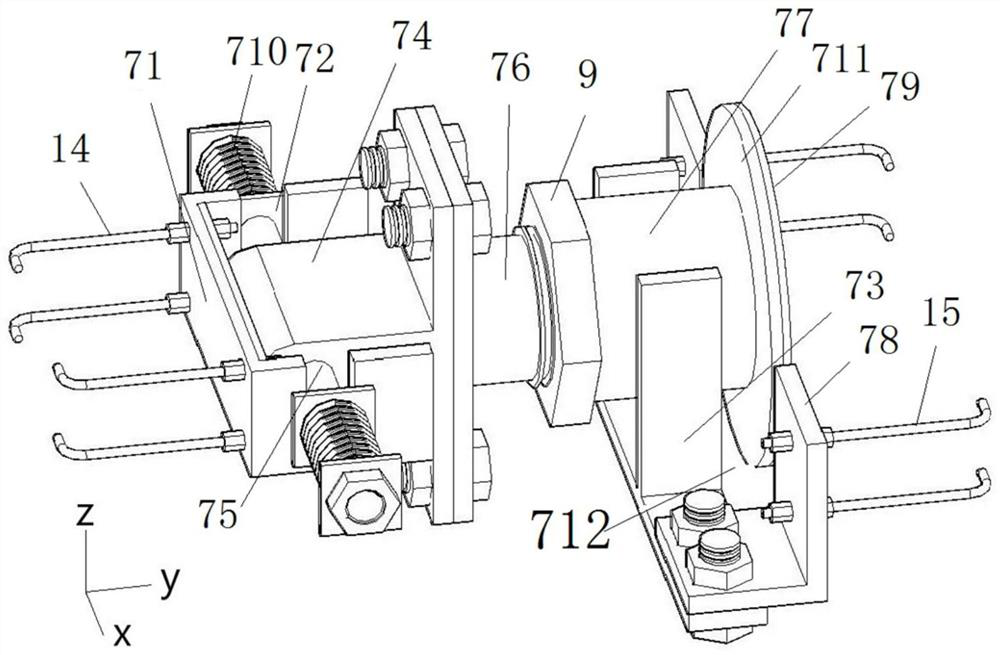

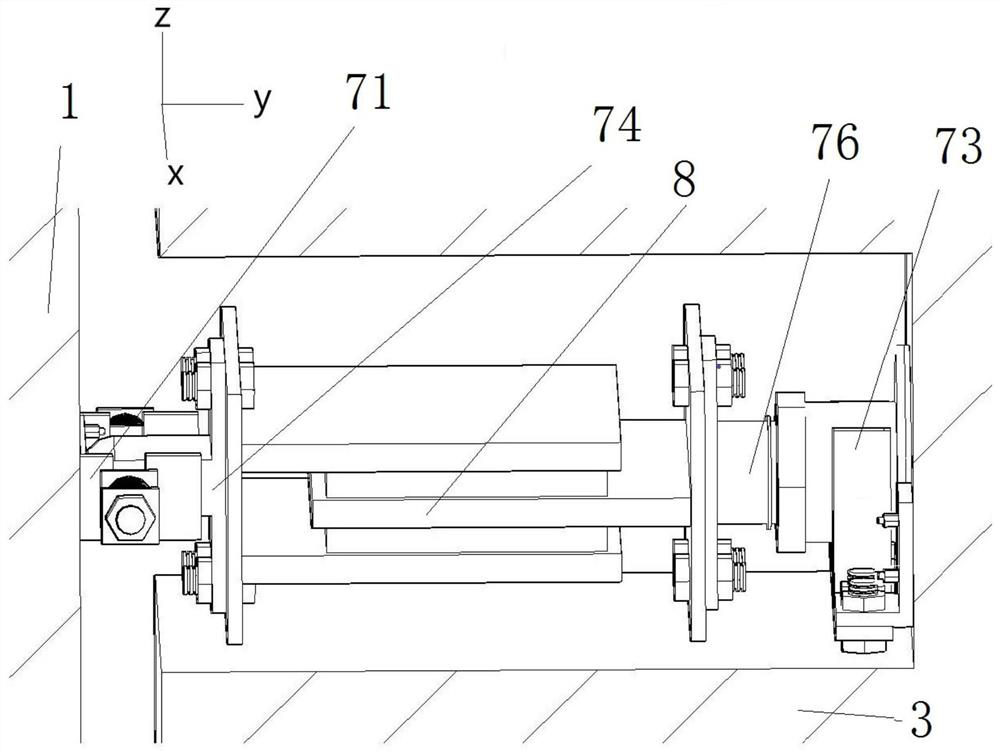

[0035] The connecting structure 7 includes a pre-embedded fixture and a connecting piece; the pre-embedded ...

Embodiment 2

[0068] On the basis of Example 1, in order to further increase the anti-seismic finishing of the wall panels, the following improvements are made: flexible fillers 6 are filled between the wall panels 4 and the frame beams and frame columns.

[0069] Wallboard 4 is a rectangular wallboard, and the rectangular wallboard includes two L-shaped sub-wallboards 41 of the same size and shape; the two L-shaped sub-wallboards 41 are rotationally symmetrically arranged with the geometric center of the rectangular wallboard; The horizontal contact interface of the sub-wall panel 41 is on both sides of the wall panel 4, and the horizontal contact interface is filled with a damping layer 5, and is connected to each other through the in-plane bending deformation energy dissipator 19 of the steel plate; the two L-shaped sub-wall panels 41 The vertical contact interface is in the middle of the wallboard 4, and the impact buffer layer 18 is fixed at the vertical contact interface, and the flexi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com