Patents

Literature

41results about How to "Increase shift speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

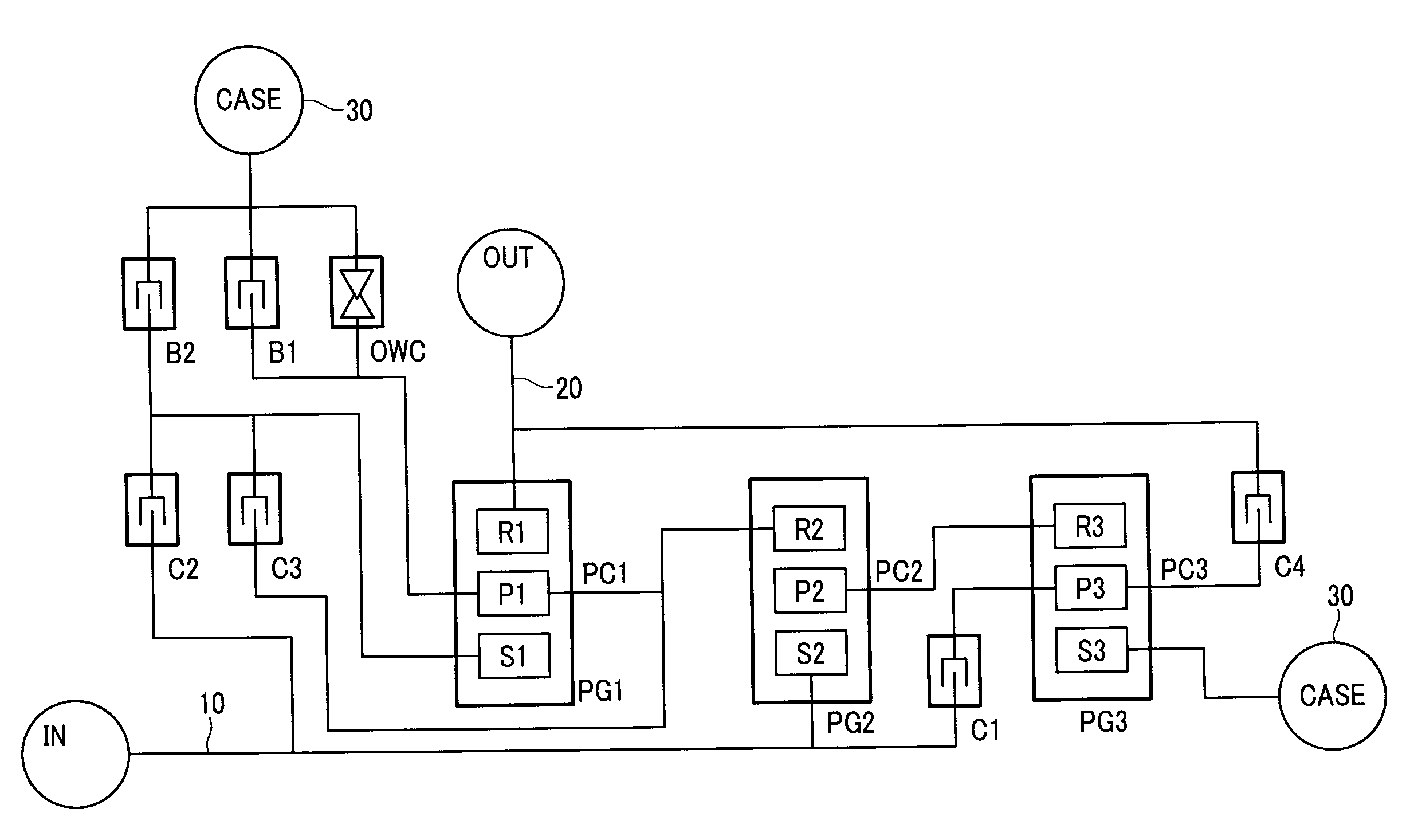

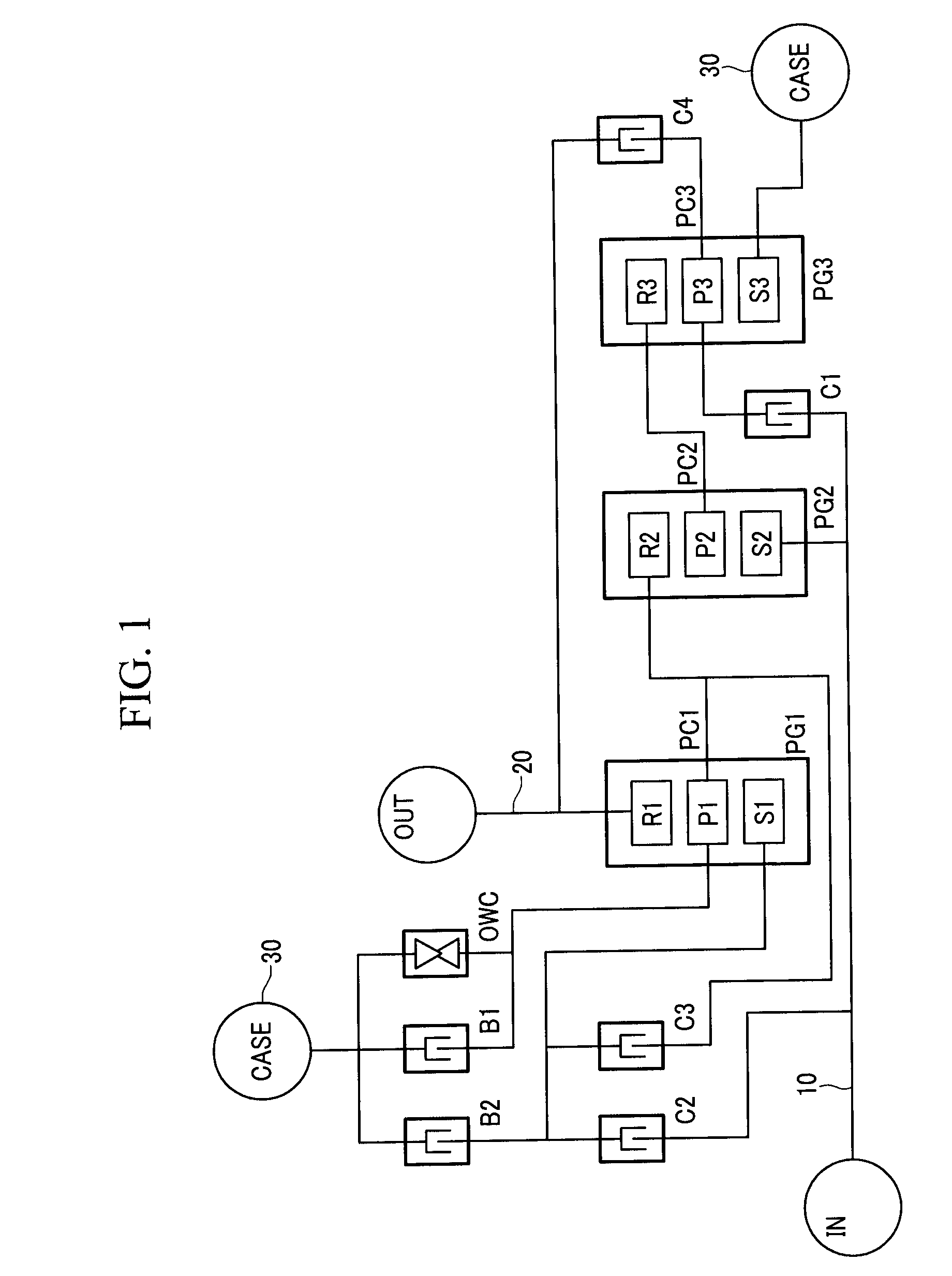

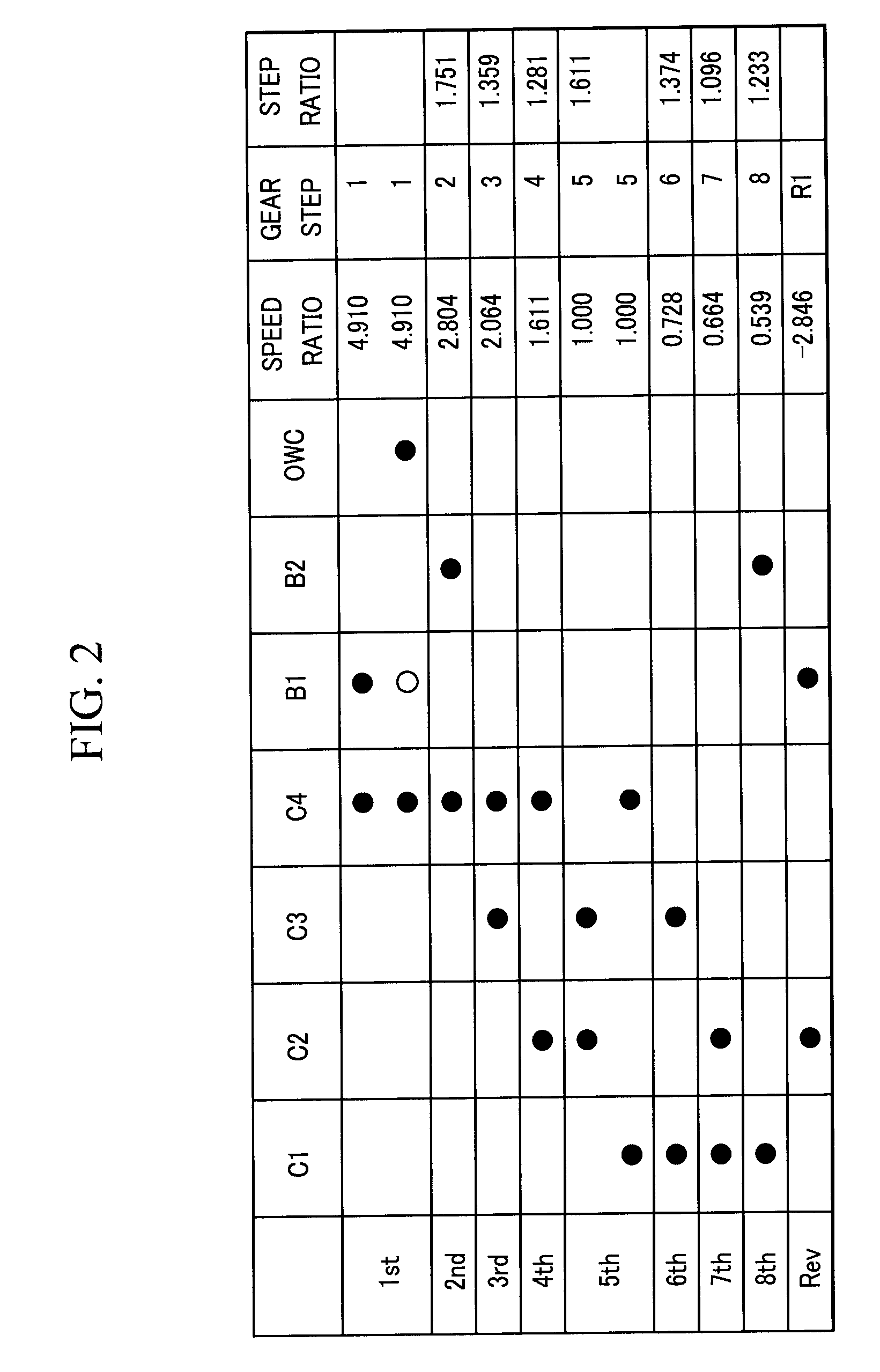

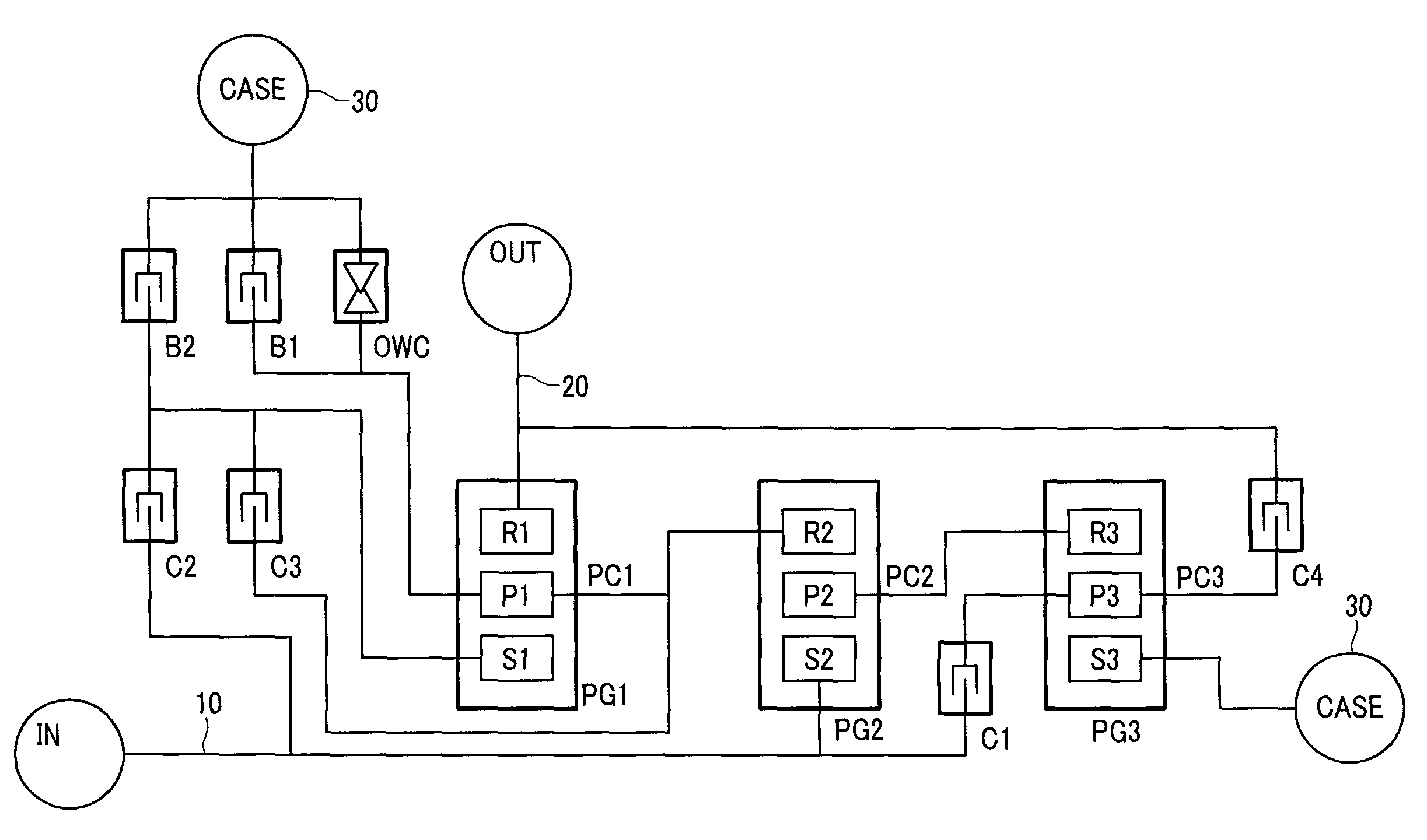

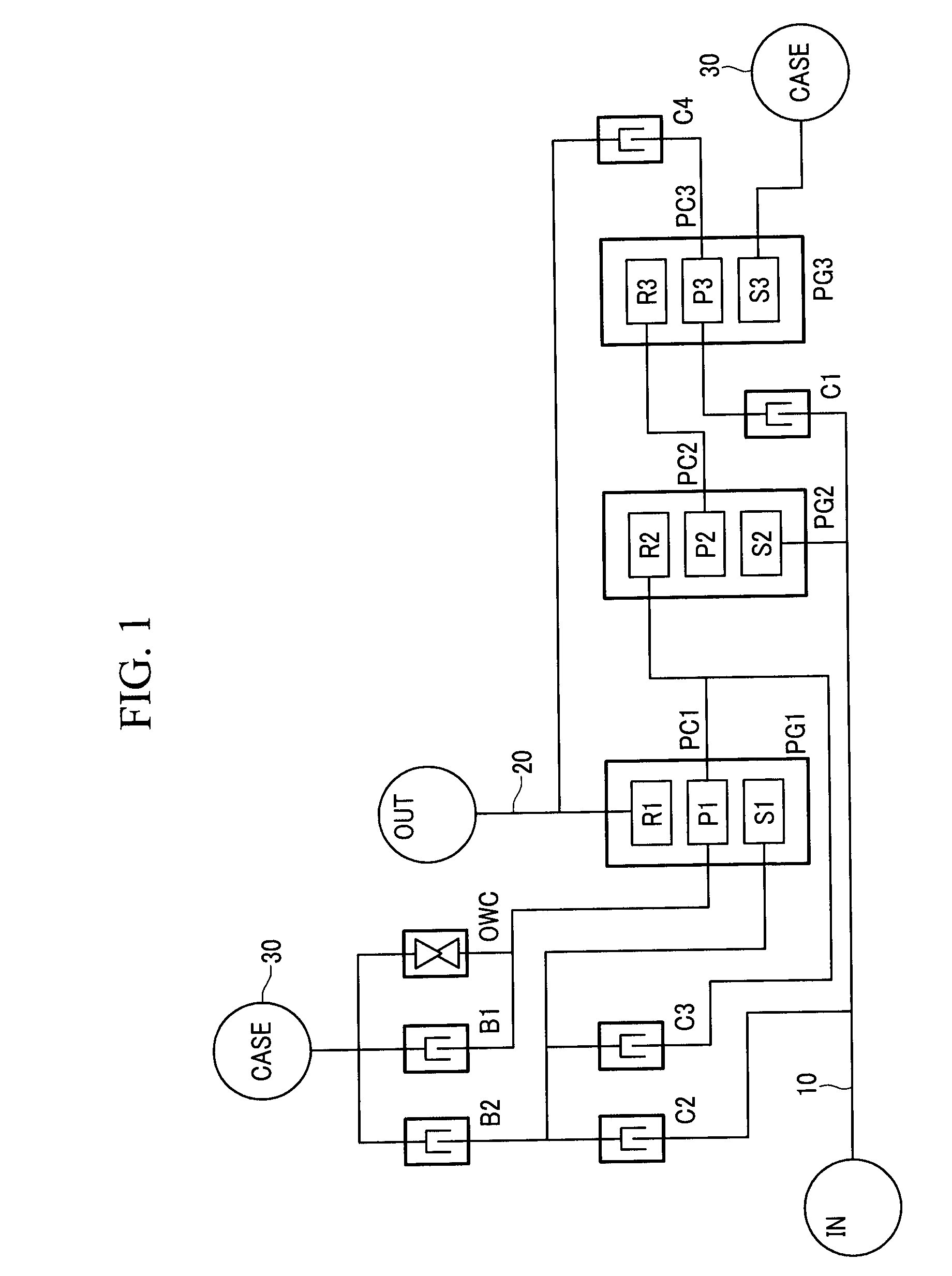

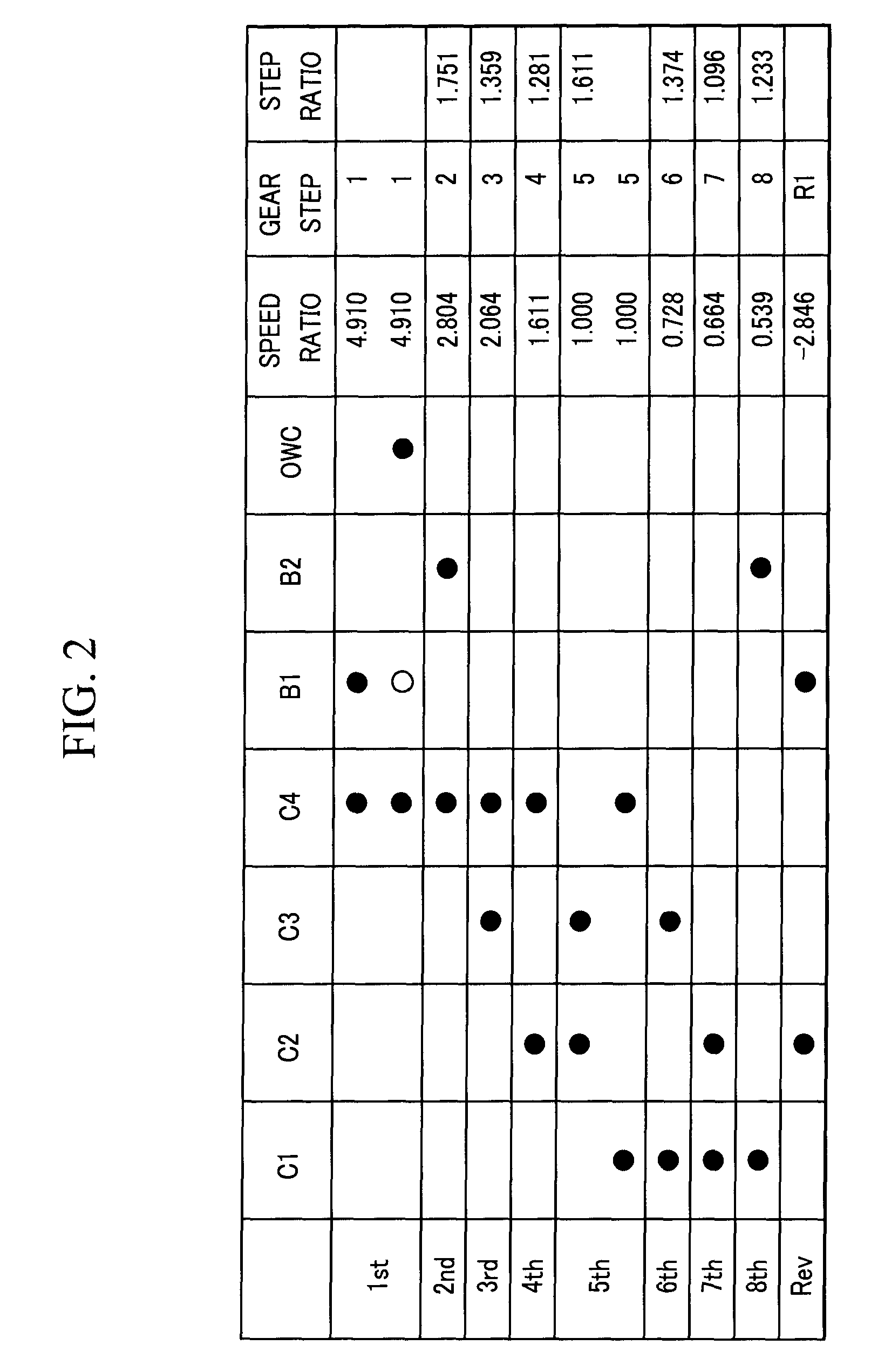

Gear Train of Automatic Transmission

InactiveUS20090298638A1Improving power delivery performanceIncrease shift speedToothed gearingsTransmission elementsAutomatic transmissionGear wheel

A gear train of an automatic transmission for a vehicle may be provided to realize eight forward speeds and one reverse speed with three single pinion planetary gear set, four clutches and two brakes.

Owner:HYUNDAI MOTOR CO LTD

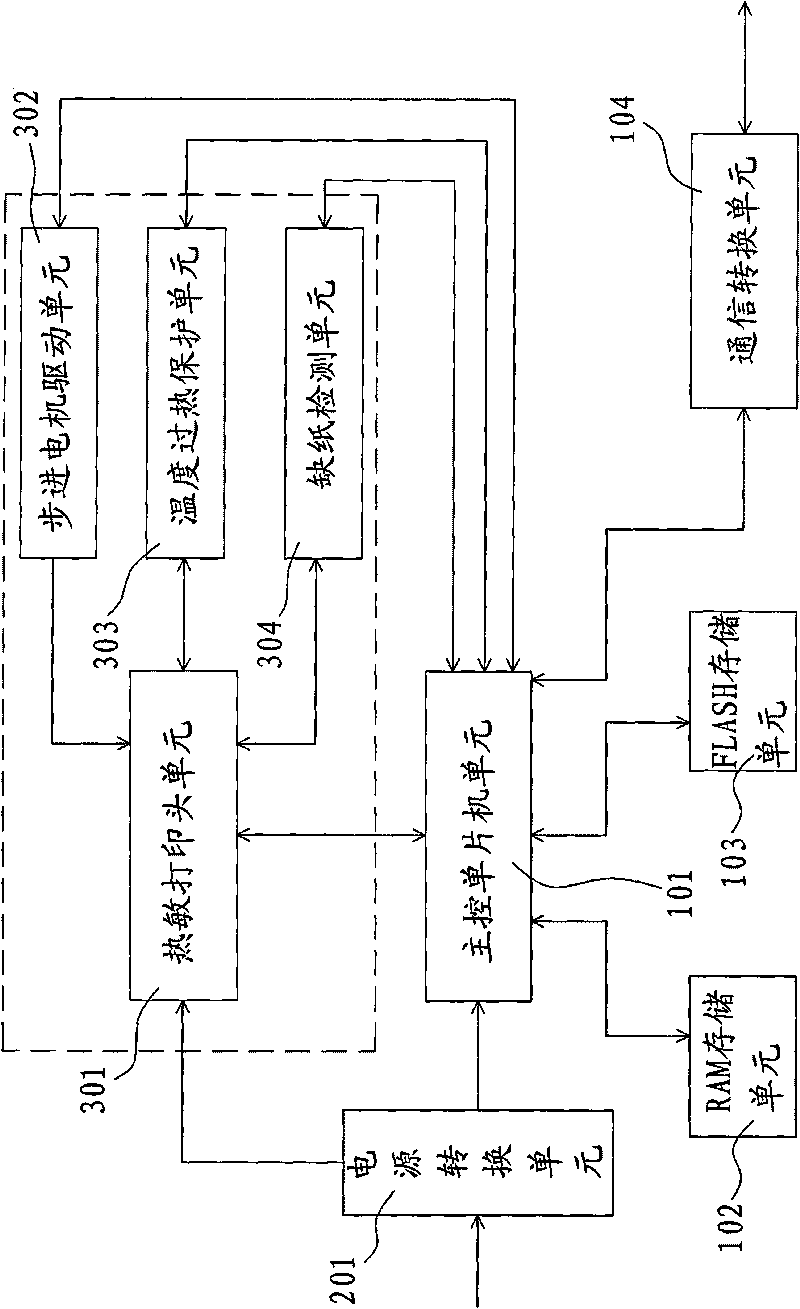

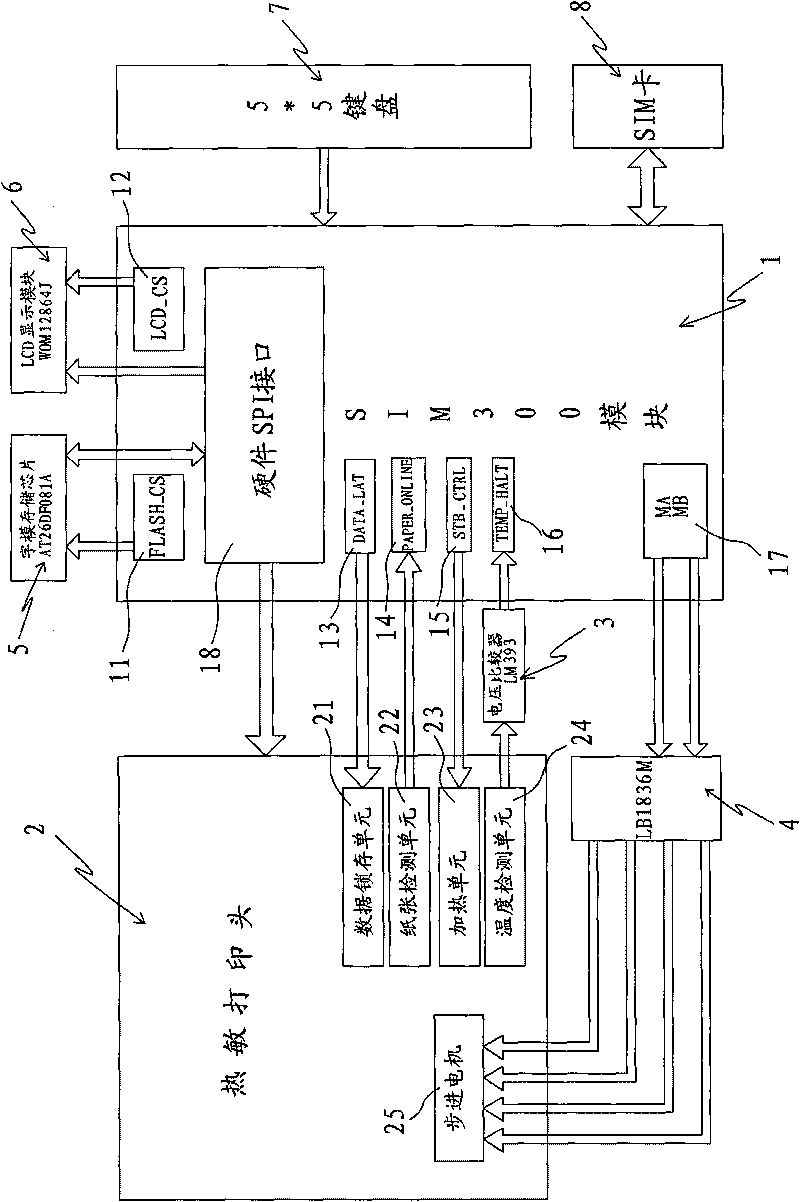

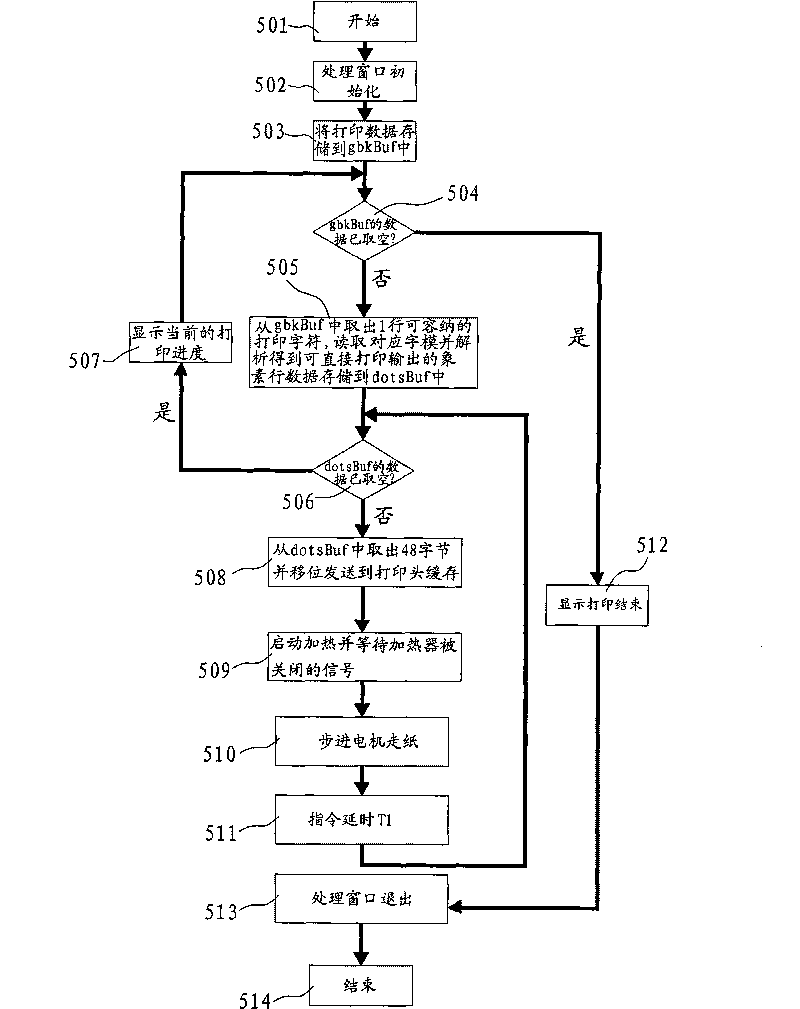

Device and method for controlling thermal printer by using GSM module with SPI interface

