Excavating tool and steel pipe forepoling method

A tool and front-end technology, applied in the field of advanced support of steel pipes, can solve the problems of reduced discharge efficiency, difficult opening and discharge of check valves, etc., and achieve the effect of preventing the reduction of discharge performance and preventing loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

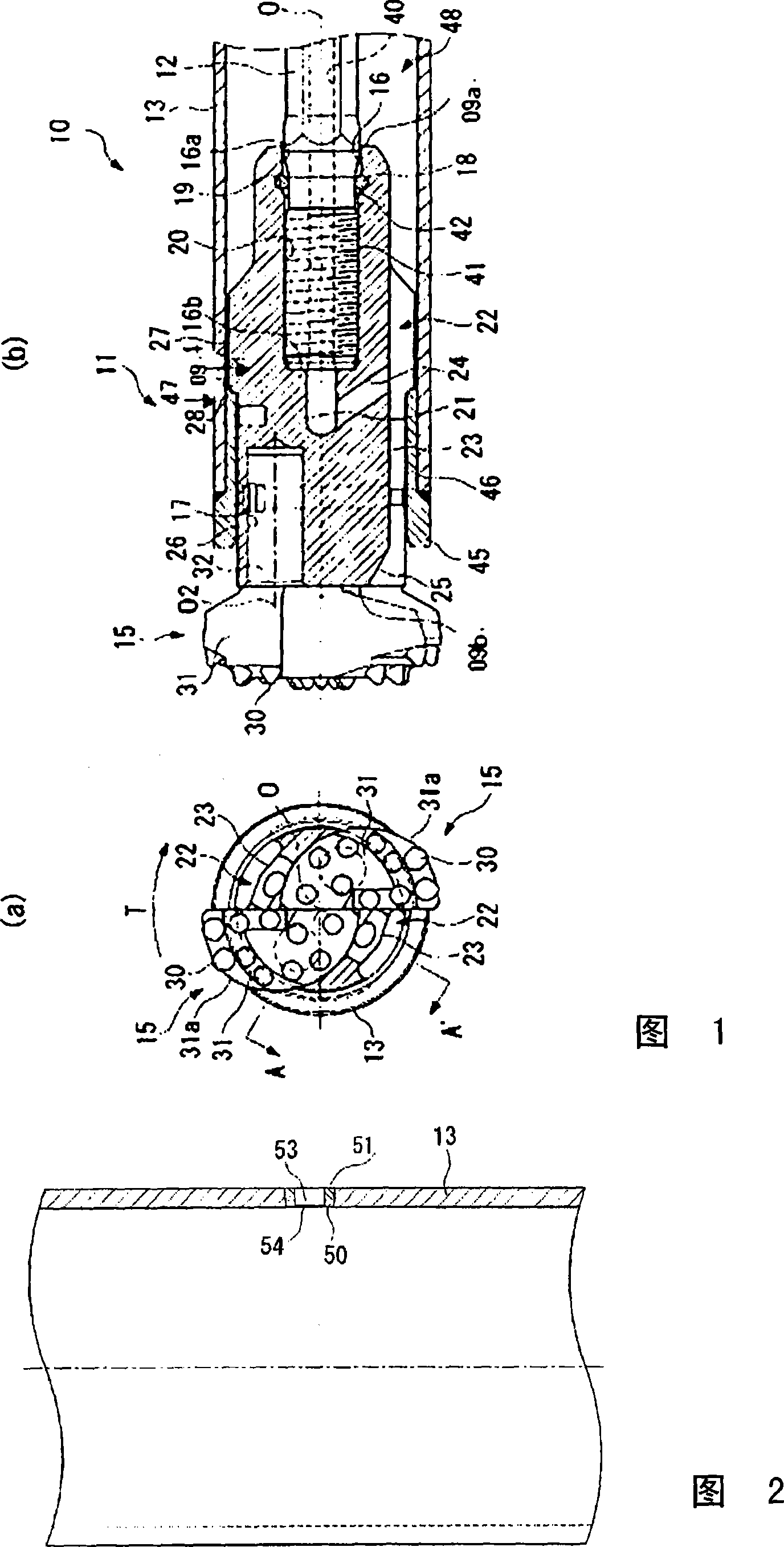

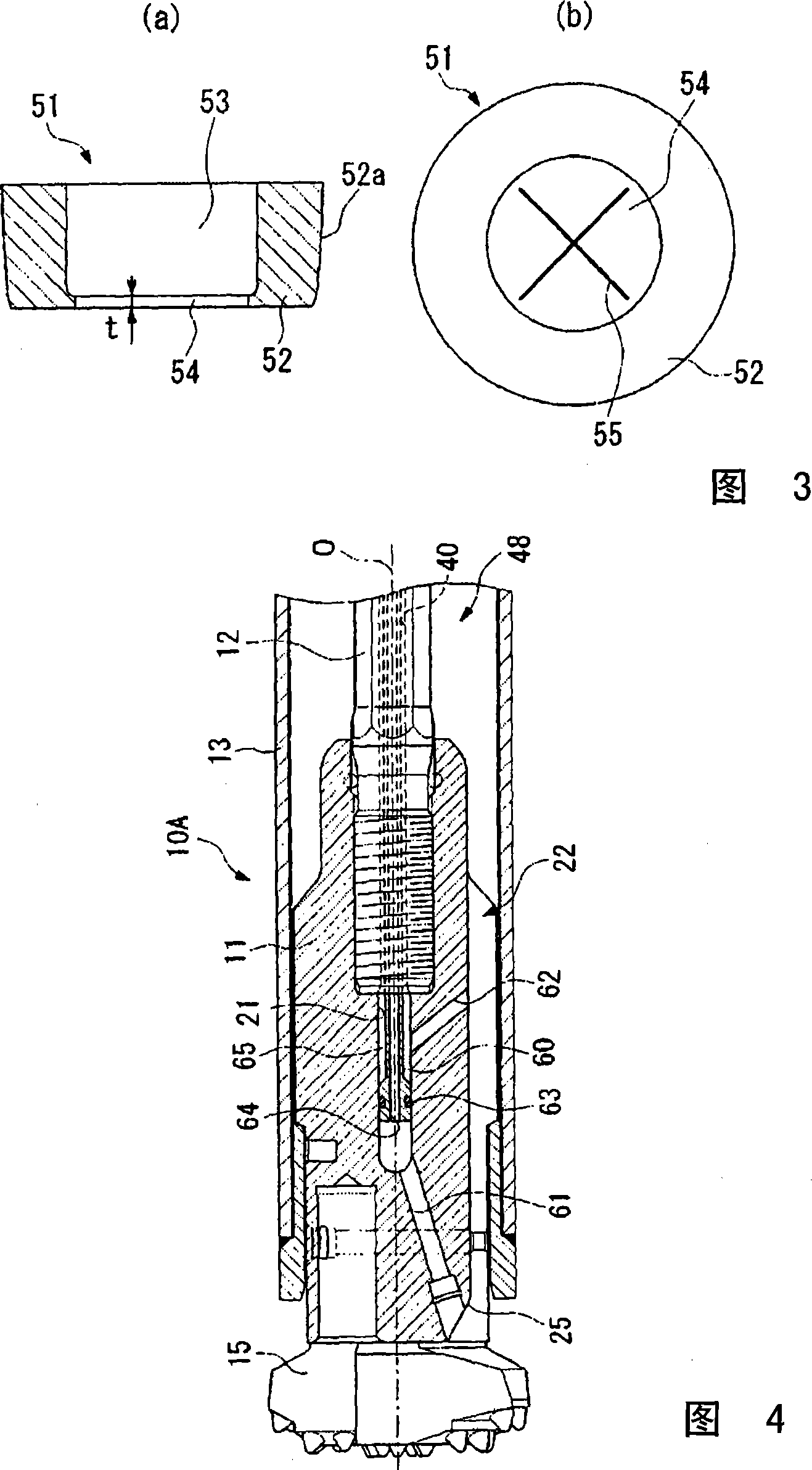

[0067] Hereinafter, Embodiment 1 of the present invention will be described with reference to FIGS. 1 to 4 .

[0068] Fig. 1 shows the front end portion of an excavating tool 10 as a first embodiment of the present invention, Fig. 1(a) is a view of the excavating tool 10 viewed from the front end side of the axis 0, and Fig. 1(b) is a partial cross section of the excavating tool 10 The side view, the cross section of Fig. 1(b) is the cross section of A-O-A' shown in Fig. 1(a). In addition, the arrow direction shown in FIG. 1( a ) is the rotation direction T during excavation, and the left side of FIG. In this embodiment, the excavating tool 10 is provided with a tool body 11 positioned at the foremost end to excavate a mountain body, a digging rod 12 that attaches the tool body 11 to the front end and transmits a driving force, and a cylindrical shaft into which the digging rod 12 can be inserted. Steel pipe 13 and constitute.

[0069] The tool main body 11 includes a device...

