Assembling light steel pipe-constraint small-diameter wood combined bearing column and manufacturing method

A technology of small-diameter wood and load-bearing columns, which is applied in the direction of columns, pier columns, pillars, etc., can solve the problems of low assembly efficiency, poor bearing capacity, and low resource utilization rate, and achieve the effect of improving bearing capacity and convenient construction and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific embodiment:

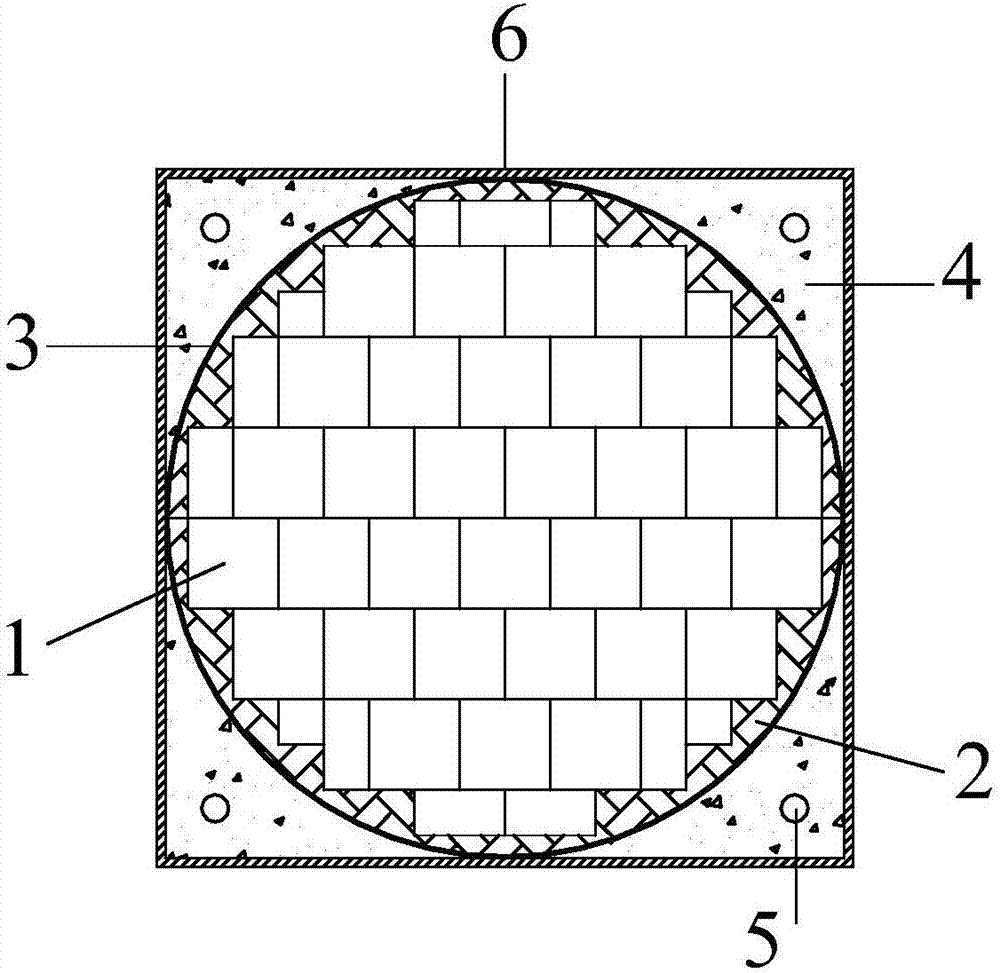

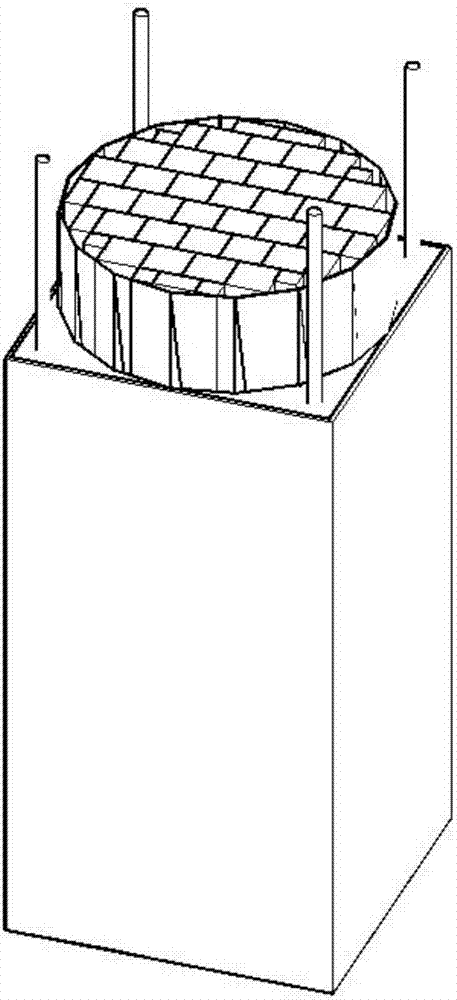

[0025] Such as Figure 1-2 As shown, a light-weight steel pipe-constrained small-diameter wood composite load-bearing column of the present invention includes small-diameter wood 1, sawdust filler 2, FRP carbon fiber cloth 3, concrete 4, pre-embedded connecting steel bars 5 and light steel pipes 6. The interior is filled with small-diameter wood, and the periphery is FRP carbon fiber cloth. At the same time, wood chip filler 2 is poured into the remaining gaps to form an internal filling structure. The external formwork composed of concrete 4, pre-embedded connecting steel bars 4 and light steel pipe 6 can realize prefabricated connection, and the construction is simple and convenient. At the same time, small-diameter timber is rationally developed and utilized, which is more green and environmentally friendly, and is suitable for low and multi-storey new building systems ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com