Drilling and slotting integrated machine for coal mines

An all-in-one machine, drilling and cutting technology, applied in cutting machinery, earthwork drilling and mining, etc., can solve problems such as long construction auxiliary time, inability to cut joints, and affect the speed of excavation, so as to improve the anti-outburst effect, improve work efficiency, and save energy. The effect of auxiliary hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

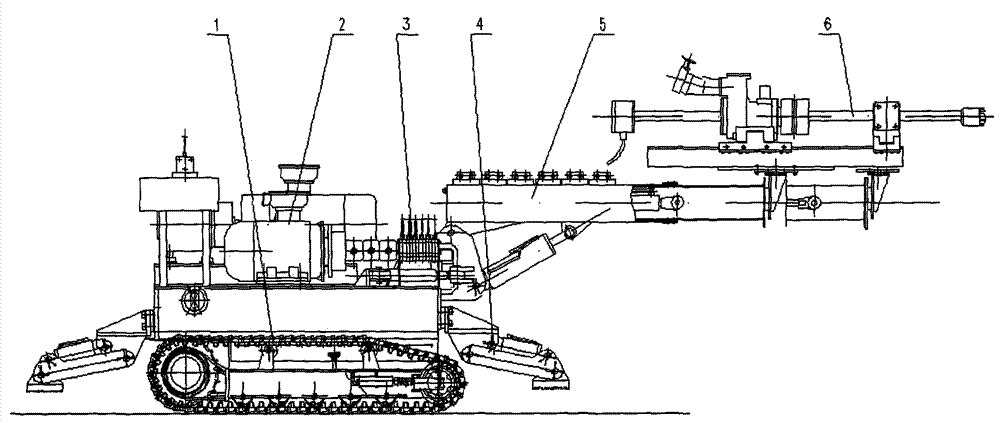

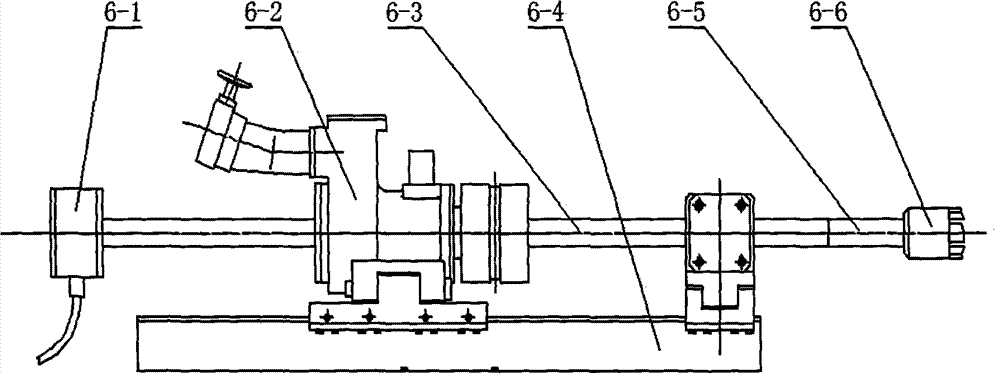

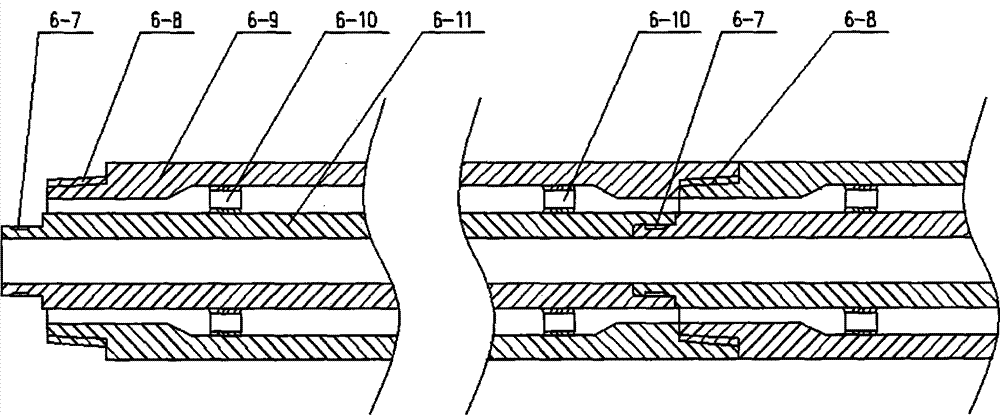

[0018] see figure 1 , the specific embodiment adopts the following technical scheme: it comprises the body, power mechanism 2 and hydraulic control system 3, the power mechanism 2 is installed on the upper end of the body, the hydraulic control system 3 is installed near the front end of the body, and the two sides of the body are equipped with Walking device, the front and rear ends of the body are equipped with supporting devices 4, the telescopic arm 5 is installed at the front end of the body, and the movement direction of the telescopic arm 5 is controlled by hydraulic parts, and the drilling rig and water jet slotting device 6 are fixed on the telescopic arm 5 At the front end, during the drilling process of the drilling rig and the water jet slitting device 6, the inserted drilling rig and the water jet slitting device 6 can be switched to the high-pressure abrasive jet slitting action according to the requirements, so as to realize the purpose of slitting while drilling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com