Anchor assembly, an anchoring structure and construction process thereof

An anchoring and component technology, which is applied in building construction, building maintenance, construction, etc., can solve the problems of carbon fiber material stress, such as unreachable and unreachable, and achieve reliable anchoring effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

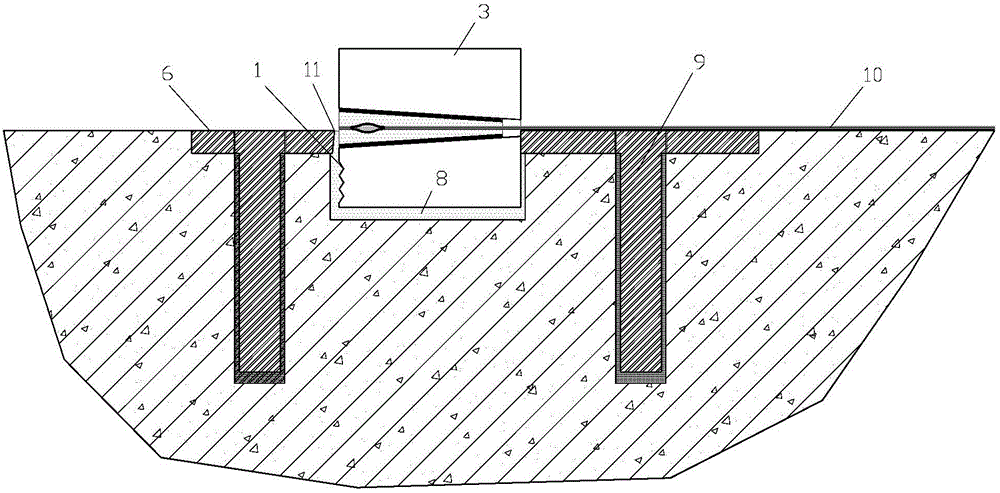

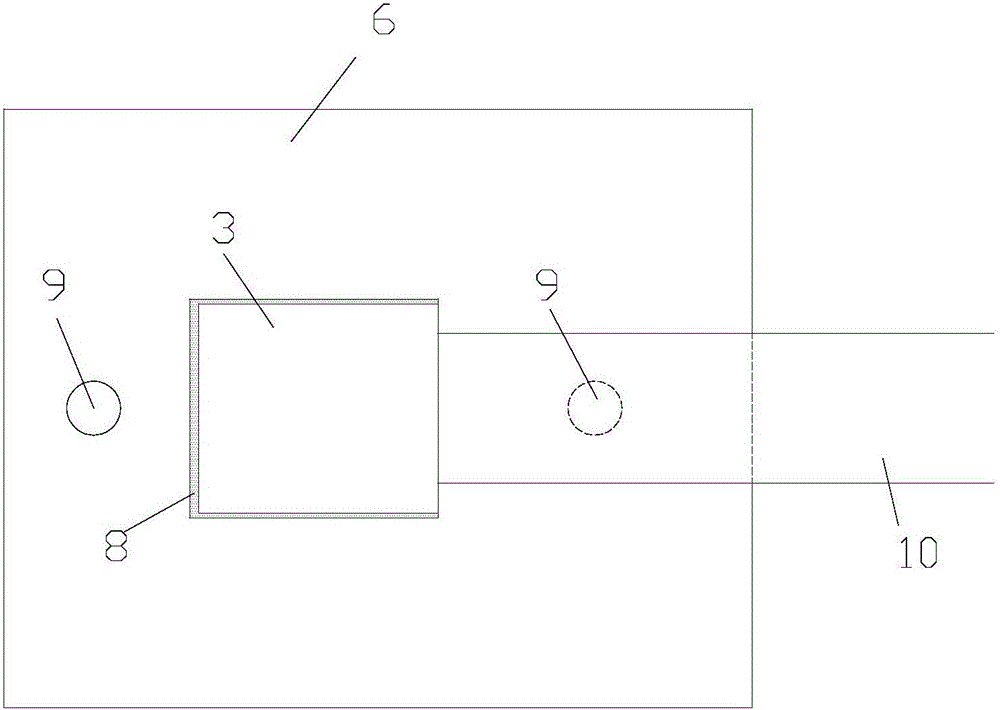

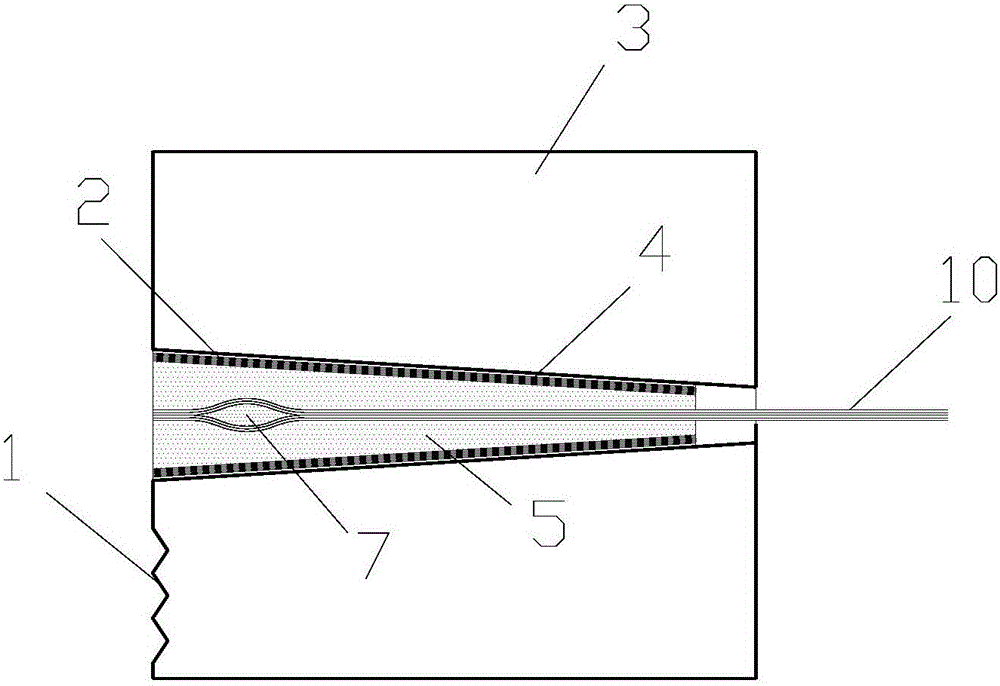

[0022] figure 1 is a structural schematic diagram of the present invention; figure 2 yes figure 1 top view of image 3 It is a schematic structural diagram of the anchor cover of the present invention; as shown in the figure, the anchor assembly of this embodiment includes an anchor cover 3 for fixing to the reinforced part, and the anchor cover 3 is provided with a glue injection cavity 5 , the injection cavity 5 is used to inject the anchor colloid for anchoring the anchored piece. When the anchored piece is anchored, one end of it can be extended into the injection cavity 5, and the inner wall of the injection cavity 5 and the anchored Anchor colloid is injected into the gap between the surfaces of the parts, and the temperature is raised to solidify the anchor colloid, and then the anchor cover 3 is fixed on the reinforced part to realize the anchoring of the anchor part. The shape of the anchor cover 3 in the present invention can be square, oval or Circular, the glue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com