Hybrid power gearbox, hybrid power driving system and vehicle

A technology of hybrid power and gearbox, which is applied to the arrangement of multiple prime movers of power plants, vehicle components, and general power plants, and can solve problems such as low transmission efficiency and complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

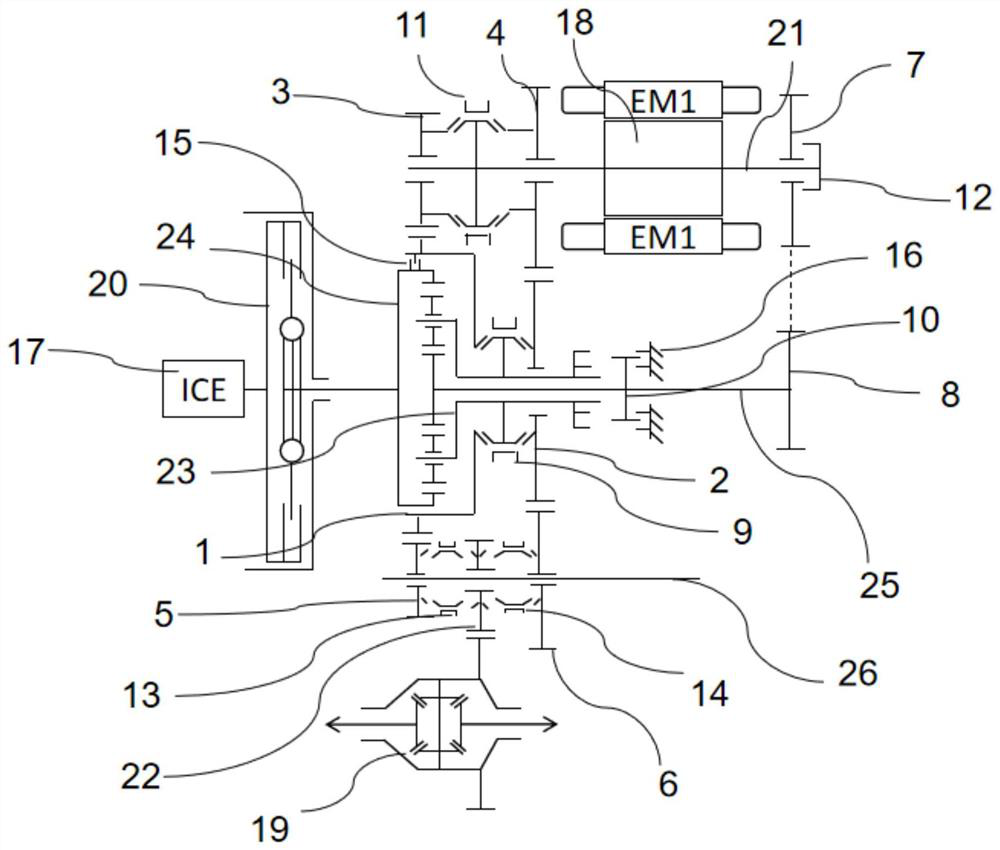

[0041] Such as figure 1 As shown, a hybrid drive system as a whole includes three main components of a hybrid transmission engine 17 and a motor 18 . in:

[0042] The engine 17 is connected to the ring gear 24 of the hybrid transmission.

[0043] The electric machine 18 is connected to an intermediate shaft 21 of the hybrid transmission.

[0044]Further, on the basis of the above-mentioned embodiments, a torsion-limiting shock absorber 20 is also provided between the ring gear 24 and the engine 17, and the torsion-limiting shock absorber utilizes disc springs, friction plates, splined hubs, etc. to transmit the torque of the engine 17 When the torque is overloaded, it relies on slipping between the friction surfaces to prevent the transmission system from being overloaded and damaged. At the same time, an arc spring torsional shock absorber is installed inside, which can attenuate the large torsional vibration angular acceleration at the flywheel end of the engine 17 to the ...

Embodiment 2

[0094] Based on the same inventive concept, the present invention also provides a vehicle, including any one of the hybrid drive system in Embodiment 1. Specifically, in this hybrid vehicle, the structure of the hybrid transmission adopts the above embodiment Except for the medium hybrid gearbox, the structure, connection relationship, installation position, etc. of other devices can refer to the relevant disclosures of the prior art, and no further description will be made here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com