Assembly type pavement structure and construction method

A prefabricated pavement technology, applied to roads, roads, and pavements paved with prefabricated blocks, etc., can solve the lack of integrity and adjustment ability of the pavement structure, pretensioning prestressing technology is not considered, and assembly construction is inconvenient and other problems, to achieve high-efficiency assembly construction design, enhance adjustment and repairability, and solve the effect of difficult quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

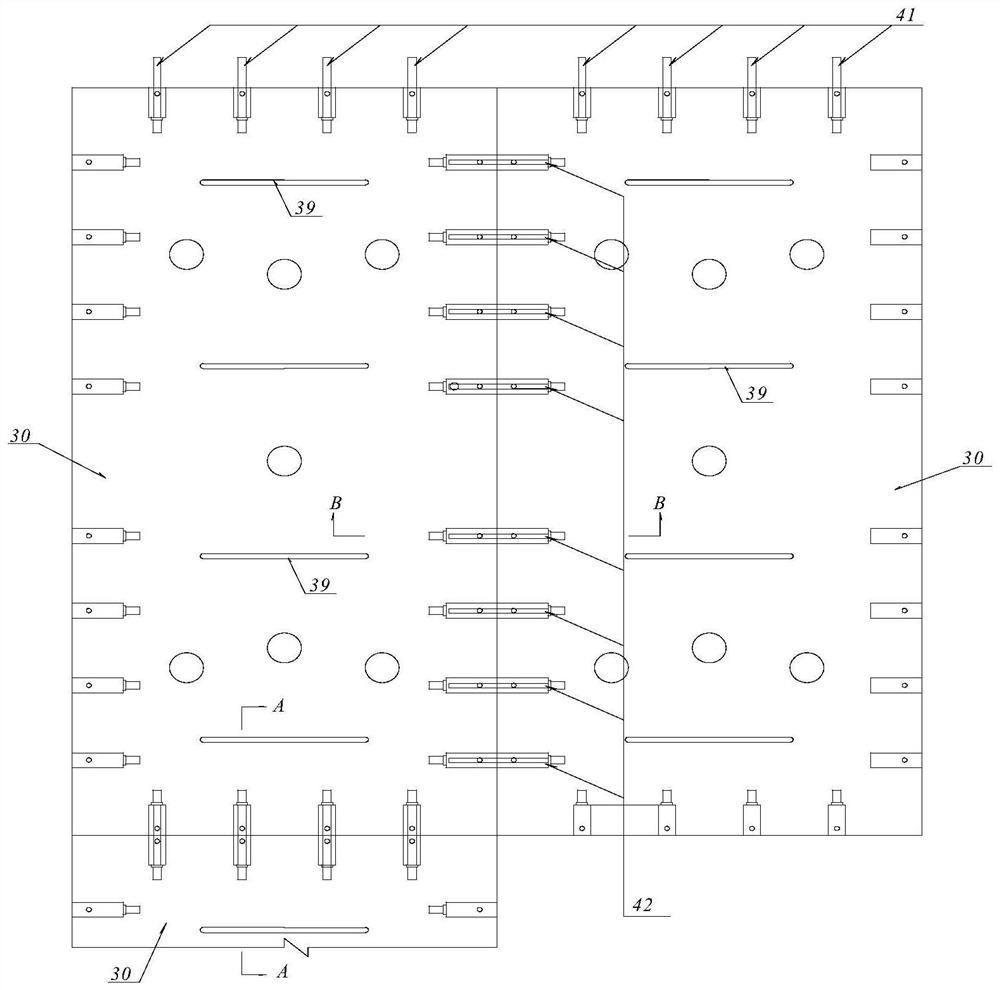

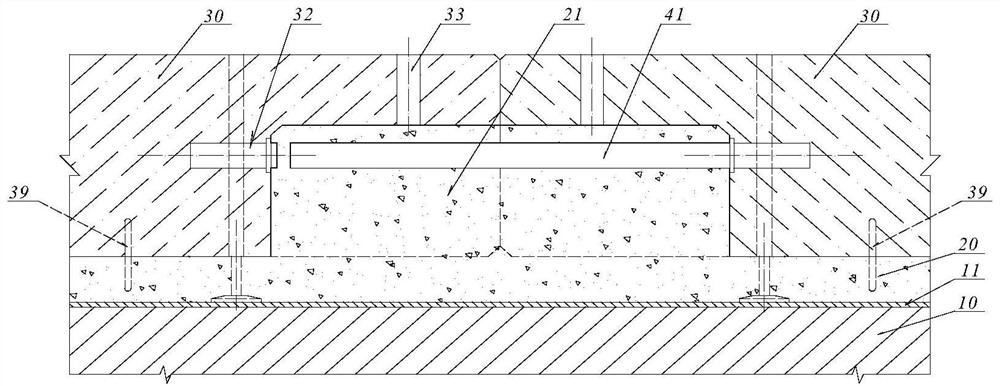

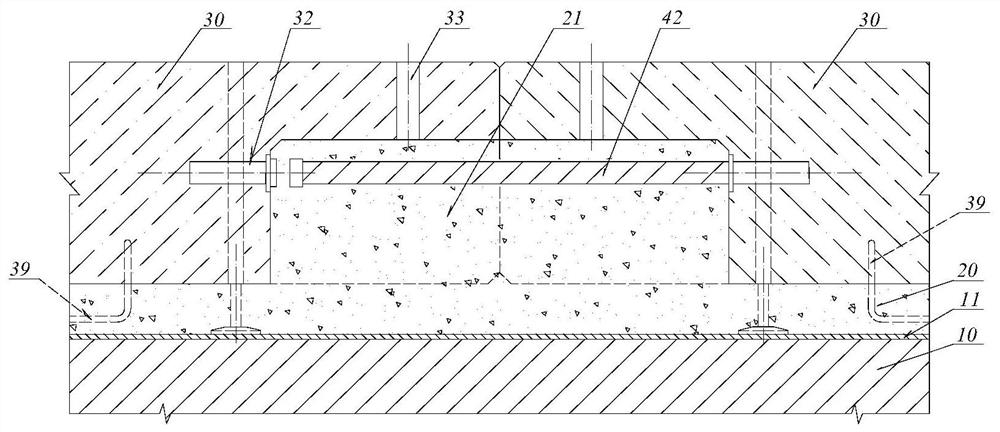

[0053] refer to figure 1 and Figure 7 , a prefabricated pavement structure of the present invention, the prefabricated pavement panel 30 is assembled on the subgrade 10 to form a prefabricated pavement. The prefabricated path panel 30 adopts prestressed reinforced concrete structure, and each precast path panel 30 is provided with vertical lower grooves 31a at intervals along the width direction at two longitudinal connection ends, and horizontal lower grooves 31b at intervals along the width direction at two transverse connection ends. Two adjacent castor panels 30 are provided with rod-shaped connecting members in corresponding longitudinal lower grooves 31a or transverse lower grooves 31b. An isolation layer 11 is laid on the surface of the roadbed 10, and after the prefabricated road panel 30 in assembly is leveled, self-compacting concrete is de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com