Three-gear gearbox with multiple gears changed

A gearbox, multi-gear technology, applied in the direction of gear transmission, gear lubrication/cooling, belt/chain/gear, etc., can solve the problem of difficult to meet the needs of users, difficult to achieve multi-gear adjustment, difficult to be popularized and applied and other issues to achieve rapid heat dissipation, improve practicality, and avoid overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

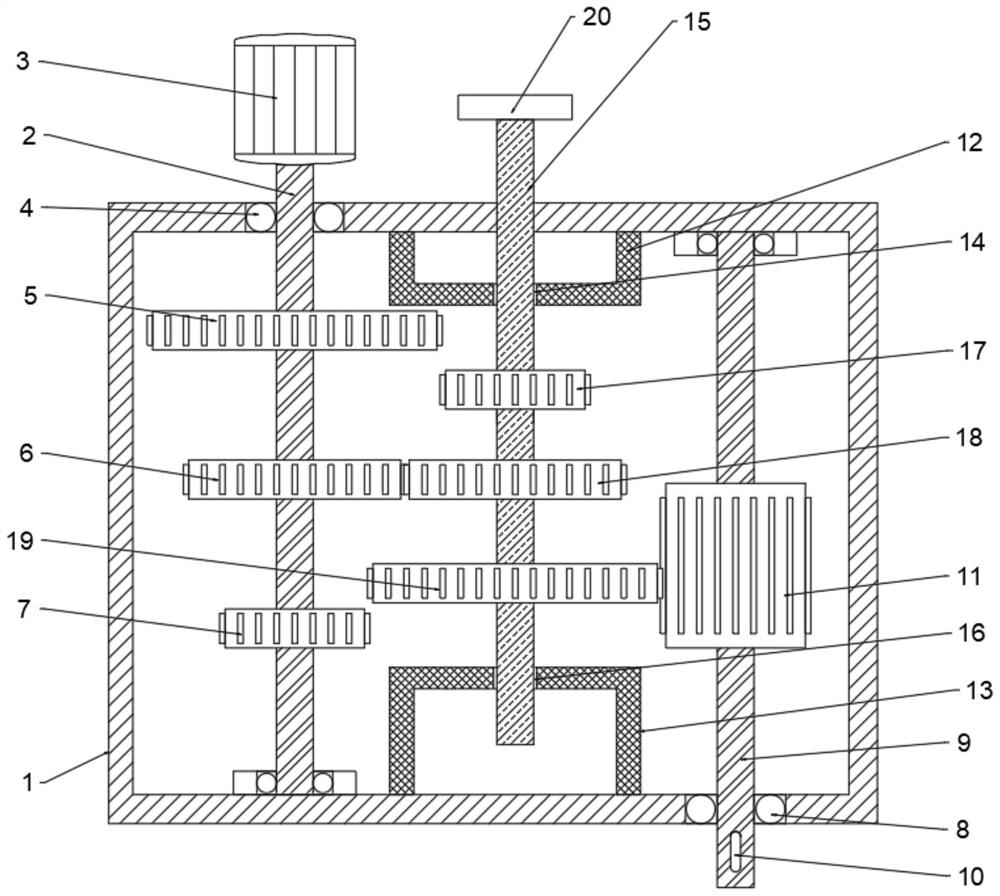

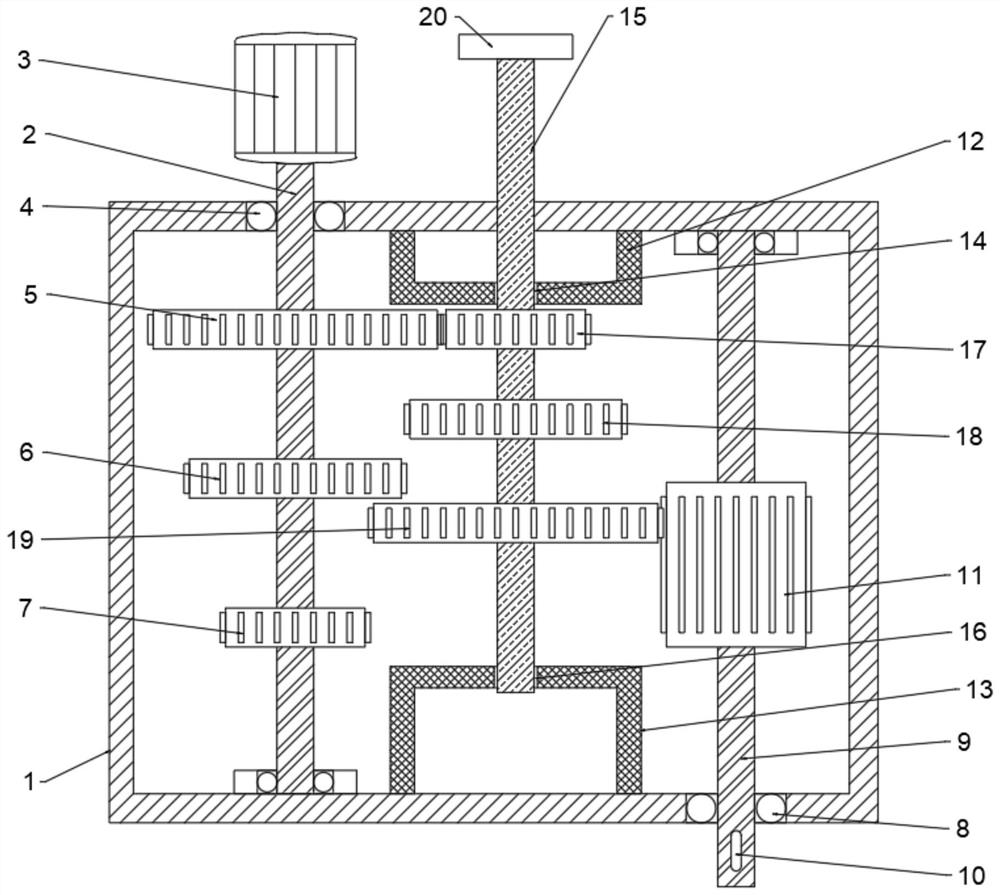

[0025] see Figure 1 ~ Figure 3 , a three-wheel gear transmission with multiple shifts, including a transmission 1, a rotating shaft 2 is provided on the left side of the transmission 1, and the top of the rotating shaft 2 runs through the top of the transmission 1 and is connected to the top of the transmission 1. The output end of the motor 3 is fixedly connected, and the outer side of the rotating shaft 2 is sequentially provided with a first gear 5, a second gear 6 and a third gear 7 from top to bottom, and an output shaft 9 is provided on the right side of the inside of the gearbox 1, so The bottom of the output shaft 9 runs through the bottom of the gearbox 1 and is fixedly connected with the input shaft of the external device. The outer side of the output shaft 9 inside the gearbox 1 is fixedly sleeved with an output gear 11. Between the rotating shaft 2 and the output shaft 9 There is a transmission assembly, the motor 3 works, the rotating shaft 2 rotates, and drives ...

Embodiment 2

[0032] see Figure 1 ~ Figure 4 , as in embodiment 1, a three-wheeled gear box with multi-gear changes, including a box box 1, a rotating shaft 2 is provided on the left side of the box 1, and the top of the box 2 runs through the top of the box 1 and is connected to the box The output end of the motor 3 located above the gearbox 1 is fixedly connected, and the outer side of the rotating shaft 2 is provided with a first gear 5, a second gear 6 and a third gear 7 in sequence from top to bottom, and the right side of the gearbox 1 is provided with There is an output shaft 9, and the bottom of the output shaft 9 runs through the bottom of the gearbox 1 and is fixedly connected with the input shaft of the external device. The outer fixed sleeve of the output shaft 9 located inside the gearbox 1 is provided with an output gear 11, and the rotating shaft 2 There is a transmission assembly between the transmission assembly and the output shaft 9, the motor 3 works, the rotating shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com