InactiveCN101691090ASolve the problem of not being able to control the temperature in timeSolve the problem of not being able to store larger fontsVisual presentation using printersOther printing apparatusComputer moduleEngineering

The invention relates to the field of electronic control, more particularly to a method for controlling a thermal printer by using a GSM module with a SPI interface. The control device of the invention is extended to connect with a memory by using a data transmission and connection capability port of the SPI interface of the GSM module so as to store font data, and controls a data latch unit, a paper detection unit and a heating unit of the thermal printer by using the data transmission and connection capability port of the SPI interface of the GSM module; a temperature detection unit of the thermal printer enters the capability port of the GSM module via a voltage comparator in order to form detection interruption; and a secondary capability port of the GSM module converts two-waveform into four-waveform through a stepping motor driver so as to drive the stepping motor of the thermal printer. Hence, ideal application effect can be obtained on SIM300 module according to the invention and the friendly display of MMI human-computer interface can also be well satisfied.

Owner:XIAMEN STELCOM INFORMATION & TECH

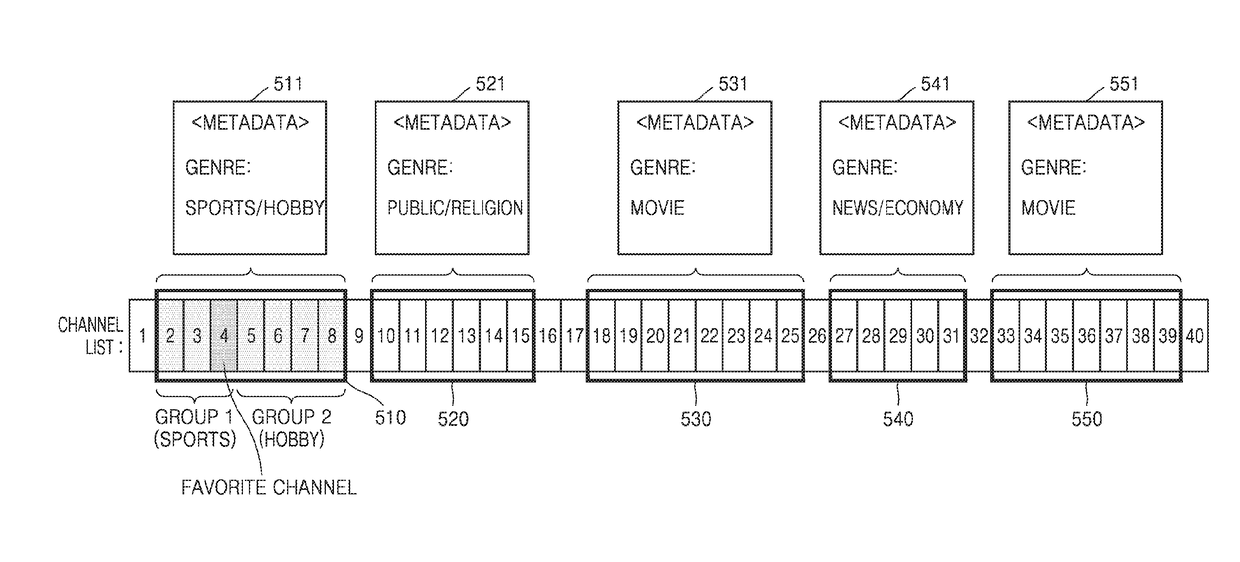

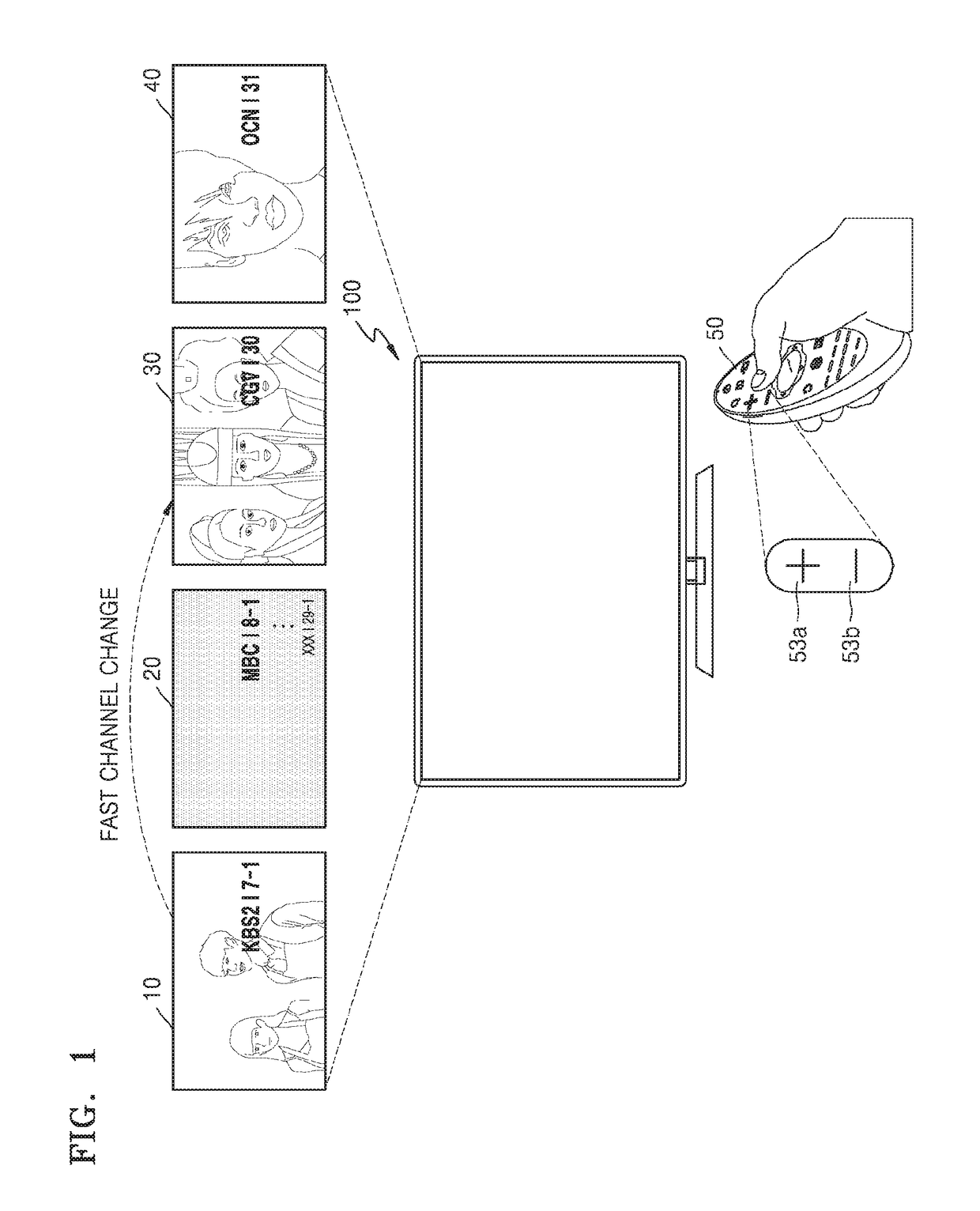

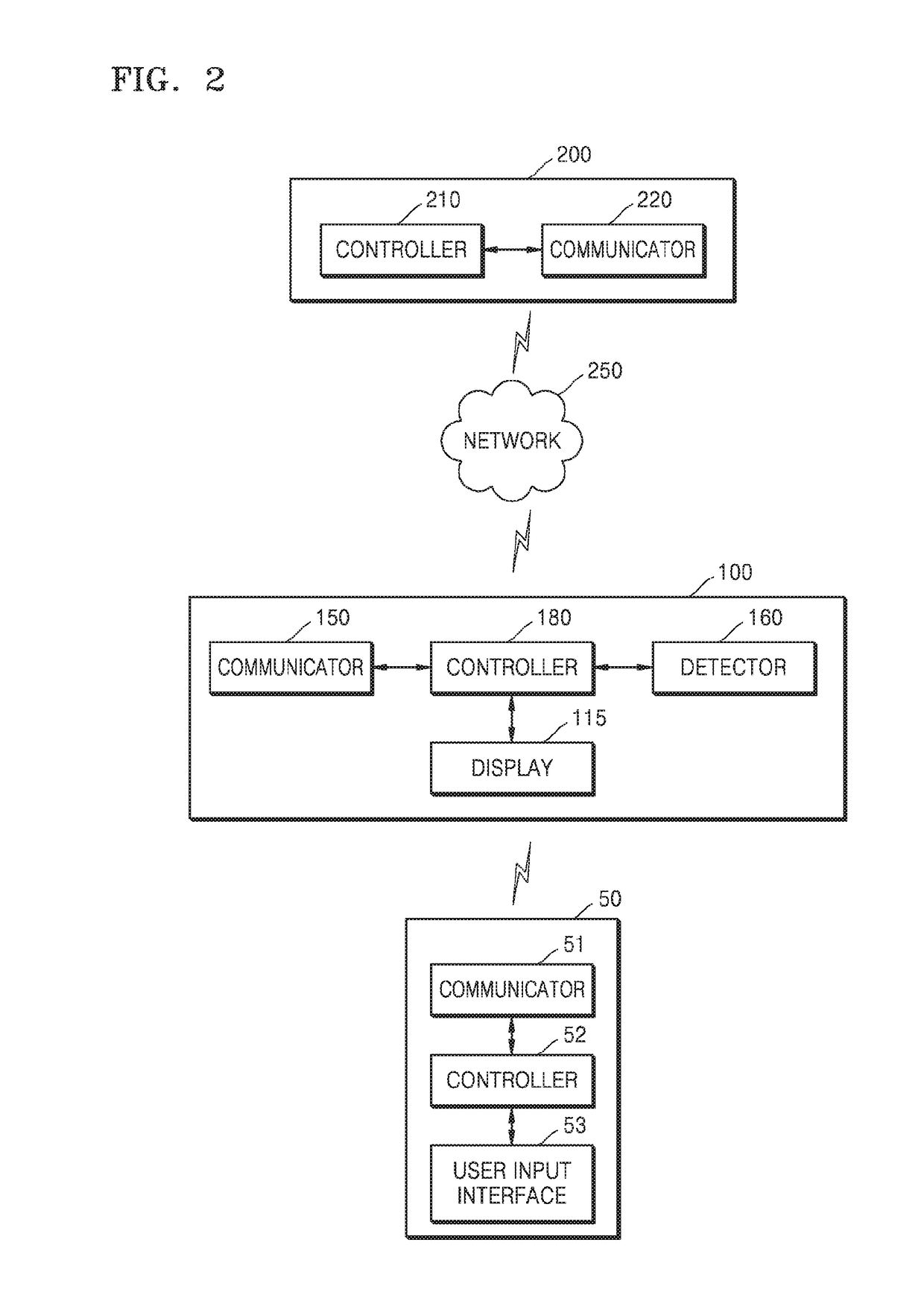

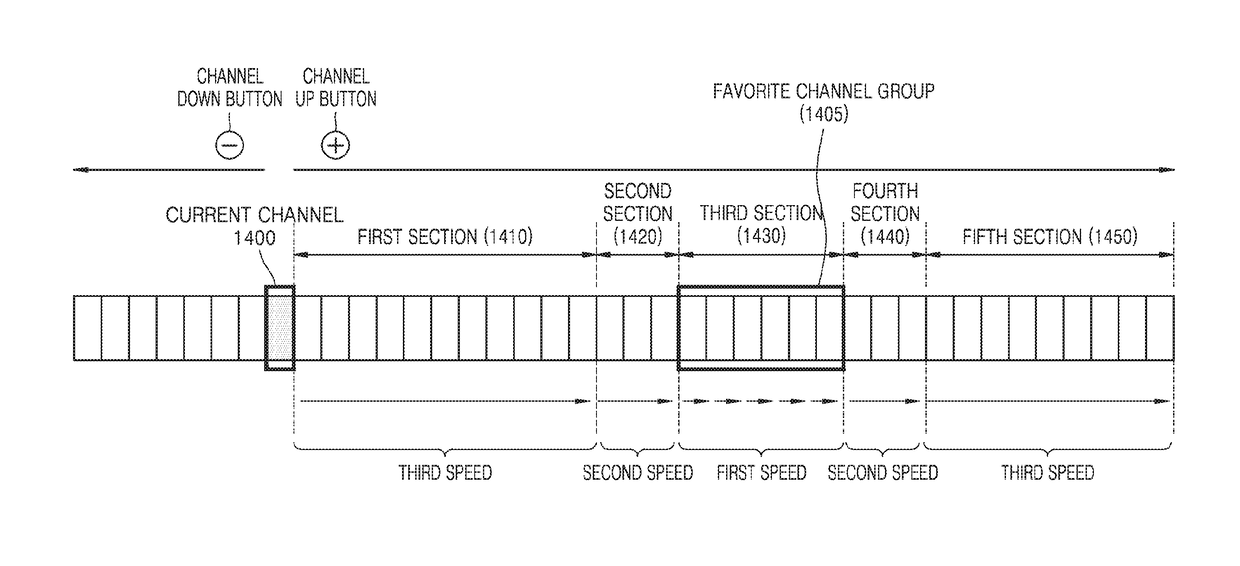

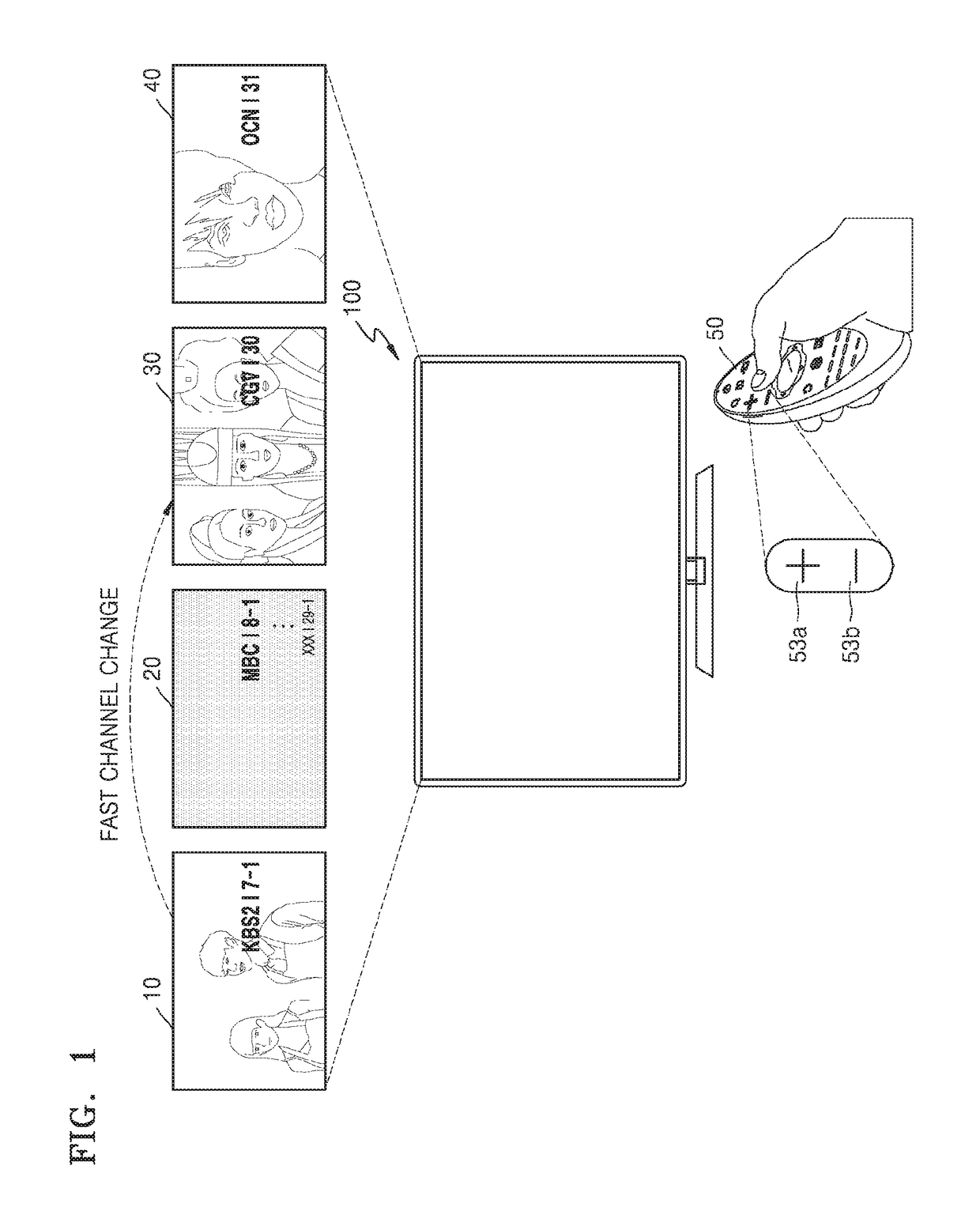

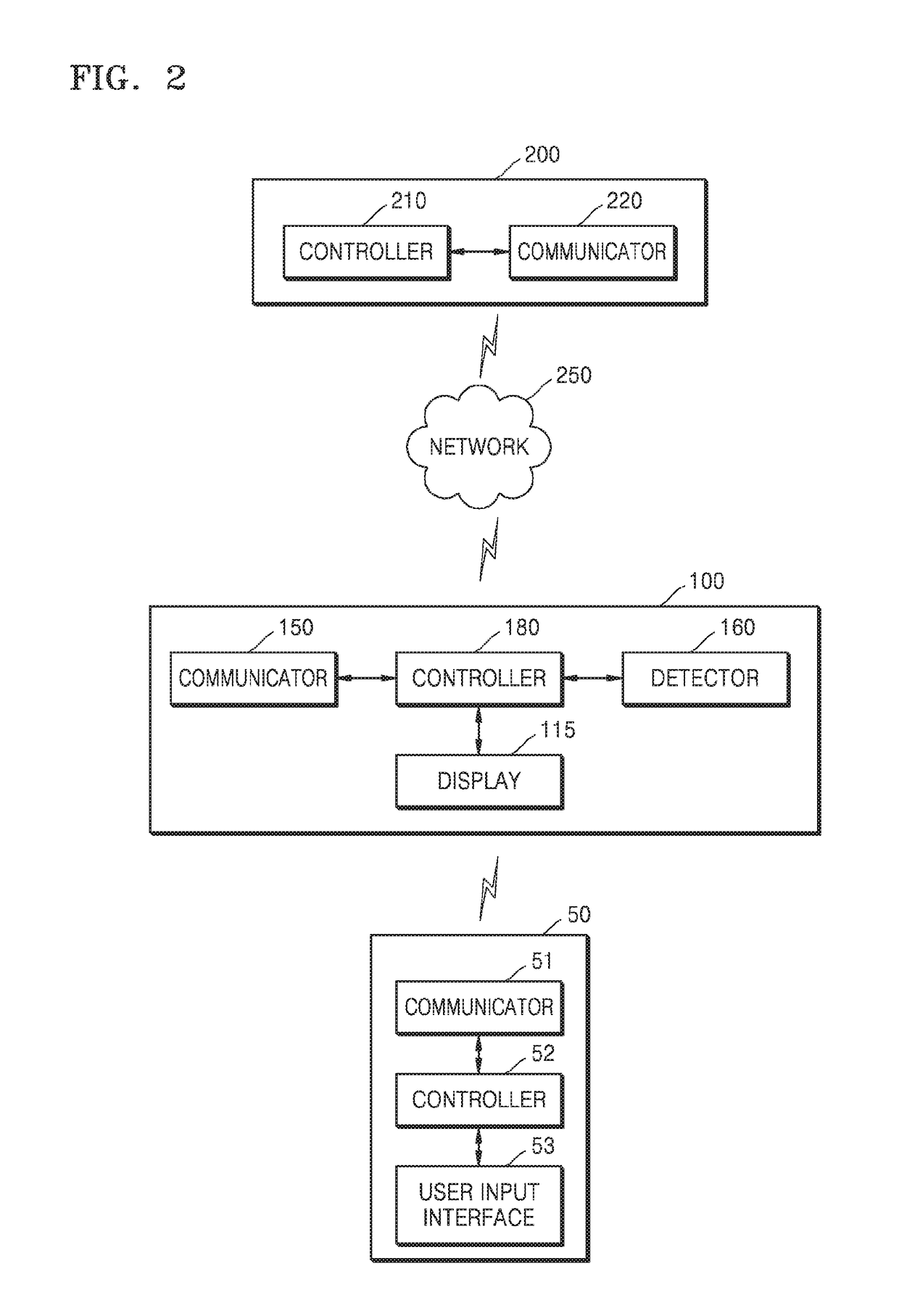

Electronic device and method of scanning channels in electronic device

ActiveUS20170180813A1Easy to scanDecrease channel shift speedSelective content distributionControl signalUser input

An electronic device includes a detector configured to detect a user input and a controller configured to determine a favorite channel group according to a user's viewing history, scan channels in response to detecting an input of a control signal corresponding to a channel shift button for a predetermined time, and decrease a channel shift speed in a favorite channel group section corresponding to the determined favorite channel group and increase the channel shift speed in a section other than the favorite channel group section.