Embodiment approach 2

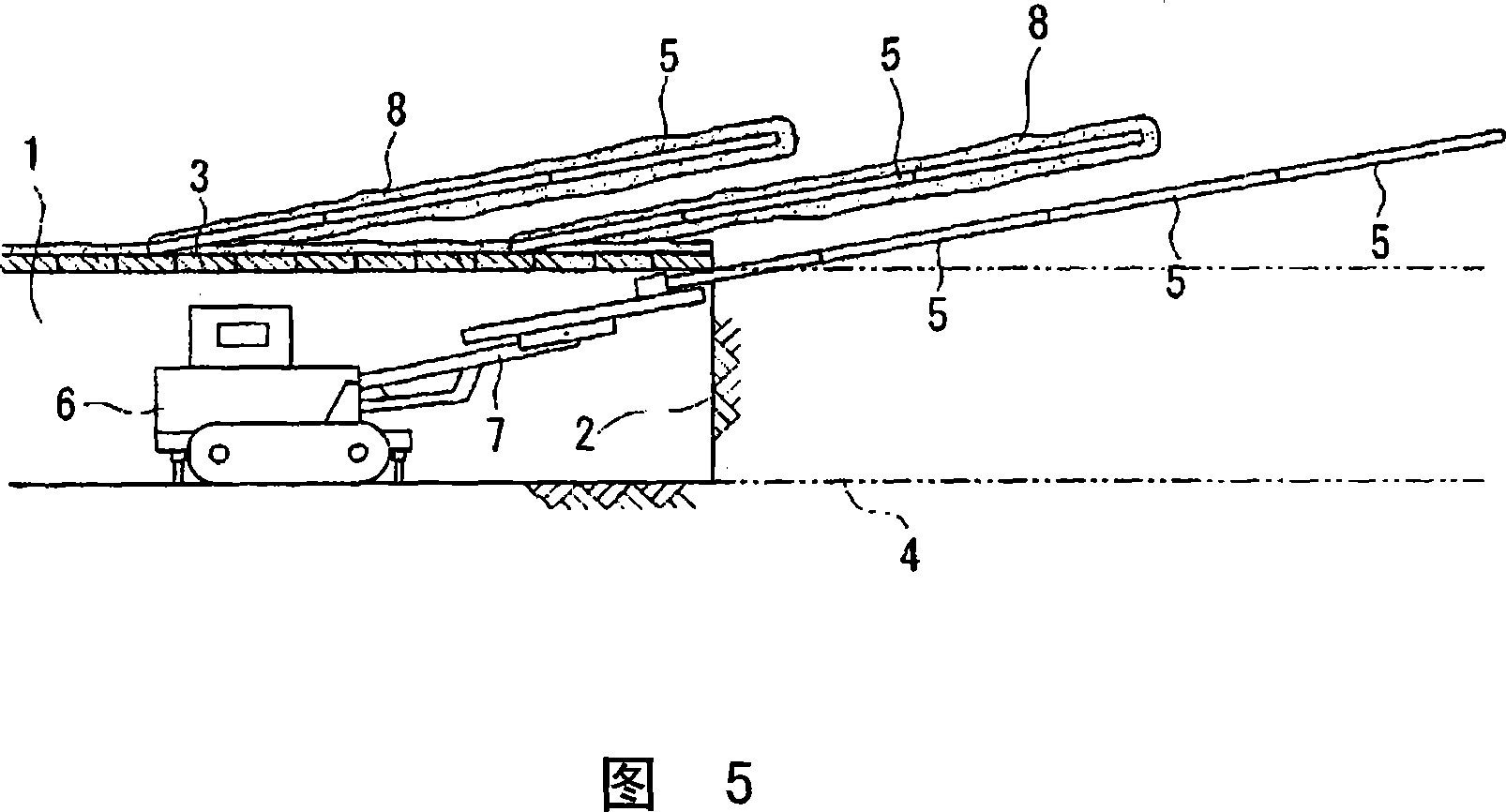

[0086] Embodiment 2 of the present invention will be described with reference to FIGS. 6 to 11 .

[0087] FIG. 6 shows the overall structure of the digging tool 10 according to the first embodiment of the present invention, and FIG. 7 shows the front end portion of the digging tool 10 . In addition, FIG. 7(a) is a view of the excavating tool 10 viewed from the front end side of the axis O, and the arrow direction indicates the rotation direction T during excavation. FIG. 7(b) is a partial cross-sectional side view of the excavating tool 10, and the left side is On the front end side of the excavating tool 10 , the front end direction is defined as the front of the excavation progress direction. The excavating tool 10 is provided with an auger bit (tool body) 11 positioned at the front end to excavate a mountain body, a digging rod 12 with the auger bit 11 mounted on the front end to transmit driving force, and a cylindrical steel pipe ( housing) 13 and an intermediate sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com