Composite structural member capable of storing/releasing charge and preparing method and application thereof

A composite material and charge-releasing technology, which is applied in the manufacture of hybrid/electric double-layer capacitors, electrical components, circuits, etc., can solve problems such as weak structural load-bearing capacity, improve structural load-bearing capacity, reduce weight and volume, and improve overall performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

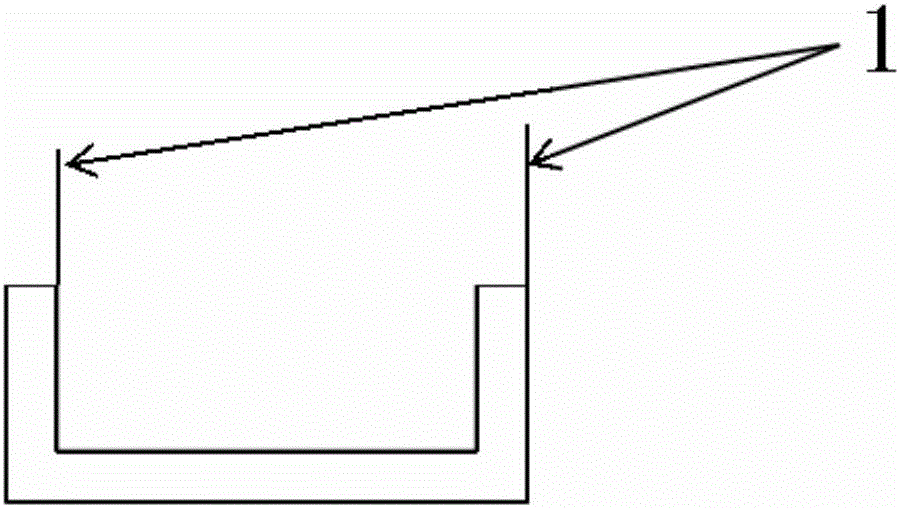

[0028] Example 1: Preparation of C-shaped beam energy storage structure

[0029] See attached figure 1 As shown, the composite C-beam energy storage structure of this kind of composite material that can store / release electric charge is superimposed by a single layered structure. The two sides of the single layered structure are symmetrical from the center to the outside. From the center to the outside are the electrolyte diaphragm, electrolyte, conductive electrode, current collector, insulation and encapsulation layer in sequence, among which:

[0030] The electrolyte diaphragm is an electrolyte diaphragm cloth, and the electrolyte diaphragm cloth is a glass fiber plain cloth with a thickness of 30μm;

[0031] The electrolyte is a solid polymer electrolyte, and the chemical composition and weight percentage of the solid polymer electrolyte are: potassium hydroxide 8wt%, polyvinyl alcohol (molecular weight 1900-2200) 4wt% and water 88wt%;

[0032] The conductive electrode is a continu...