Owner:SAMSUNG ELECTRONICS CO LTD

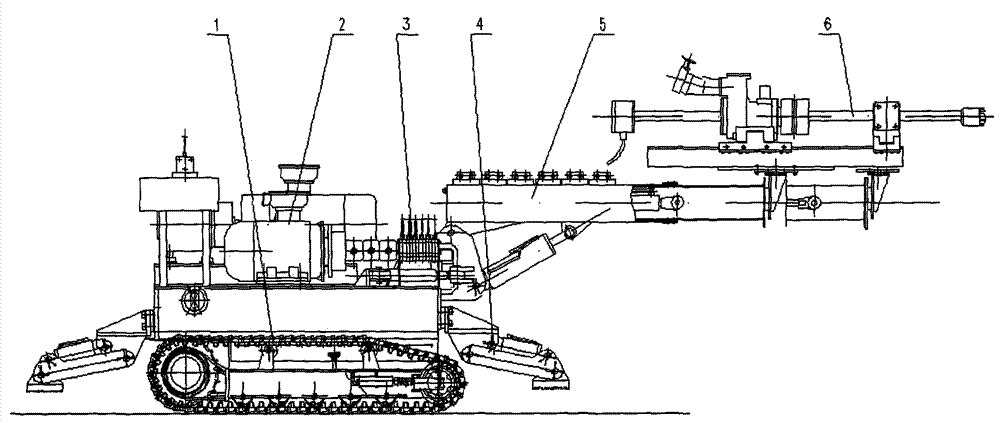

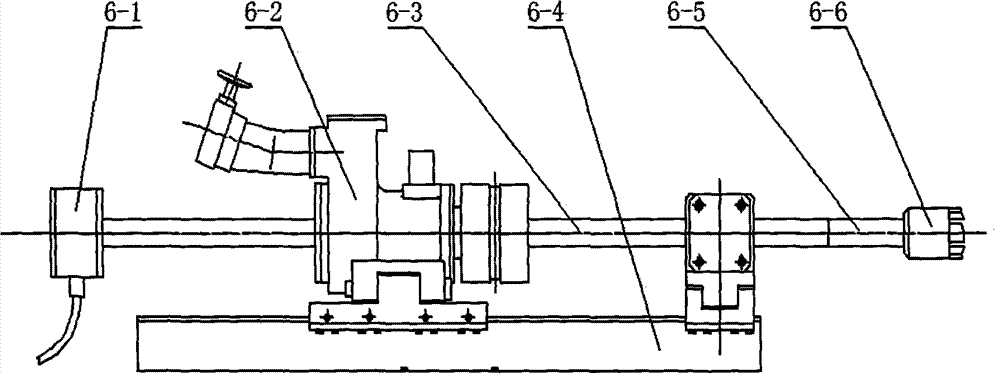

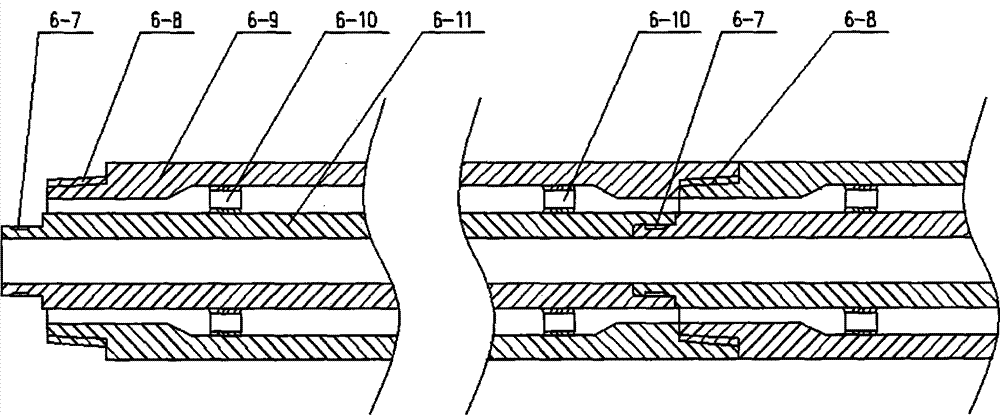

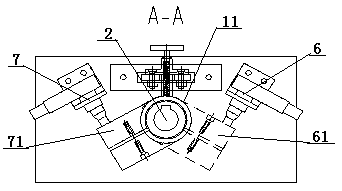

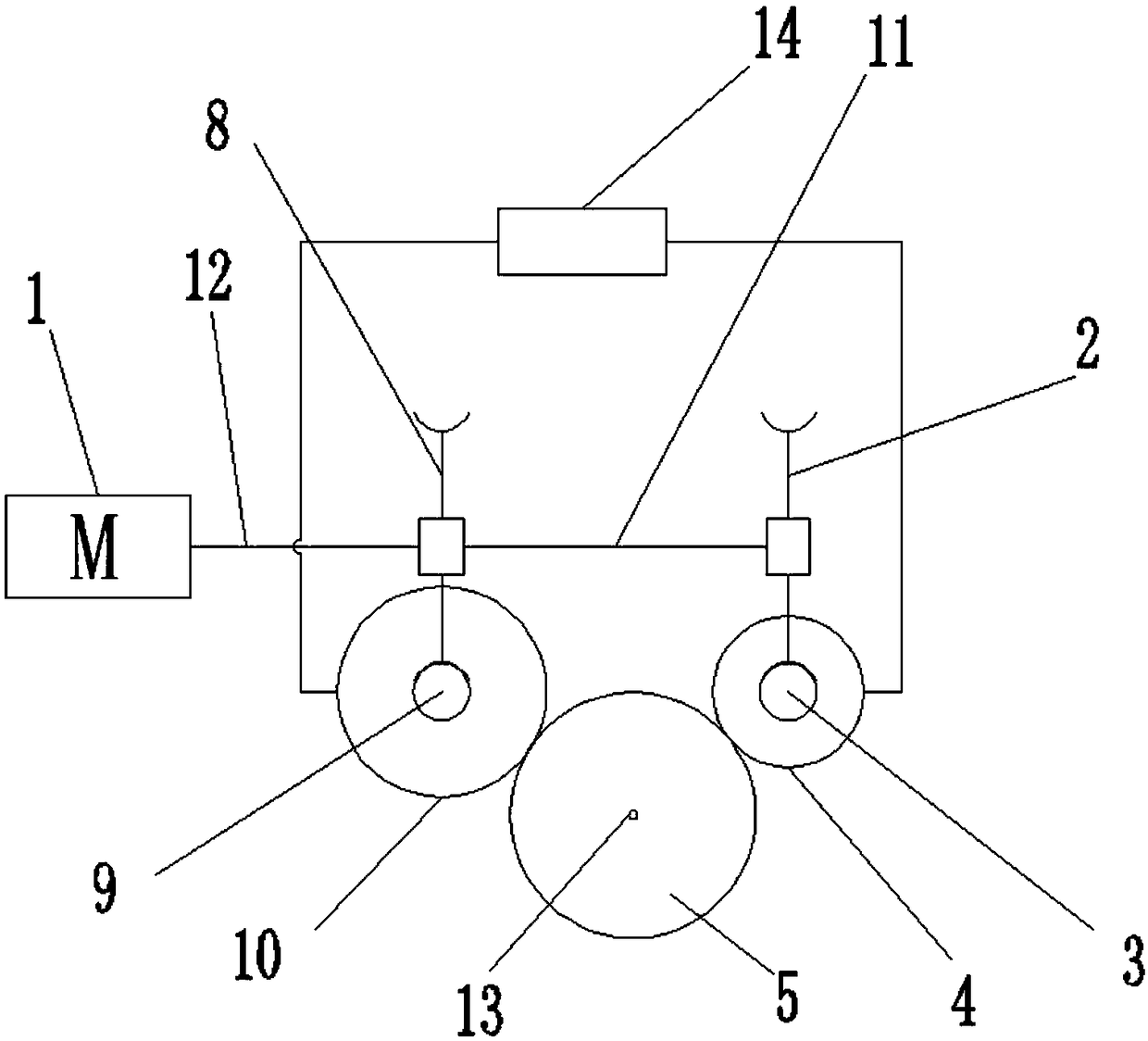

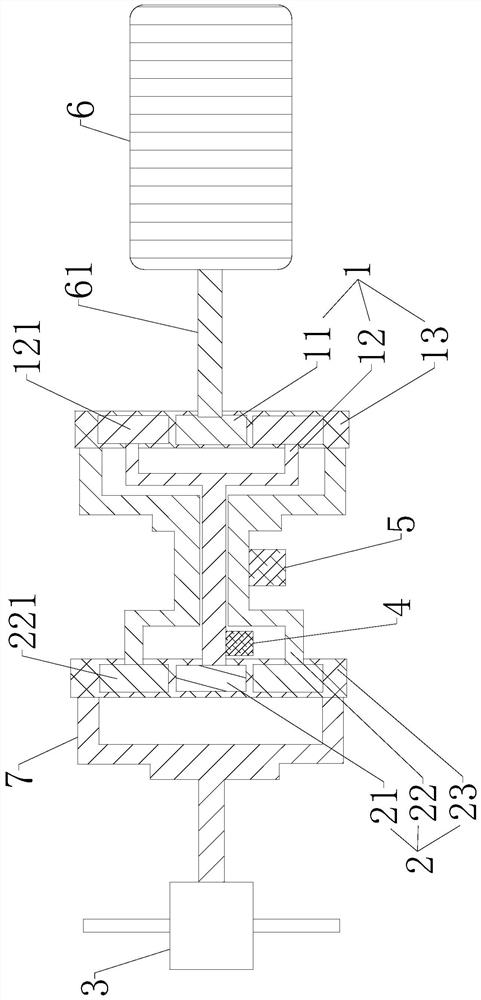

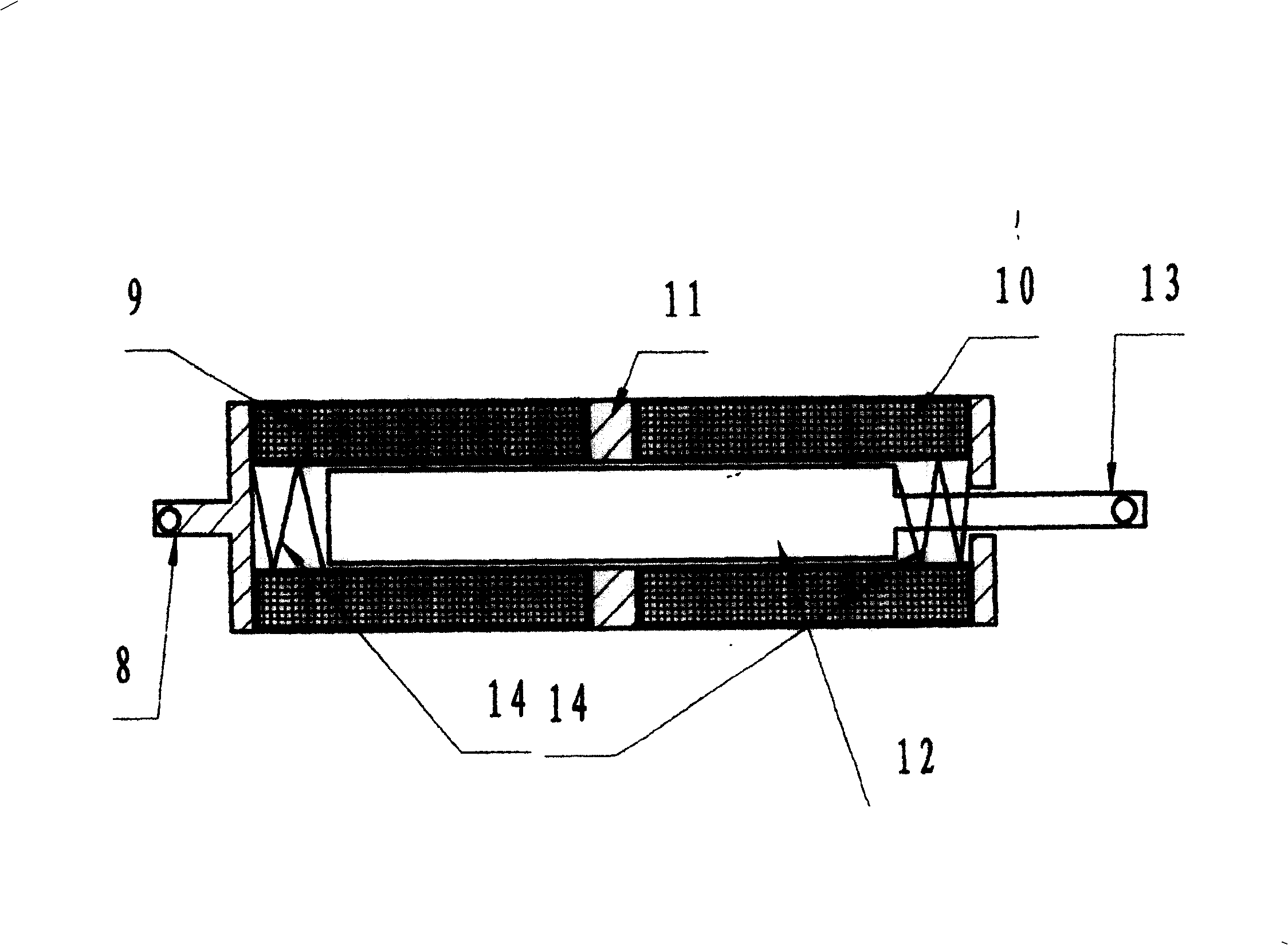

Drilling and slotting integrated machine for coal mines

InactiveCN103670402AImprove work efficiencyImprove anti-shock effectCutting machinesControl systemEngineering

The invention discloses a drilling and slotting integrated machine for coal mines. The machine comprises a machine body, a power mechanism and a hydraulic control system, wherein the power mechanism is arranged at the upper end of the machine body; the hydraulic control system is arranged near the front end of the machine body; traveling gears are arranged on two sides of the machine body; support devices are arranged at front and rear ends of the machine body; a telescopic boom is arranged at the front end of the machine body; the movement direction of the telescopic boom is controlled through hydraulic parts; a drilling and water jet slotting device is fixed at the front end of the telescopic boom. According to the invention, different from a conventional device of performing slotting operation after the drilling is completed, the machine disclosed by the invention can switch the movement of the inserted drilling and water jet slotting device into high-pressure abrasive jet slotting movement in the drilling process of the drilling and water jet slotting device on request, so that the purpose of drilling while slotting is achieved, the problem that water jet slotting knife of the drilling and water jet slotting device cannot extend to a hole and perform slotting, caused by phenomena, such as hole collapse, can be effectively solved and the working efficiency is remarkably increased in the meantime.

Owner:HENAN POLYTECHNIC UNIV

Control device for vehicular power transmitting device

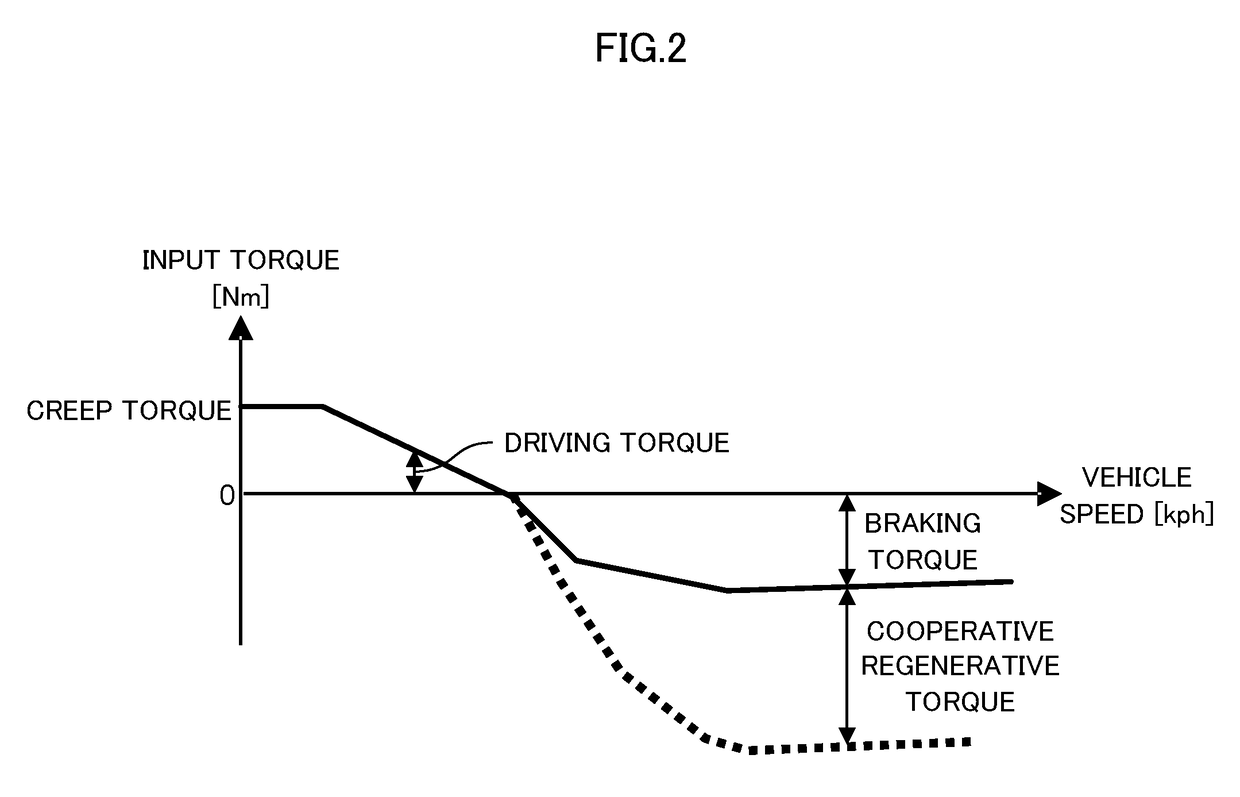

InactiveUS20090029825A1Minimize electric power consumptionRegeneration amount can be increasedAuxillary drivesGearing controlElectric power systemEngineering

This invention relates to a control device for a vehicular power transmitting device. The control device has shifting-point altering means 108 operative such that when a second electric motor M2 is operated with priority to obtain a charging efficiency and / or electric power generating efficiency, a shifting point for a vehicle to run under a decelerating state (during a coast running state) is altered to a point on a higher vehicle speed than that at which a shifting point for a running-performance-conscious state is set. Therefore, when the second electric motor M2 is operated with priority for generating electric power, a downshift is initiated at a high vehicle speed than that at which the downshift is initiated at a shifting point for a running-performance-conscious state. This increases a rotation speed NM2 of the second electric motor M2, resulting in an increase in regeneration amount (electric power generation amount) of the second electric motor M2.

Owner:TOYOTA JIDOSHA KK

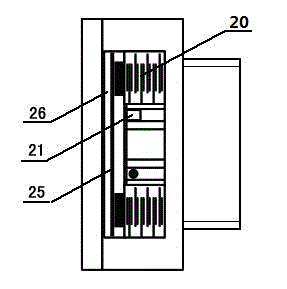

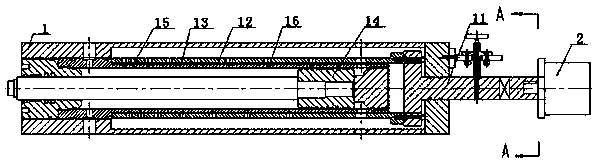

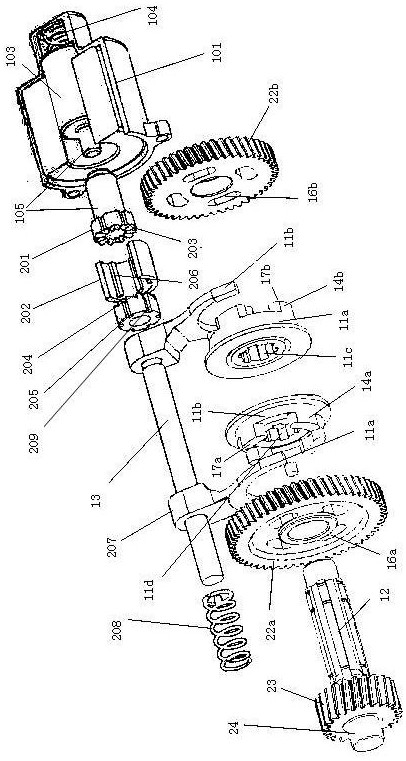

Single-clutch and multi-level automatic transmission

InactiveCN105370879ASimple and smooth shifting procedureNo shift interference issuesGearing controlAutomatic transmissionEngineering

The invention relates to a single-clutch and multi-level automatic transmission. A power input shaft (1) is provided with a plurality of drive gears. Each drive gear corresponds to one gear. A plurality of driven gears are correspondingly arranged on a power output shaft (2), and each driven gear corresponds to one gear. The single-clutch and multi-level automatic transmission is characterized in that the power input shaft (1) is internally provided with a gear shifting shaft (4), a piston (24) is fixed to one end of the gear shifting shaft (4), and a first oil pressure cavity (18) used for controlling gear shifting is formed in the outer side of the piston (24); each drive gear is internally provided with a one-way clutch (21) and a clutch (20), wherein the clutch (20) can be controlled by oil pressure of the first oil pressure cavity (18) to be in a combined state; and the power input shaft (1) drives the work ends of the drive gears to rotate through the clutches (20), and the work ends of the drive gears are engaged with the driven gears on the power output shaft.

Owner:解利

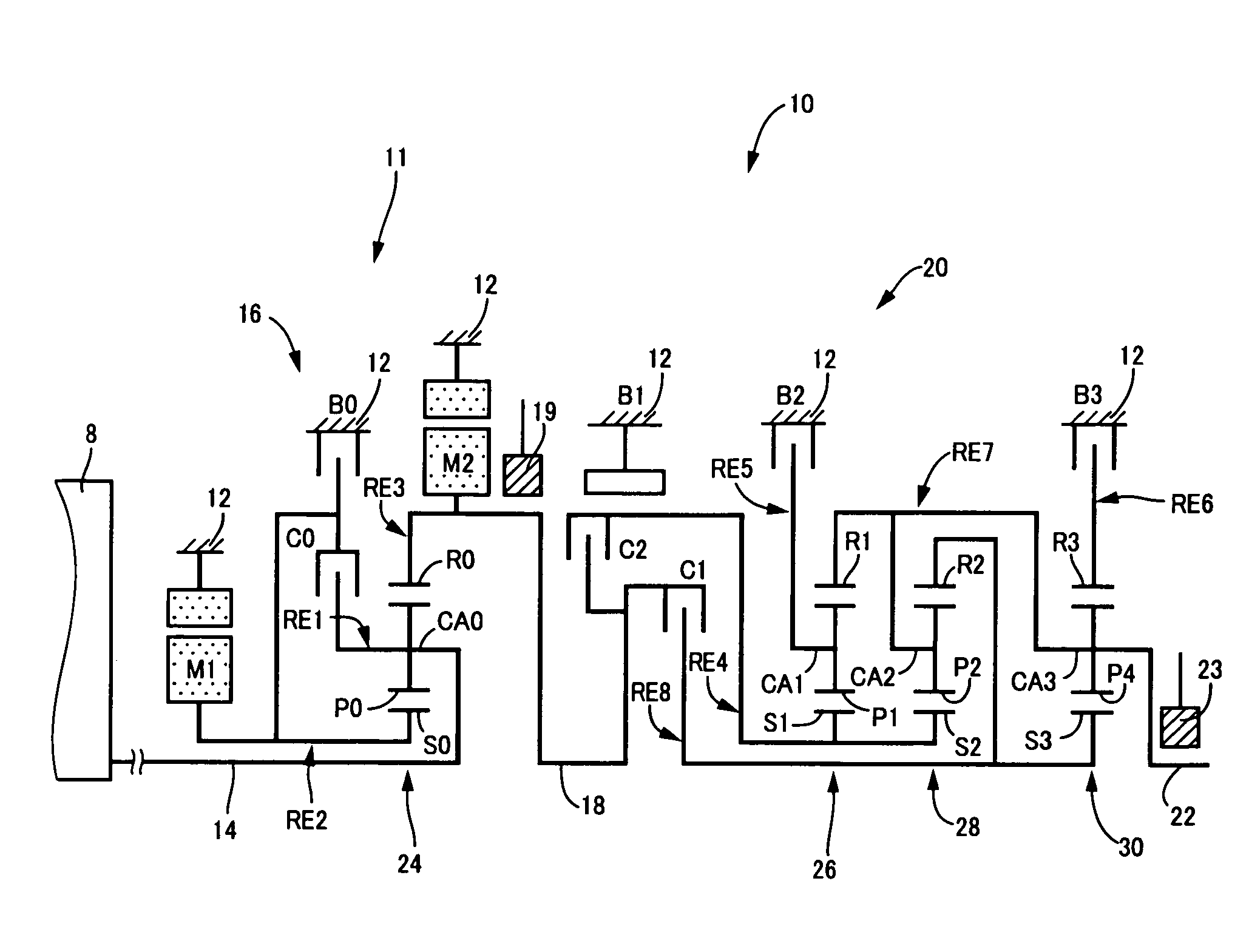

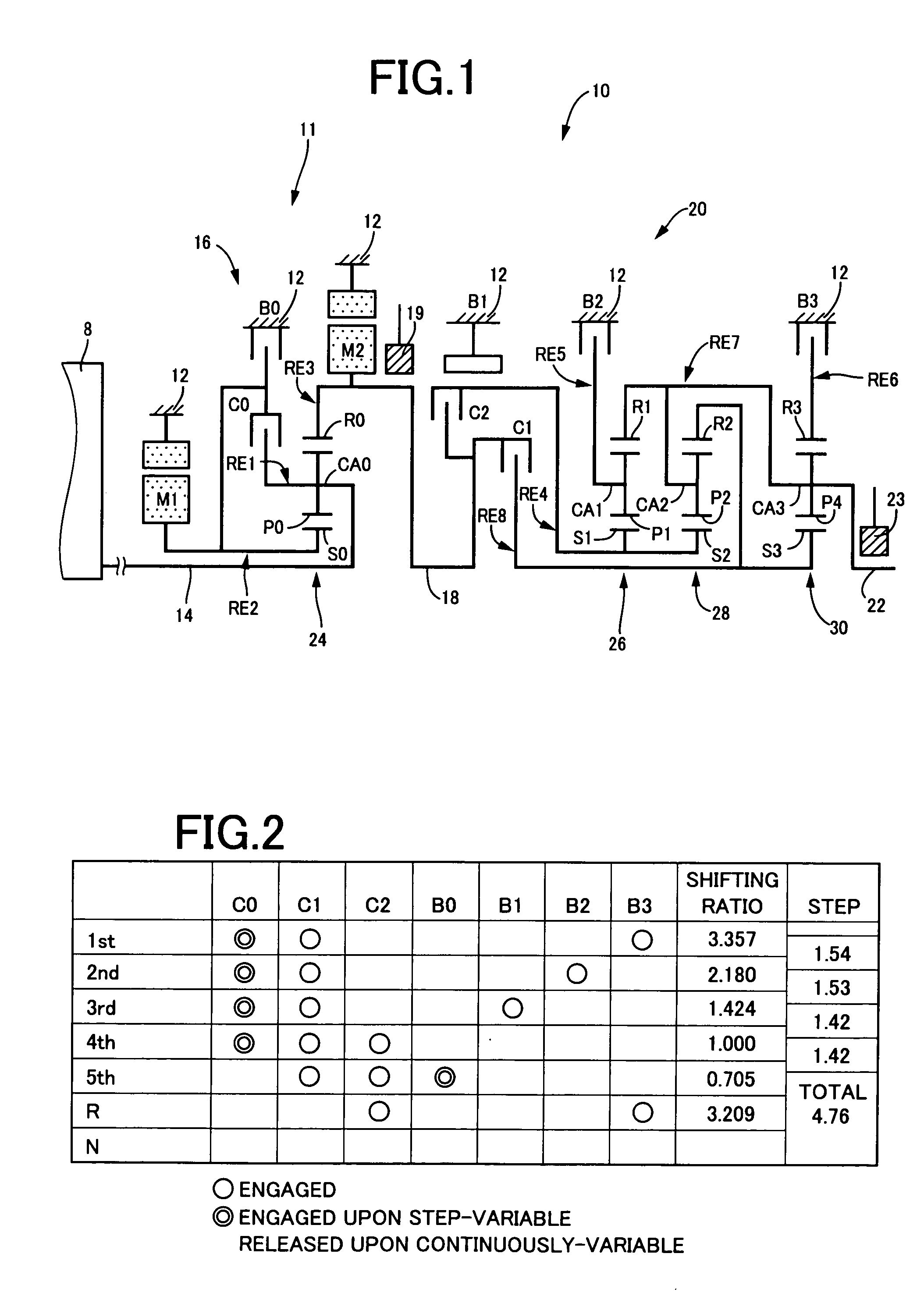

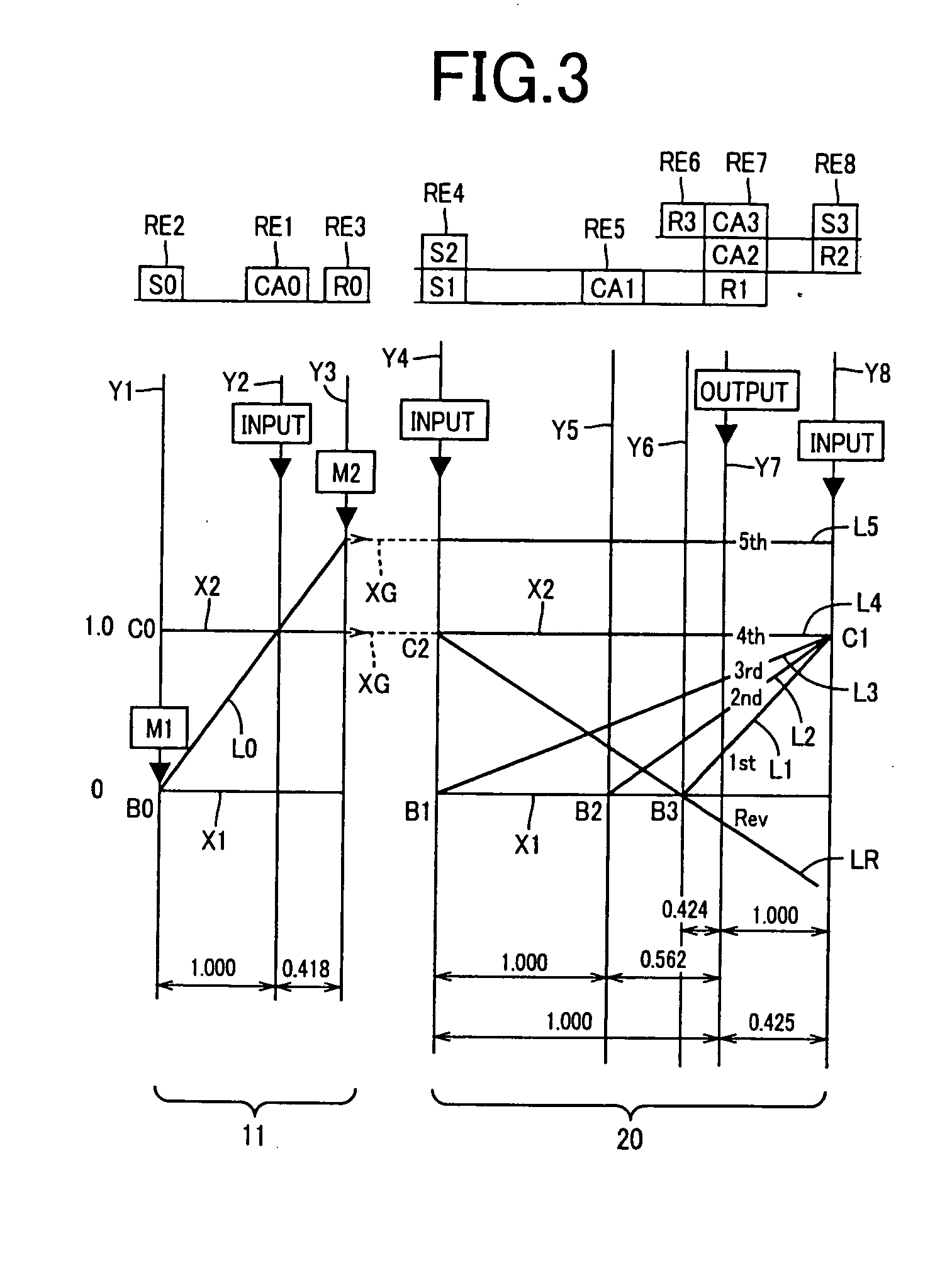

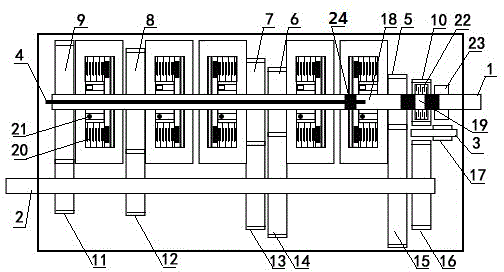

Gear train of automatic transmission

InactiveUS7985160B2Improve performanceIncrease shift speedToothed gearingsTransmission elementsAutomatic transmissionEngineering

A gear train of an automatic transmission for a vehicle may be provided to realize eight forward speeds and one reverse speed with three single pinion planetary gear set, four clutches and two brakes.

