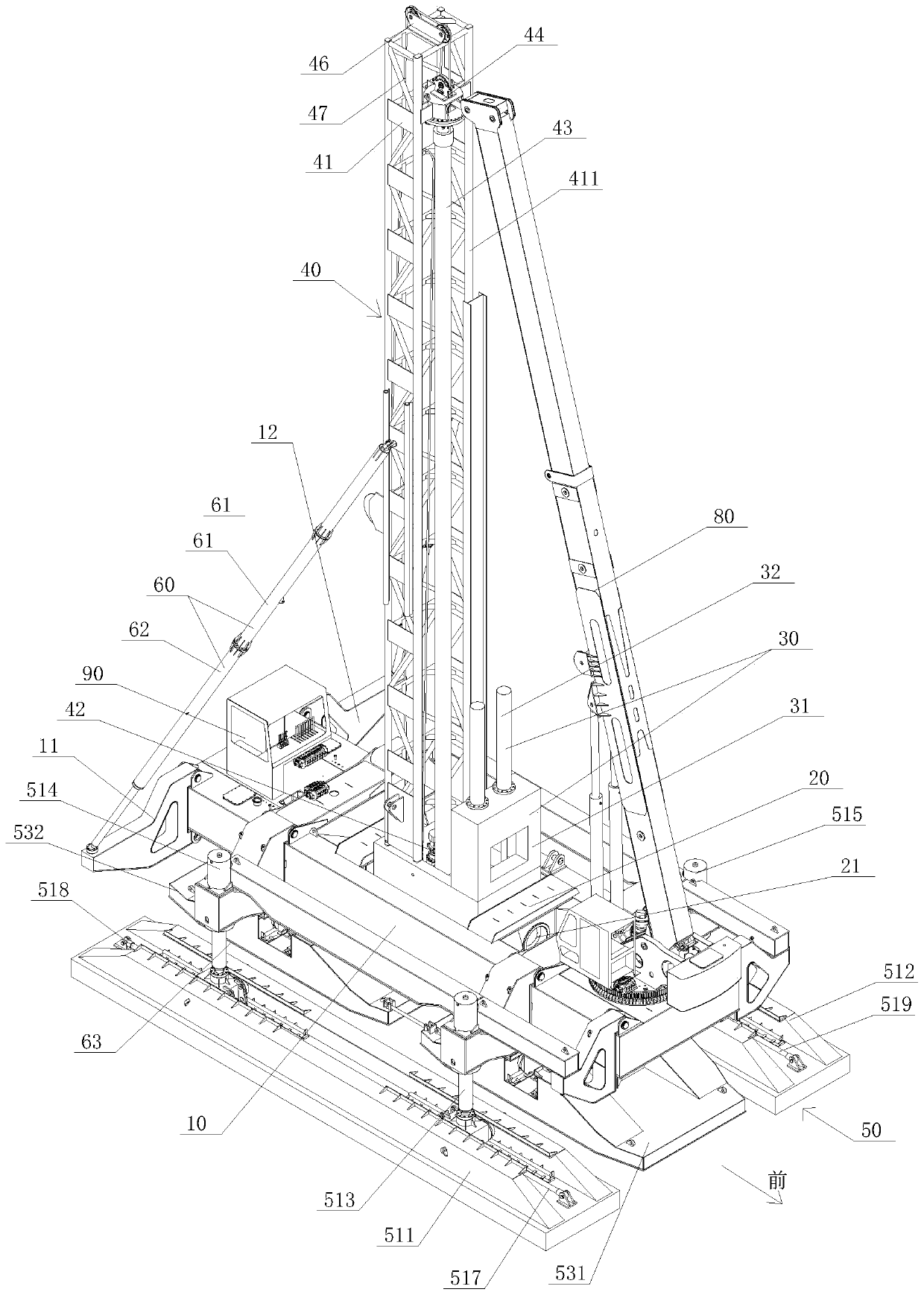

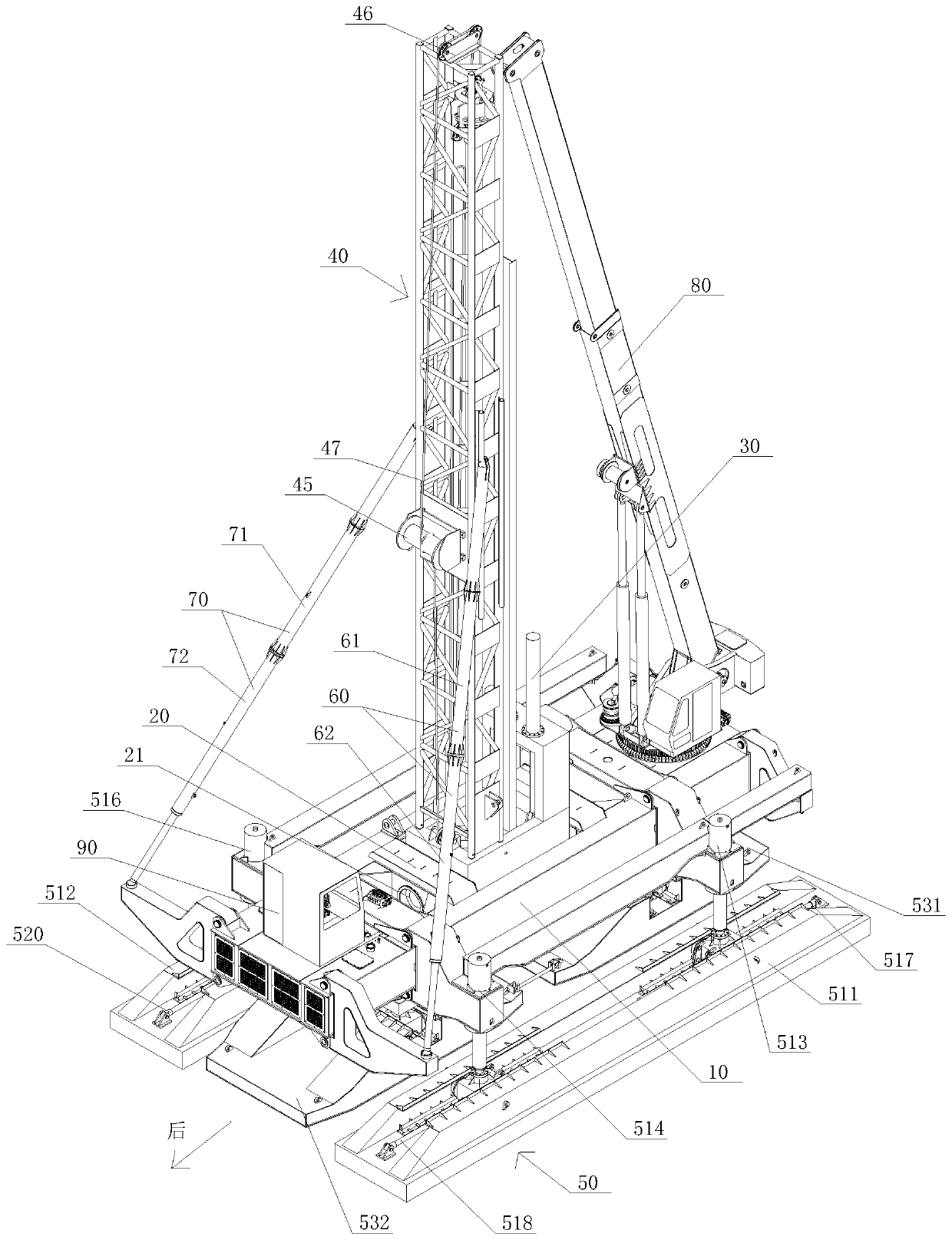

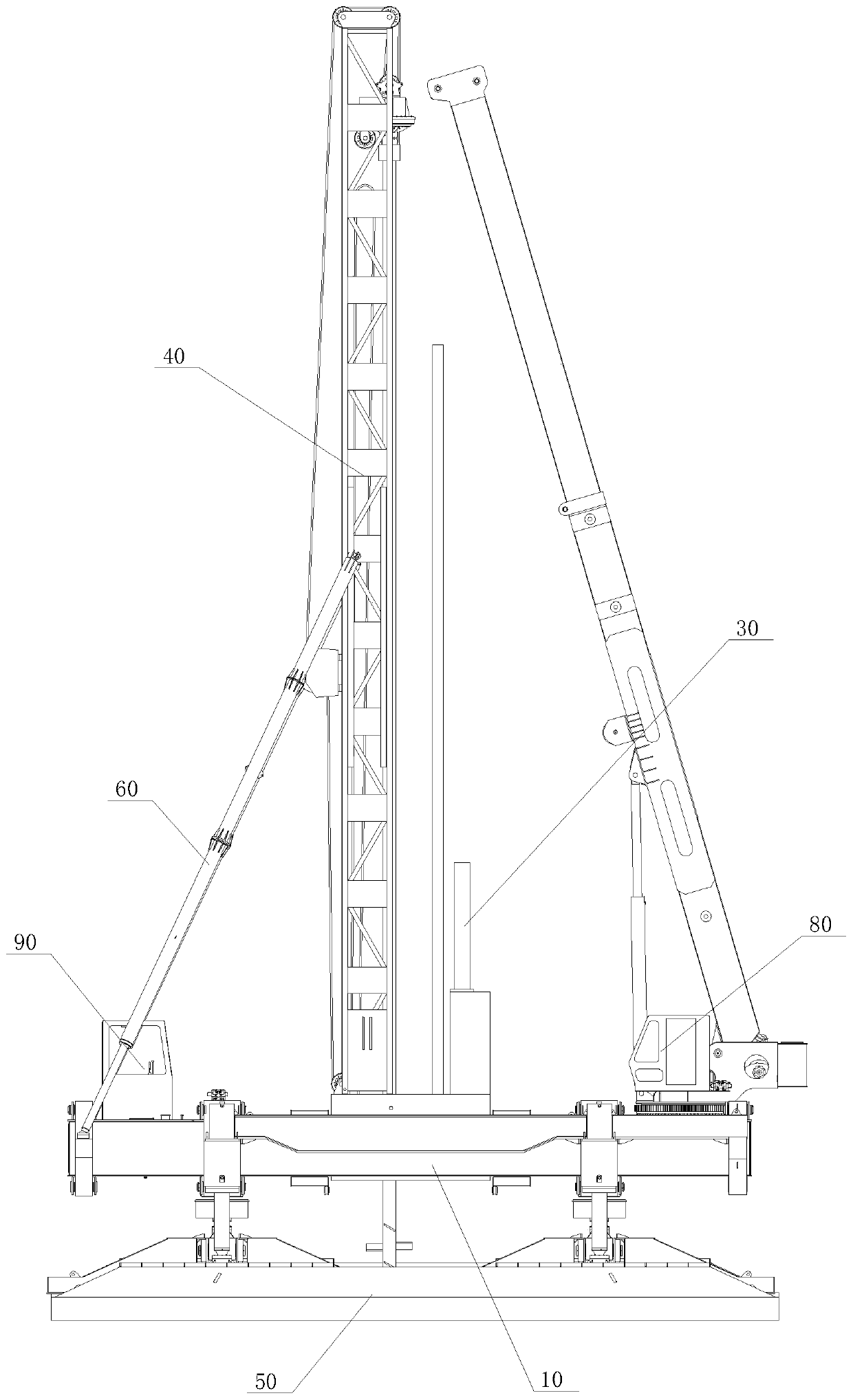

End-supporting variable-amplitude stirring and pile pressing integrated machine as well as construction method thereof

A technology of end support and construction method, which is applied in the direction of sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of reduced bearing capacity of pile composite foundation, low construction efficiency, limited construction occasions, etc., to maintain the balance of the center of gravity , Improve construction quality and efficiency, and achieve high concentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Embodiments of the present invention will be described in detail below.

[0053] The construction method of the end-support luffing-amplitude mixing pile-pressing integrated machine provided in this embodiment includes the following steps:

[0054] Step 1: When the pile driver is in place, its hydraulic pressure pile mechanism and agitating pile drilling mechanism are respectively installed on the rotating support of the main engine platform; the end of the main engine platform is provided with a first telescopic diagonal brace and a second telescopic diagonal brace; The end support luffing type mixing pile pressing machine is moved to the area to be constructed, and the drilling center of the end supporting luffing type mixing pile pressing machine is located directly above the pile position of the pile foundation to be constructed;

[0055] Step 2: adjust the tilt angle, telescopically adjust the extension length of the first telescopic diagonal brace 60 and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com