Synchronous gear shifting type wet hydraulic clutch for automatic gearbox

An automatic transmission and hydraulic clutch technology, applied in the clutch field, can solve the problems of low work stability and transmission efficiency, unreasonable design, inconvenient installation, etc., to improve work stability and transmission efficiency, reduce daily maintenance costs, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

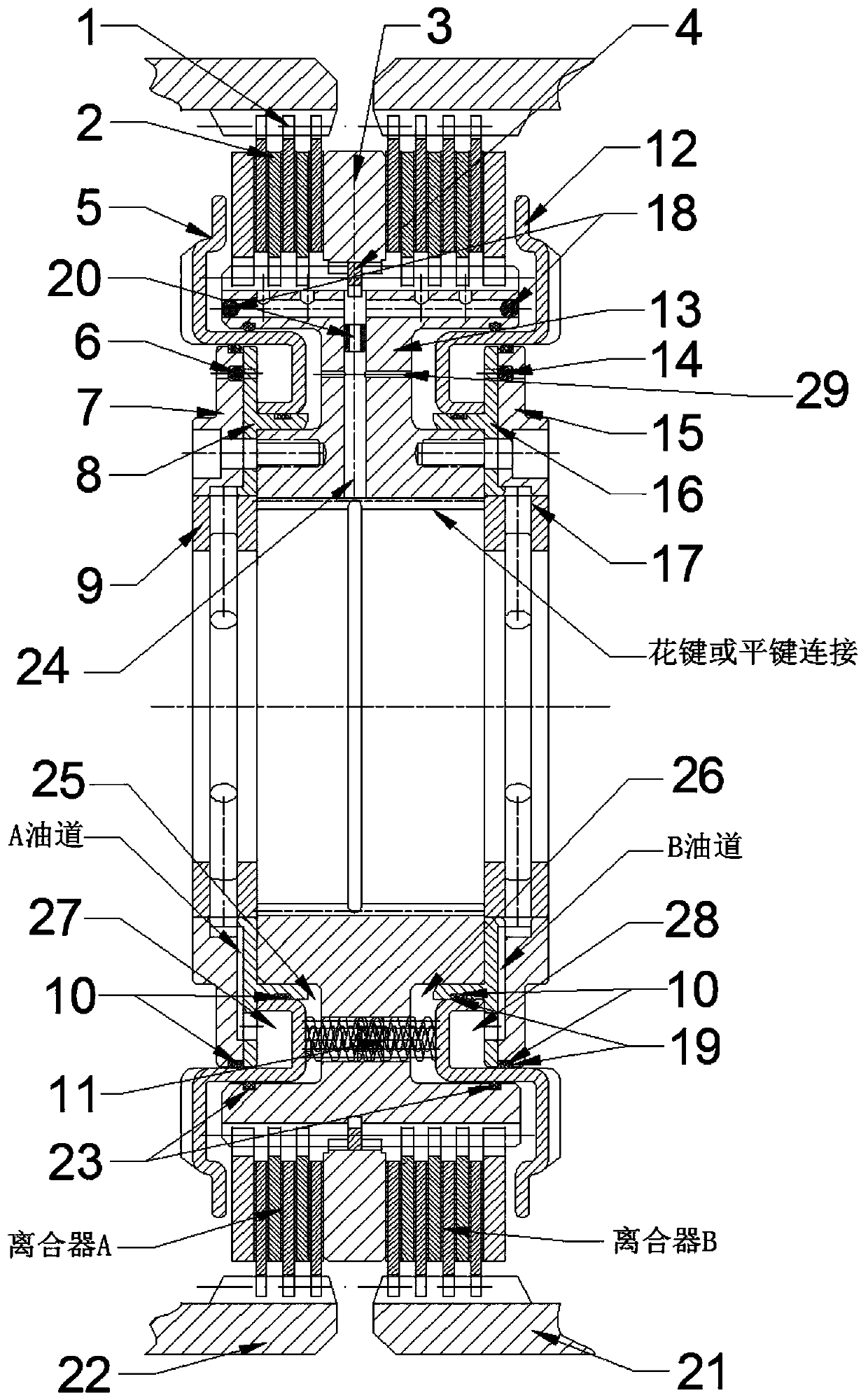

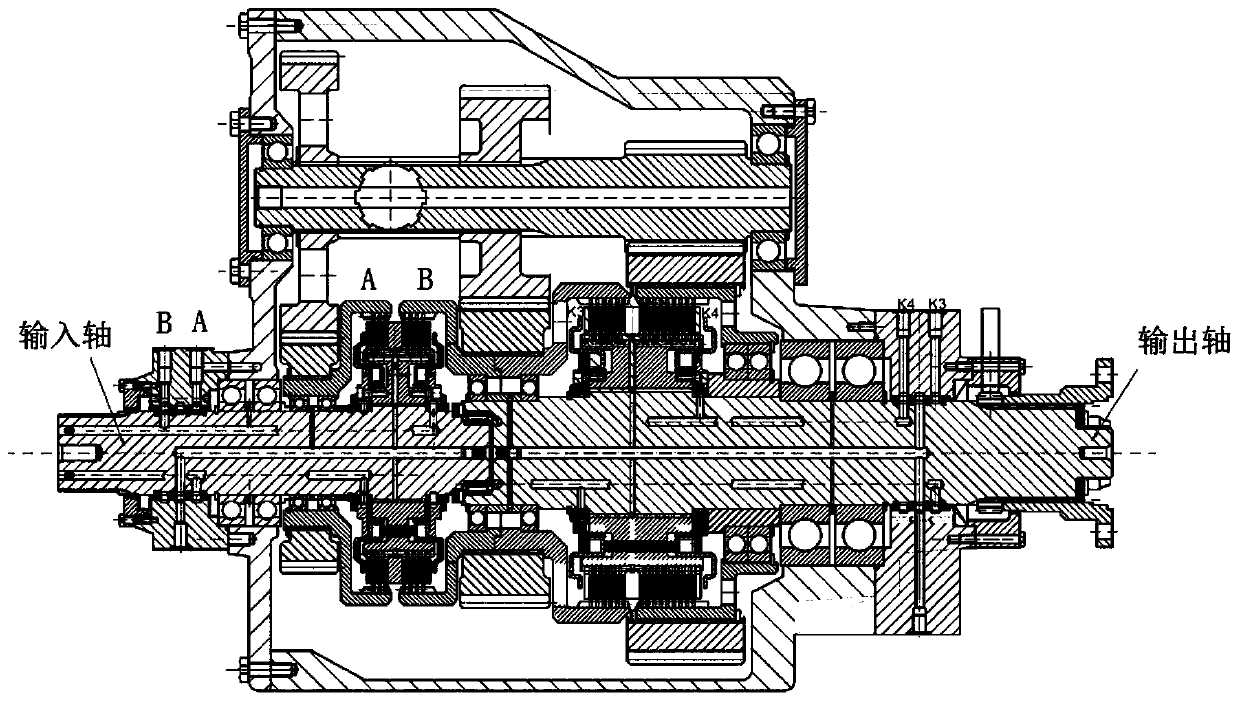

[0025] Such as Figure 1~2 As shown, this embodiment provides a synchronous shift wet hydraulic clutch for automatic transmission, including power input and output components, control execution components and synchronous feedback components; wherein,

[0026] The power input and output assembly includes the clutch hub 13, the outer ring gear B21 and the outer ring gear A22. The clutch hub 13 is used as the clutch main body, and the clutches A and B share one clutch hub 13 . The inner hole of the clutch hub 13 is processed with splines or flat keys for connecting the central power shaft. The outer circle of the clutch hub 13 is processed with splines for connecting and fixing the steel sheet 2 with internal splines. The middle of the outer spline of the clutch hub 13 is processed with a circlip groove, and the stop ring 3 is fitted on the outer spline of the clutch hub 13 through the inner spline, and the stop ring 4 is used to limit the position, so that the clutch hub 13 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com