Owner:HYUNDAI MOTOR CO LTD

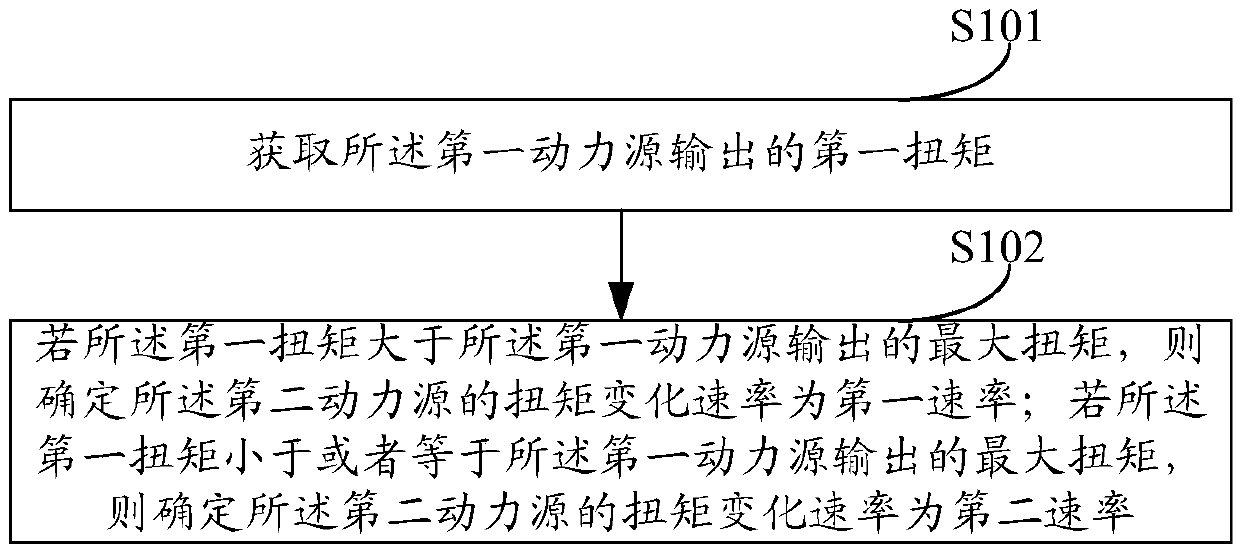

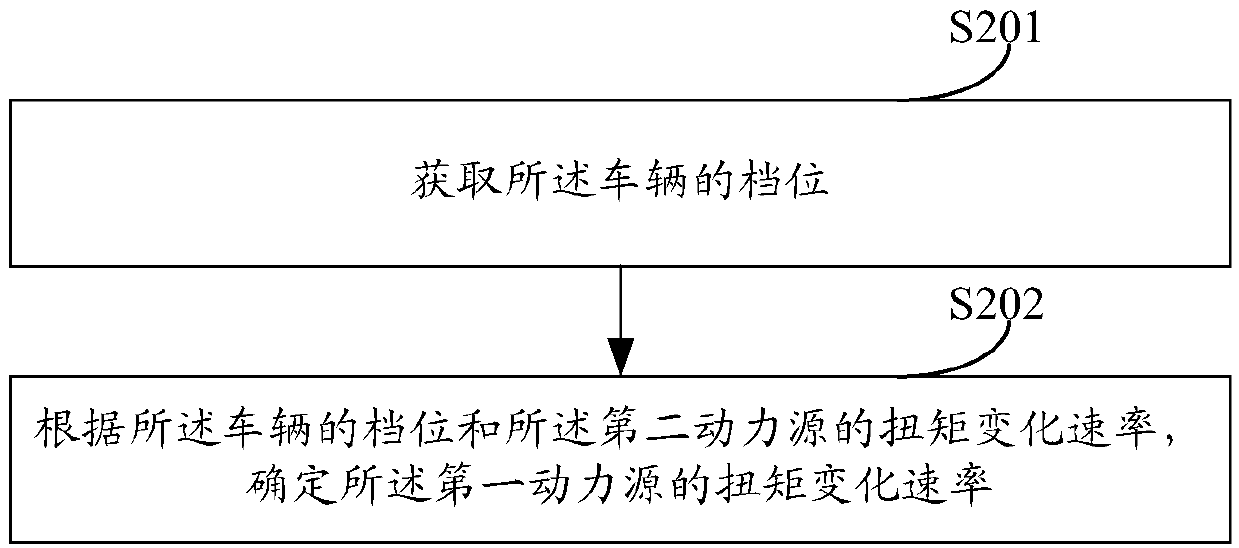

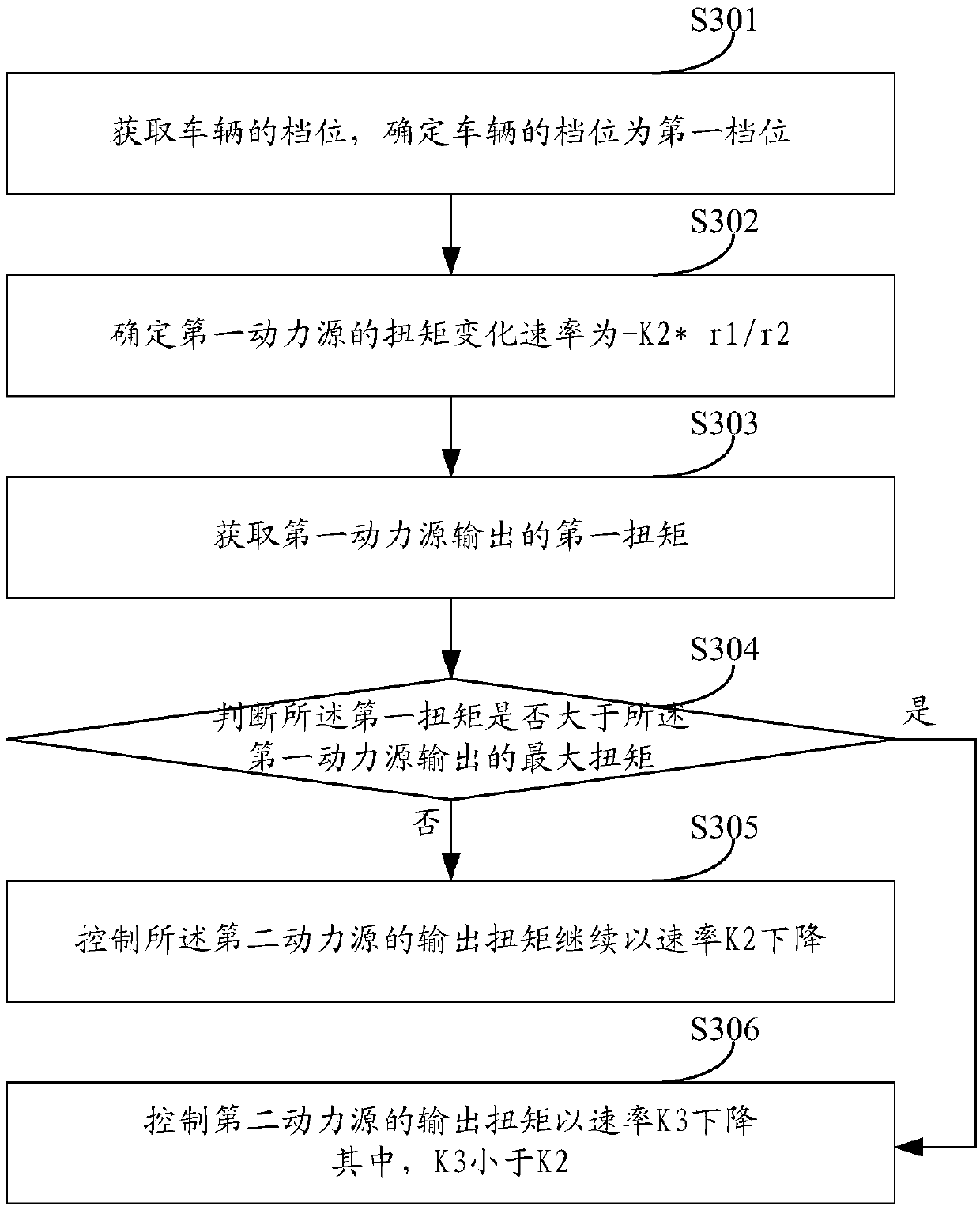

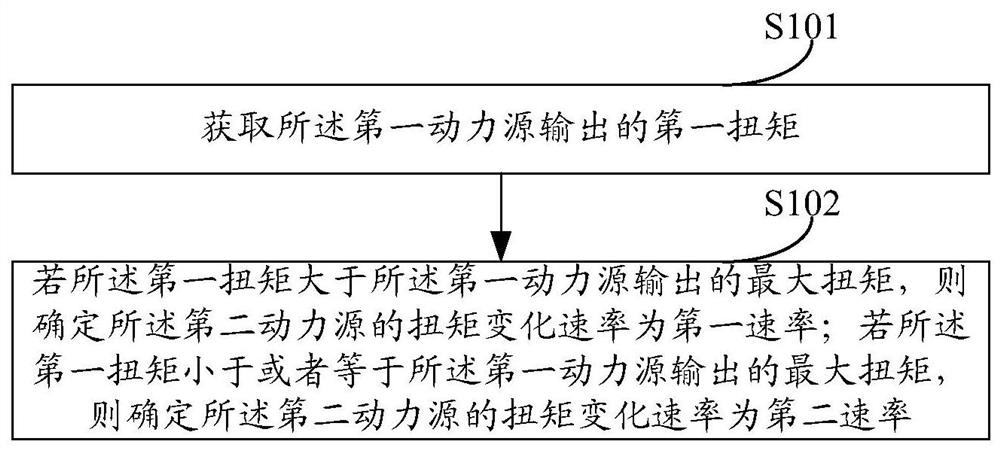

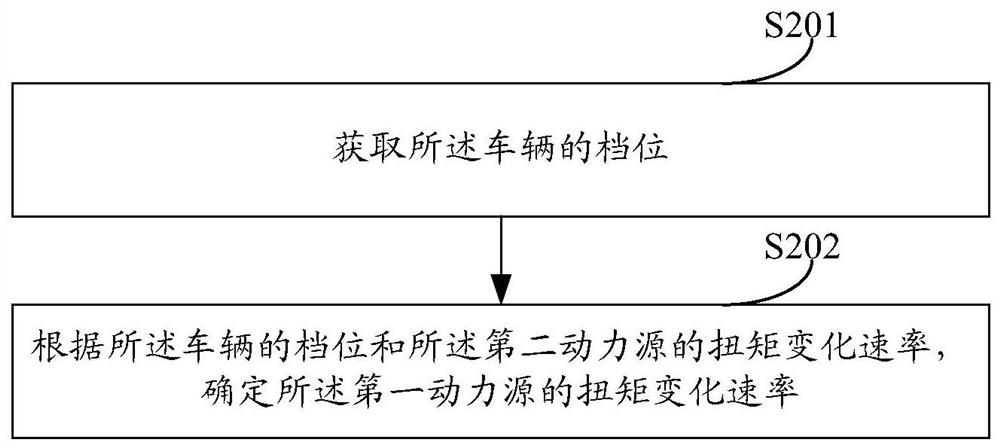

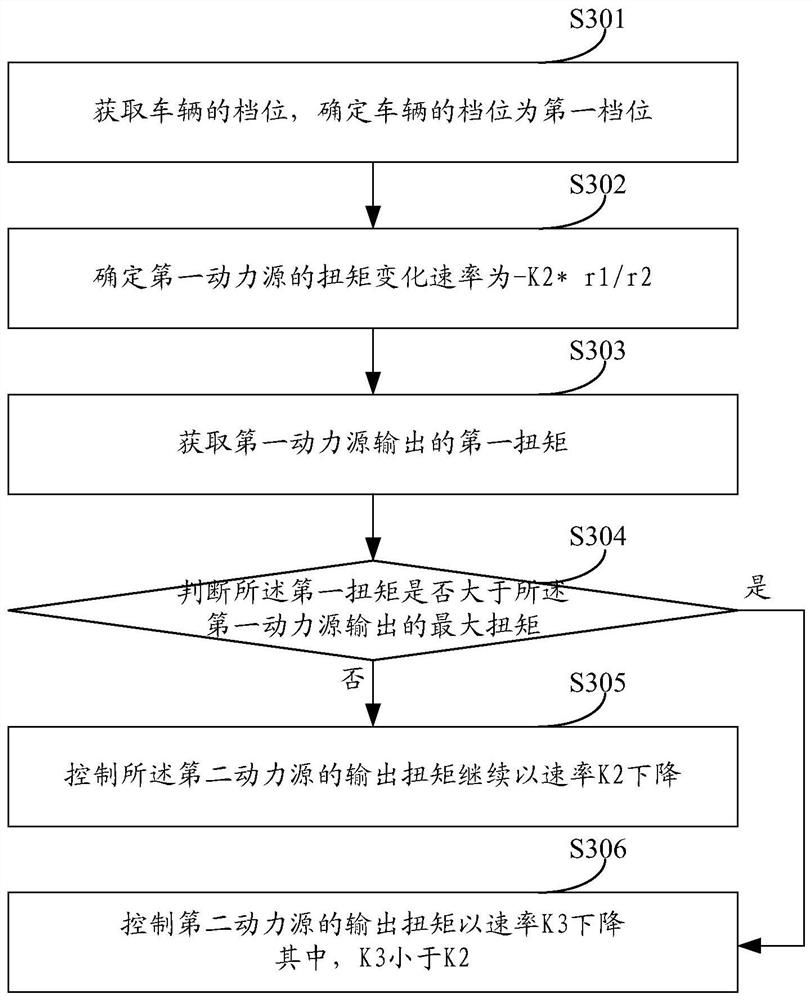

Method and device for adjusting torque of vehicle

ActiveCN111098843AImprove driving comfort performanceEnsure driving comfortHybrid vehiclesSpeed controllerMaximum torqueControl theory

The invention discloses a method and device for adjusting the torque of a vehicle. The vehicle comprises a first power source and a second power source. The method comprises steps that the first torque outputted by the first power source is obtained; if the first torque is greater than the maximum torque outputted by the first power source, the torque change rate of the second power source is determined as a first rate; if the first torque is smaller than or equal to the maximum torque outputted by the first power source, the torque change rate of the second power source is determined as a second rate; the first rate is smaller than the second rate, namely, when the first torque outputted by the first power source does not reach the maximum torque outputted by the first power source, the change rate of the torque output by the second power source is increased so as to increase the gear shifting speed; when the first torque outputted by the first power source reaches the maximum torqueoutputted by the first power source, the change rate of the torque outputted by the second power source is decreased to optimize the driving comfort, and the driving comfort of the vehicle can be guaranteed on the premise that the gear shifting time is proper.

