Cage type crushing device for compound fertilizer production

A technology of crushing device and compound fertilizer, applied in grain processing and other directions, can solve the problem of easy wear and tear of cage bars, and achieve the effect of increasing rotating area, reducing wear and increasing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

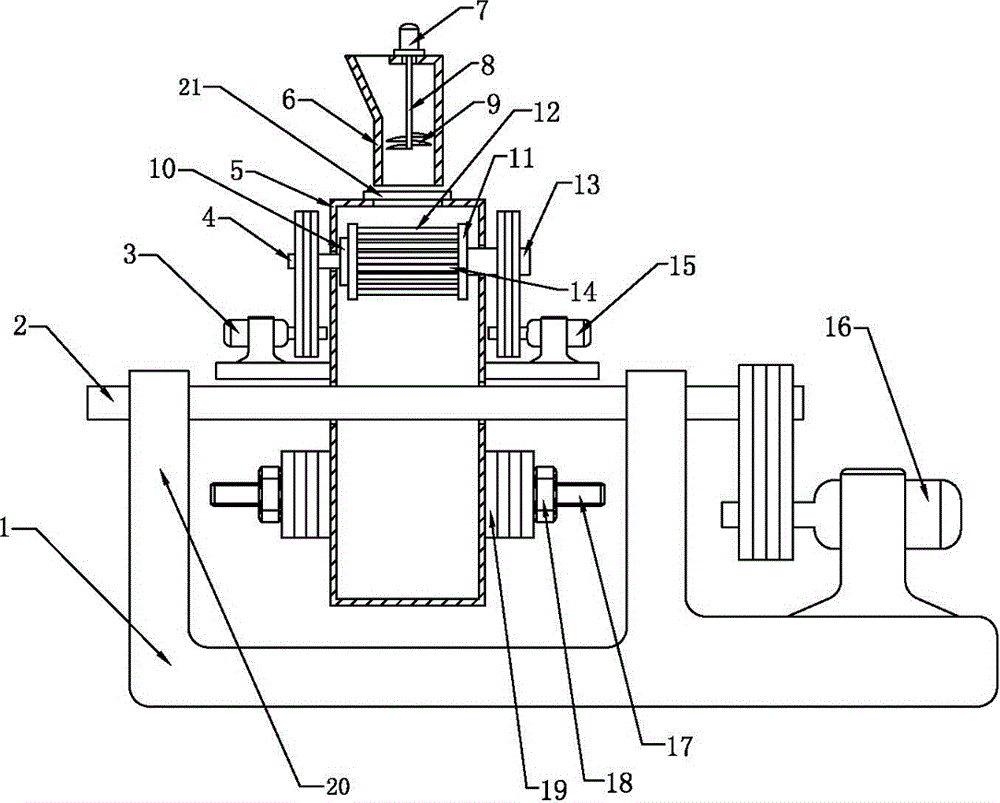

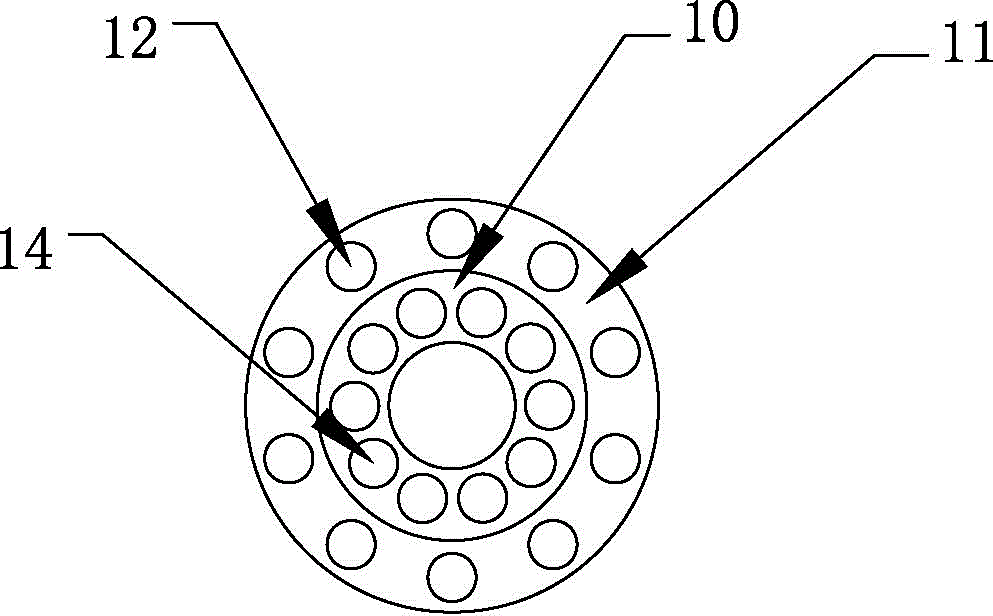

[0019] The reference signs in the accompanying drawings of the description include: bracket 1, main shaft 2, first rotating cage motor 3, first rotating shaft 4, cabinet 5, feeding hopper 6, third motor 7, rotating rod 8, rotating knife 9, the first One rotating cage 10, the second rotating cage 11, the second cage bar 12, the second rotating shaft 13, the first cage bar 14, the second rotating cage motor 15, the second motor 16, threaded rod 17, nut 18, counterweight 19, bearing frame 20, cover 21.

[0020] The embodiment is basically as attached figure 1 and figure 2 Shown: make compound fertilizer cage-type crushing device, comprise the crushing cage that is made up of two rotating cages, two rotating cages are the first rotating cage 10 and the second rotating cage 11, the first rotating cage 10 comprises two first rotating cages Circular plate, there are some fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com