Template reinforcing tool and method for reinforcing wall pier template by using template reinforcing tool

A formwork reinforcement and wall stacking technology, which is applied in the field of wall stacking formwork reinforcement tools, wall stacking formwork reinforcement, and formwork reinforcement tools, can solve the problem of runaway formwork at the outer corners of concrete shear walls, unreliable reinforcement of outer corner formwork, and concrete quality defects and other problems, to achieve the effect of eliminating the easy run-out of the positive corner, good promotion prospects, and reliable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

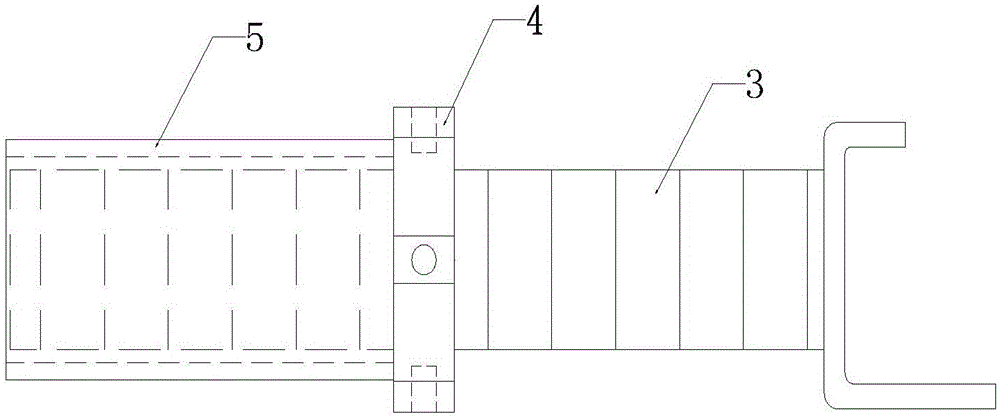

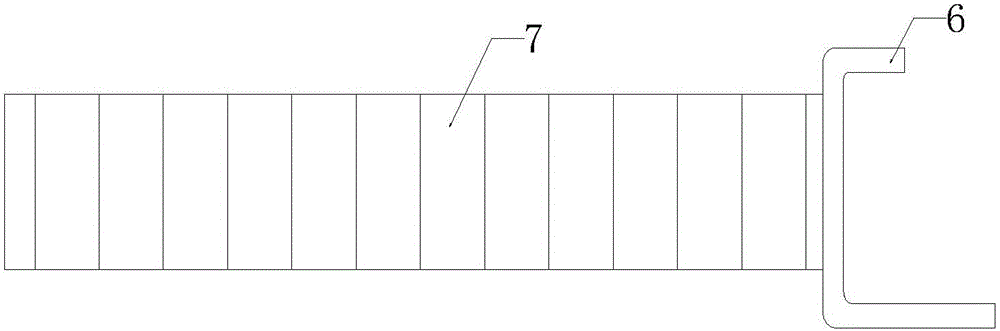

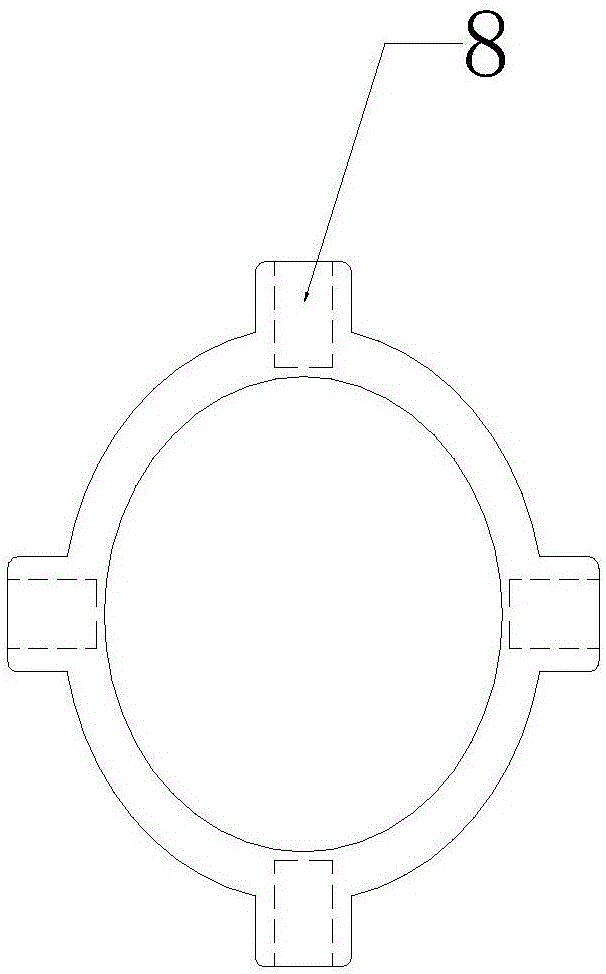

[0024] as attached Figure 1-Figure 6 As shown, it is a template reinforcement tool, which includes a jacking 1 and an O-shaped card 2. The jacking 1 includes a screw A3 with external threads and a special nut 4 threaded with the screw A3. The outer wall of the special nut 4 is provided with a plurality of rocker holes 8 into which a rocker can be inserted, and one end of the screw rod A3 is fixed with a U-shaped supporting plate 6 . The O-shaped clip 2 includes an O-shaped sleeve 10, which can be set on the steel pipe used to reinforce the template. A rectangular plate-shaped clamping arm 9 is fixedly connected to the outer wall of the O-shaped sleeve 10, the O-shaped sleeve 10 is arranged parallel to the width direction of the clamped arm 9, and the clamped arm 9 is placed on the Both radial sides of the O-shaped sleeve 10 have outwardly extending ends respectively. A screw hole 11 is provided on one of the extending ends of the locking arm 9 , and the length of the other ...

Embodiment 2

[0030] Such as Figure 1-Figure 8 Shown, a kind of method that utilizes the formwork reinforcement tool described in embodiment 1 to carry out wall stack formwork reinforcement, it comprises the steps:

[0031] (1) First, use steel pipes, wooden squares, pull bolts 15, and 3-shaped clips 17 to support the front and rear sides of the wall stack, the formwork 12 on the end face of the wall stack, and the adjacent wall formwork 21 according to the general technology, and the formwork is reinforced on the outside of the formwork Set up two rows of horizontal steel pipes and several wooden squares, and use 3-shaped clips 17 and pull bolts 15 to reinforce them. The upper row of steel pipes (or the lower row of steel pipes) used to reinforce the front horizontal steel pipes 18 of the wall stack front formwork And the upper row of steel pipes (or the lower row of steel pipes) of the horizontal steel pipes 22 on the rear side of the wall stack that are used to reinforce the formwork at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com