Surface strengthening method for magnesium alloy

A surface strengthening and magnesium alloy technology, which is applied in the field of magnesium alloy surface strengthening, can solve the problems of not improving strength, affecting fine grain strengthening, and difficulty in deformation, and achieves the effects of reducing equipment investment, excellent performance, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

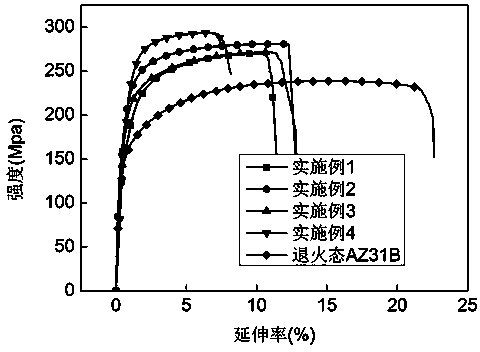

Embodiment 1

[0018] The surface strengthening method of the magnesium alloy of the present embodiment specifically comprises the following steps:

[0019] (1) The 1mm AZ31B magnesium alloy plate is subjected to conventional annealing treatment at 350°C for 2 hours to make it recrystallize;

[0020] (2) At room temperature, the frequency of the surface nanometerization testing machine in a vacuum environment is 50 Hz, and 100 steel balls are respectively impacted and deformed on the two surfaces for 5 minutes to prepare a surface with extremely high hardness, improved strength and good tensile properties. Extensible AZ31B magnesium alloy material, the surface hardness can reach 0.95GPa, the yield strength can reach 210Mpa, and the elongation can reach 14%.

Embodiment 2

[0022] The surface strengthening method of the magnesium alloy of the present embodiment specifically comprises the following steps:

[0023] (1) The 3mm AZ31B magnesium alloy plate is subjected to conventional annealing treatment at 200°C for 3 hours to make it recrystallize;

[0024] (2) At room temperature, the frequency of the surface nanometerization testing machine in a vacuum environment is 20Hz, and 200 steel balls are subjected to impact deformation treatment on the two surfaces for 30 minutes respectively, and the surface hardness is extremely high, the strength is improved, and it also has good tensile properties. Extensible AZ31B magnesium alloy material, the surface hardness can reach 1.25GPa, the yield strength can reach 235Mpa, and the elongation can reach 12%.

Embodiment 3

[0026] The surface strengthening method of the magnesium alloy of the present embodiment specifically comprises the following steps:

[0027] (1) The 1mm AZ31B magnesium alloy plate is subjected to conventional annealing treatment at 400°C for 1 hour to make it recrystallize;

[0028] (2) Under the condition of feeding liquid nitrogen, the frequency of the surface nanometerization testing machine is 40 Hz, and 150 steel balls are respectively impacted and deformed on the two surfaces for 5 minutes, and the surface hardness is extremely high, the strength is improved, and it also has Good tensile plastic AZ31B magnesium alloy material, the surface hardness can reach 1.05GPa, the yield strength can reach 191Mpa, and the elongation can reach 12.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com