Multi-baffle counterflow photo-catalytic reaction device

A catalytic reaction, countercurrent light technology, applied in the detailed information of chemical/physical/physical chemical reactors, chemical instruments and methods, chemical/physical processes, etc., can solve the problem that the contact area between the reaction solution and the catalyst is not much improved, Can not fully mix the solid-liquid two phases, can not be fully stirred, etc., to achieve the effect of less catalyst consumption, easy separation, and high utilization of light energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

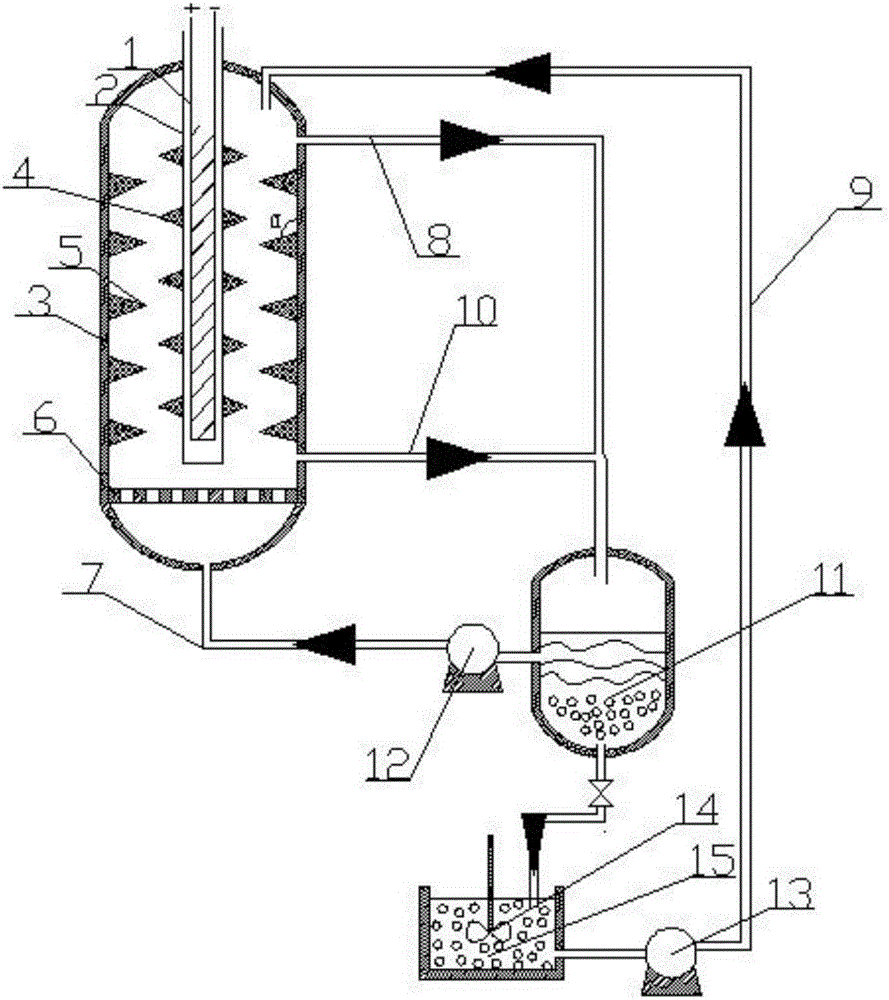

[0020] Such as figure 1 As shown, the action process of the device is as follows,

[0021] S1 closes the valve at the bottom of the catalyst settling tank 11, and adds the reaction liquid, and when the liquid level of the reaction liquid exceeds the reaction liquid inlet 7, open the pump 12. When the reaction liquid in the cylindrical-conical reaction tower 3 can flow back to the catalyst settling tank 11 from the reaction liquid outlet 8, stop adding the reaction liquid to realize liquid phase circulation.

[0022] S2 turns on light source 1.

[0023] S3 adds solid catalyst from the upper part of the cylindrical conical reaction tower 3, and the static mixing through the multi-stage baffle can fully contact with the reaction solution. 11 The bottom settles, open the valve at the bottom of the catalyst settling tank 11, and add a certain amount of reaction solution.

[0024] S4 When the catalyst suspension liquid level exceeds the blade agitator 14, open the blade agitator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com