Beam-column, a wooden form reinforcement for beam--column-joint and construction method thereof

A construction method and junction technology are applied in the field of reinforcement at the junction of cast-in-place steel concrete structure column-beam formwork, which can solve the problems of insufficient reinforcement, easy expansion of molds, waste of materials and human resources, etc., to save wood and construction quality. Good, labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited thereto.

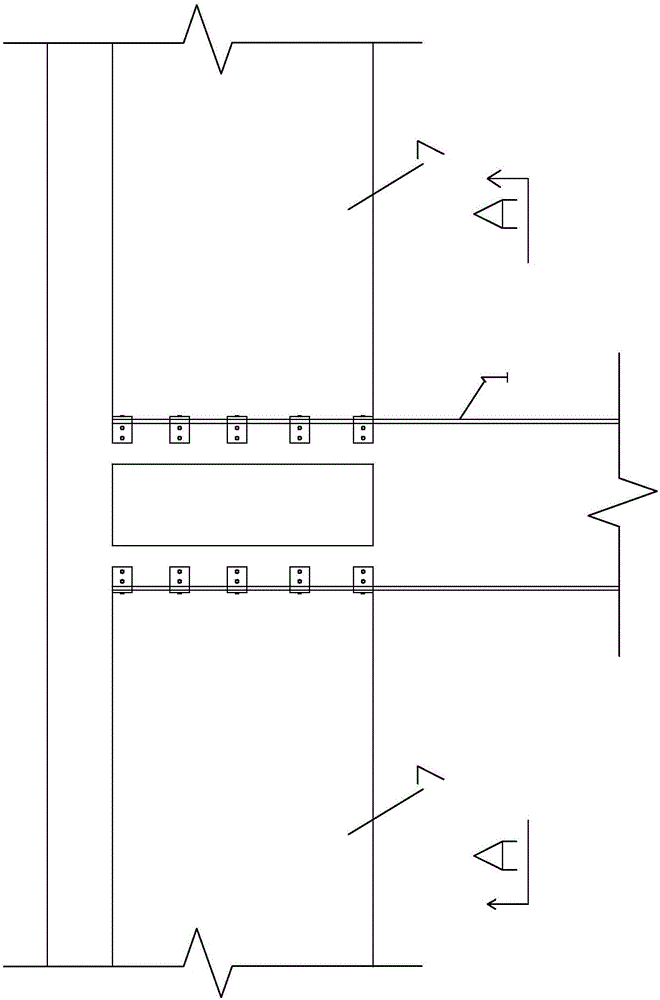

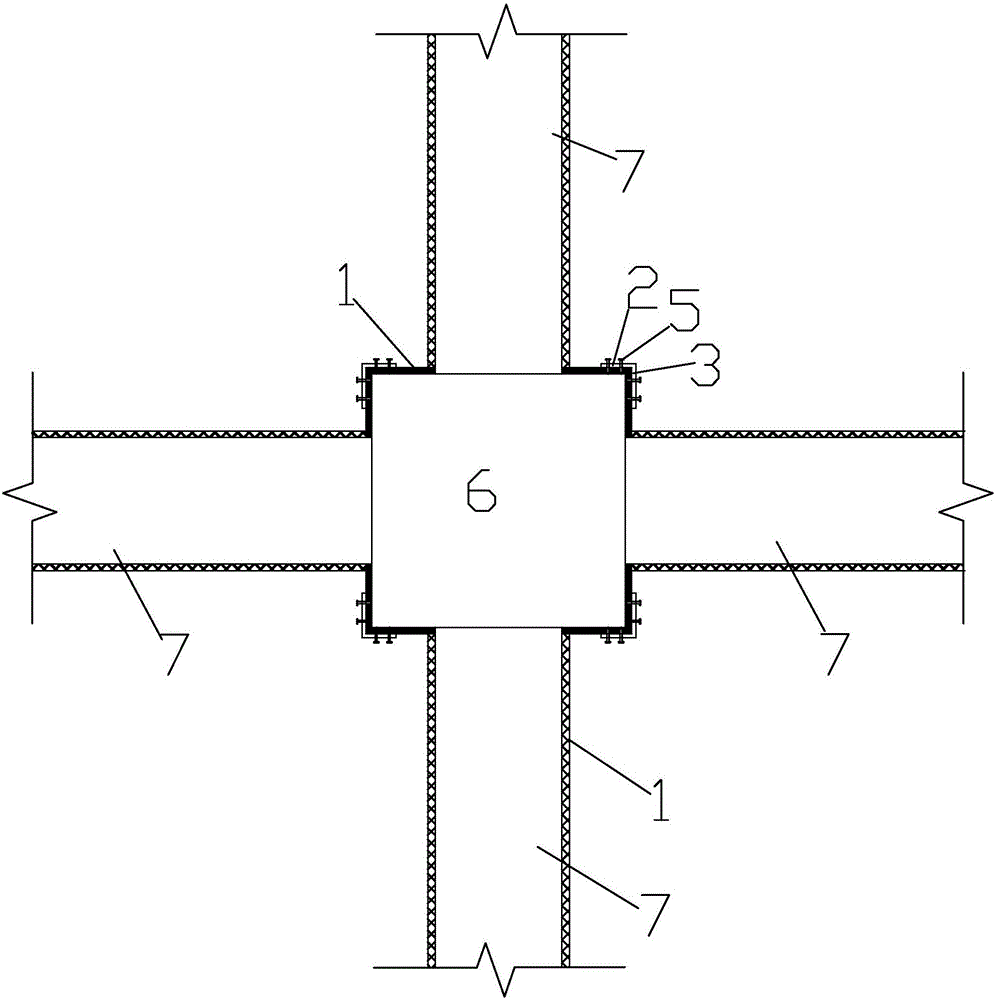

[0020] Such as Figure 1-3 Shown, the construction method of the wooden formwork reinforcing piece of post-beam of the present invention and post-beam junction, comprises the following steps:

