Assembly joint of prefabricated column and integrated prefabricated beam plate and construction method of assembly joint

A technology for assembling nodes and prefabricated columns, applied in floors, building components, buildings, etc., can solve the problems of low standardization design and industrialized production of prefabricated components, affecting the overall stiffness and seismic performance of nodes, unfavorable construction efficiency and construction quality, etc. Achieve the effect of reducing temporary auxiliary support, reducing manufacturing difficulty and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

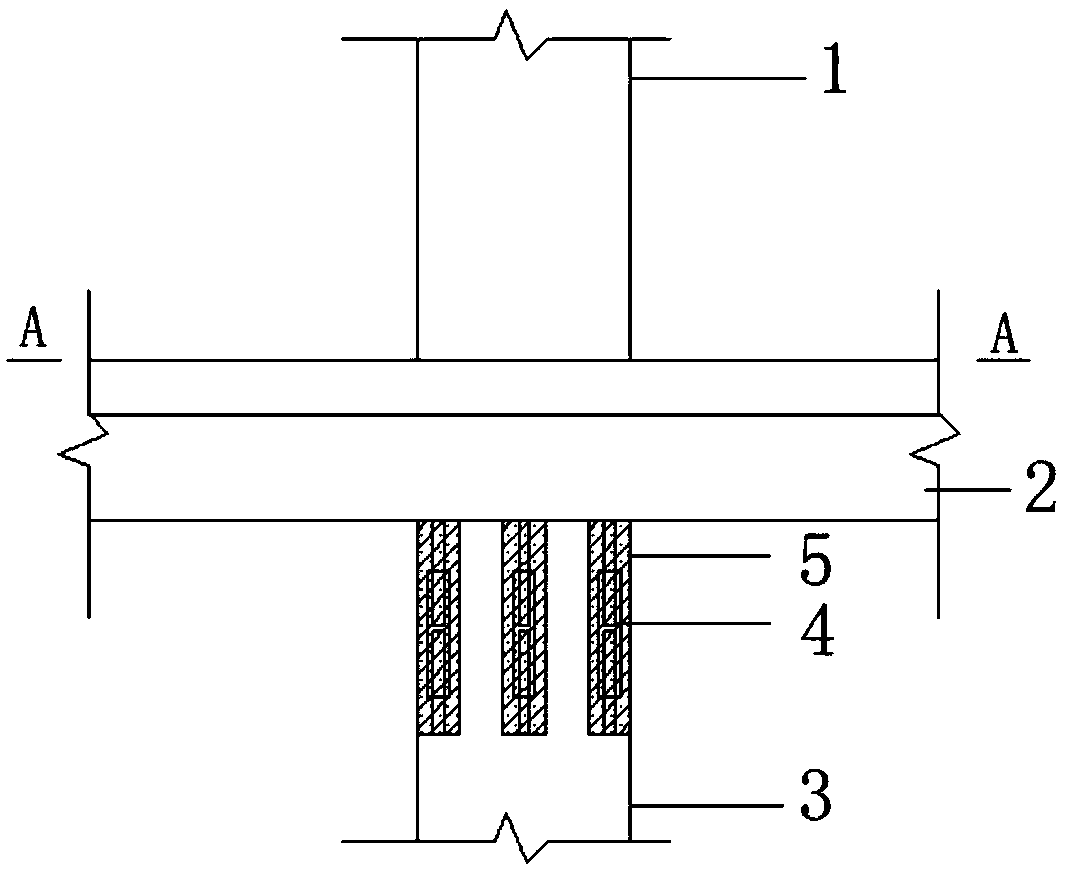

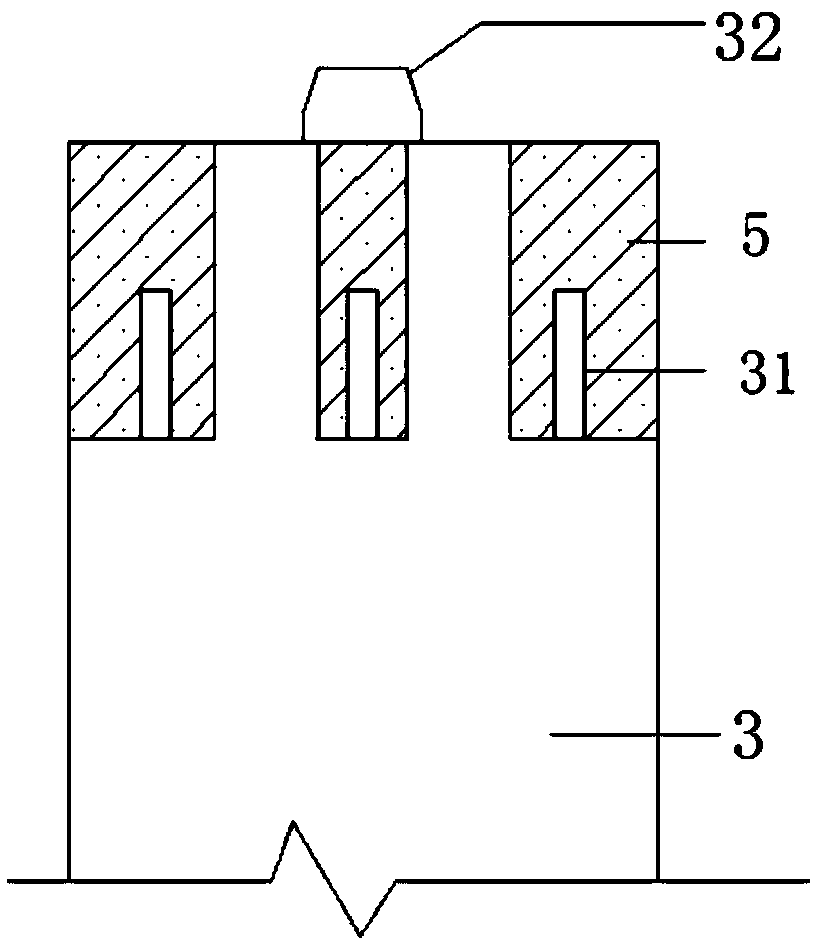

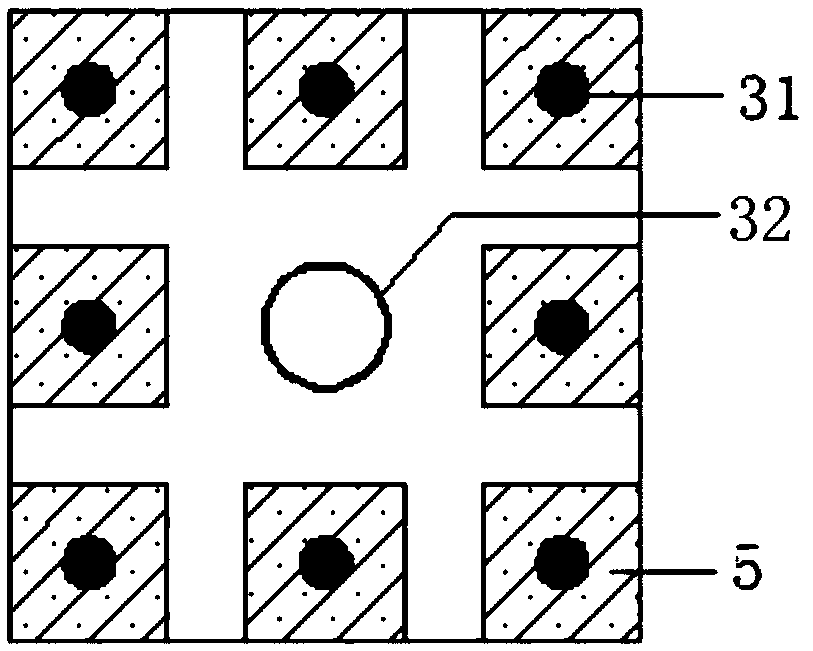

[0049] see Figure 1-3 , the assembly node of the prefabricated column and the integrated prefabricated beam slab of the specific embodiment includes a horizontal integrated prefabricated beam slab 2 and a vertical prefabricated column; the prefabricated column includes a lower prefabricated column 3 and an upper prefabricated column 1; the lower precast column The upper surface of 3 is provided with a concave post-casting connection area 5, and the lower prefabricated column 3 is reserved with several vertical upward reserved longitudinal ribs 31, and the upper reserved longitudinal ribs 31 are connected from the post-casting The bottom surface of the area 5 extends out and the extended length is less than the depth of the post-pouring connection area 5, the number of the post-pouring connection area 5 corresponds to the upper reserved lon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com