Railway large-bore tunnel overhead contact built-in sliding chute construction method

A tunnel contact and construction method technology, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of slow installation progress, low safety and durability, and uneven appearance, and achieve simple reinforcement, improved work efficiency, and smooth appearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

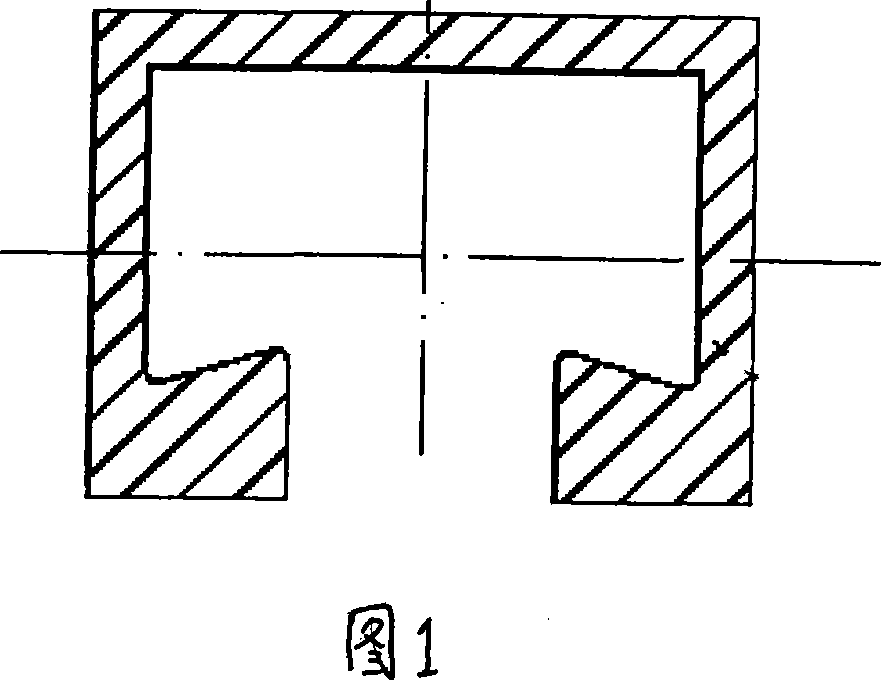

[0011] A method for constructing pre-embedded chutes in railway large-section tunnel catenary, comprising the following steps: (1) Opening holes in the formwork of the lining trolley: according to the embedding position, quantity, length and spacing of the chutes in the lining, determine the position on the formwork of the lining trolley. The opening position of the positioning hole, the positioning hole is a rectangular hole, and the size is length × width = 4 × 2cm; (2) The positioning of the lining trolley: it is determined according to the distance between the catenary suspension columns, the processing length of the lining trolley and the actual construction length of the lining concrete The overlapping length of the lining trolley and the poured lining is generally 8-10cm. When measuring and setting out, the mileage control point is accurately determined on the inverted arch filling surface according to the actual construction length of the lining concrete and the total le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com