Owner:SAIC MOTOR

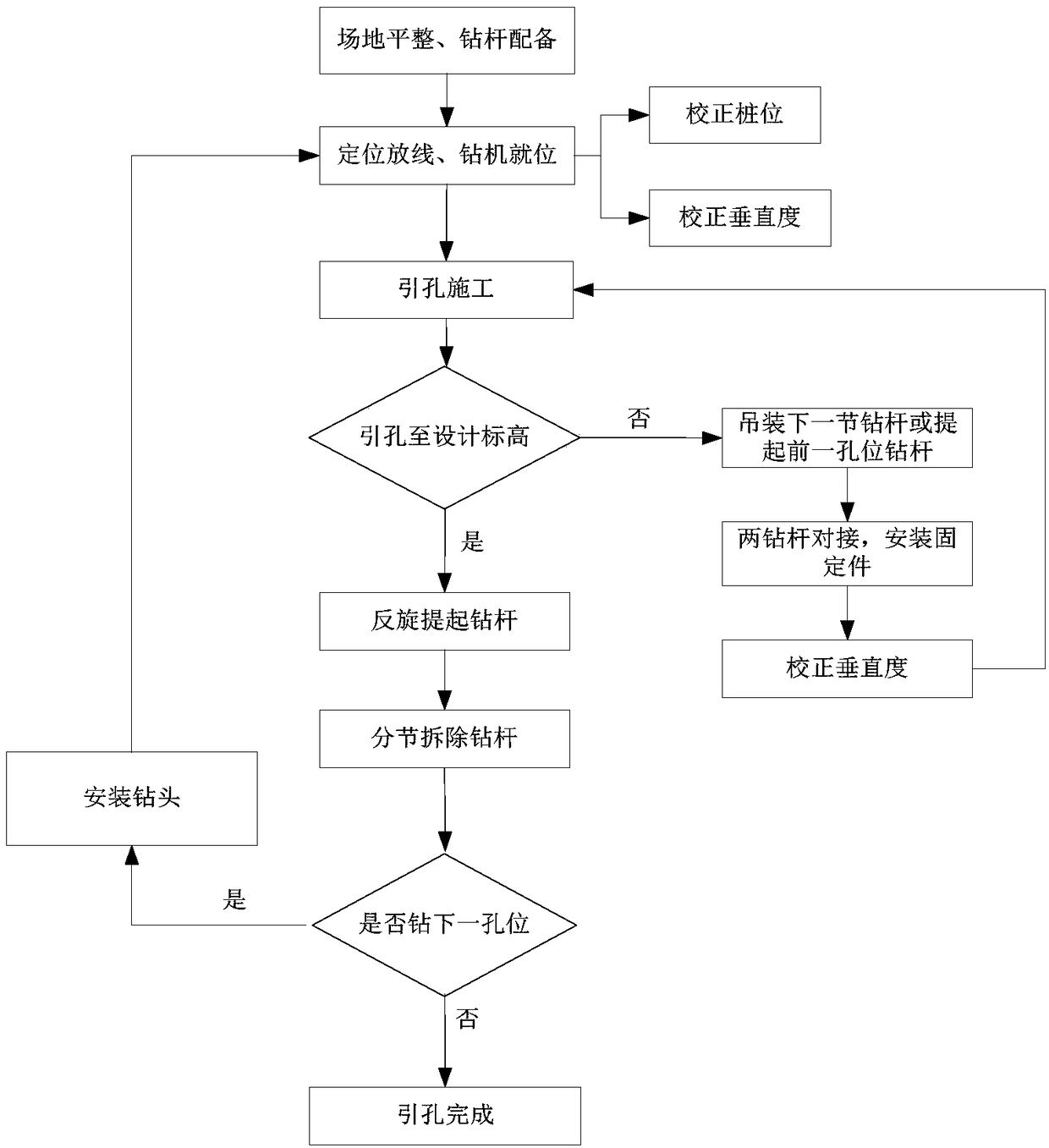

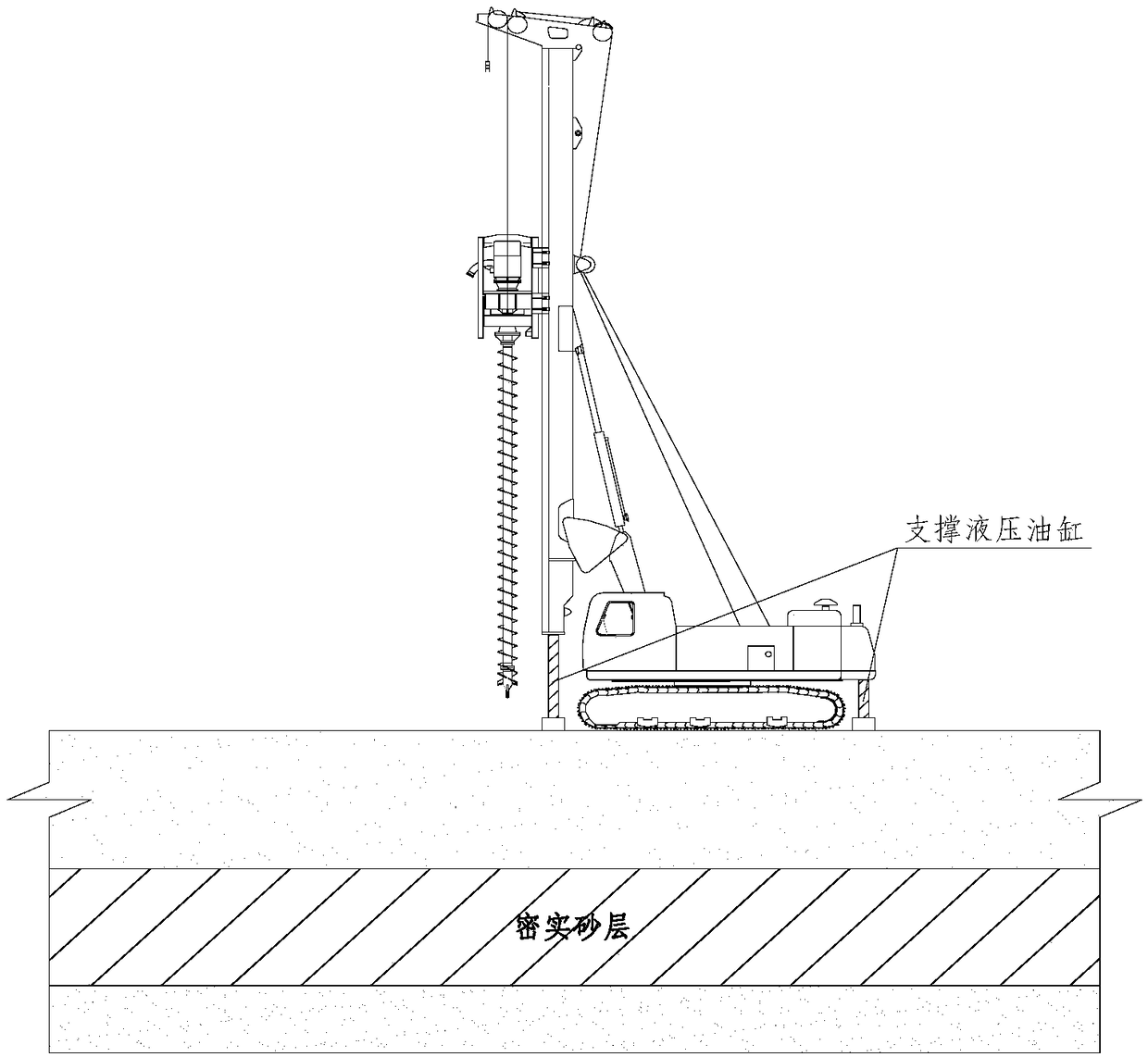

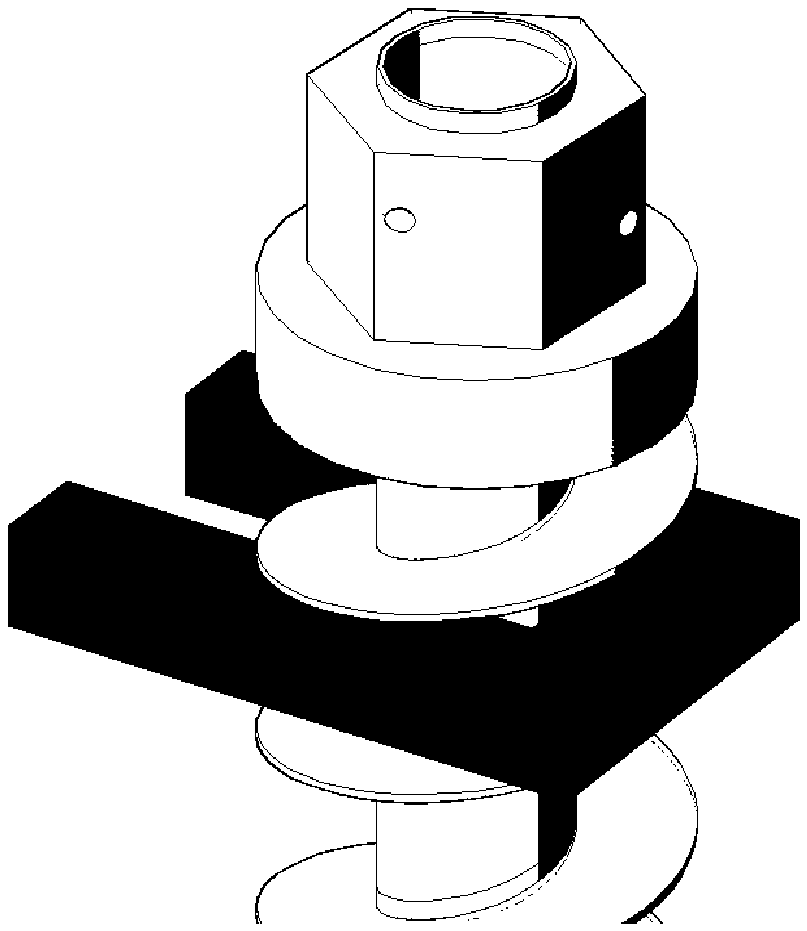

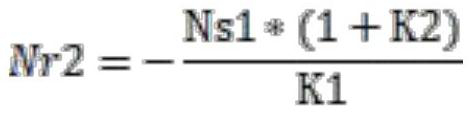

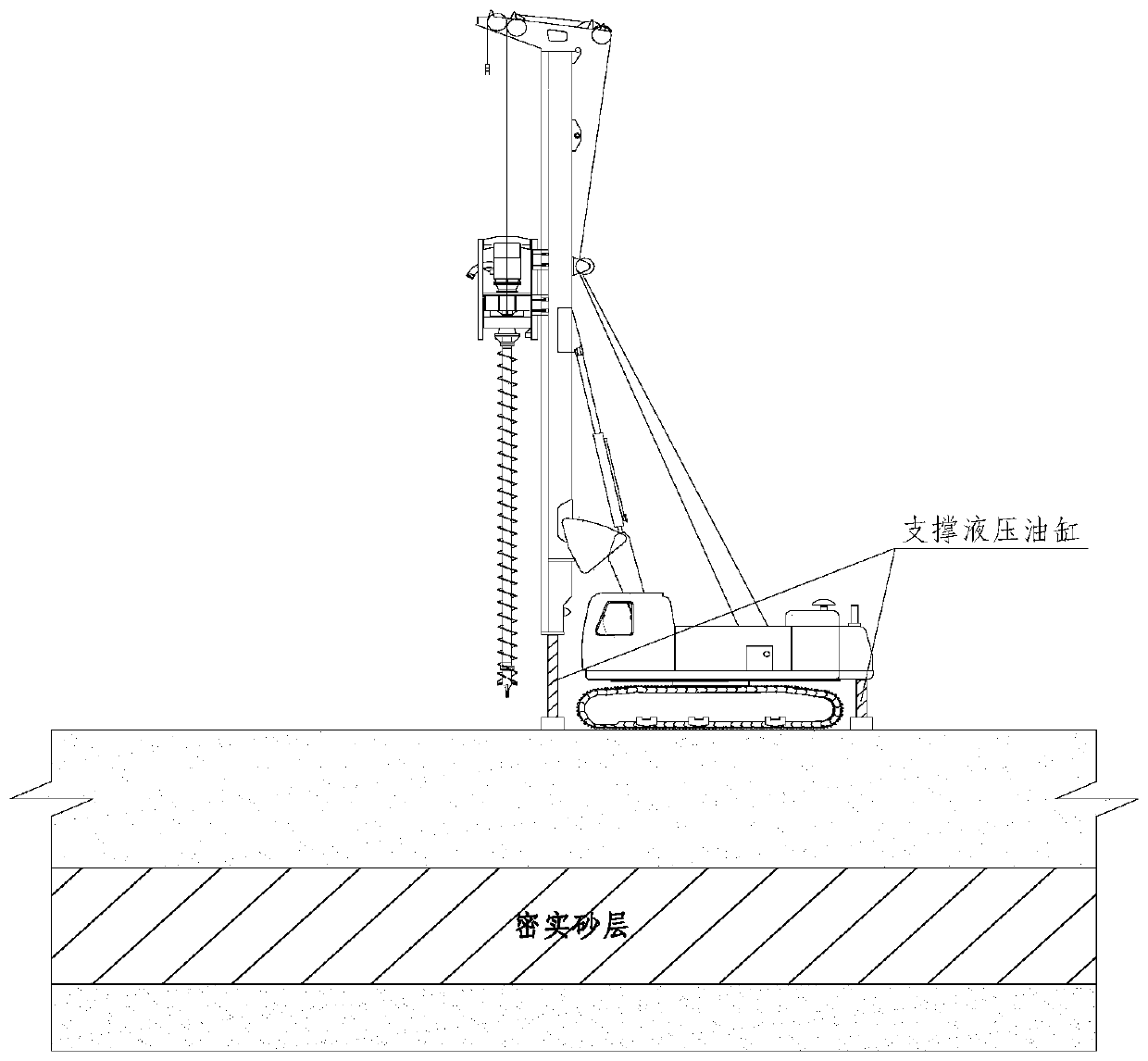

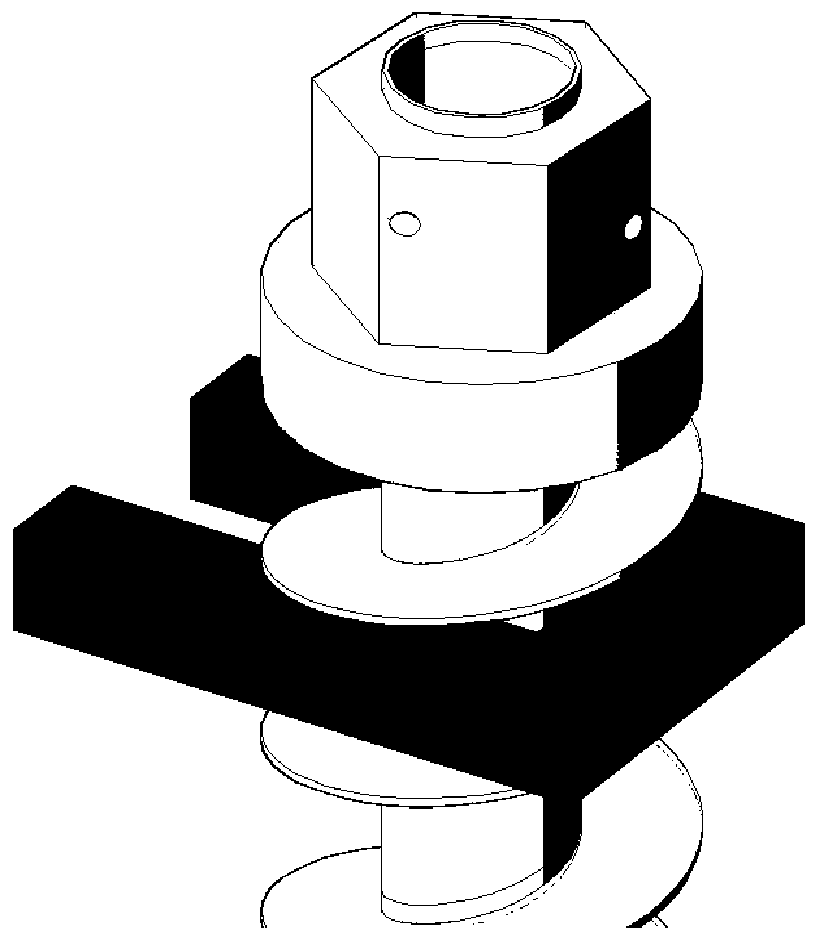

Ultra-deep and extra-thick dense sand stratum prestressed pipe pile long spiral lead hole construction method

ActiveCN109025816AFirmly connectedMeet the constructionDrilling rodsDirectional drillingTotal stationEngineering

The present invention discloses an ultra-deep and extra-thick dense sand stratum prestressed pipe pile long spiral lead hole construction method. The method comprises the following steps of: S1: siteformation and drill stem equipping: performing leveling and compaction for a site prior to place taking, or bedding a steel plate to facilitate place taking of a pile machine, and regulating equippingof the corresponding quantity of drill stems according to the depth of the lead holes to ensure the lead hole operation flow construction, wherein two lead hole drills are arranged on the site; and S2: location, paying-off and place taking of the pile machine: employing a total station to perform laying-off for preset lead hole stake positions, taking a drill machine in place to complete correction of the vertical degree of the drill stem and the centering of the center of the drill, and after location, putting down a support oil cylinder at the lower portion of a front-end mast and two support oil cylinders at the tail portion of the machine body of the drill machine. The ultra-deep and extra-thick dense sand stratum prestressed pipe pile long spiral lead hole construction method can extend the drill stem at will through connection according to pore-forming demands by employing a design of the hexagonal joint of the drill stem, can effectively ensure the reliable connection of the drill stem by only using a dual-way fixed plug pin after the drill stem is inserted when being connected and can meet the construction of an overlength pile hole.

Owner:SHENZHEN GONGKAN GEOTECHN GRP

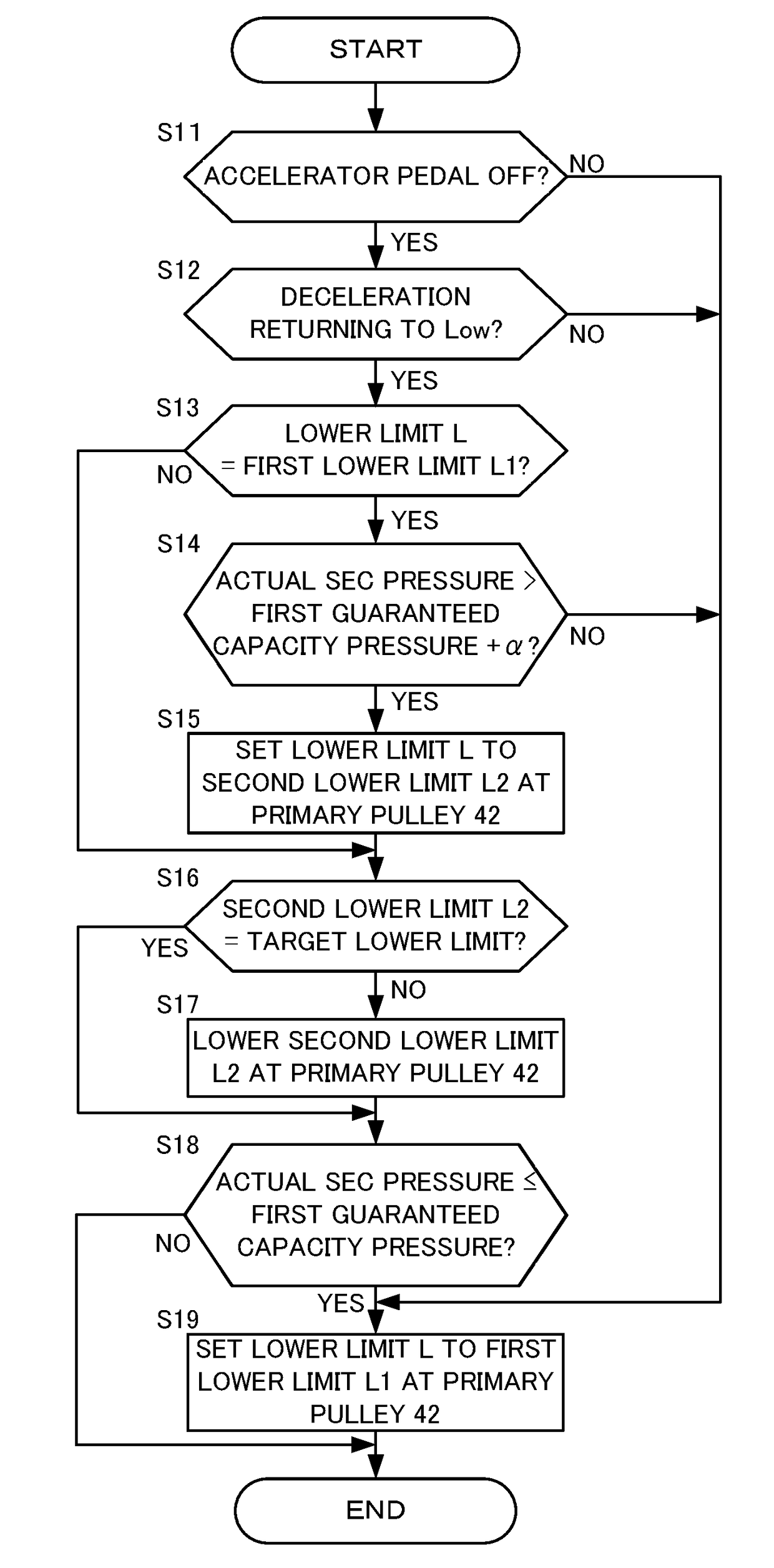

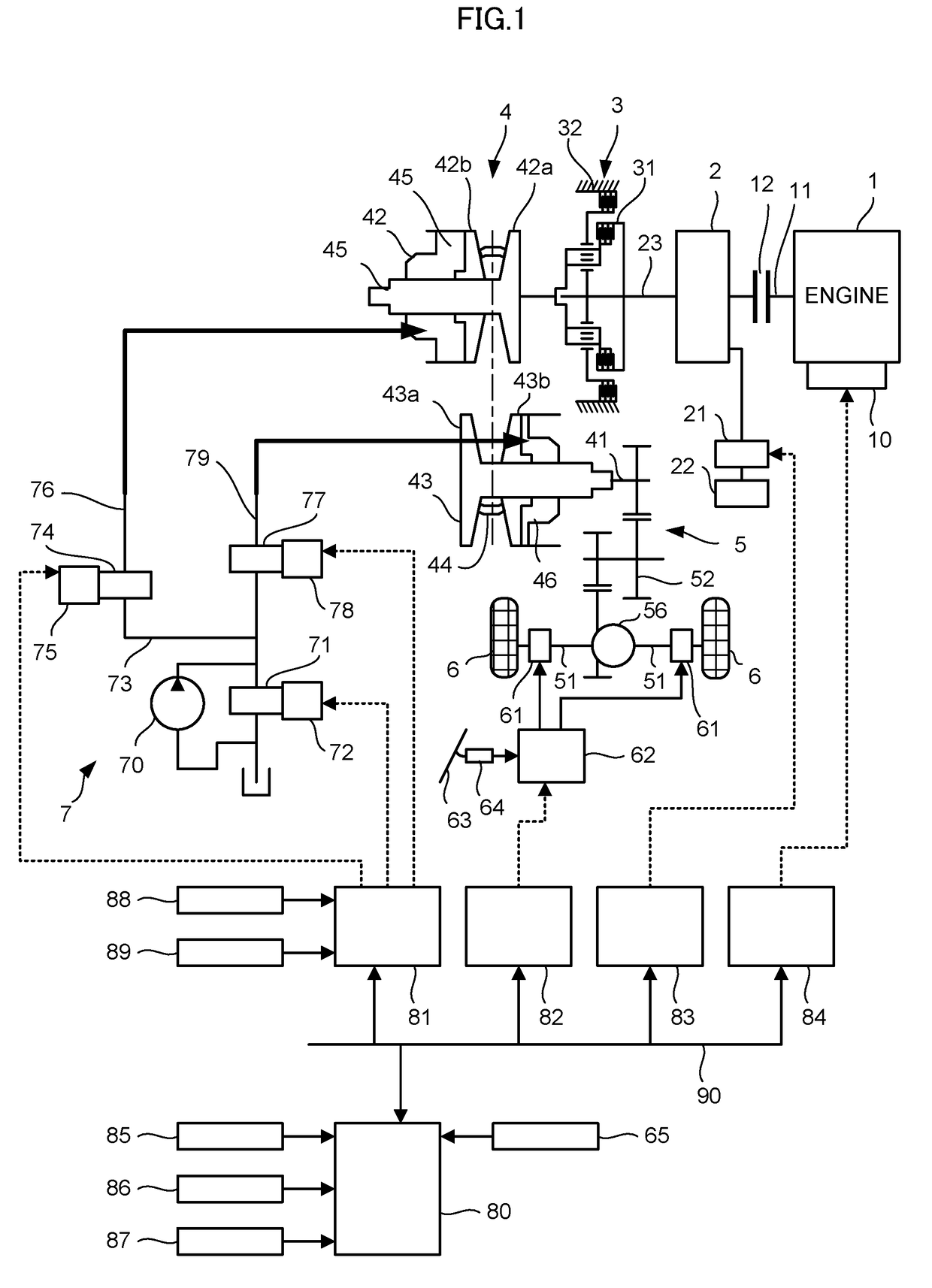

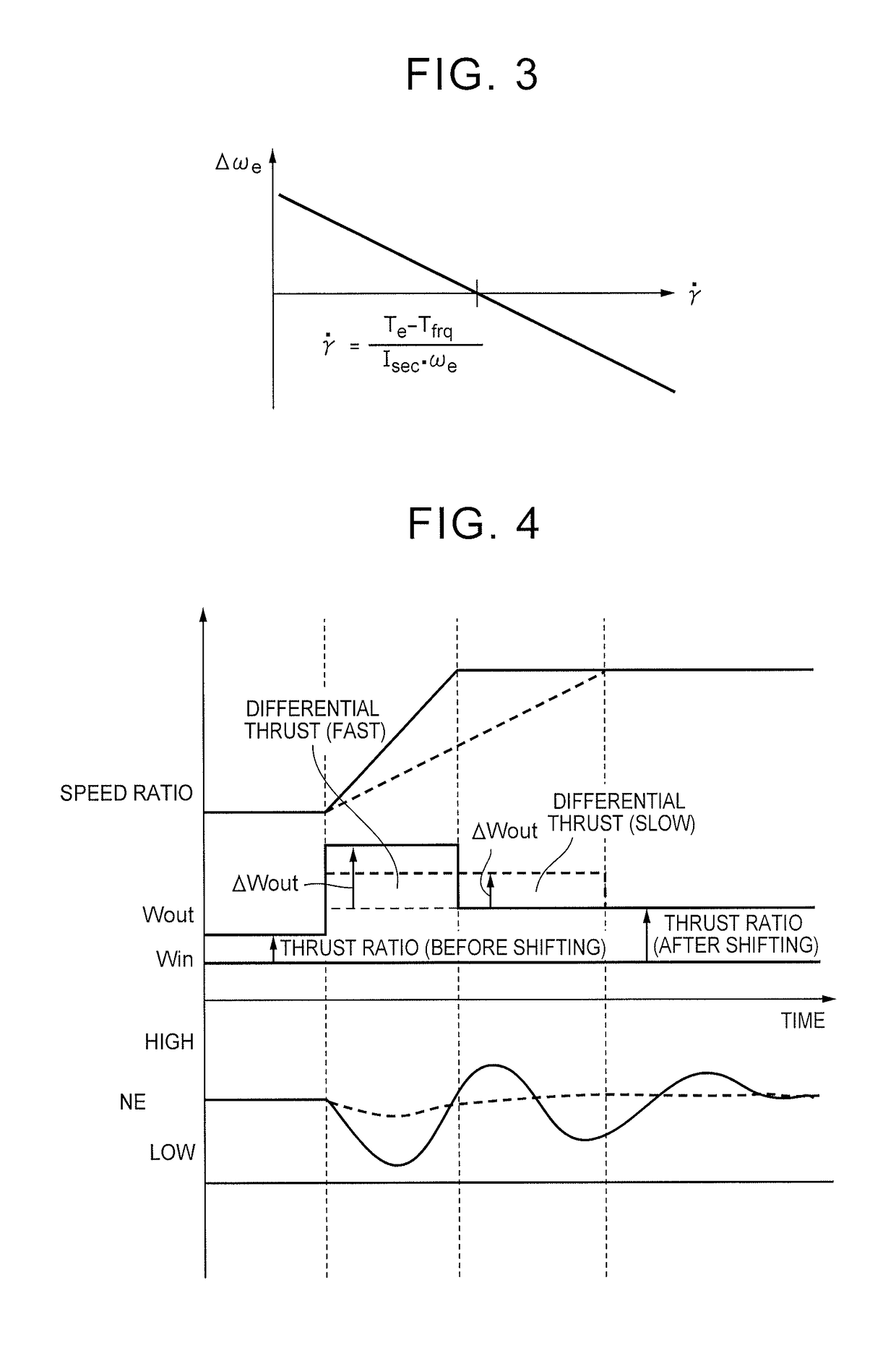

Vehicle and method for controlling the same

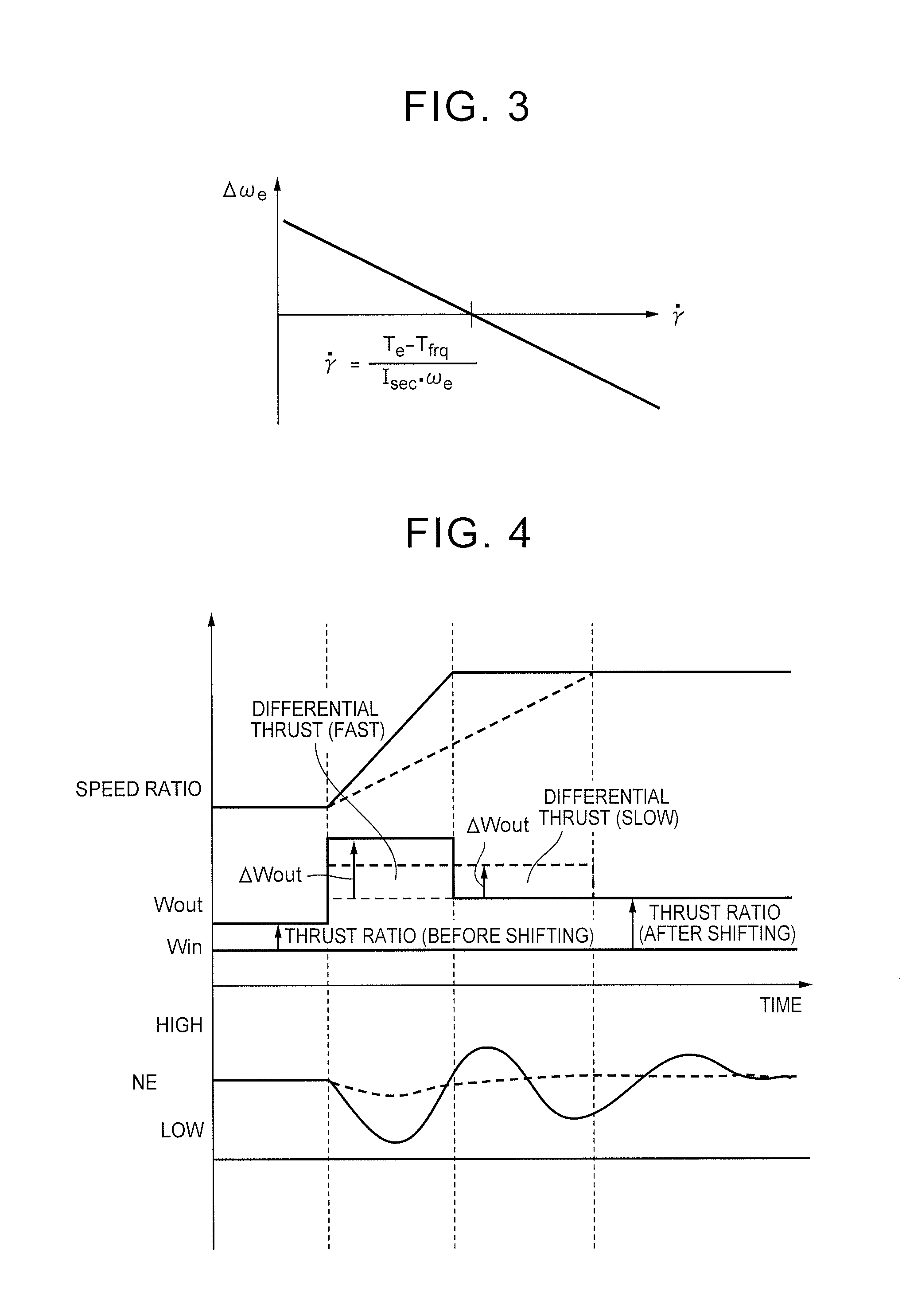

ActiveUS20180080553A1Easy transferIncrease the differential pressureHybrid vehiclesSpeed controllerLower limitHydraulic control unit

The present invention is related to a vehicle including a motor-generator, a transmission, a shift hydraulic control unit, and a CVT control unit (CVTCU). When a downshift of the transmission is performed without an acceleration request from a driver, the CVTCU sets a pulley thrust at a secondary pulley on the basis of a first lower limit as a lower limit, which is a sum of a fundamental thrust and a first correction thrust. The CVTCU also sets a pulley thrust at a primary pulley on the basis of a second lower limit as a lower limit, which is a sum of the fundamental thrust and a second correction thrust.

Owner:JATCO LTD +1

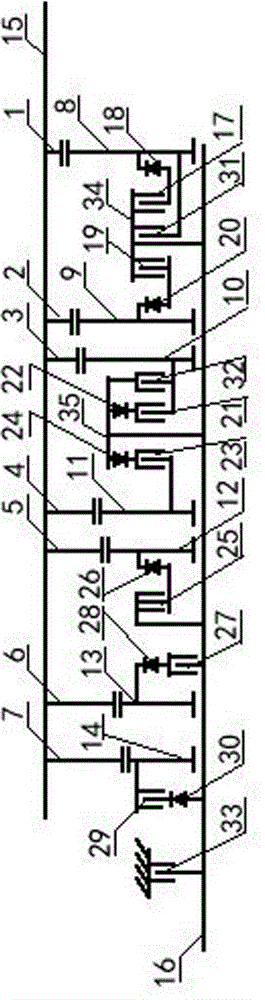

Gear position overlapped type multistage automatic transmission

InactiveCN104633017ASimple and smooth shifting procedureNo shift interference issuesToothed gearingsTransmission elementsAutomatic transmissionEngineering

The invention discloses a gear position overlapped type multistage automatic transmission. The gear position overlapped type multistage automatic transmission comprises a power input shaft and a power output shaft. A plurality of driving gears are mounted on the power input shaft. Each driving gear corresponds to one gear position. At least seven driven gears are correspondingly mounted on the power output shaft. Each driven gear corresponds to one gear position. The outer side of each driven gear is provided with a clutch and an overrunning clutch. The clutches are controlled by gear shift oil pressure. The power output shaft drives the working ends of the driven gears to rotate through the clutches and the overrunning clutches. The working ends of the driven gears are meshed with the driving gears on the power input shaft. Compared with the prior art, the gear position overlapped type multistage automatic transmission has the advantages that when the clutches conduct upshifting, the engaged low-gear clutches do not need to be disengaged; when the clutches conduct downshifting, downshifting can be achieved just by disengaging the clutches one by one from the top gear; the gear shifting process is simple and smooth, and the gear shifting speed can be effectively increased.

