Bearing-socket type prefabricated pier connecting structure and construction method thereof

A connection structure, socket-type technology, applied in infrastructure engineering, bridges, bridge parts, etc., can solve the problems of hidden safety hazards, difficulty in checking the fullness of grouting, and high construction fault tolerance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

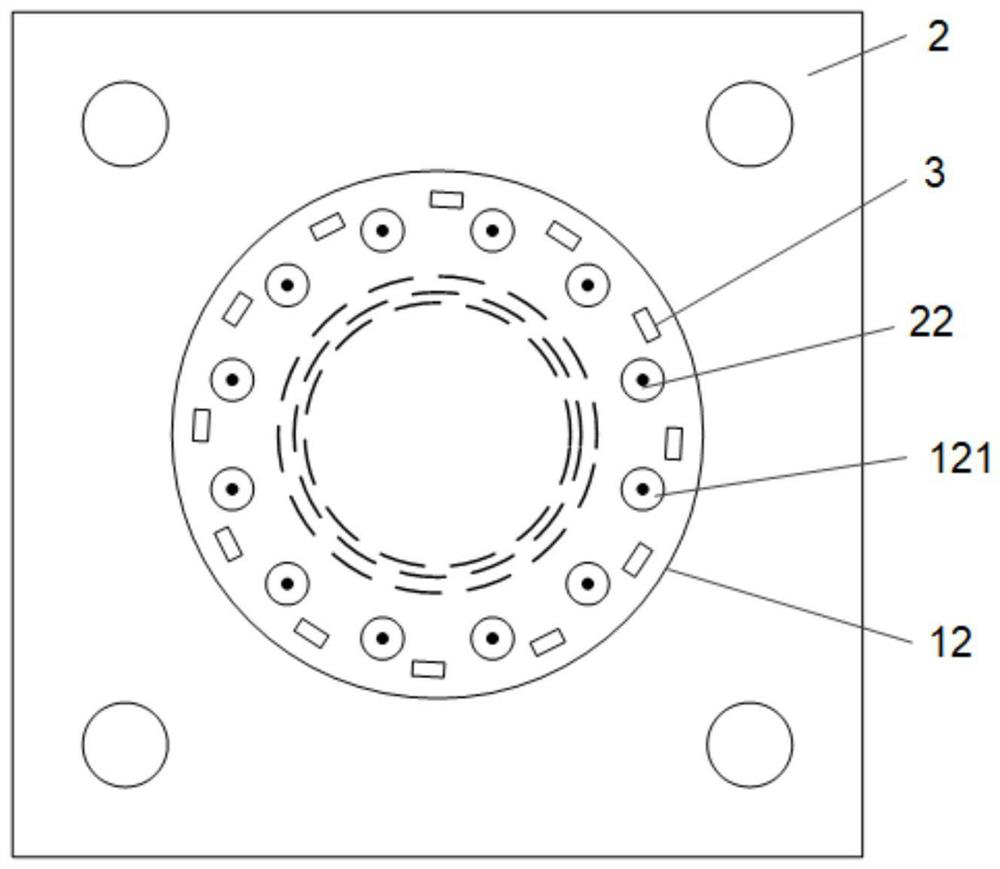

[0035] see Figure 1 to Figure 3 As shown, the present invention provides a supporting-socket type prefabricated bridge pier connection structure, including a prefabricated pier body 1 and a cap 2 arranged under the prefabricated pier body 1;

[0036] The middle part of the platform 2 is provided with a platform groove 21 with an upward opening along the vertical direction, see figure 1 As shown, there are several pre-buried steel bars 22 arranged vertically in the platform cap 2, see figure 2 As shown, in this embodiment, a total of twelve steel bars 22 reserved for the cap are provided, and the twelve steel bars 22 reserved for the cap are distributed on the outer side of the groove 21 of the cap along the circumference, and the reserved steel bars 22 for the cap are A certain length of free end protrudes from the upper surface of the bearing platform 2. In this embodiment, the reserved steel bar 22 of the bearing platform is a vertical steel bar with a 90° hook at the bot...

