Dam compacting equipment

A technology of dams and equipment, which is applied in the field of ramming dam equipment, can solve problems such as dyke breakage, water overflowing dams, and dams without tamping and reinforcement, and achieve the effect of easy reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

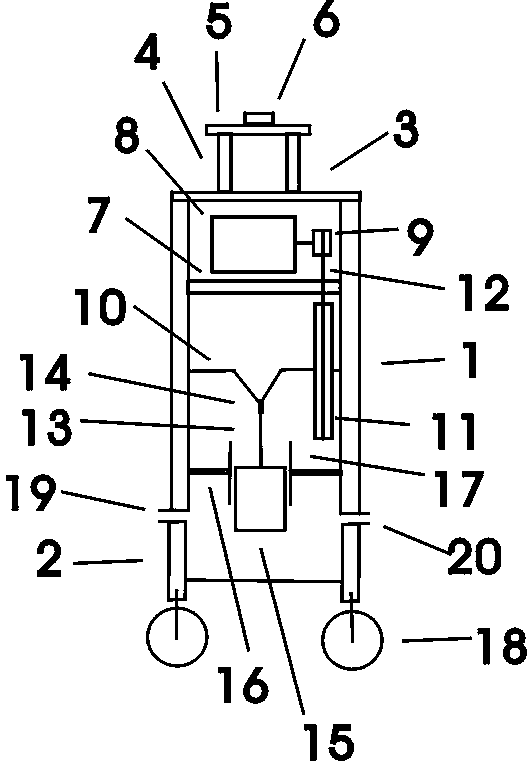

[0018] To ram the embankment equipment, first fabricate a mounting frame. The installation frame is divided into upper frame 1 and base 2. The installation frame is approximately a cube shape. The top plate 3 central positions of the mounting bracket upper frame are screw holes at the corners of the four corners of a square.

[0019] Make a butt plate 5 slightly larger than the square formed by the screw holes in the center of the top plate on the mounting frame. There are screw holes at the four corners of the butt plate. The central position on one side of the docking plate is the same screw hole part 6 as the screw hole part of the bucket docking arm of the excavator. The docking stick includes hydraulic equipment on the docking stick. The bucket of the excavator is removed, and the butt plate can be completely butted with the screw hole parts on the bucket rod of the excavator through the screw hole parts at the center of the butt plate. Including docking with hydraul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com