Vertical-shaft gang-tool corn straw header mechanism

A technology of corn stalks and vertical shafts, which is applied to harvesting platforms, harvesters, agricultural machinery and implements, etc., can solve the problems of large power consumption, high cost, and complex structure, and achieve improved utilization, good crushing uniformity, and improved labor efficiency. productivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

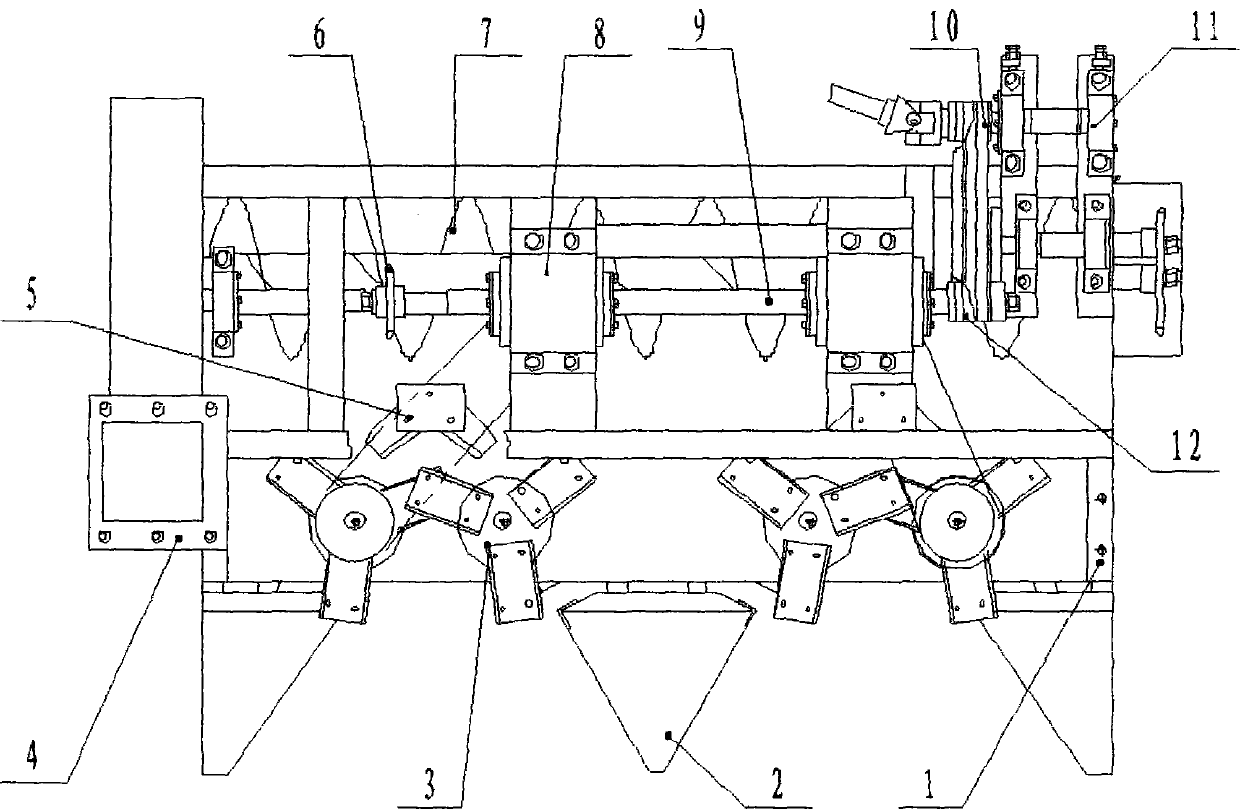

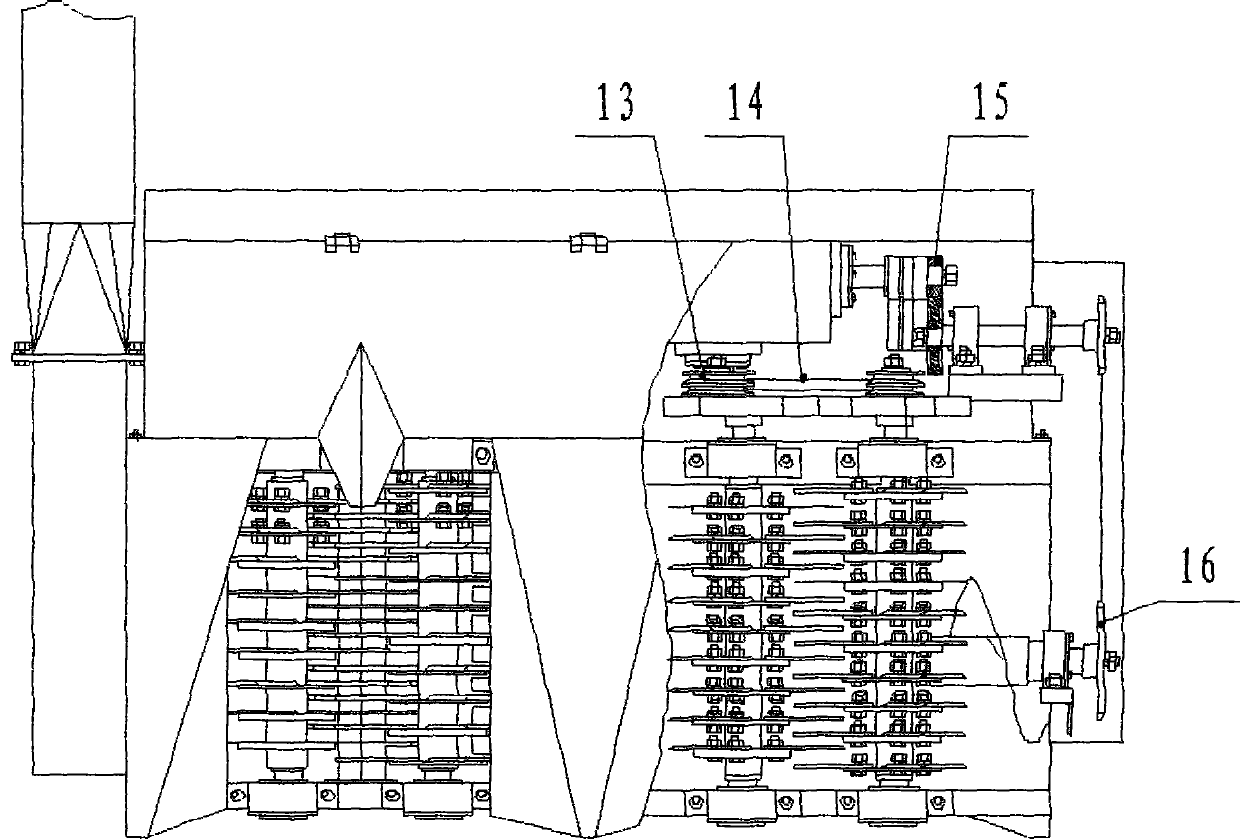

