Fine type textile fiber grinding and pulping production equipment

A textile fiber and production equipment technology, applied in the field of fine textile fiber grinding and beating production equipment, can solve the problems of rough slurry and low production efficiency, achieve stable quality, high production efficiency, and improve the uniformity of crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

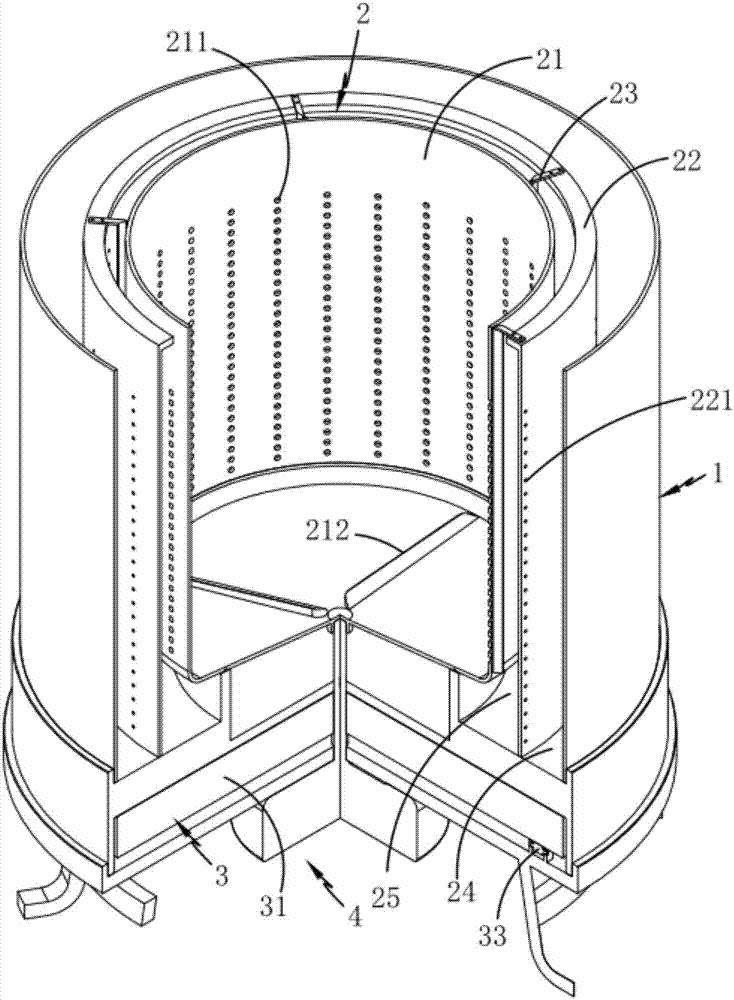

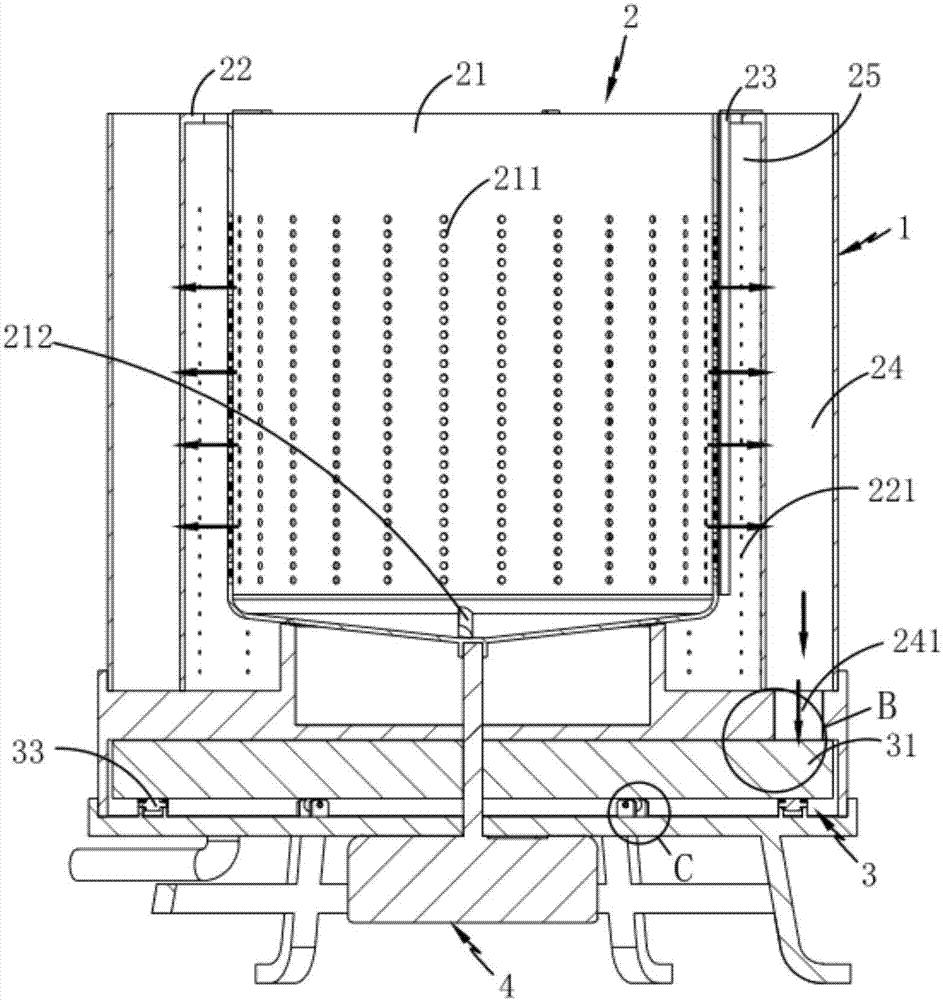

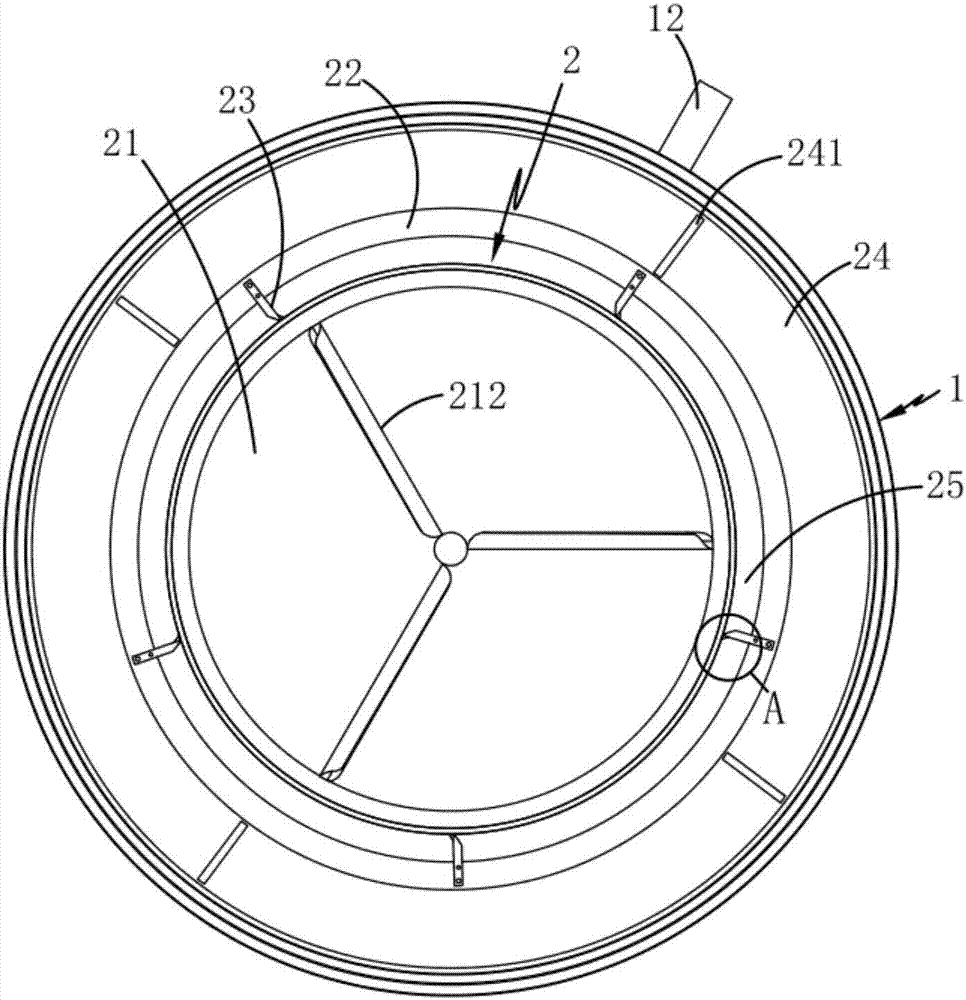

[0034] Such as figure 1 , 2 , 3, 4 and 5, a kind of fine textile fiber grinding and beating production equipment includes a cylindrical beating chamber 1, a crushing mechanism 2 and a grinding mechanism 3, and the crushing mechanism 2 is installed in the inside of the beating chamber 1 , which includes a rotating feed bin 21, a partition 22 fixedly arranged on the periphery of the feed bin 21, and a plurality of partitions fixedly installed on the partition 22 and tangentially matched with the outer circumferential surface of the feed bin 21. A cutter 23, the two sides of the partition plate 22 respectively form a primary separation area 24 and a secondary separation area 25, the rotation of the feed bin 21 drives the material in its internal waters to rotate, and the centrifugal force generated by it On the material, the material is sheared and pulverized by the cutter 23 during the passage of the material along a number of primary screen holes 211 set on the feed bin 21 and...

Embodiment 2

[0036] The inventor believes that in order to better implement the technical solution, further specific implementation methods are necessary, so the inventor describes the second embodiment on the basis of the first embodiment.

[0037] Such as figure 1 , 2 , 3, 4 and 5, a kind of fine textile fiber grinding and beating production equipment includes a cylindrical beating chamber 1, and also includes:

[0038] Pulverizing mechanism 2, described pulverizing mechanism 2 is installed in the inside of described beating chamber 1, and it comprises the feeding bin 21 that is rotatably arranged, the dividing plate 22 that is fixedly arranged on the periphery of this feeding bin 21 and is fixedly installed on this dividing plate 22 A plurality of cutting knives 23 arranged on the top and tangent to the outer circumferential surface of the feed bin 21, the two sides of the partition 22 respectively form a primary partition 24 and a secondary partition 25, the feed bin 21 rotates to dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com