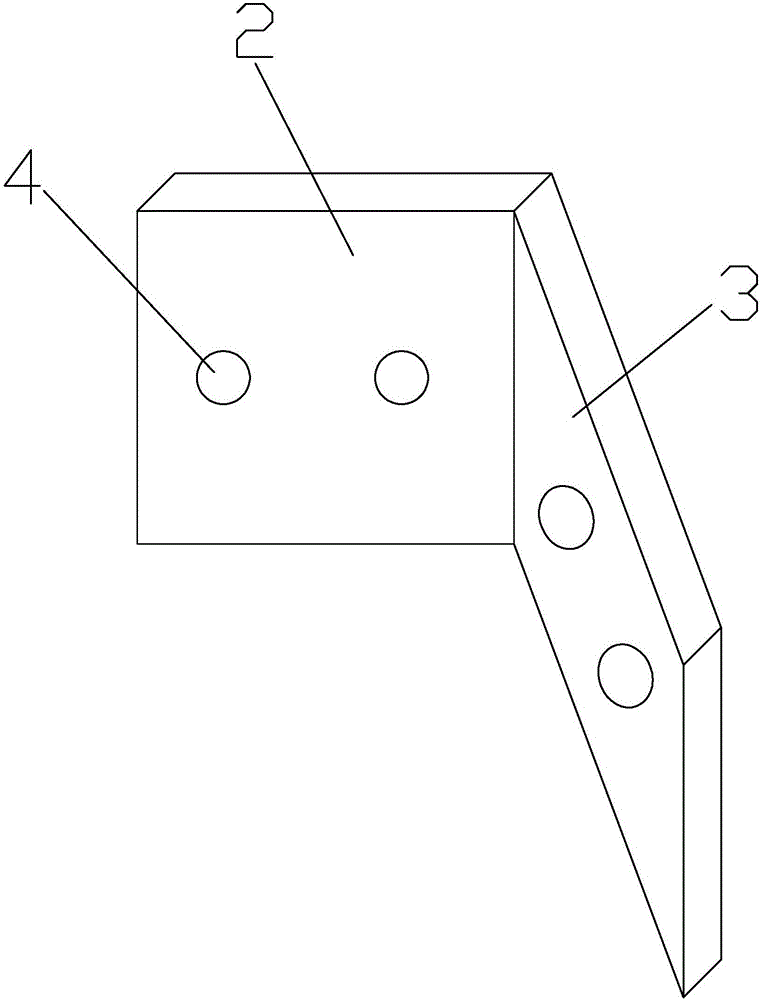

[0021] (1) Assemble corner module one 2 and corner module two 3 into a right-angle shape to form a corner module;

[0022] (2) Use nails 5 to nail the corner modules to the wooden mold 1 one by one, the upper and lower distances of the corner modules are not more than 20cm; the nails 5 are three-inch nails, and half of the nails 5 are exposed outside the wooden mold, making it easy to remove;

[0023] (3) When the template is removed, just pull out the nail 5.

[0024] Wooden formwork reinforcement among the present invention comprises the wooden formwork 1 that is installed in post 6 and beam 7 intersections, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com