Gear position overlapped type multistage automatic transmission

An automatic transmission, superimposed technology, applied in vehicle gearboxes, multi-gear ratio transmissions, transmission elements, etc., can solve the problems of shifting interference, many control procedures, and high failure rates, and achieve simple and smooth shifting procedures. The effect of shifting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

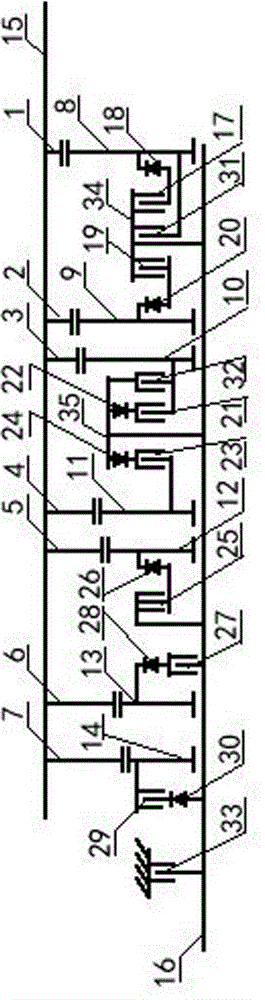

[0027] A gear superposition type multi-stage automatic transmission, comprising a power input shaft 15 and a power output shaft 16, the power input shaft 15 is equipped with at least seven driving gears, each driving gear corresponds to a gear position, and the power output shaft corresponds to At least seven driven gears are installed, and each driven gear corresponds to a gear position. In this example, see figure 1 , There are 7 driving gears and 7 driven gears. This power input shaft 15 is provided with first gear driving gear 1, second gear driving gear 2, third gear driving gear 3, fourth gear driving gear 4, fifth gear driving gear 5, sixth gear driving gear 6 and The seventh gear driving gear 7. The power output shaft 16 is provided with the first gear driven gear 8, the second gear driven gear 9, the third gear driven gear 10, the fourth gear driven gear 11, the fifth gear driven gear 12, the sixth gear The driven gear 13 and the seventh-speed driven gear 14 . Clu...

Embodiment 2

[0035] A gear superimposed multi-stage automatic transmission, each driving gear is equipped with a clutch and an overrunning clutch on the outside, the clutch is controlled by the gear shifting oil pressure, the power input shaft drives the working end of the driving gear to rotate through the clutch and the overrunning clutch, the driving gear The working end meshes with the driven gear on the power take-off shaft. Wherein, the first-speed driving gear and the second-speed driving gear are connected in a common clutch; the third-speed driving gear and the fourth-speed driving gear are connected in a co-overrunning clutch; the fifth-speed driving gear, the first-speed driving gear The sixth-speed driving gear is respectively connected with the power input shaft via a clutch-connected shaft, and the seventh-speed driven gear is connected with the power input shaft through an overrunning clutch-connected shaft.

[0036] That is: each driving gear side is provided with an overru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com