PC light composite sandwich thermal-insulated integrated wallboard

A lightweight, integrated technology, applied in the direction of insulation, walls, building components, etc., can solve the problems of unsatisfactory thermal performance of PC insulation integrated board, inconvenient transportation and construction hoisting, and unfavorable force of the main structure, so as to improve the overall insulation Energy-saving effect, light weight, convenient construction and hoisting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

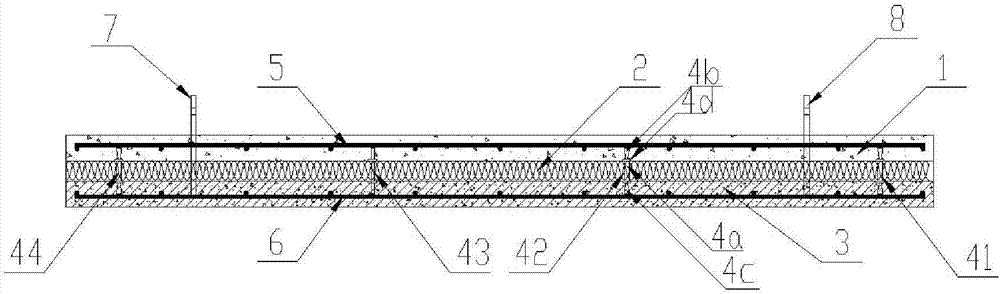

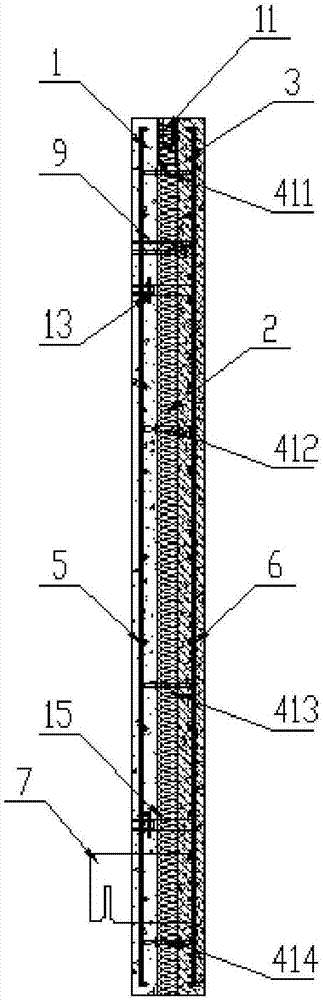

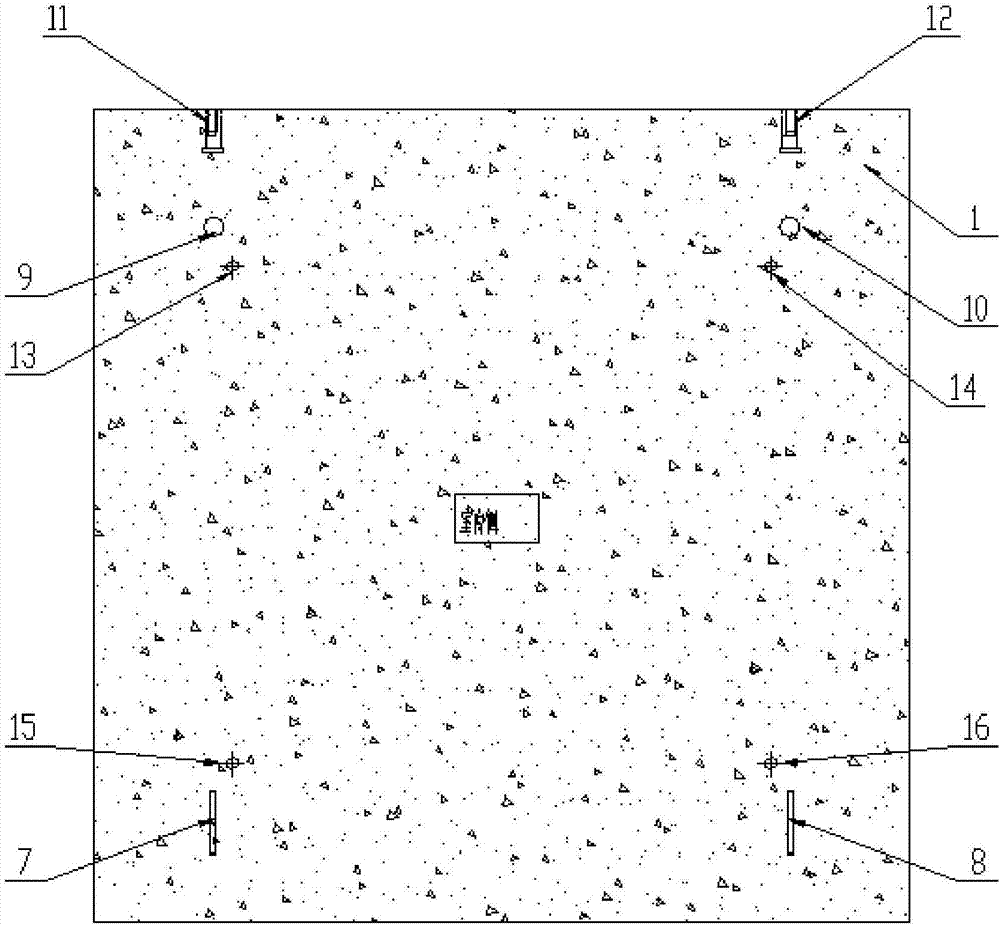

[0022] In this embodiment, the PC lightweight composite sandwich insulation integrated wallboard, combined with figure 1 and figure 2 , comprising an inner blade 1, an insulation layer 2 and an outer blade 3 in turn, the inner mesh 5 is set in the inner blade 1, and the outer mesh 6 is arranged in the outer blade 3; the outer mesh 6 and the inner mesh 5 are connected with several connectors 41, 42, 43, 44 and 411, 412, 413, 414, and the outer mesh 6 is provided with embedded parts 7, 8, which penetrate the insulation layer 2 And the inner vane 1, the outer end of which protrudes above the inner surface of the inner vane 1.

[0023] In order to achieve a better use effect, the above scheme can be further configured: the outer leaf plate 3 is formed by solidification of ordinary concrete, and the inner leaf plate 1 is formed by solidification of lightweight high-strength foamed concrete slabs. The outer leaf plate 3 is made of ordinary concrete material, which is located on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com