Water-rich sand layer shield tunnel construction method

A technology of shield tunneling and water-rich sand layers, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of poor self-stability, low bearing capacity, sand collapse and other problems, and achieves simple steps and low manpower and material resources. The effect of less and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

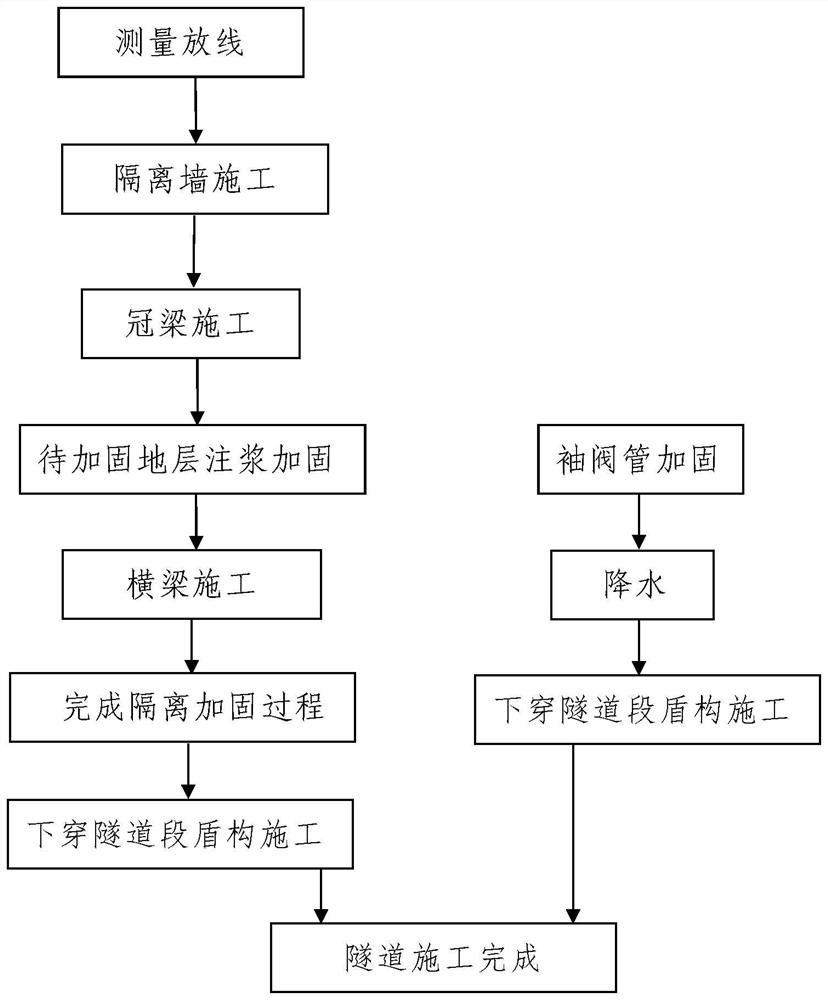

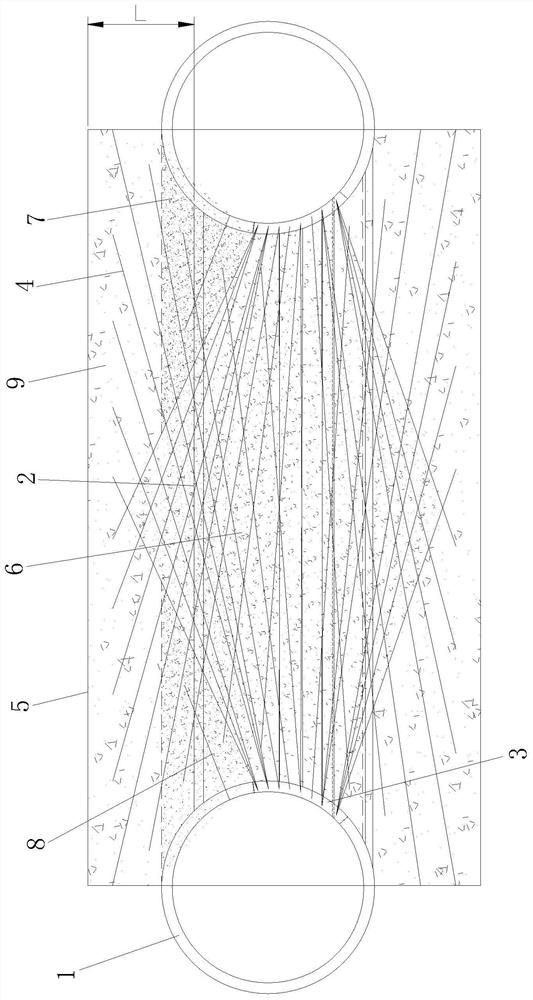

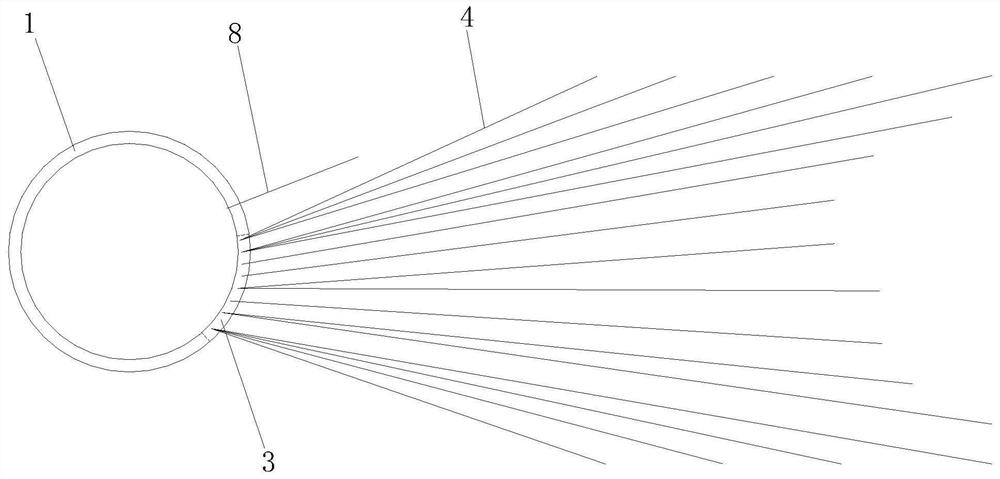

[0081] Such as figure 1 The construction method of a shield tunnel in a water-rich sand layer is shown. The tunnel to be constructed is a double-cavity tunnel and it is an underground excavation tunnel whose body is located in a water-rich sand layer. The two tunnel holes of the constructed tunnel are both shield tunnels. Tunnel 1; the constructed tunnel includes an underpassing viaduct tunnel section and a non-underpassing viaduct tunnel section connected with the underpassing viaduct tunnel section, a tunnel hole of the underpassing viaduct tunnel section passes through an existing viaduct and the tunnel hole In order to pass under the tunnel section, the two tunnel holes of the non-underpassed viaduct tunnel section are connected through the connecting passage 2, see figure 2 ;

[0082] When constructing the constructed tunnel, the two tunnel holes of the underpassed viaduct tunnel section and the two tunnel holes of the non-underpassed viaduct tunnel section are construc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com