Isomerization reactor component made from sealing fabric and preparation method of isomerization reactor component

A reactor and isomerization technology, which is applied in the field of isomerization reactor components and its preparation, can solve the problems of lengthening or truncating heavy workload, long installation and disassembly time-consuming, cumbersome bell jar design and manufacture, etc. Achieve the effects of increasing the effective filling volume, easy splicing, and convenient block preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

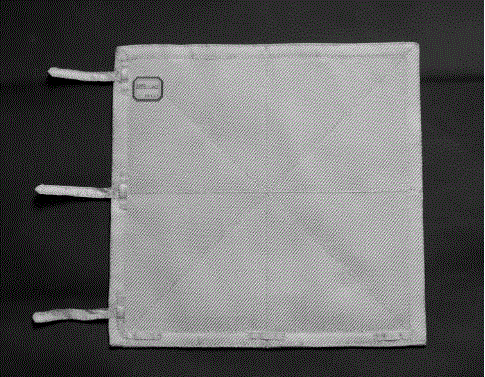

[0042] a kind of like Figure 1-Figure 3 The isomerization reactor component of the sealing fabric material of the present invention is shown, the isomerization reactor component is formed by combining and splicing a plurality of square fabric unit blocks; each fabric unit block is a multi-layer fabric stitching structure , including a sandwich structure of an upper laying layer, an intermediate layer and a lower laying layer, wherein both the upper laying layer and the lower laying layer adopt a ceramic fiber fabric structure, and the ceramic fiber fabric structure adopts a single layer of twill quartz fiber cloth, and the twill quartz The thickness of the fiber cloth is 0.7 mm, the weaving parameter is 12 threads / cm in warp density, and 10 threads / cm in weft density, and a layer of 316L stainless steel foil with a thickness of 0.03 mm is used for the middle layer. A plurality of the aforementioned fabric unit blocks are spliced together by connecting pieces.

[0043] Such...

Embodiment 2

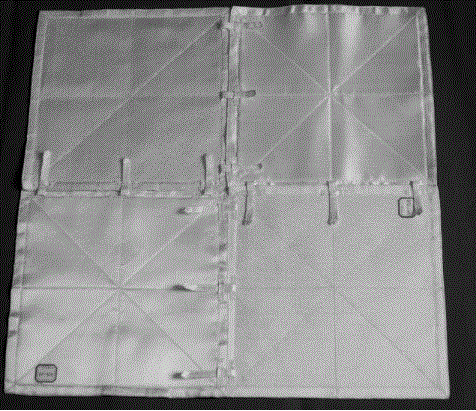

[0052] a kind of like Figure 4 The isomerization reactor component of the sealing fabric material of the present invention is shown, the isomerization reactor component is formed by combining and splicing a plurality of square fabric unit blocks; each fabric unit block is a multi-layer fabric stitching structure , including a sandwich structure of an upper laying layer, an intermediate layer and a lower laying layer, wherein both the upper laying layer and the lower laying layer adopt a ceramic fiber fabric structure, and the ceramic fiber fabric structure adopts a twill silicon carbide fiber cloth laid in a single layer, and the twill The thickness of the silicon carbide fiber cloth is 0.4 mm, the weaving parameters are 9 wires / cm in warp density, 5 wires / cm in weft density, and a layer of 304L stainless steel foil with a thickness of 0.05 mm is used for the middle layer. A plurality of the aforementioned fabric unit blocks are spliced together by connecting pieces.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com