Owner:解利

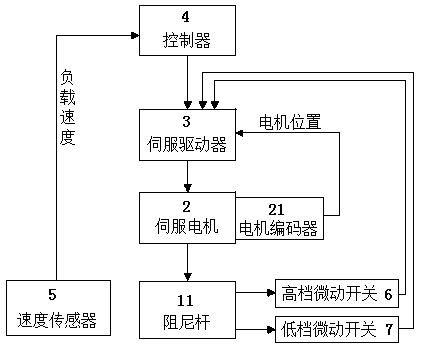

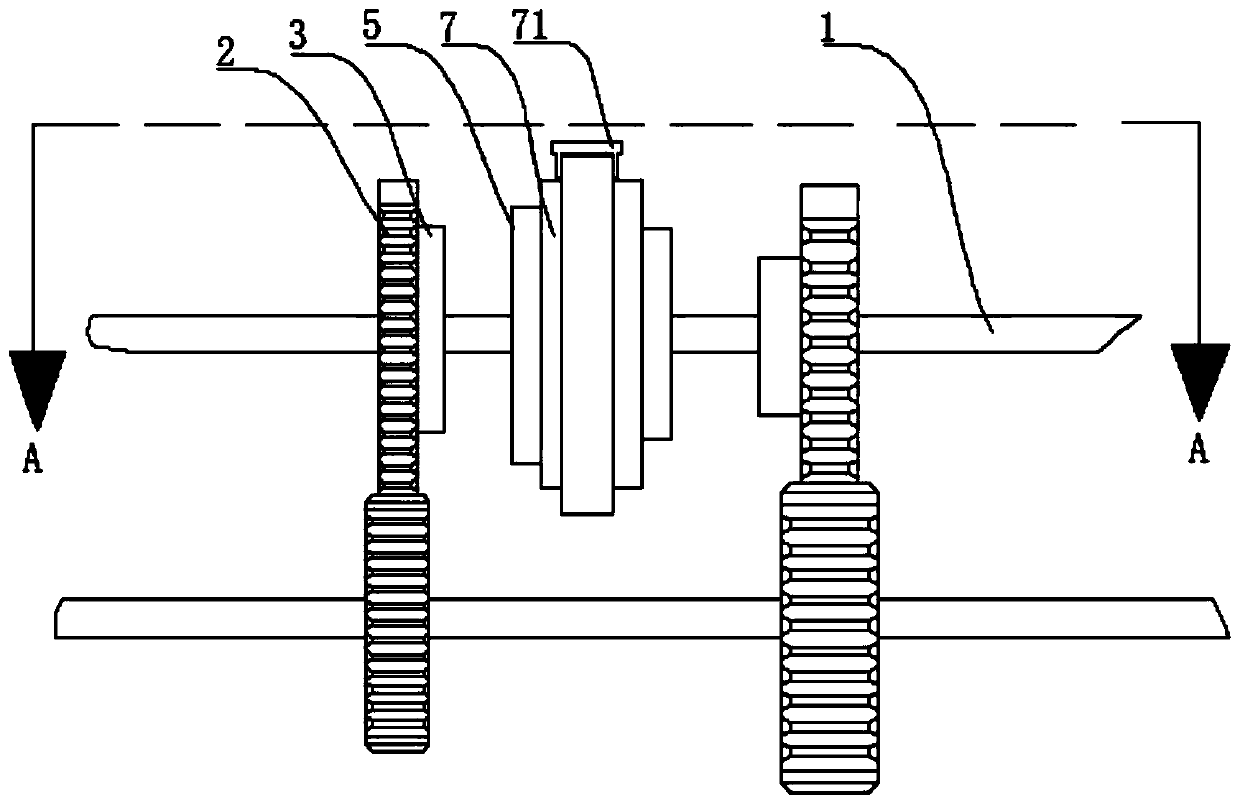

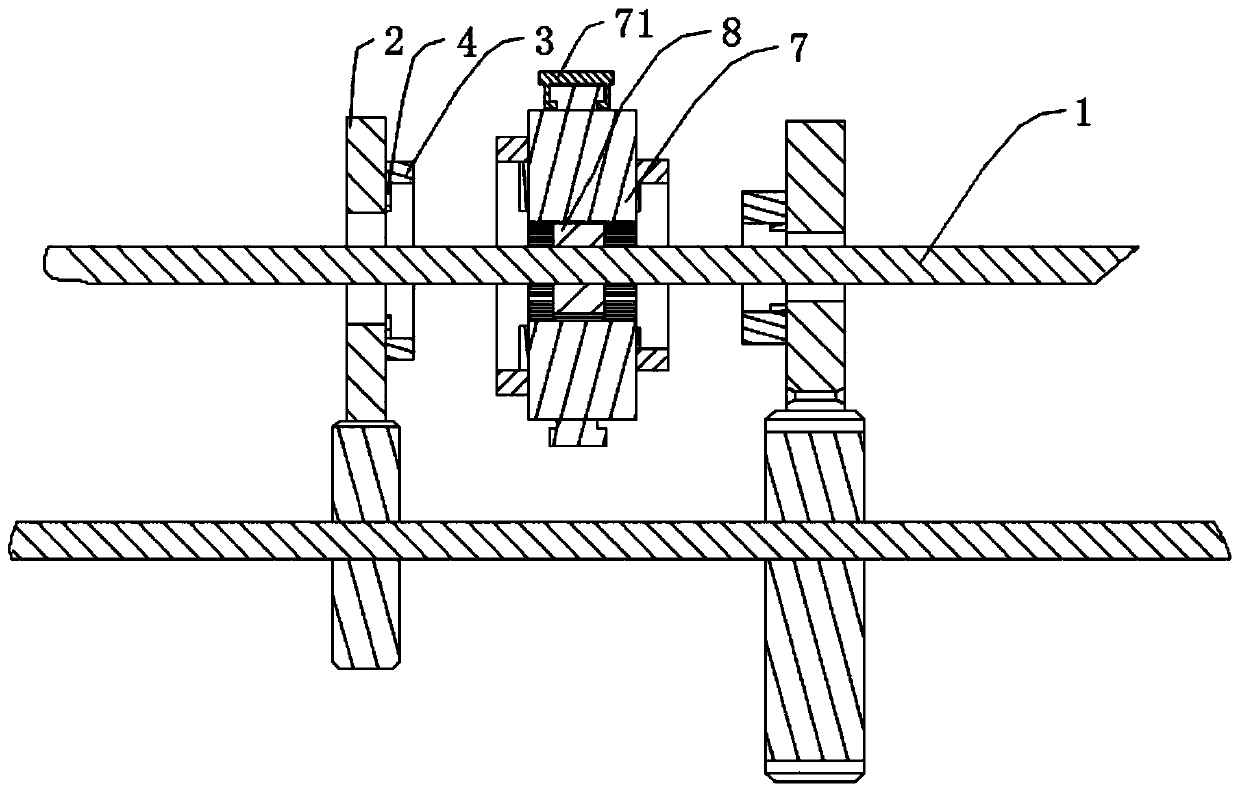

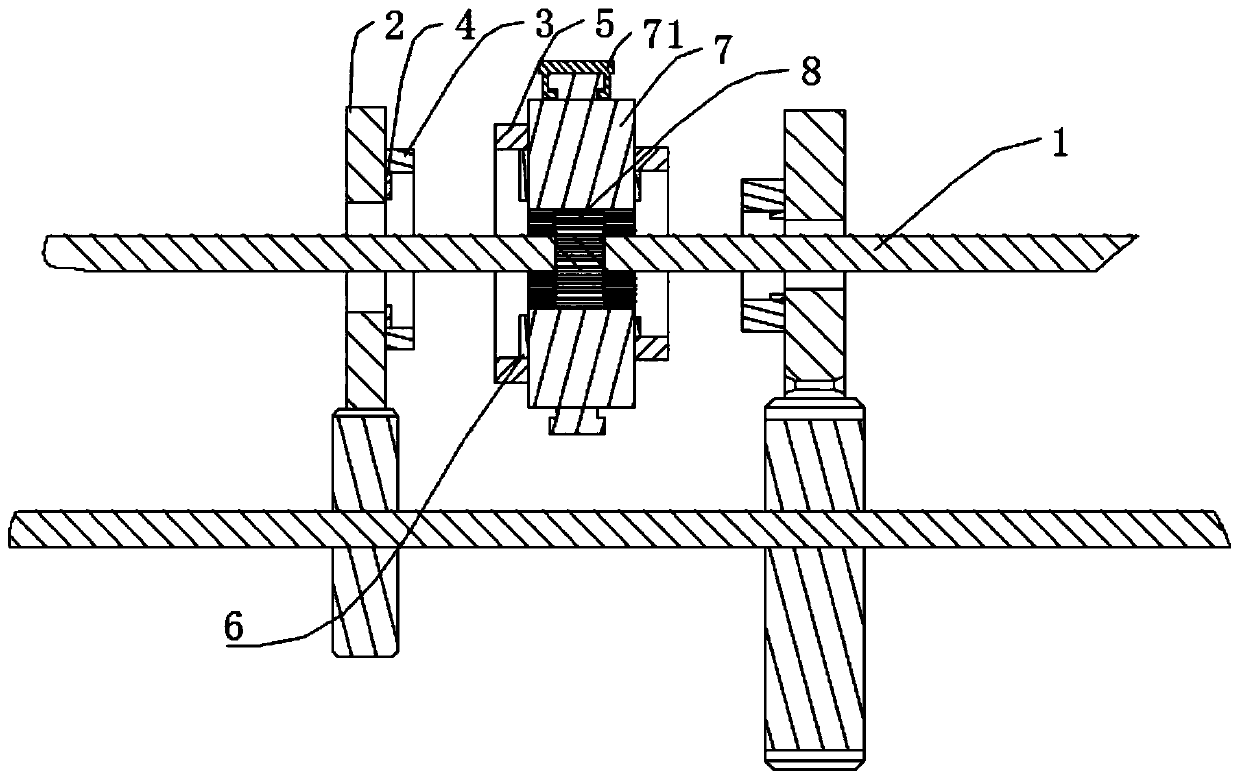

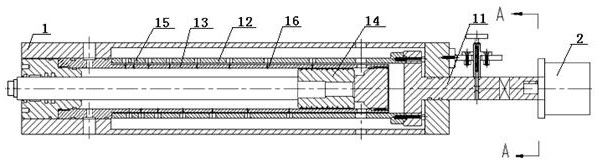

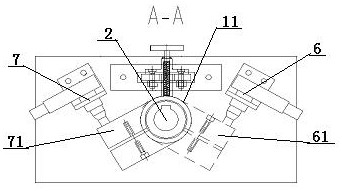

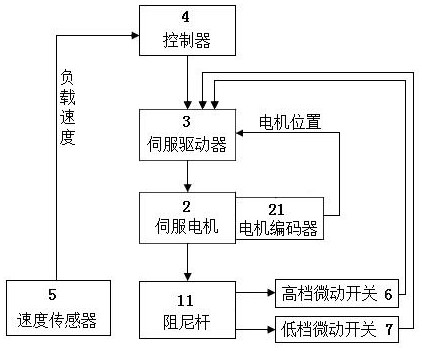

Accurate control method for buffer oil cylinder

ActiveCN108916295AEasy to controlPrecise Design ControlSpringsSprings/dampers design characteristicsFeedback controlEncoder

The invention discloses an accurate control method for a buffer oil cylinder. Signal output ends of a high-position microswitch and a low-position microswitch are both in signal connection with a signal input end of a servo driver, a signal output end of the servo driver is in signal connection with a control end of a servo motor, a signal output end of a motor encoder of the servo motor is in signal connection with the servo motor, the servo driver is in signal connection with a controller, and the controller is in signal connection with a signal output end of a speed sensor on a load. The method includes: step one, load speed acquisition and control instruction sending; step two, servo motor rotation under PID control; step three, switch feedback control; step four, position shifting completion. High position shifting speed, high reliability and high position shifting accuracy are realized.

Owner:WUHAN MARINE MACHINERY PLANT

Magnetic synchronizer and transmission

PendingCN111207157ALow costEasy to manufactureMechanical actuated clutchesMagnetically actuated clutchesGear wheelControl theory

The invention provides a magnetic synchronizer and a transmission. The magnetic synchronizer comprises a gear hub, a joint sleeve, a first magnetic piece and a second magnetic piece, wherein the gearhub is used for being coaxially connected with an output shaft; the joint sleeve is coaxially arranged on the gear hub in a sleeving mode and used for freely sliding in the axial direction of the gearhub when being driven by external force; a plurality of N poles and S poles which are arranged in a staggered manner are arranged on the first magnetic piece, and the first magnetic piece is used forbeing fixedly connected with an idle gear which idles on the output shaft; the second magnetic piece is fixedly connected with the joint sleeve, and a plurality of N poles and S poles which are arranged in a staggered manner are arranged on the second magnetic piece; and when the magnetic synchronizer is used for gear shifting operation, a magnetic field generated by the first magnetic piece is matched to drive the joint sleeve and the idle gear to rotate synchronously. The magnetic synchronizer provided by the invention has no noise, and the structure of the synchronizer cannot be abraded; and friction is not generated in the gear shifting process, and the gear shifting speed is improved. The magnetic synchronizer also has the characteristics of low cost, convenient manufacture and longservice life.

Owner:HARBIN INST OF TECH AT WEIHAI

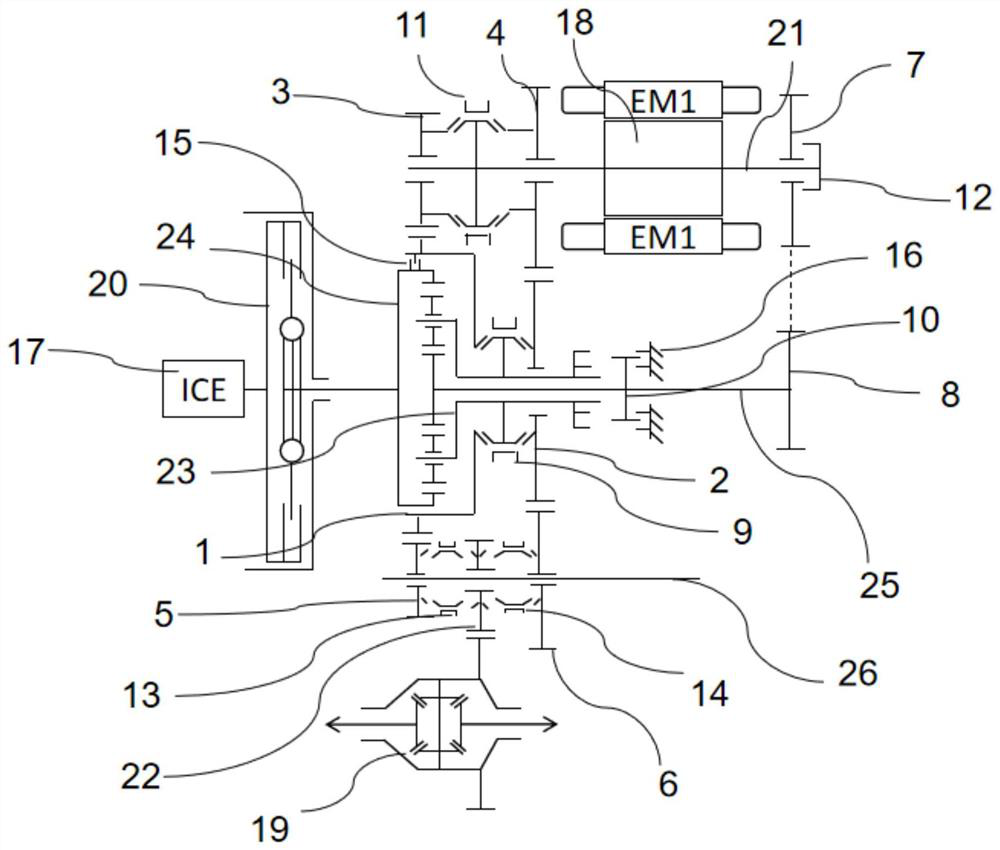

Hybrid power gearbox, hybrid power driving system and vehicle

ActiveCN114274758ARealize multi-gear outputSolve the starter functionHybrid vehiclesGas pressure propulsion mountingGear wheelControl engineering

The invention discloses a hybrid power gearbox, a hybrid power driving system and a vehicle. The hybrid power gearbox comprises a box body, a single planet row, an intermediate shaft, a parallel gear set, an output transmission mechanism and seven executing mechanisms, and the first executing mechanism is selectively connected with a first parallel gear or a second parallel gear; the second actuating mechanism is selectively connected with the planet carrier or the box body; the third executing mechanism is selectively connected with the third parallel gear or the fourth parallel gear; the fourth executing mechanism is used for connecting or disconnecting the seventh parallel gear and the intermediate shaft; the fifth executing mechanism selectively connects or disconnects the fifth parallel gear and the output gear; a sixth executing mechanism selectively connects or disconnects a sixth parallel gear and the output gear; according to the invention, power output by the engine and the motor is distributed and guided through the plurality of executing mechanisms and the plurality of parallel gears, so that multi-gear output under the premise of dual power of the engine and constant-speed-ratio output of a planet row are realized.

Owner:DONGFENG MOTOR GRP

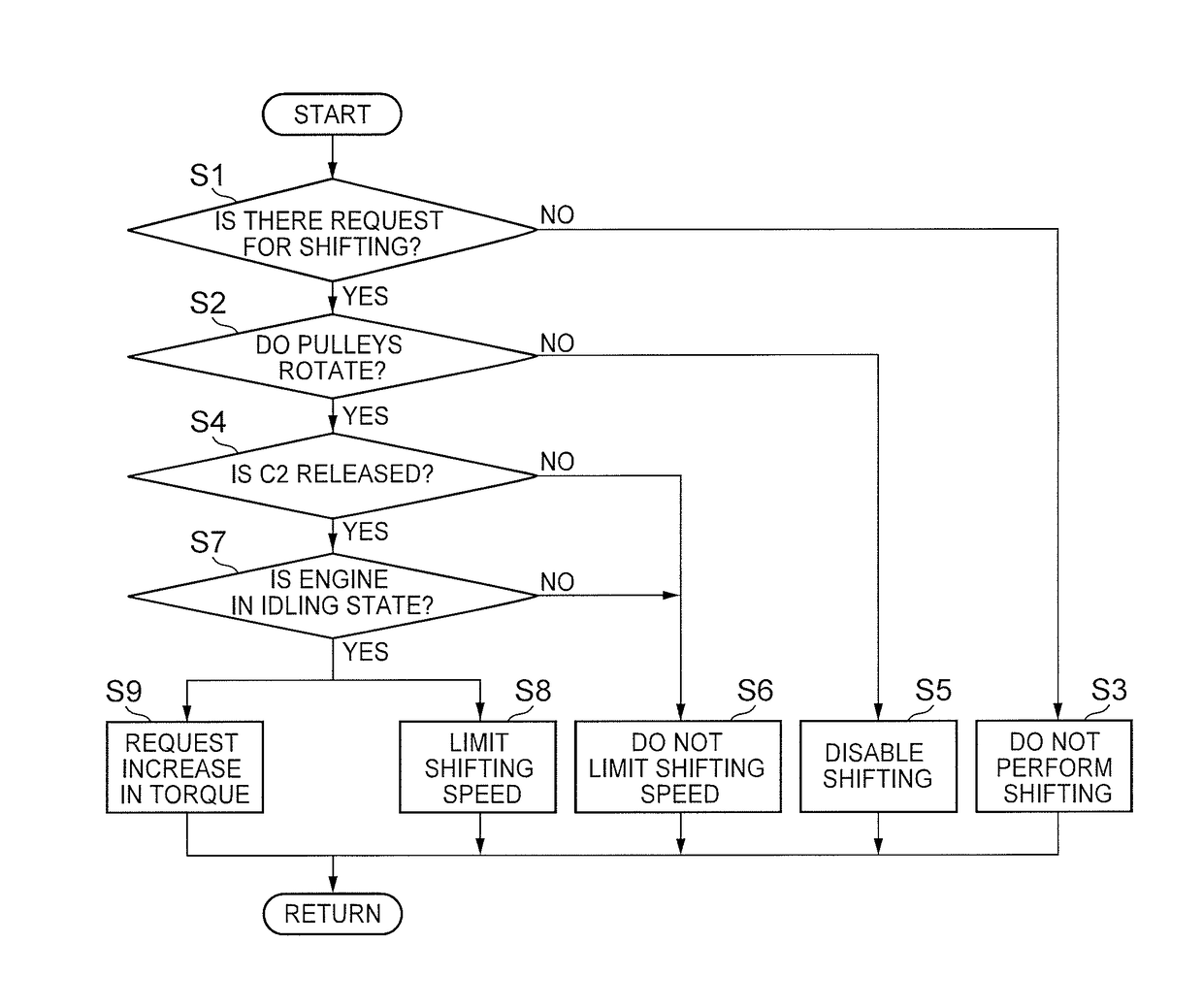

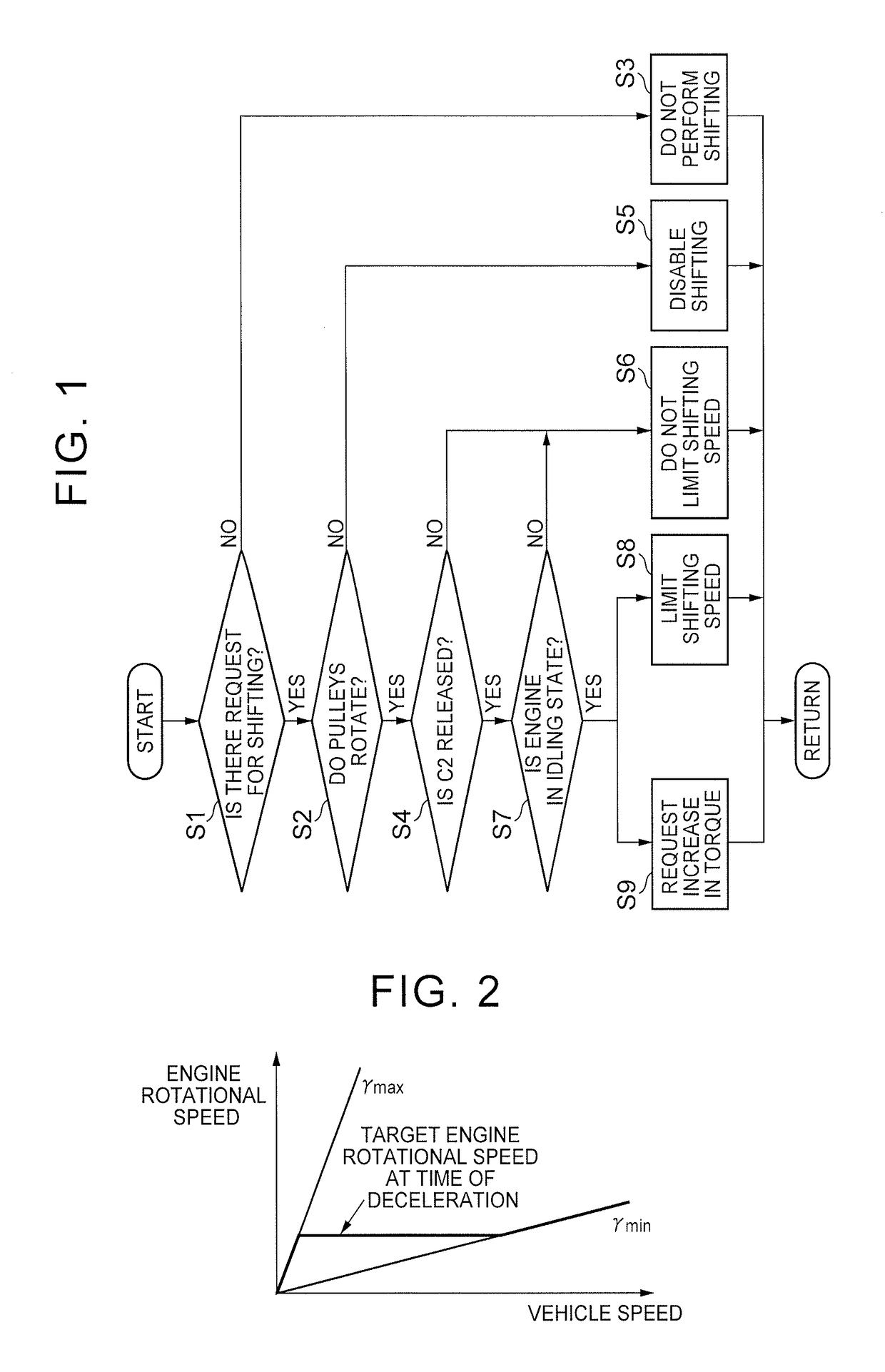

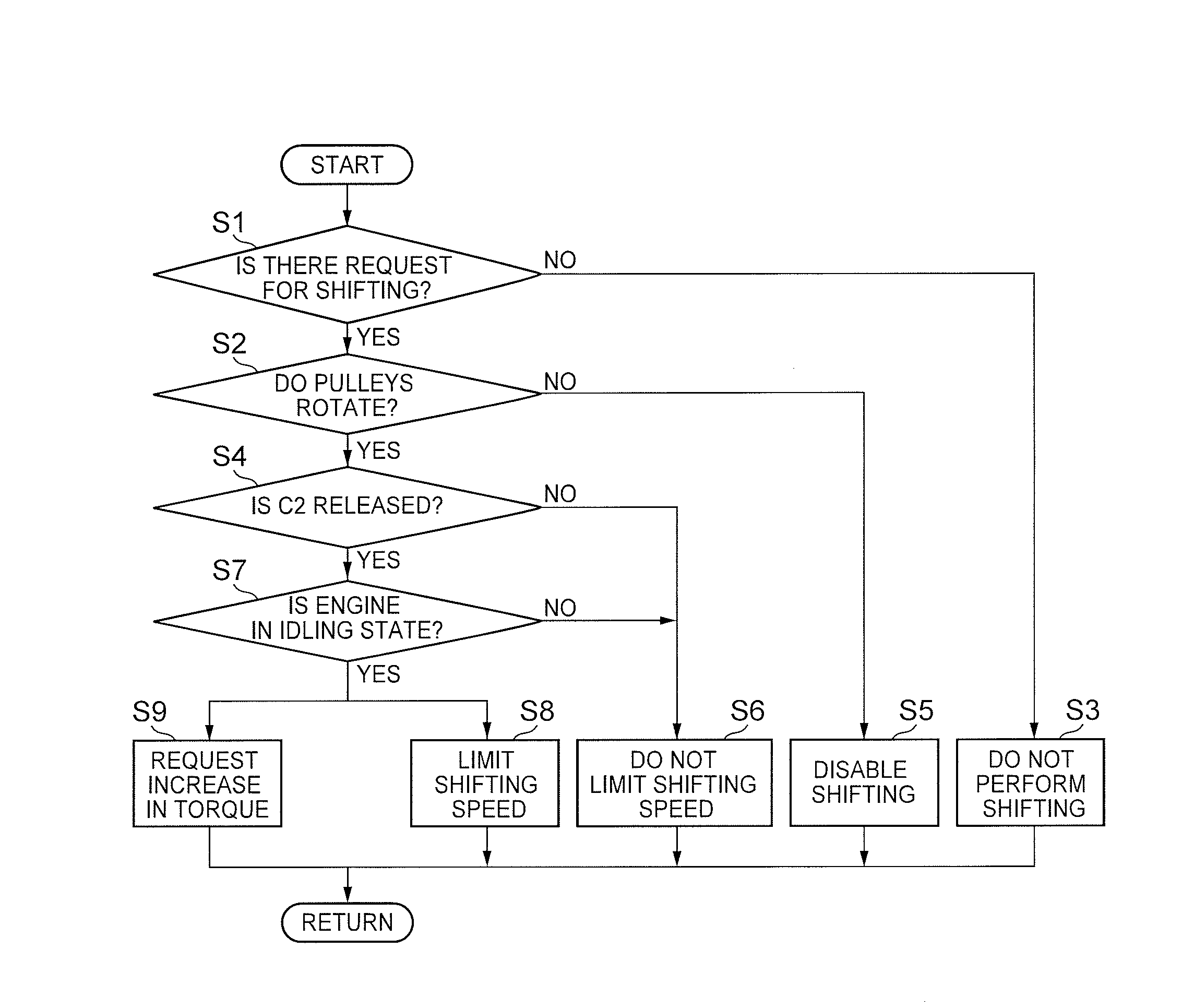

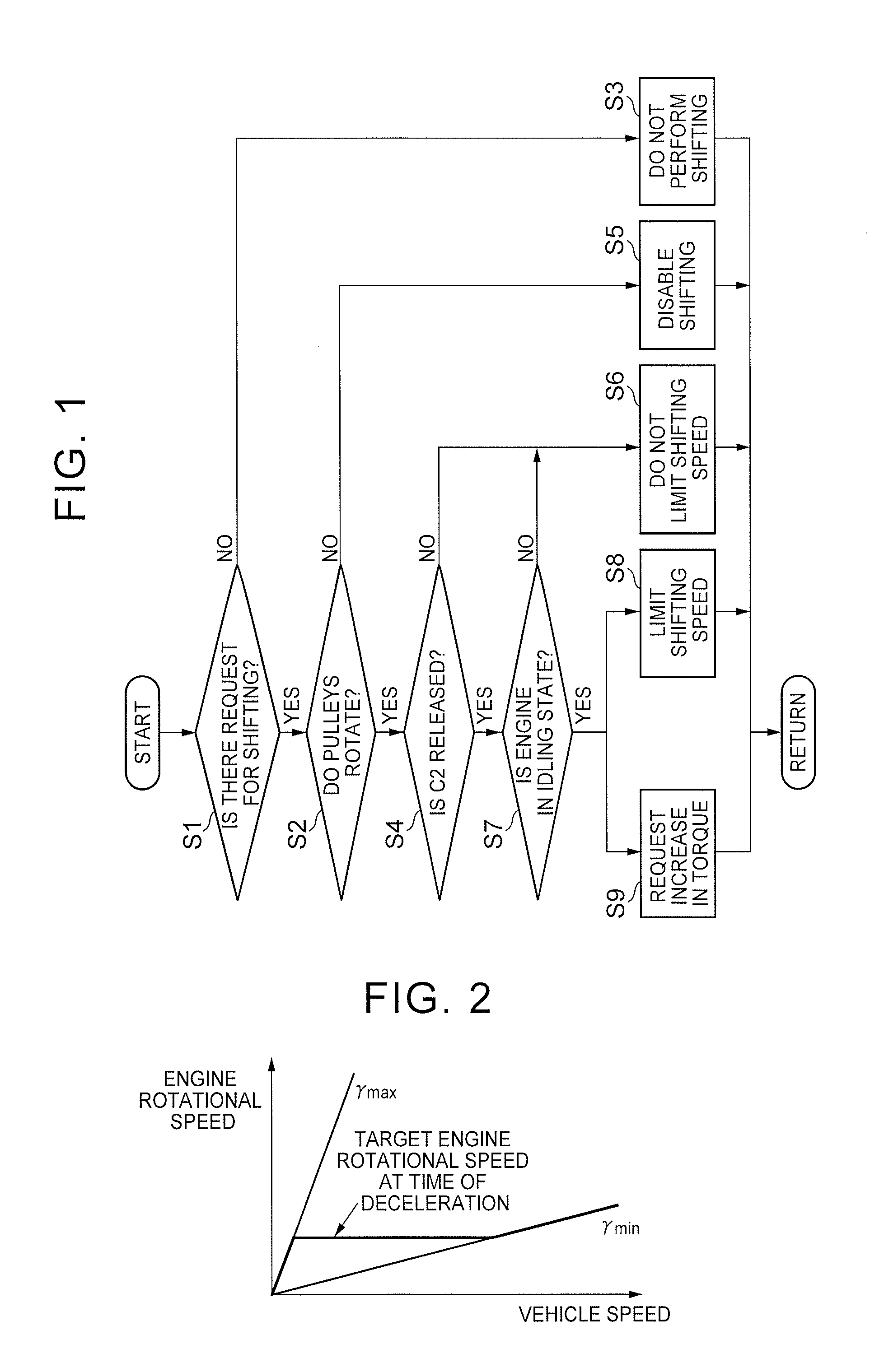

Control apparatus for transmission for vehicle

ActiveUS9663110B2Prevent and restrain rotational speedPrevent speedingGearingGearing controlDrive wheelTorque transmission

A vehicle transmission has a continuously variable speed change mechanism provided between an input shaft to which a torque output by a driving force source is transmitted and an output shaft from which a torque is output to a driving wheel. The transmission is able to selectively block torque transmission between the mechanism and the output shaft. The mechanism is rotated by the driving force source with torque transmission between the mechanism and the output shaft blocked. A control apparatus limits a shifting speed of the mechanism to or below an upper-limit speed determined in advance in a case where a speed ratio of the mechanism is changed with the mechanism rotated by the driving force source that is subjected to idling rotational speed control, while the mechanism is blocked from the output shaft such that no torque is transmitted between the mechanism and the output shaft.

