Transverse anchorage system outside hollow slab bridge body and construction process thereof

A hollow slab bridge and anchoring technology, applied in the direction of bridge reinforcement, bridges, bridge parts, etc., can solve the problems of corrosion, reduce the lateral prestress of the slab bottom, loosen the lining plate of the section steel anchor, achieve accurate calculation, mature technology, Ease of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

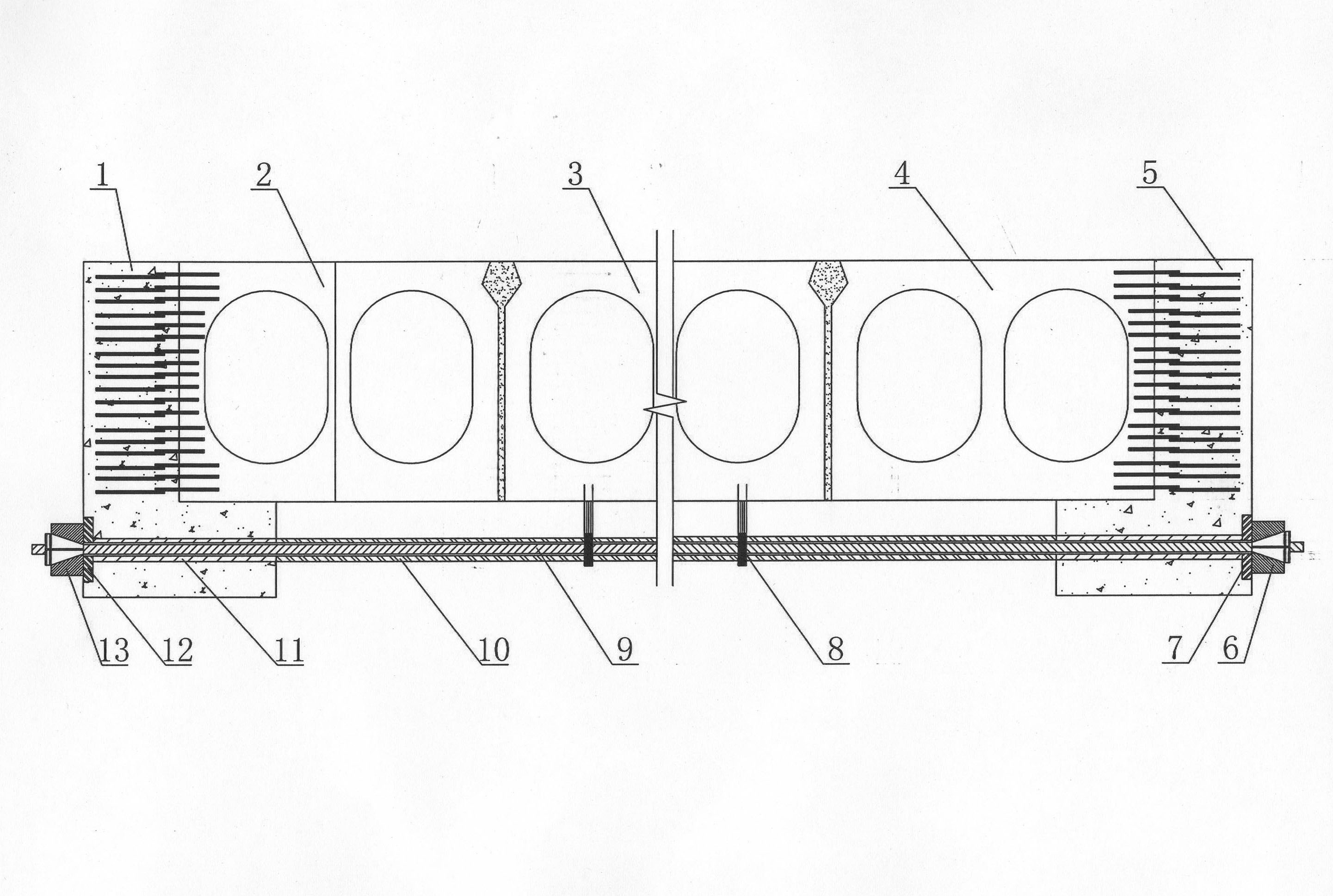

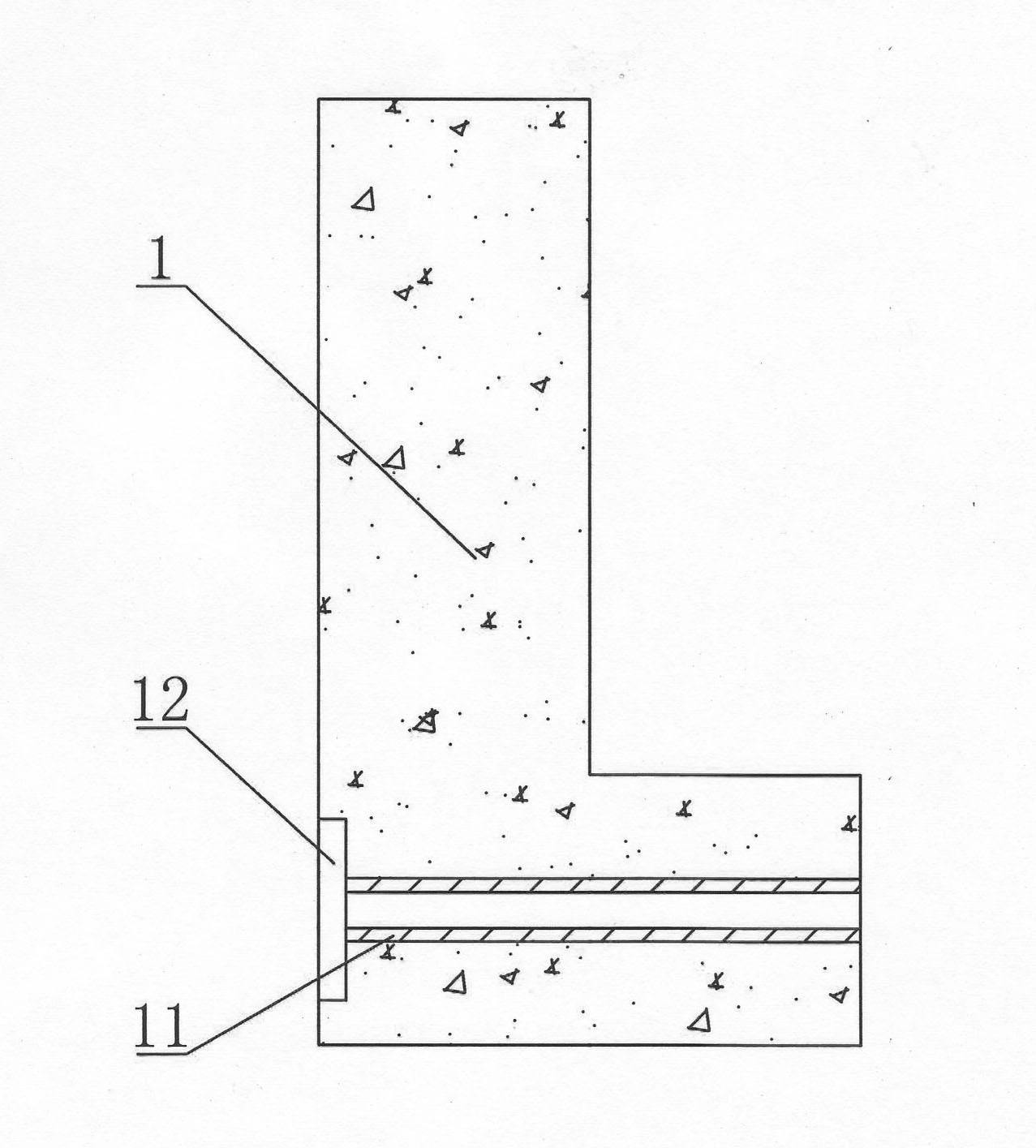

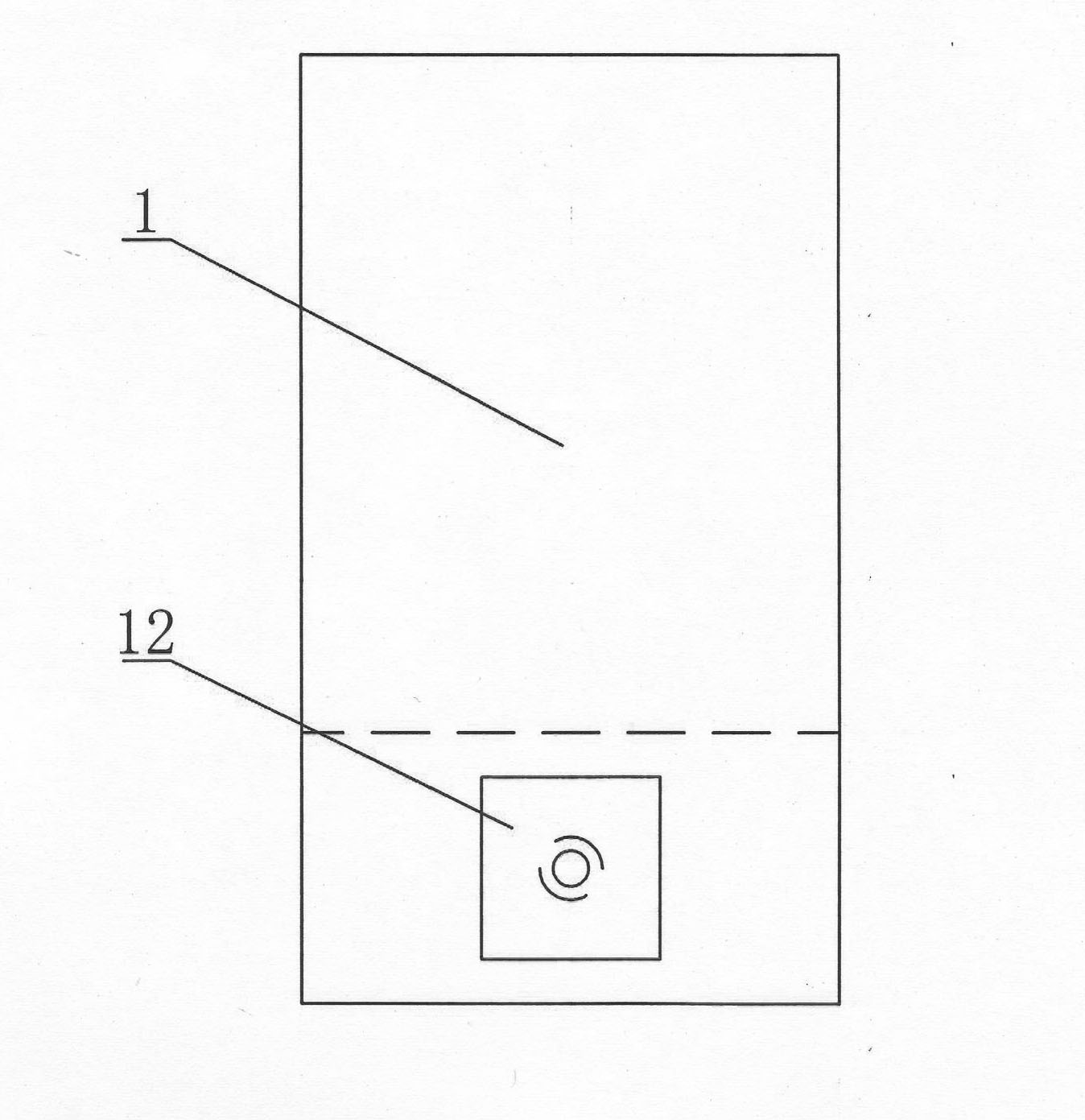

[0042] Such as figure 1 , figure 2 , image 3 As shown, a transverse anchoring system outside the body of a hollow slab bridge, which includes a left plate 2, a middle plate 3 and a right plate 4, the left plate 2 is provided with a left corbel 1, the right plate 4 is provided with a right