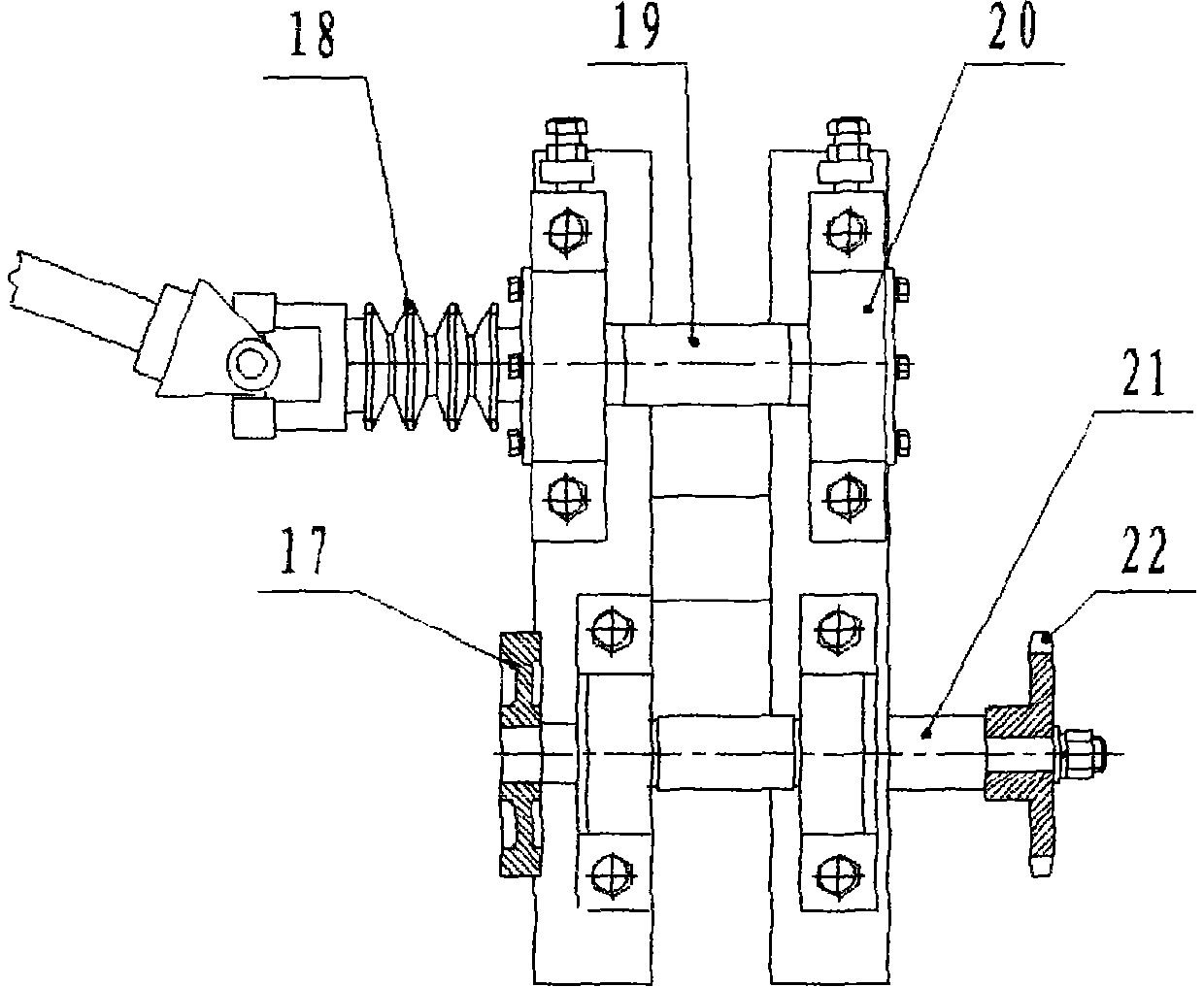

[0024] Before harvesting corn stalks, first place the header at a suitable stubble cutting height, then perform dry running, and the power transmission mechanism (11) fixed on the frame (1) through the bearing seat (20) works, and the transmission shaft I ( 19) rotate, drive the input pulley (18) to rotate at the same time, and transmit the power to the main shaft (9) through the belt I (10) and the output pulley (12), the main shaft (9) rotates, and drives the gearbox (8), reversing Gear II (15) and sprocket III (6) work.

[0025] When the gearbox (8) works, the transmission pulley I (13) connected to it rotates, and is driven by the belt II (14) and fixed on the frame (1) by the upper bearing seat (27) and the lower bearing seat (23) The vertical shaft moving knife mechanism (3) works, and the transmission pulley II (29) on it rotates, and the power is transmitted to the two vertical shaft gears (28) that are meshed with each other, so the vertical shaft II (30) and the vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com