Method for extracting catechin, and application thereof

A technology of catechins and extracts, which is applied in the direction of anti-toxic agents, organic chemistry, anti-viral agents, etc., can solve the problems that it cannot be used to prepare catechin conjugates, the synthesis pathway does not provide distinction, and the synthesis of metabolites is not reported. , to achieve the effects of improving solubility and stability, improving thermal degradation, and improving the uniformity of crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

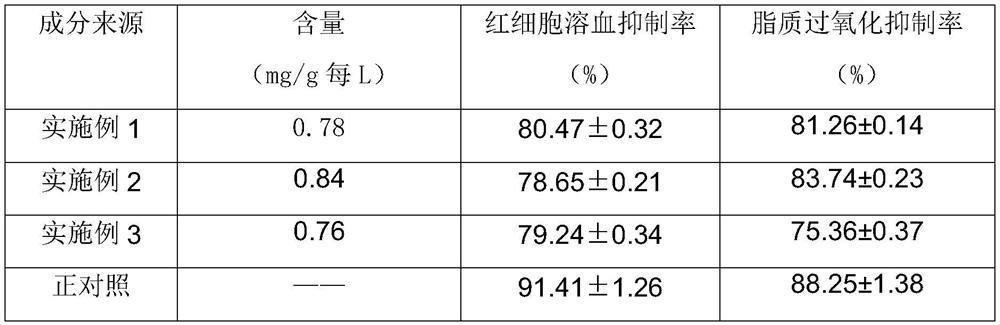

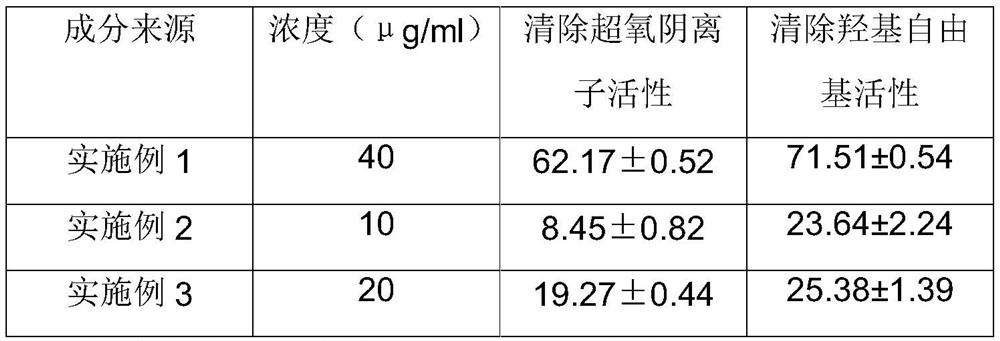

Examples

Embodiment 1

[0035] A method for extracting catechins, comprising the steps of:

[0036] (1) The plant tissues of the tea tree are roots, stems and leaves. Grind the plant tissue of the tea tree with a pulverizer until it can pass through a sieve with a pore size of 1.3mm, and then soak in water at room temperature for 3 hours; ultrasonic treatment, 300W ultrasonic treatment at 50°C for 30min. Add compound enzyme solution, enzymolyze at 45°C for 8 hours, then stand still or centrifuge and take the supernatant as the enzymatic hydrolysis product; compound enzymes include cellulase, xylanase, amygdalinase, cellulase, The mass ratio of xylanase and amygdalinase is 4.5:5:1.2, and it is configured into a composite enzyme aqueous solution with a mass concentration of 5%; wherein cellulase is 420U / mg, xylanase is 5U / mg, bitter Amygdalinase is 8U / mg.

[0037] (2) Take the enzymatic hydrolysis product and add quaternary ammonium salt and stabilizer, the stabilizer is 4-picolinic acid, and then he...

Embodiment 2

[0042] A method for extracting catechins, comprising the steps of:

[0043] (1) The plant tissue of the tea tree is one or more of roots, stems and leaves. Grind the plant tissue of the tea tree with a pulverizer until it can pass through a sieve with a pore size of 1.55 mm, and then soak in water at room temperature for 3 hours; ultrasonic treatment at 50 °C for 30 min at 300 W. Add compound enzyme solution, enzymolyze at 65°C for 5 hours, then stand still or centrifuge and take the supernatant as the enzymatic hydrolysis product; compound enzymes include cellulase, xylanase, amygdalinase, cellulase, The mass ratio of xylanase and amygdalinase is 4.5:5:1.2, and it is configured into a composite enzyme aqueous solution with a mass concentration of 5%; wherein cellulase is 420U / mg, xylanase is 5U / mg, bitter Amygdalinase is 8U / mg.

[0044] (2) Take the enzymatic hydrolysis product and add quaternary ammonium salt and stabilizer, the stabilizer is 4-picolinic acid, and then hea...

Embodiment 3

[0049] A method for extracting catechins, comprising the steps of:

[0050] (1) The plant tissue of the tea tree is one or more of roots, stems and leaves. Grind the plant tissue of the tea tree with a pulverizer until it can pass through a sieve with a pore size of 1.55 mm, and then soak in water at room temperature for 2 hours; ultrasonic treatment at 50 °C for 30 min at 300 W. Add compound enzyme solution, enzymolyze at 65°C for 8 hours, then stand still or centrifuge and take the supernatant as the enzymatic hydrolysis product; compound enzymes include cellulase, xylanase, amygdalinase, cellulase, The mass ratio of xylanase and amygdalinase is 4.5:5:1.2, and it is configured into a composite enzyme aqueous solution with a mass concentration of 5%; wherein cellulase is 420U / mg, xylanase is 5U / mg, bitter Amygdalinase is 8U / mg.

[0051] (2) Take the enzymatic hydrolysis product and add quaternary ammonium salt and stabilizer, the stabilizer is 4-picolinic acid, and then hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com