Buried pipeline construction method

A construction method and technology of buried pipelines, which are applied in pipeline laying and maintenance, pipes/pipe joints/fittings, lifting equipment braking devices, etc., which can solve problems such as high mechanical shift costs, difficult operation, and short pipeline lengths , to achieve the effect of saving the cost of mechanical shifts, reducing the difficulty of operation, and easily grouping and constructing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is further described below.

[0030] The buried pipeline construction method disclosed by the present invention comprises the following steps:

[0031] a. Excavate pipe trenches and transport materials in place;

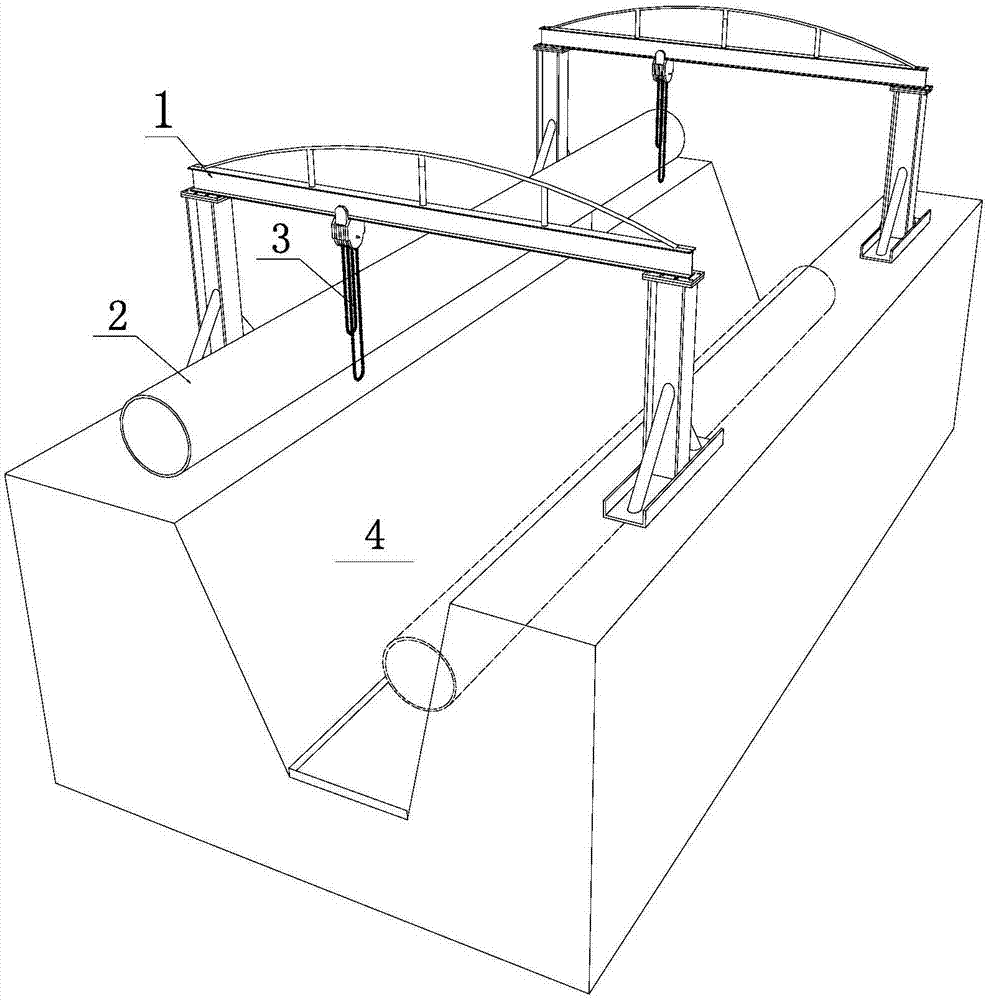

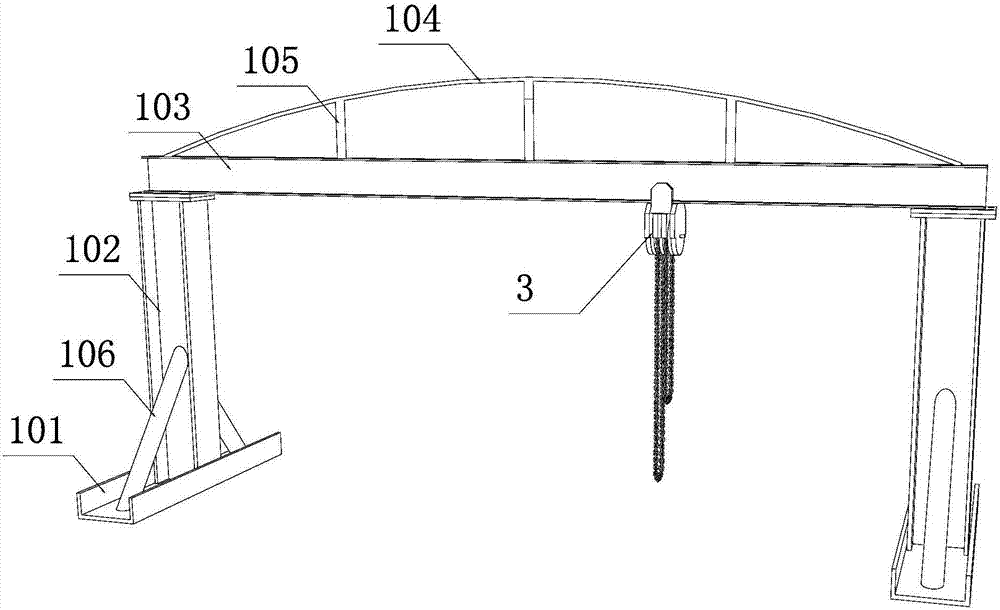

[0032] b. After the trench is excavated and the materials are in place, set up the trench pipeline transfer frame. The trench pipeline transfer frame includes at least two portal frames 1, and the portal frame 1 includes a base 101, a column 102, and a hoisting beam And upside down, the base 101 is set on both sides of the gantry 1, the column 102 is set on the base 101, the lifting beam 103 is set above the columns 102 on both sides, and the lifting beam 103 has a beam slide rail, the beam slide rail is provided with an inverted chain,

[0033] The gantry 1 is erected across and arranged above the pipe ditch, and a distance for placing the pipe 2 is reserved between a base 101 of the gantry 1 and the pipe ditch;

[0034] During constr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com