Embodiment 2

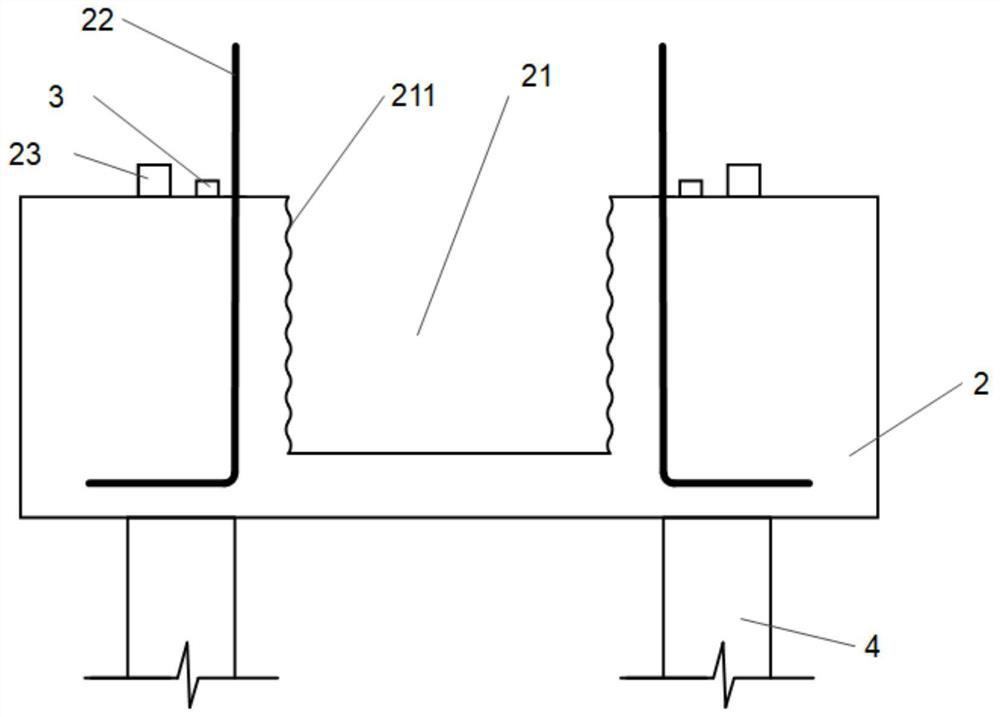

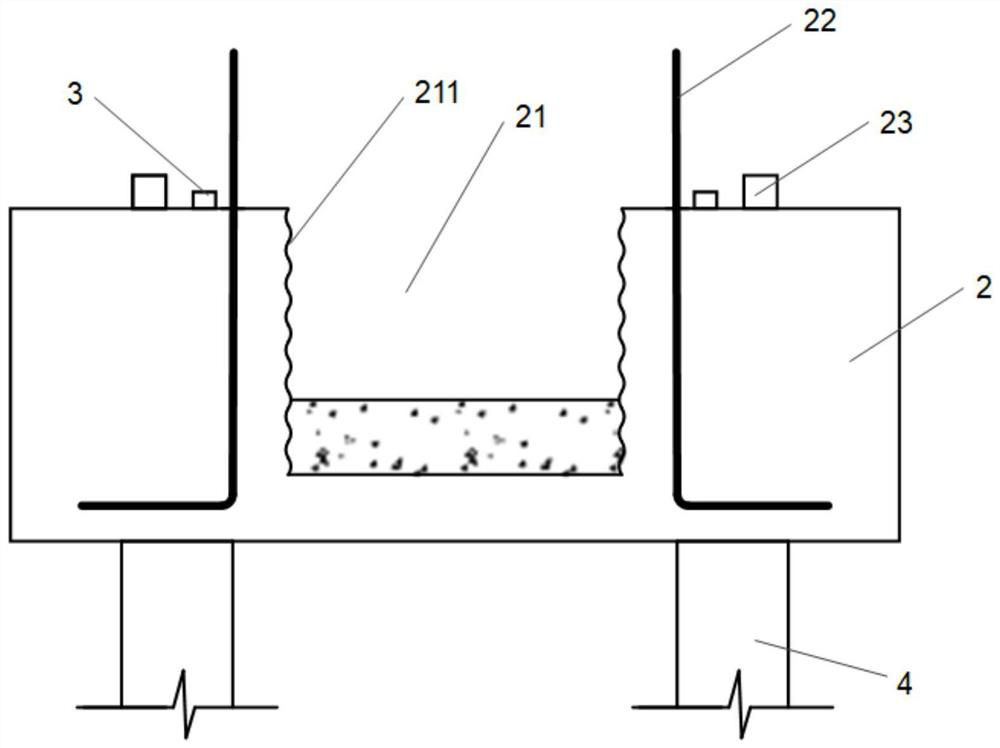

[0044] Based on the same inventive idea, see Figure 4 to Figure 7 As shown, the present invention also provides a construction method for a supporting-socket type prefabricated pier connection structure, comprising the following steps:

[0045] The cap 2 is fixed on the bridge pile foundation 4, and the cap 2 is provided with a cap groove 21 with an upward opening, and a number of pre-embedded steel bars 22 for the cap are embedded in the cap 2 along the vertical direction. The platform reserved steel bars 22 are distributed on the outer side of the platform groove 21 along the circumference, and the platform reserved steel bars 22 extend a certain length of free end from the upper surface of the platform 2;

[0046] see Figure 4 As shown, pour an appropriate amount of high-strength grouting material in the cap groove 21;

[0047] see Figure 5 As shown, the prefabricated pier body 1 is hoisted on the cap 2, and the gasket 3 is set on the cap 2 to adjust the vertical conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com