Novel recycled block concrete prefabricated assembly type constructional column and construction method thereof

A prefabricated and concrete technology, applied in building structures, columns, pillars, etc., can solve the problems of cast-in-place structural columns not easy to vibrate, increase labor costs, and poor quality of structural columns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

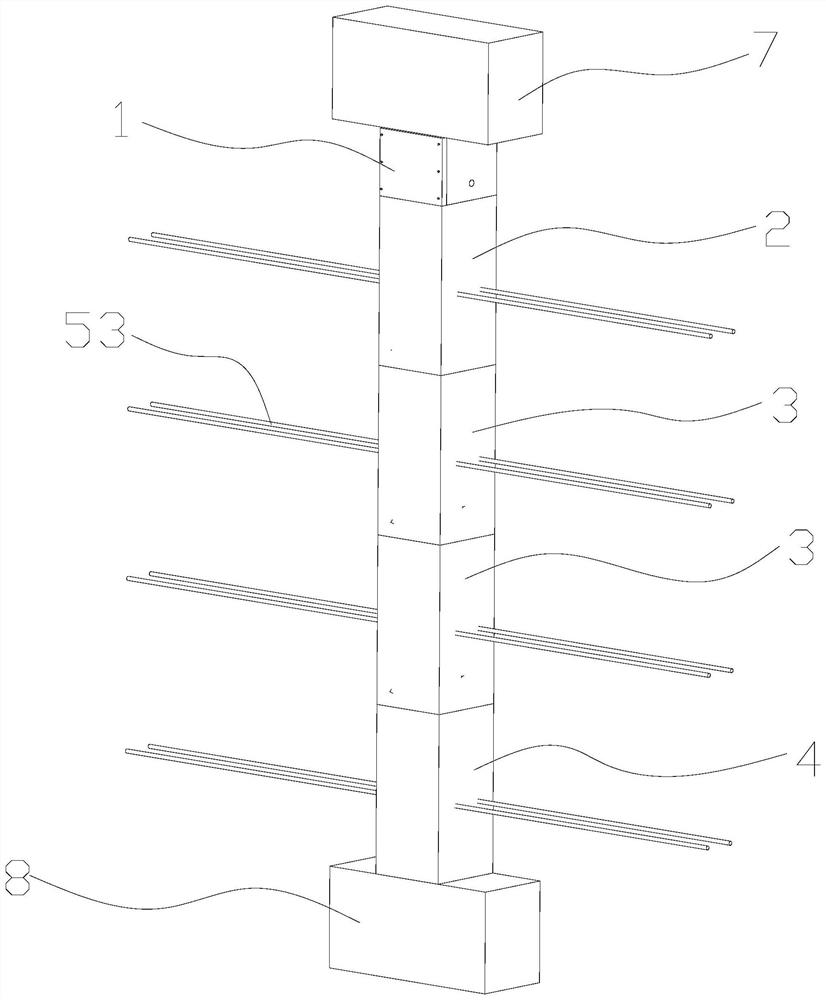

[0042] Such as figure 1 As shown, this embodiment provides a new type of recycled block concrete prefabricated construction column, which includes a top grouting formwork 1 , an upper section 2 , two middle sections 3 and a lower section 4 .

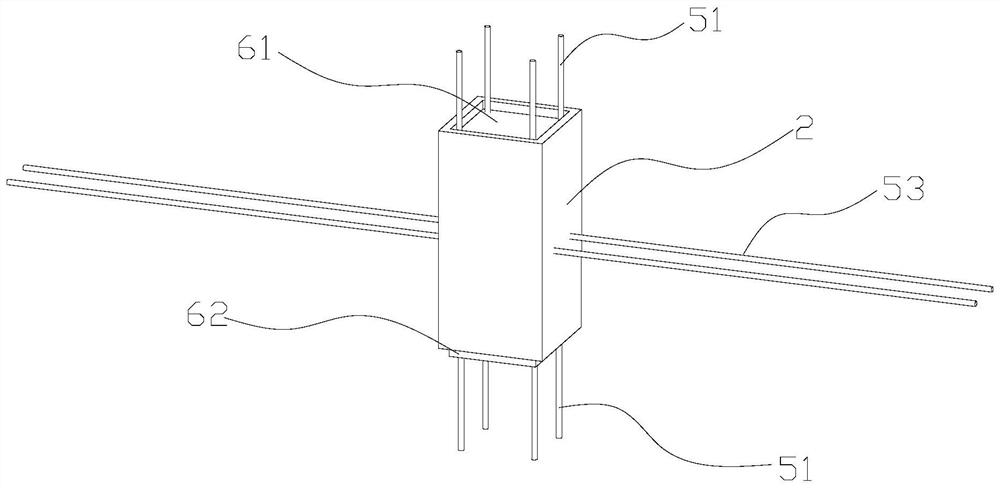

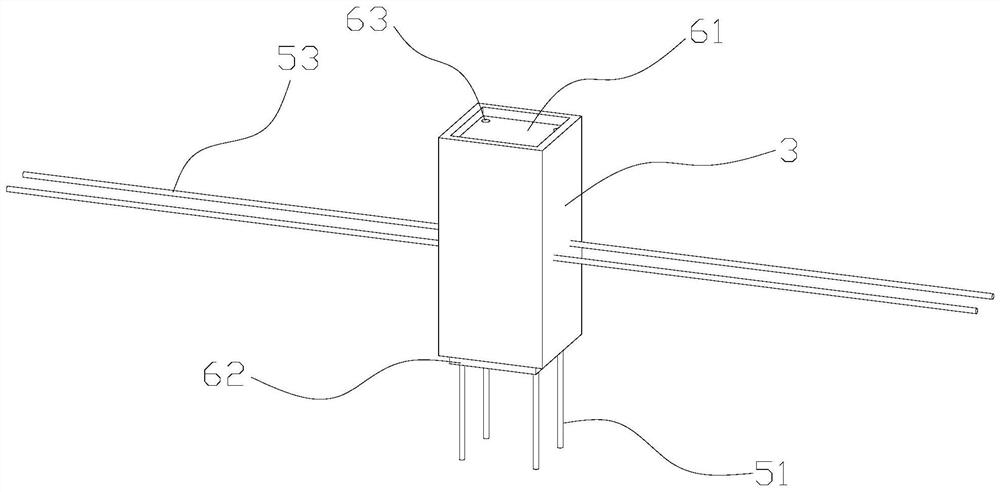

[0043] Such as figure 2 , image 3 , Figure 4 , Figure 5 As shown, the upper segment, the middle segment and the lower segment all include inner longitudinal reinforcement 51, inner stirrup 52, lateral wall reinforcement 53, waste concrete block 54 and ordinary concrete, and the inner longitudinal reinforcement and inner stirrup are bound A reinforcement cage is formed, and the lateral reinforcement bars penetrate the reinforcement cage. The abandoned concrete block is located in the reinforcement cage. Ordinary concrete covers the reinforcement cage and the abandoned concrete block. The inner longitudinal reinforcement of the upper section extends from the upper and lower two On the end face, the inner longitudinal ribs of the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com