corbel 5, the left The corbel 1 and the right corbel 5 are reinforced concrete corbels, the cross-sectional shapes of the left corbel 1 and the right corbel 5 are both "L" shaped, and bellows 11 are arranged on the left corbel 1 and the right corbel 5, The prestressed cable 9 is installed in the bellows 11, the left corbel 1 and the right corbel 5 are connected by the prestressed cable 9, the prestressed cable 9 is an unbonded prestressed steel strand, and the left end of the prestressed cable 9 passes through the left anchor The tool 13 is fixed with the left corbel 1, the left anchor 13 is set on the outside of the left corbel 1, the right end of the prestressed cable 9 is fixed with th...

Embodiment 2

[0064] Repeat embodiment one, following difference is arranged, present embodiment is to carry out the horizontal anchoring of hollow slab bridge outside the hollow slab bridge with the span of 20m as example, seven prestressed cables 9 are set on every span hollow slab bridge, the prestressed cables 9 The diameter is 15.2mm, and a prestressed cable 9 is set in the middle of each span of the hollow slab bridge, and a prestressed cable 9 is set in the 1 / 4 and 3 / 4 positions of each span of the hollow slab bridge, and then, on both sides of the middle span, A prestressed cable 9 is respectively arranged at a position 1m away from the midspan, and a prestressed cable 9 is respectively arranged at a position 2.5m away from the midspan on both sides of the midspan.

[0065] The anchoring system provided by the present invention is not only suitable for strengthening the existing hollow slab bridges with external transverse prestress, but also suitable for newly-built assembled hollow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com