Embodiment 2

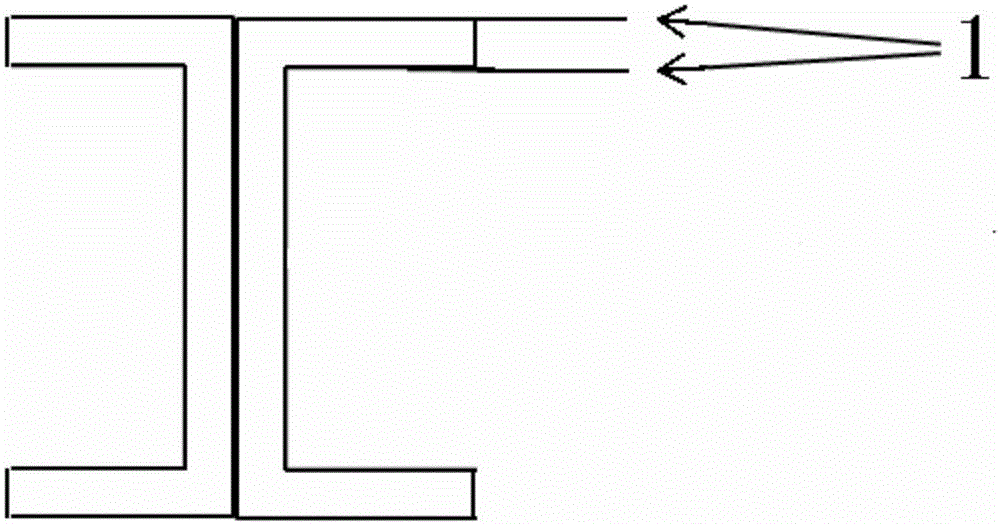

[0044] Example 2 Preparation of I-beam energy storage structure

[0045] See attached figure 2 As shown, the composite I-beam energy storage structure capable of storing / releasing charges is formed by superimposing the structural members of the layered structure. The two sides of the structural members of the layered structure are symmetrical from the center to the outside. From the center to the outside are the electrolyte diaphragm, electrolyte, conductive electrode, current collector, insulation and encapsulation layer in sequence, among which:

[0046] The electrolyte diaphragm is an electrolyte diaphragm cloth, and the electrolyte diaphragm cloth is a glass fiber plain cloth with a thickness of 30μm;

[0047] The electrolyte is a solid polymer electrolyte, and the chemical composition and weight percentage of the solid polymer electrolyte are: potassium hydroxide 5wt%, polyvinyl alcohol (molecular weight 1900-2200) 5wt% and water 90wt%;

[0048] The conductive electrode is a con...

Embodiment 3

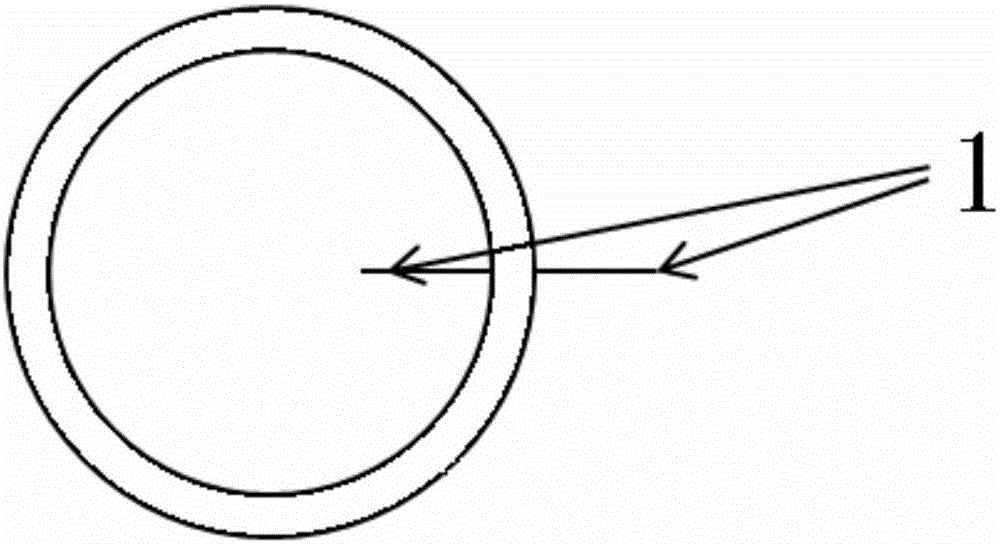

[0063] Example 3: Preparation of circular tube energy storage structure

[0064] See attached image 3 As shown, this kind of composite material circular tube energy storage structure that can cyclically store / release charges is made up of laminated structure monomers, and the two sides of the laminated structure monomers go from the center to the outside Symmetrical, from the center to the outside, there are electrolyte membrane, electrolyte, conductive electrode, current collector, insulation and encapsulation layer in order, among them:

[0065] The electrolyte diaphragm is an electrolyte diaphragm cloth, and the electrolyte diaphragm cloth is a glass fiber plain cloth with a thickness of 30μm;

[0066] The electrolyte is a solid polymer electrolyte, and the chemical composition and weight percentage of the solid polymer electrolyte are: potassium hydroxide 8.3wt%, polyvinyl alcohol (molecular weight 1900-2200) 4.1wt% and water 87.6wt%;

[0067] The conductive electrode is a conti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com