Gear shifter provided with diameter-variable drum springs

A shifter, variable diameter technology, applied in the direction of components with teeth, belts/chains/gears, mechanical equipment, etc., can solve problems such as shifting drum dislocation, shifting feel jerky, etc., to prevent eccentric displacement , obvious effect, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

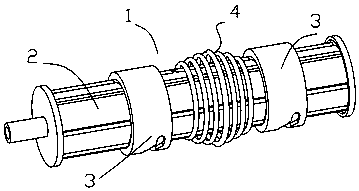

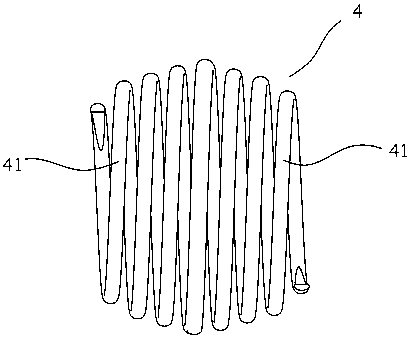

[0014] Such as Figure 1 to Figure 2 As shown, the shifter 1 with variable-diameter drum springs includes a drum shaft 2, on which a shift drum array composed of shift drums 3 is arranged, and the adjacent shift drums 3 are respectively A shift spring 4 is provided, and the shift spring 4 includes a pair of tapered diameter-reducing spring bodies 41 connected by welding.

[0015] This shift spring 4 is made of stainless steel.

[0016] During use, the user sleeves the shift drum 3 and the shift spring 4 onto the drum shaft 2 , and makes the shift spring 4 stuck between the shift drums 3 . Since the variable diameter spring body 41 is conical, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com