Overhead line system hard cross beam connected in welded manner and construction method thereof

A welding connection and construction method technology, which is applied in the processing of building materials, overhead lines, building types, etc., can solve the problems of complex construction process requirements, difficult construction, and many processes, so as to eliminate the phenomenon of rework, simplify the construction process, Guarantee the effect of construction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A construction method of a welded catenary hard beam, comprising the following steps:

[0034] Step 1: Foundation pouring, use theodolite to measure to ensure that the centerlines of each foundation are in a straight line, and use a level to measure the elevation of each foundation, and use a laser rangefinder and a level to measure the center between two adjacent foundations distance;

[0035] Step 2: Calculate the laxity required for the crossbeam of the hard crossbeam according to the vertical load received by the hard crossbeam under normal operating conditions. The vertical load includes the self-weight of the crossbeam, the maintenance load and the static load. The static load is a suspension installation After the catenary, the load generated due to the self-weight of the catenary;

[0036] Step 3: According to the foundation elevation measured in Step 1, determine the height of each steel column of the hard beam and perform prefabrication;

[0037] Step 4: Acc...

Embodiment 2

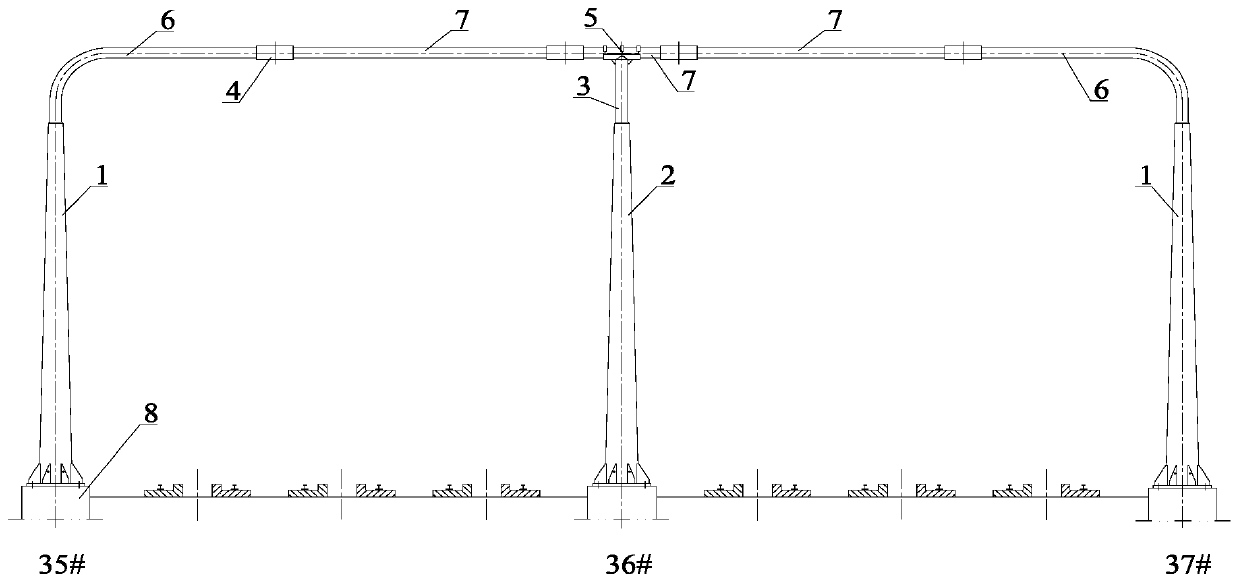

[0043] Such as figure 1 As shown, a kind of catenary hard beam connected by welding includes several steel columns, and the steel columns include two side columns 1 and several intermediate columns 2, and column top columns 3 are arranged on the top of the intermediate columns 2 . The catenary hard crossbeam also includes several crossbeams, and the crossbeam includes a crossbeam side section 6 and a crossbeam straight section 7 , and the crossbeam side section 6 and the crossbeam straight section 7 are assembled and connected by connecting sleeves 4 .

[0044] Both the steel column and the crossbeam are prefabricated structural parts, the height of the steel column is determined according to the measured elevation of the foundation 8, the length of the crossbeam is determined according to the measured center distance between the two foundations 8, and the crossbeam The negative sag is determined according to the vertical load on the beam under normal operating conditions. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com