Accurate control method for buffer oil cylinder

A buffer oil cylinder and precise control technology, applied in the design characteristics of spring/shock absorber, spring, shock absorber, etc., can solve the problem of low adjustment accuracy, achieve high universality, ensure reliability, and facilitate popularization and application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

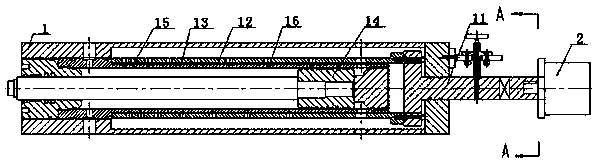

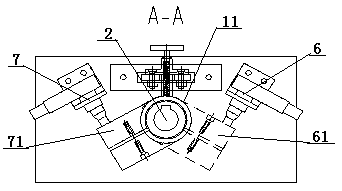

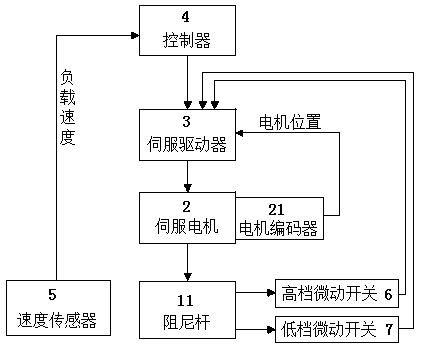

[0047] A precise control method for a buffer oil cylinder, the end of the buffer oil cylinder 1 is provided with a damping rod 11, one end of the damping rod 11 is connected to the power output shaft of the servo motor 2, and the other end of the damping rod 11 It is fixedly connected with the oil cylinder damping adjustment cylinder 12 in the buffer oil cylinder 1, the power output shaft of the servo motor 2 is driven and matched with the oil cylinder damping adjustment cylinder 12 through the damping rod 11, and the oil cylinder damping adjustment cylinder 12 is provided with a piston cylinder 13 , the piston barrel 13 is provided with an oil cylinder piston 14 that slides with it, the inner wall of the oil cylinder damping adjustment barrel 12 is in contact with the outer wall of the piston barrel 13, and the oil cylinder damping adjustment barrel 12 is rotatably matched with the piston barrel 13, so A plurality of outer oil holes 15 are opened on the damping adjustment cyli...

Embodiment 2

[0060] Embodiment 2 is basically the same as Embodiment 1, and its difference is:

[0061] The speed judgment value X in the first step is 4 meters per second.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com