Owner:TOYOTA JIDOSHA KK

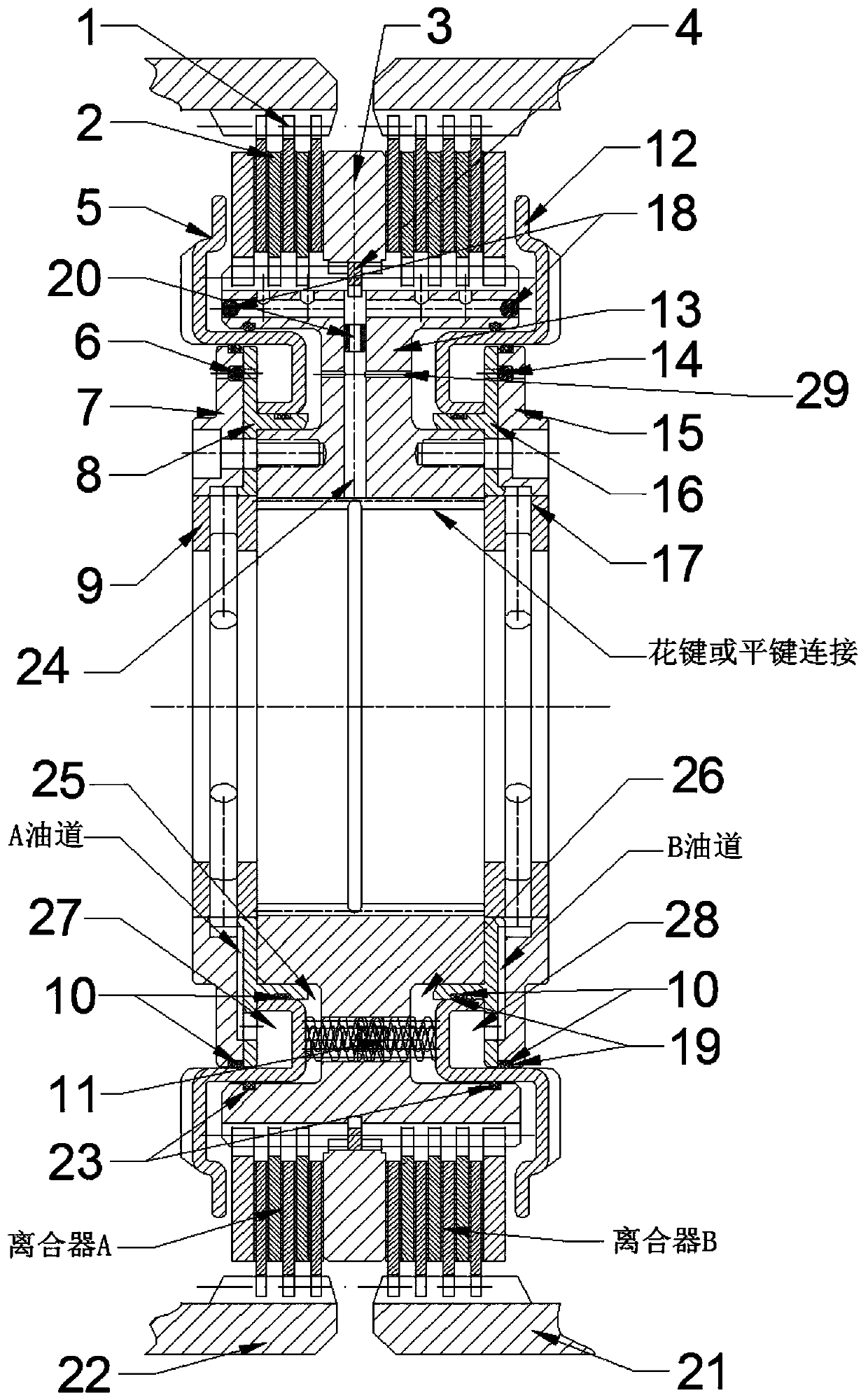

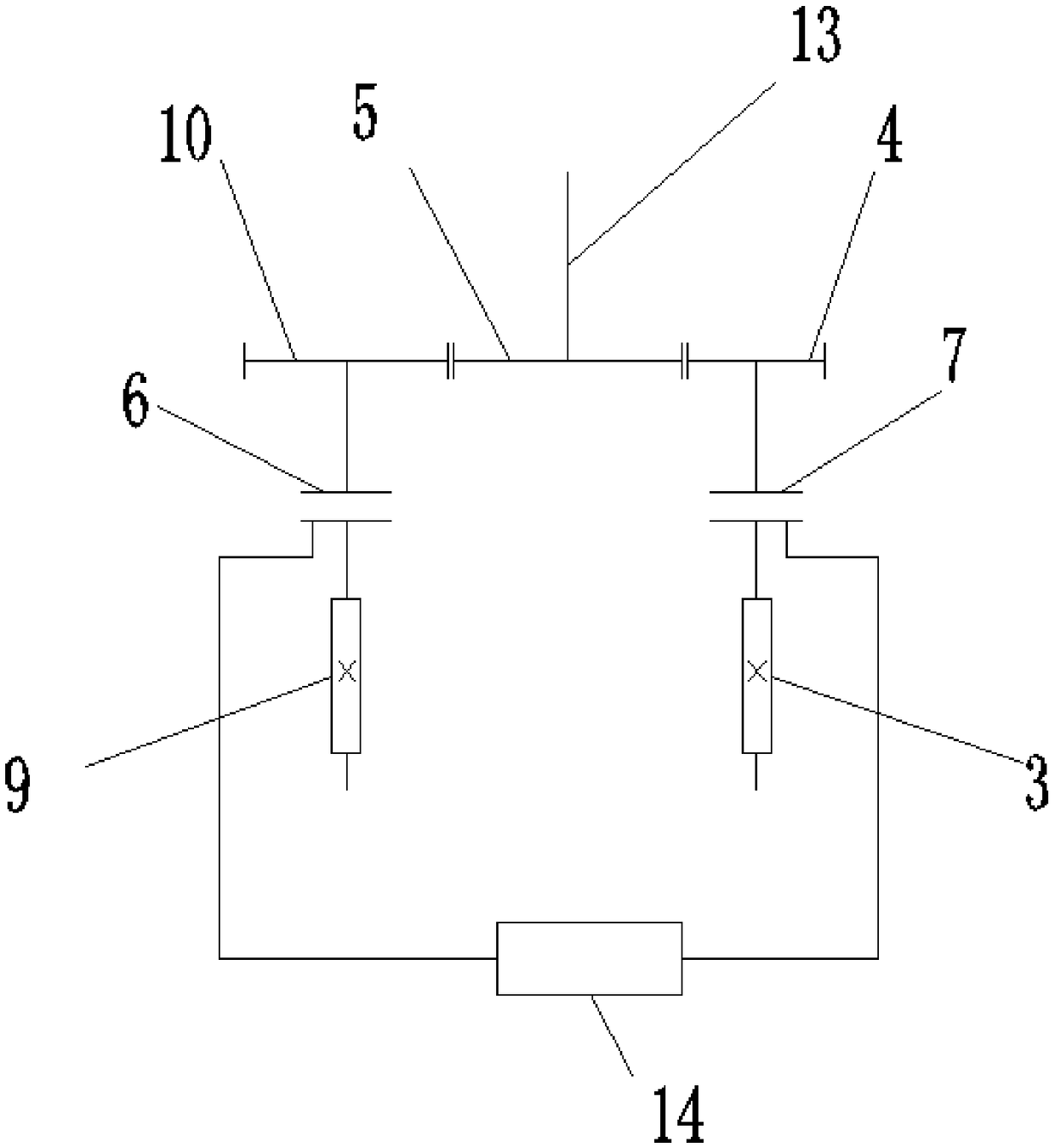

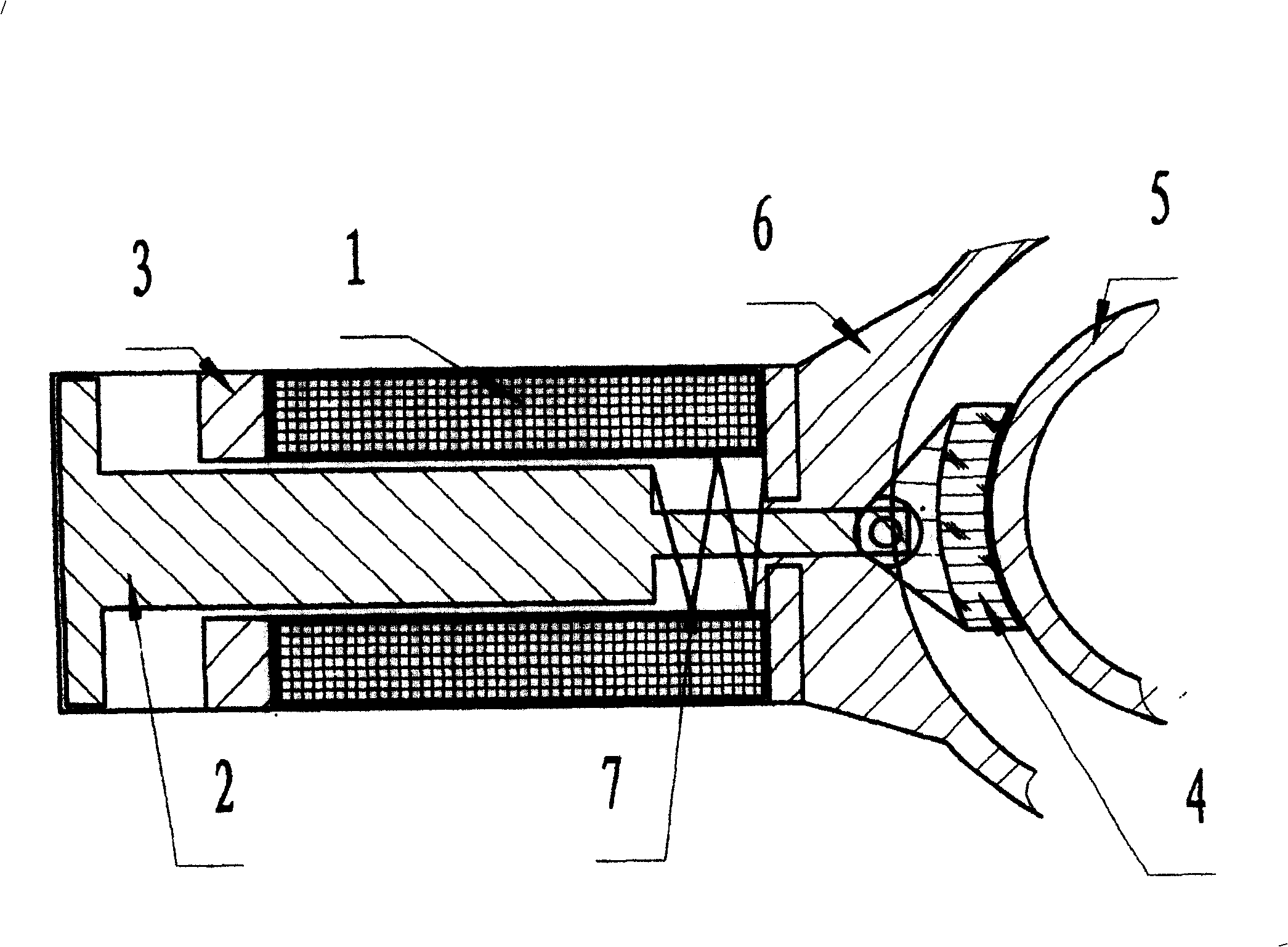

Synchronous gear shifting type wet hydraulic clutch for automatic gearbox

PendingCN110701209APrevent wrong gear shiftingIncrease shift speedFluid actuated clutchesPhysicsClutch

The invention discloses a synchronous gear shifting type wet hydraulic clutch for an automatic gearbox. The synchronous gear shifting type wet hydraulic clutch comprises a power input and output component, a friction pair assembly, a control execution component, a synchronous feedback component and a sealing component. The synchronous gear shifting type wet hydraulic clutch is of an integrated design and integrates four parts of control, execution, cooling and lubrication; the working stability and the transmission efficiency of the clutch are improved through the integrated design; the dailymaintenance cost is reduced; the installation space is saved, and the use method is simpler, more convenient and more flexible. A friction pair is of a wet multi-piece structure formed by alternatelymounting steel and sintered / paper substrates, the specific pressure is high, the friction coefficient is large, the wear coefficient is small, and the heat capacity is high; the characteristics of thefriction pair determine that the size of the clutch is small, and the generated torque is large; the combined structure form can generate very high torque under very small inertia, and maintenance isbasically not needed; the friction pair is made of a metal sintered material, no asbestos component exists, and the environment cannot be polluted; and the ratio of the dynamic friction coefficient to the static friction coefficient of the multi-piece structure is small, meshing balance is achieved, and noise cannot be generated.

Owner:SHANGHAI LIANGQI ELECTROMECHANICAL EQUIP CO LTD

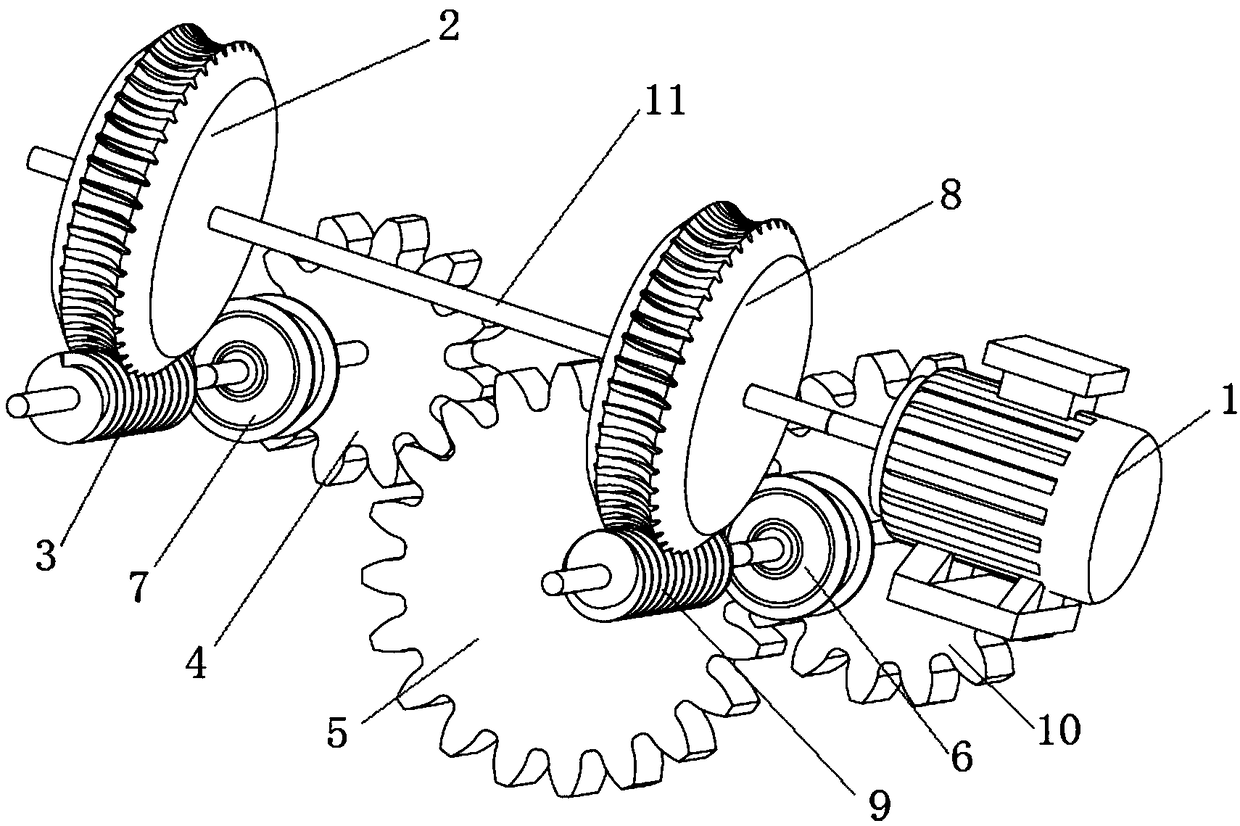

Novel worm gear type speed changer and speed changing method thereof

InactiveCN109340325AIncrease shift speedReduce volumeToothed gearingsGearing controlClutchWheel and axle

The invention discloses a novel worm gear type speed changer and a speed changing method thereof. In the speed changer, a first-gear worm gear and a second-gear worm gear are coaxially connected, an input shaft is fixedly connected to a worm gear shaft, the first-gear worm gear is engaged with a first-gear worm, the second-gear worm gear is engaged with a second-gear worm, the first-gear worm is coaxially connected to an axle of a first-gear speed reducing gear through a first-gear clutch, the second-gear worm is coaxially connected to an axle of a second-gear speed reducing gear through a second-gear clutch, the first-gear speed reducing gear and the second-gear speed reducing gear are both engaged with an output gear, an output shaft is fixedly connected with an axle of the output gear,and the second-gear clutch and the first-gear clutch are connected to a gear-shifting control device. The transmission ratio of the novel worm gear type speed changer is large, and the size of the speed changer is also reduced. In addition, during engagement of the gears, the gears are in rolling contact mainly, the worm gears and the worms are in sliding contact mainly, and therefore, factors forgeneration of noises and vibration are less.

Owner:HUAINAN UNITED UNIVERSITY

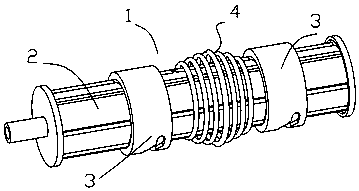

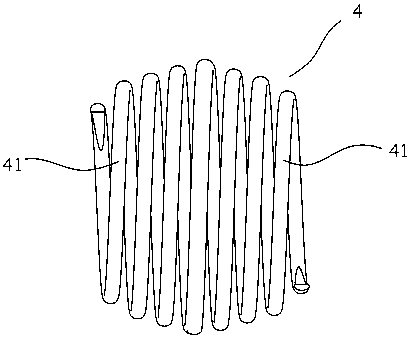

Gear shifter provided with diameter-variable drum springs

InactiveCN107606136AIncrease shift speedStrong impact resistanceGearing controlEngineeringMechanical engineering

The invention discloses a gear shifter provided with diameter-variable drum springs. The gear shifter provided with the diameter-variable drum springs comprises a drum shaft, a gear shifting drum array composed of gear shifting drums is arranged on the drum shaft, and gear shifting springs are arranged between every two adjacent gear shafting drums. Each gear shifting spring comprises a pair of cone-shaped diameter-variable spring bodies which are connected with each other in a welded mode. The gear shifting springs are made of stainless steel. In the using process, a user makes the gear shifting drums and the gear shifting springs to be connected to the drum shaft in a sleeving mode, so that the gear shifting springs are clamped between the gear shifting drums. Because the diameter-variable spring bodies are in cone shapes, the diameter-variable spring bodies can be directly clamped at the centers of the gear shifting drums, decentration and displacement of the gear shifting springs can be prevented effectively, thus the gear shifting speed of the gear shifter is effectively improved, and the impact resistance is high. The gear shifter provided with the diameter-variable drum springs is simple in structure, obvious in effect, low in cost and high in practicality.

Owner:泰州市翔宇动力机械厂

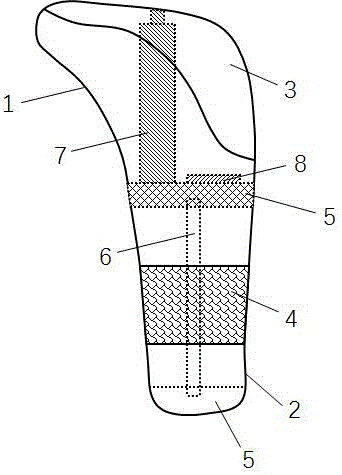

Telescoping gear lever

InactiveCN106438974AAuto height adjustmentImprove shift comfortGearing controlEngineeringPressure sensor

The invention discloses a telescoping gear lever comprises a lever body, a pedestal, a pressure-sensitive housing, a leather sheath, a mount groove, a lifting rod, a pressure sensor and a control board; the leather sheath is arranged on the bottom of the lever body, and connected with the top end of the pedestal; the pressure-sensitive housing is arranged on the top of the lever body; the mount groove is arranged in the lever body; two ends of the lifting rod are respectively fixed in the mount groove; the pressure sensor is fixed in the mount groove and tightly attached to the pressure-sensitive housing; the control board is arranged in the lever body, and connected with the pressure sensor and the lifting rod; the bottom of the lifting rod is provided with a vehicle electronic control unit interface; the telescoping gear lever can automatically adjust the gear lever height according to the pressure applied on the gear lever by the driver, thus adapting to different driver positions, improving driver gearshift comfort level, and accelerating gearshift speed.

Owner:SUZHOU UNIV OF SCI & TECH

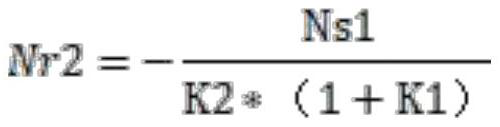

Double-speed transmission for electric automobile

PendingCN114294386ASuitable for useSimple structureToothed gearingsGearing detailsDrive shaftGear wheel

The invention discloses a double-speed transmission for an electric vehicle, which comprises a first planetary gear set, a second planetary gear set, a differential mechanism, a first brake and a second brake, and is characterized in that the first planetary gear set comprises a first sun gear, a first planetary gear carrier and a first annular gear ring which are distributed from inside to outside; the first sun gear is used for being connected with a driving shaft of a driving motor, the second planetary gear set comprises a second sun gear, a second planetary gear carrier and a second annular gear ring which are distributed from inside to outside, and the second annular gear ring is used for being connected with a differential mechanism; wherein the first annular gear ring is fixedly connected with the second planetary gear carrier, the first planetary gear carrier is fixedly connected with the second sun gear, the first planetary gear carrier is connected with the first brake, and the second planetary gear carrier is connected with the second brake. The gear shifting mechanism is simple in structure, low in manufacturing cost, high in gear shifting speed and high in transmission efficiency, and is very suitable for being used in the electric automobile.

Owner:花潍

Construction method of long spiral pilot hole for prestressed pipe pile in ultra-deep and ultra-thick dense sand layer

ActiveCN109025816BFirmly connectedMeet the constructionDrilling rodsDirectional drillingPre stressPipe

The present invention discloses an ultra-deep and extra-thick dense sand stratum prestressed pipe pile long spiral lead hole construction method. The method comprises the following steps of: S1: siteformation and drill stem equipping: performing leveling and compaction for a site prior to place taking, or bedding a steel plate to facilitate place taking of a pile machine, and regulating equippingof the corresponding quantity of drill stems according to the depth of the lead holes to ensure the lead hole operation flow construction, wherein two lead hole drills are arranged on the site; and S2: location, paying-off and place taking of the pile machine: employing a total station to perform laying-off for preset lead hole stake positions, taking a drill machine in place to complete correction of the vertical degree of the drill stem and the centering of the center of the drill, and after location, putting down a support oil cylinder at the lower portion of a front-end mast and two support oil cylinders at the tail portion of the machine body of the drill machine. The ultra-deep and extra-thick dense sand stratum prestressed pipe pile long spiral lead hole construction method can extend the drill stem at will through connection according to pore-forming demands by employing a design of the hexagonal joint of the drill stem, can effectively ensure the reliable connection of the drill stem by only using a dual-way fixed plug pin after the drill stem is inserted when being connected and can meet the construction of an overlength pile hole.

Owner:SHENZHEN GONGKAN GEOTECHN GRP

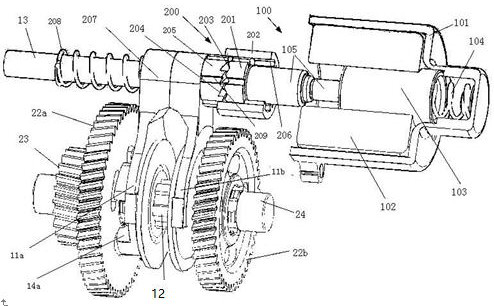

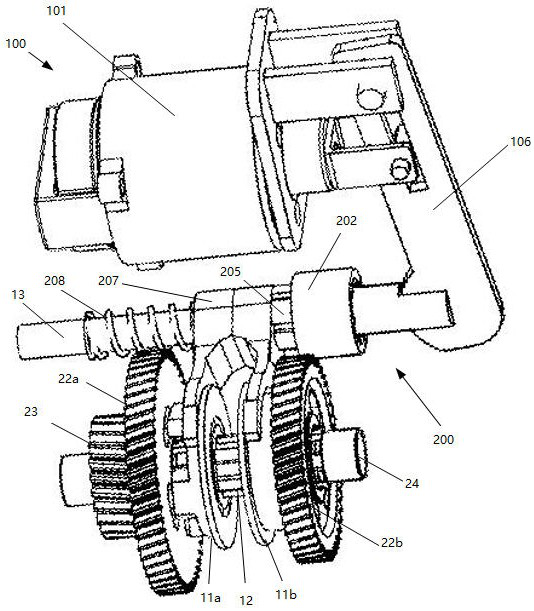

Transmission gear shifting device

PendingCN113606335AEnable mobilityImprove securityHybrid vehiclesControlled membersReciprocating motionElectric cars

The invention discloses a transmission gear shifting device and belongs to the field of electric vehicles. The shifting device comprises a push-pull mechanism, a rotating mechanism and a shifting mechanism, wherein the push-pull mechanism comprises a linear reciprocating motion mechanism and a connecting rod or a lever connected with the linear reciprocating motion mechanism; the rotating mechanism comprises a push-pull barrel and a shifting rotating barrel opposite to the push-pull barrel; fixing sleeves are arranged on the peripheries of the push-pull barrel and the shifting rotating barrel; and a motion decomposition mechanism is arranged on the inner circumference of the fixing sleeve, the motion decomposition mechanism transmits axial motion to the shifting fork and simultaneously performs circumferential rotation, the circumferential rotation changes the pause position of the axial motion, and the shifting rotating barrel pauses once at the starting point or the ending point of the axial motion every time the axial motion is performed, so that the shifting rotating barrel is shifted once between a low-speed gear and a high-speed gear. According to the transmission gear shifting device, the gear shifting mode can be simplified, the gear shifting speed is increased, the driving hidden danger in the vehicle driving process is reduced, and the vehicle driving safety is improved.

