actuator assembly

A technology of actuators and assemblies, applied in the direction of elements with teeth, transmission control, belt/chain/gear, etc., can solve the problem of impossible to operate two shift rails at the same time, and the shift shaft cannot be rotated, etc. Achieve precise shifting, avoid wrong shifting, and avoid tolerance chains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

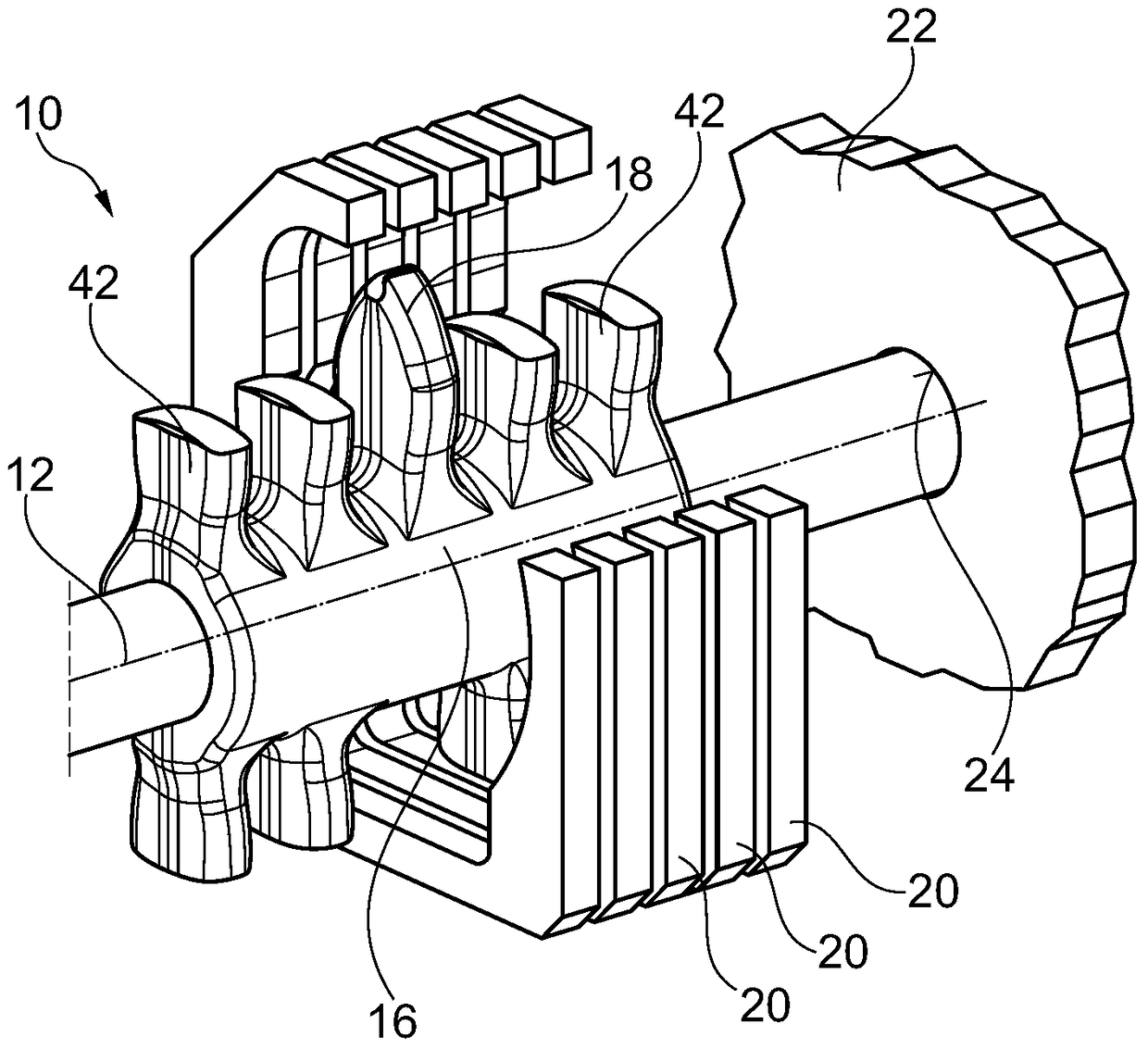

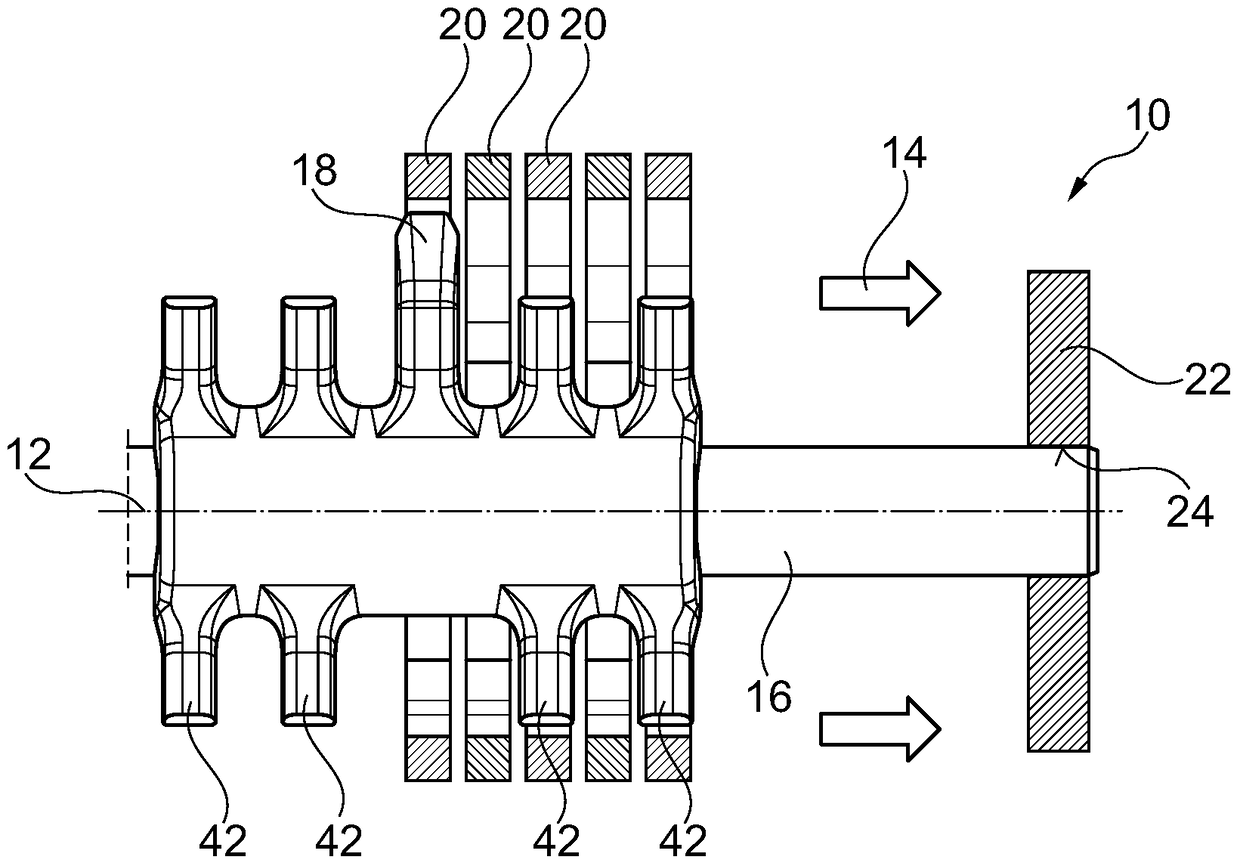

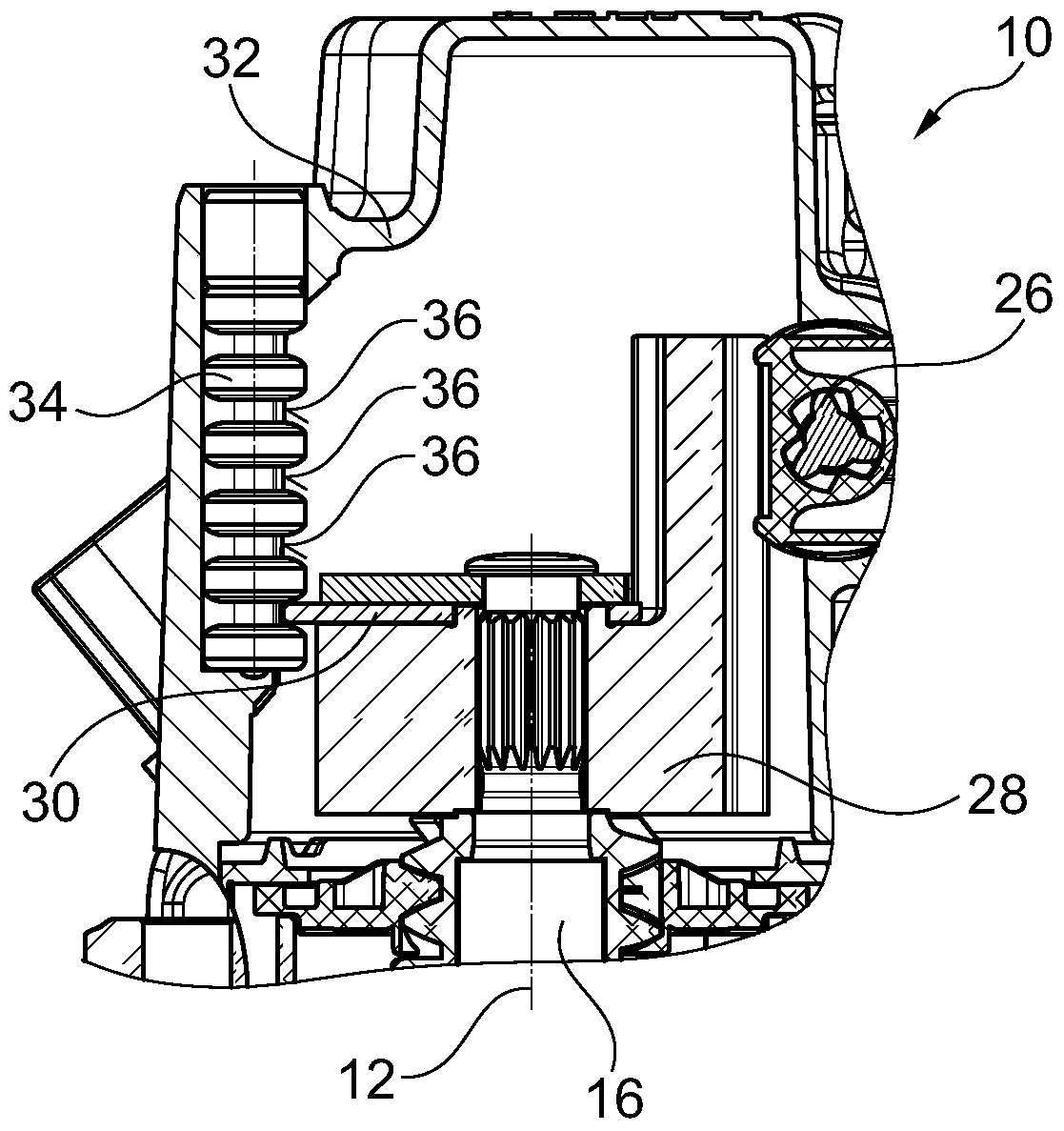

[0023] In the actuator assembly 10 according to the present invention at Figure 4 and Figure 5 In the embodiment shown, with the actuator 10 in the figure 1 , figure 2 and image 3 In contrast to the embodiment shown in , the link guide for the selector shaft 16 is not arranged in the actuator housing 32 , but is formed at the opposite end of the selector shaft 16 by means of a slide bearing 24 superior. In the illustrated embodiment, the convex part of the gate guide is formed by the shift shaft 16 and the recess of the gate guide is formed by the plain bearing 24 , wherein this can also be configured kinematically opposite. For this purpose, the selector shaft 16 has a plurality of radially protruding cams 38 , between which intermediate spaces 40 are formed in each case. The number of intermediate spaces 40 corresponds to the number of shift rails 20 , wherein one cam 38 is provided more than the number of shift rails 20 . The shift finger 18 is spaced significantl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com