Owner:杨勇

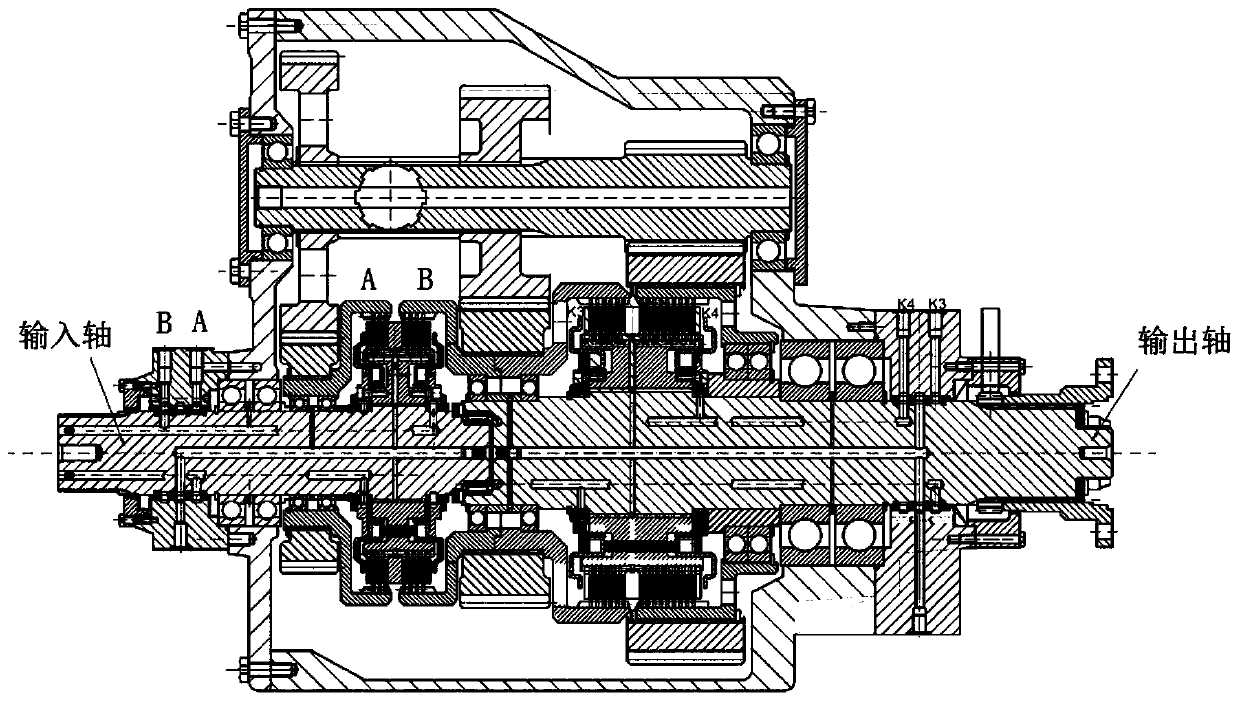

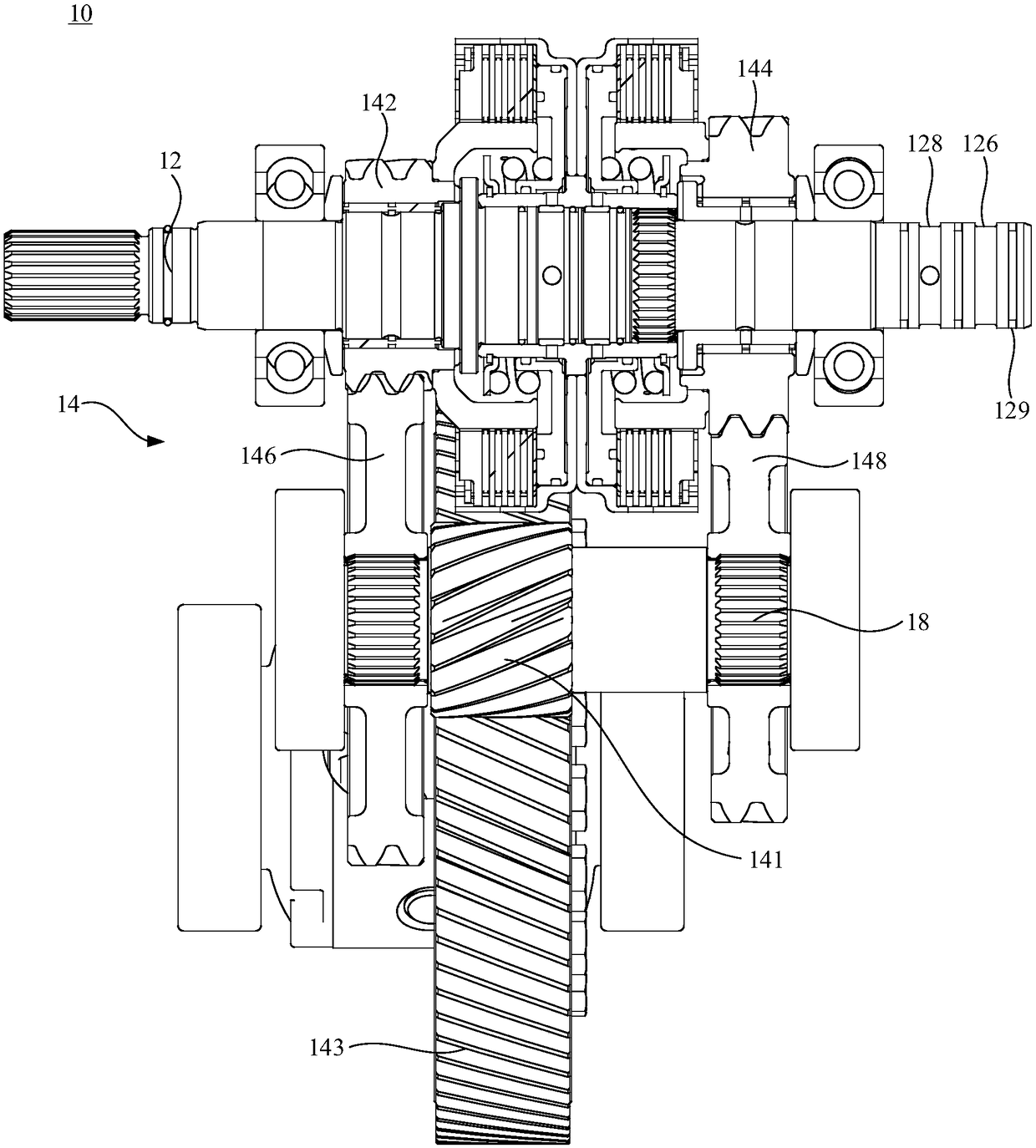

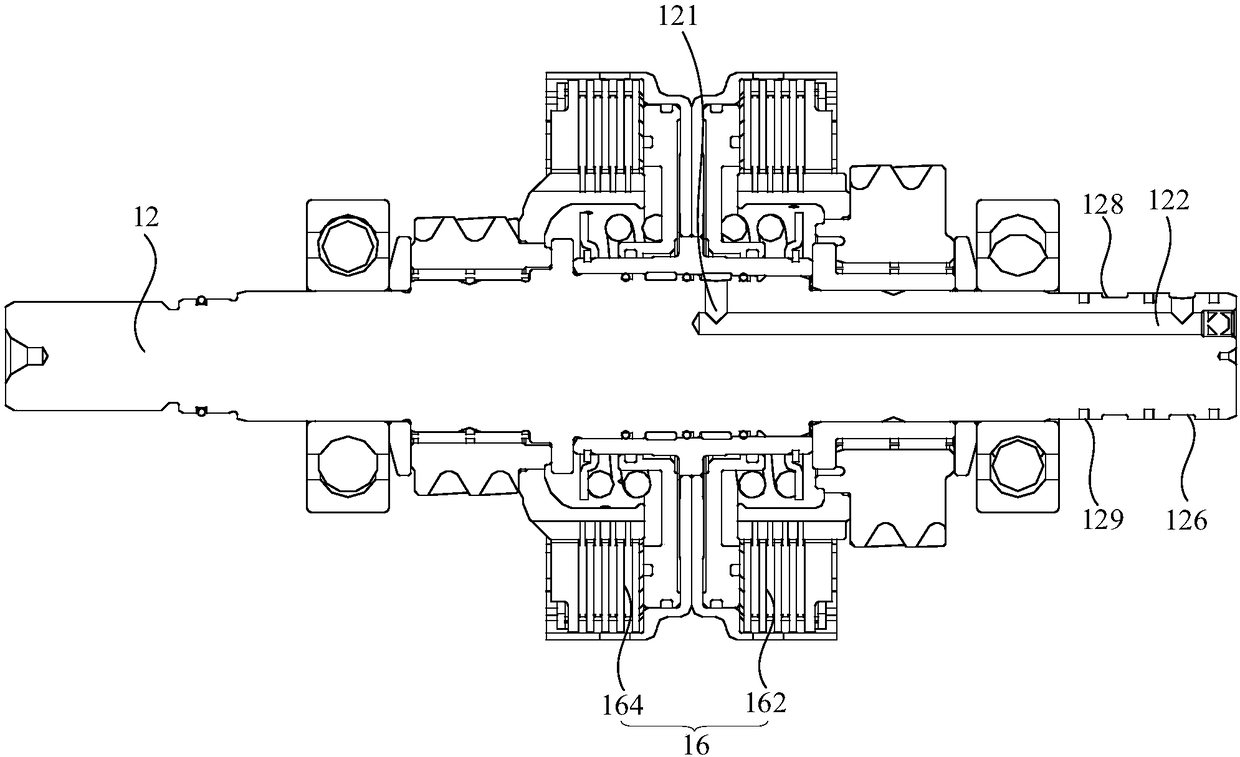

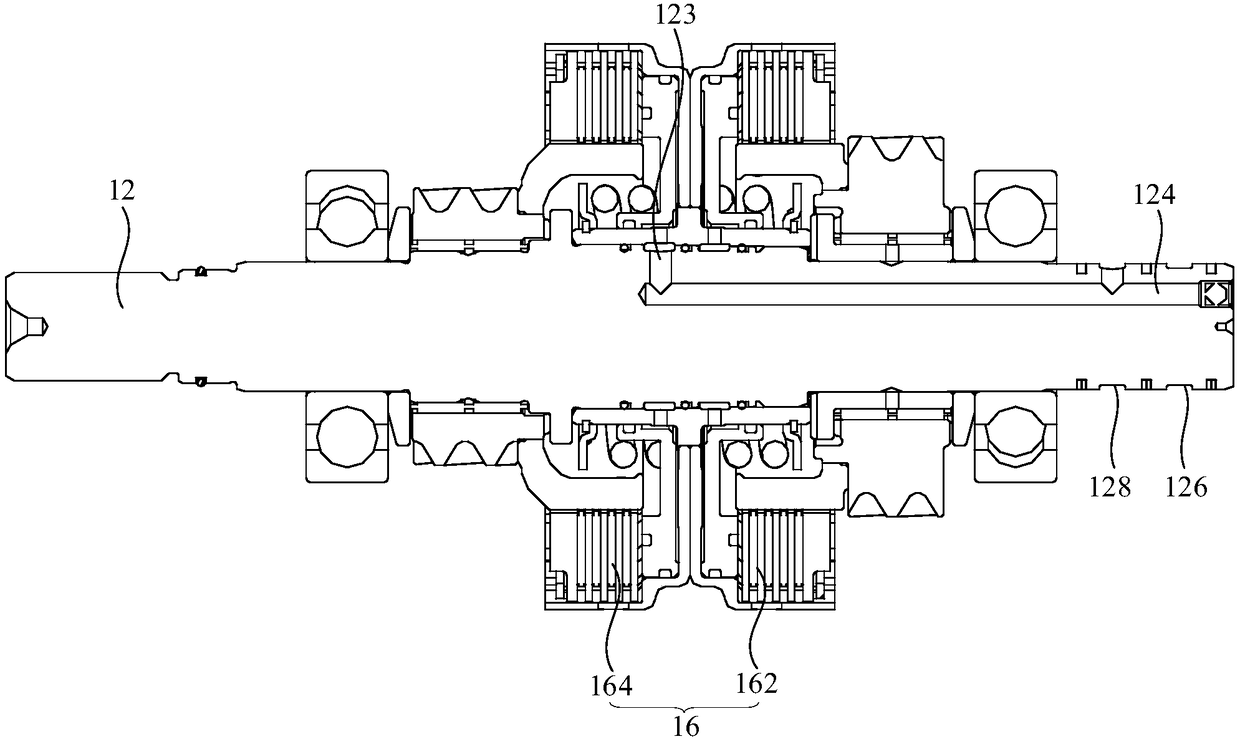

Transmission and electric vehicle

The invention relates to a transmission. The transmission is characterized in that hydraulic oil enters into a first oil transportation passage and a second oil transportation passage through a firstcircular groove and a second circular groove which are formed in an input shaft, and the hydraulic oil is transported to a first friction disk controller or a second friction disk controller through the first oil transportation passage or the second oil transportation passage, the first friction disk controller is matched with a first driving gear or the second friction controller is matched witha second driving gear, and the first driving gear or the second driving gear starts rotating. According to the transmission, the oil transportation passages of the hydraulic oil are arranged in the input shaft, the structure of the transmission is simplified to reduce the size of the transmission, the oil transportation passages of the hydraulic oil can be prevented from external interference, andthe hydraulic controlling manner of the friction plate controllers is adopted as a clutch controlling manner, so that gear shifting time is reduced and shifting speed is improved. The invention further relates to an electric vehicle.

Owner:ZHUZHOU GEAR CO LTD

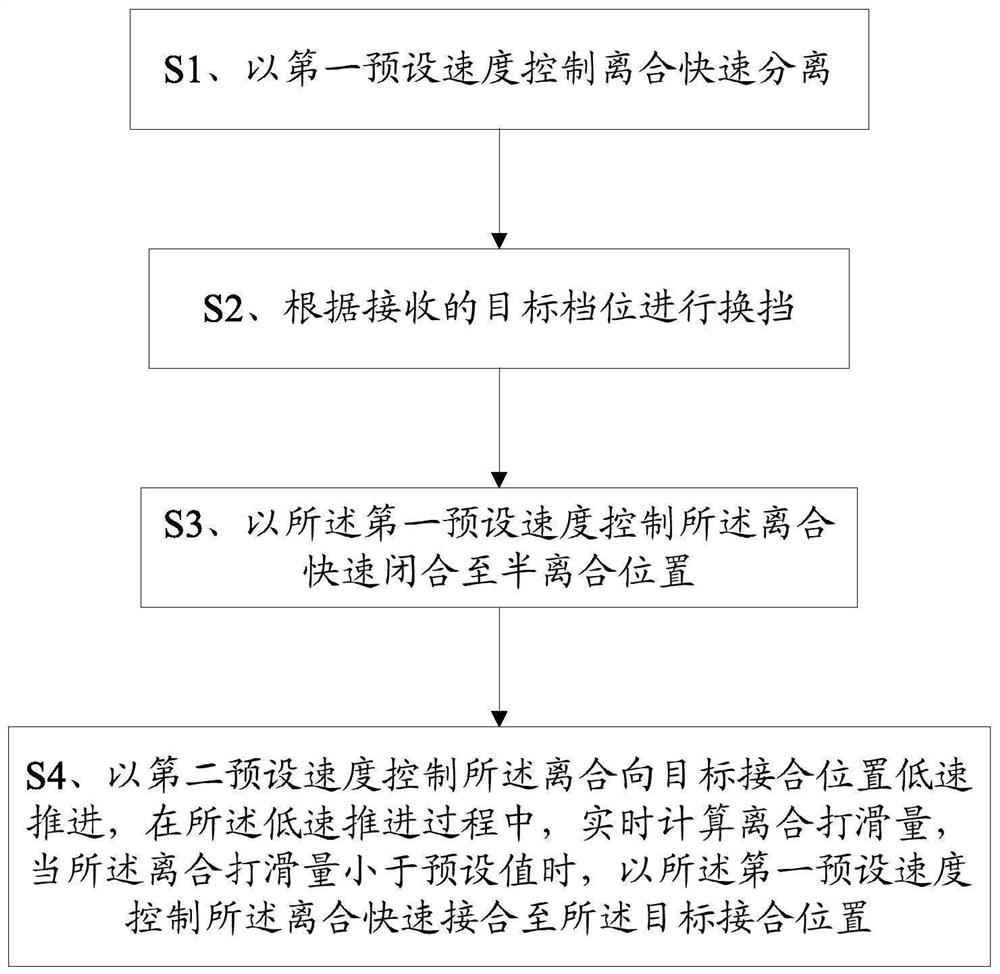

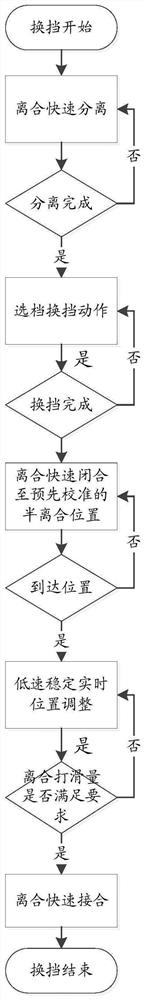

A clutch control method and terminal

The present invention discloses a clutch control method and a terminal, which control the quick disengagement of the clutch at a first preset speed; perform gear shifting according to the received target gear; and control the quick closing of the clutch to a half-clutch position at the first preset speed ; Control the clutch to advance toward the target engagement position at a low speed at a second preset speed. During the low-speed propulsion process, calculate the clutch slippage in real time. When the clutch slippage is less than a preset value, use the first preset Set the speed to control the clutch to quickly engage to the target engagement position; during the clutch engagement process, at the beginning and end stages, the clutch is quickly engaged to reduce the clutch movement time in the whole process, and the clutch is half-engaged to stably control the clutch to make the vehicle speed and rotation speed match stably , so as to make the vehicle run stably. Through the fast and stable clutch control, the stability and comfort of starting can be realized, the situation of stalling at the start can be avoided, and the starting quality can be fully improved. The fast and reliable control of the clutch can increase the shifting speed.

Owner:福建盛海智能科技有限公司

Autosynchronous shifting arrangement for automobile

The invention relates to a vehicle automatic synchronous shift device, which is characterized in that: it comprises a speed variable device, an engine, and a clutch as the controlled system, and an electric controller and variable sensors. The frame of engine flywheel is fixed with an open electromagnetic brake; therefore, the automatic shift device controlled by microprocessor can shift without separating the clutch. The invention can improve the shift speed to reduce the impact of clutch most. Therefore, the clutch can avoid be replaced in the whole life of vehicle.

Owner:李岳

Electronic device and method of scanning channels in electronic device

ActiveUS9973824B2Easy to scanDecrease channel shift speedTelevision system detailsColor television detailsControl signalUser input

An electronic device includes a detector configured to detect a user input and a controller configured to determine a favorite channel group according to a user's viewing history, scan channels in response to detecting an input of a control signal corresponding to a channel shift button for a predetermined time, and decrease a channel shift speed in a favorite channel group section corresponding to the determined favorite channel group and increase the channel shift speed in a section other than the favorite channel group section.

Owner:SAMSUNG ELECTRONICS CO LTD

A Precise Control Method of Buffer Oil Cylinder

ActiveCN108916295BEasy to controlPrecise Design ControlSpringsSprings/dampers design characteristicsControl engineeringElectric machinery

A precise control method for a buffer oil cylinder, the signal output terminals of the high-grade micro switch and the low-grade micro switch are connected to the signal input terminal signal of the servo drive, and the signal output terminal of the servo drive is connected to the control terminal signal of the servo motor connected, the signal output end of the motor encoder of the servo motor is connected to the signal of the servo driver, the signal of the servo driver is connected to the controller, and the signal of the controller is connected to the signal output end of the speed sensor provided on the load; including the second Step 1: Acquisition of load speed and sending of control commands, Step 2: PID control of servo motor rotation, Step 3: Switch feedback control, Step 4: Complete gear switching. This design is not only fast in shifting speed, but also good in reliability and high in shifting precision.

Owner:WUHAN MARINE MACHINERY PLANT

Method and device for adjusting vehicle torque

ActiveCN111098843BImprove driving comfort performanceEnsure driving comfortHybrid vehiclesSpeed controllerMaximum torqueControl theory

The present application discloses a method and device for adjusting the torque of a vehicle. The vehicle includes a first power source and a second power source. The method includes: obtaining the first torque output by the first power source; if the first torque is greater than the first power If the maximum torque output by the source is determined, the torque change rate of the second power source is determined to be the first rate; if the first torque is less than or equal to the maximum torque output by the first power source, then the torque change rate of the second power source is determined to be the second rate. rate; where the first rate is less than the second rate. That is, when the first torque output by the first power source has not reached the maximum torque output by the first power source, the rate of change of the torque output by the second power source is accelerated to increase the shifting speed; When the first torque reaches the maximum torque output by the first power source, the rate of change of the output torque of the second power source is slowed down to optimize the driving comfort, which can ensure the driving comfort of the vehicle under the premise of appropriate shift time.

Owner:SAIC MOTOR

Control apparatus for transmission for vehicle

ActiveUS20160272212A1Rotational speed of be restrainLimit resultGearingGearing controlVariatorMoving speed

A vehicle transmission has a continuously variable speed change mechanism provided between an input shaft to which a torque output by a driving force source is transmitted and an output shaft from which a torque is output to a driving wheel. The transmission is able to selectively block torque transmission between the mechanism and the output shaft. The mechanism is rotated by the driving force source with torque transmission between the mechanism and the output shaft blocked. A control apparatus limits a shifting speed of the mechanism to or below an upper-limit speed determined in advance in a case where a speed ratio of the mechanism is changed with the mechanism rotated by the driving force source that is subjected to idling rotational speed control, while the mechanism is blocked from the output shaft such that no torque is transmitted between the mechanism and the output shaft.

Owner:TOYOTA JIDOSHA KK

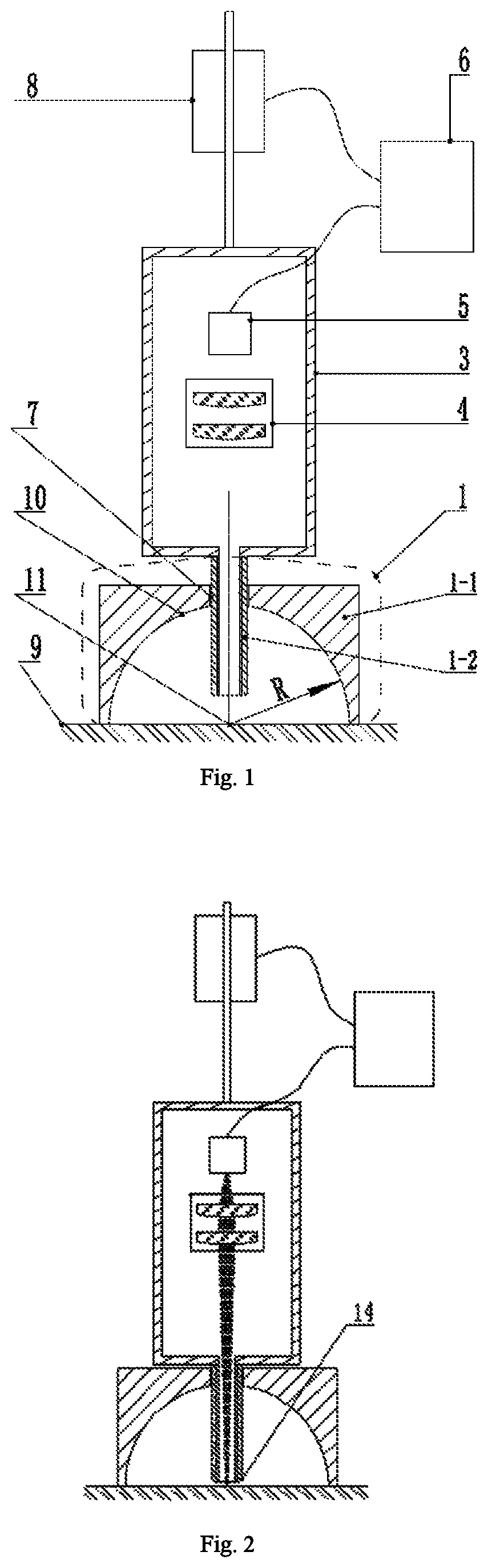

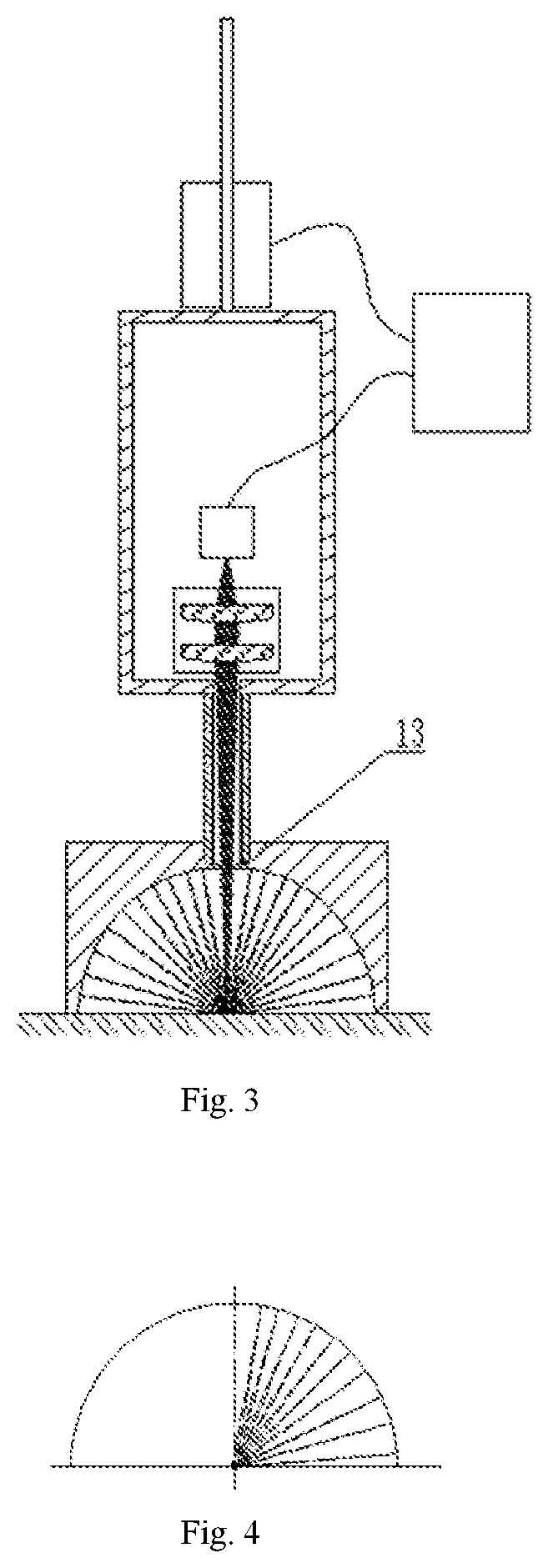

Measurement device and measurement method for measuring temperature and emissivity of a measured surface

ActiveUS11047739B2Accurate measurementLight in massScattering properties measurementsSensing radiation from moving bodiesConvertersEmissivity

measurement device and a measurement method for measuring a temperature and an emissivity of a measured surface are provided. The measurement device includes a reflection converter, an optical receiver and a data processor. The reflection converter includes a reflector having a through hole and an absorber tube shifted between a first measurement position and a second measurement position relative to the reflector. In the first measurement position, the light incident end of the absorber tube approaches or contacts the measured surface, such that the optical receiver forms a first electrical signal. In the second measurement position, the light incident end of the absorber tube is located at or outside the through hole, such that the optical receiver forms a second electrical signal. The data processor is configured to determine a temperature and an emissivity of the measured surface according to the first electrical signal and the second electrical signal.

Owner:SHENYANG TAIHE METALLURGY MEASUREMENT & CONTROL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com