Telescopic crushing type PDC drill bit for petroleum drilling and using method

A technology for oil drilling and drill bits, which is applied in the direction of drill bits, drilling equipment, drill pipes, etc. It can solve the problems of poor connection strength between the broken drill bit and the drill bit body, and the failure of the crushing ability to achieve the expected effect, so as to reduce drilling costs and reduce diversity. , the effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

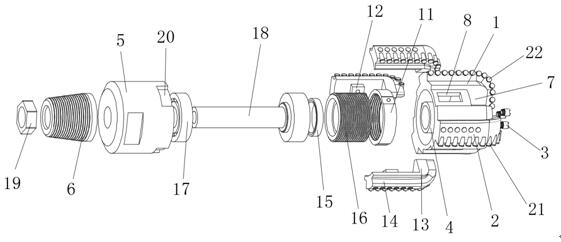

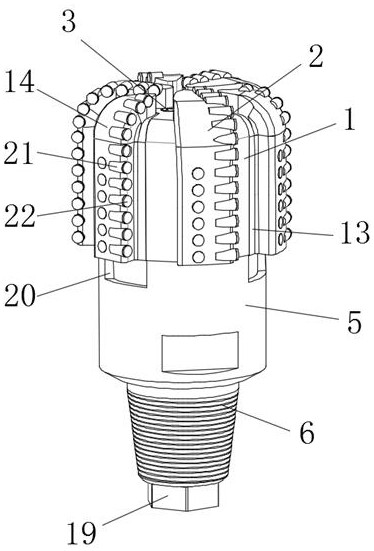

[0030] Embodiment 1, with reference to Figure 1-Figure 6 , a retractable broken PDC drill bit for oil drilling mentioned in the present invention, including a drill body 1, a fixed wing 2, a nozzle 3, a fixed cylinder 4, a connecting cylinder 5, a tapered pipe thread cylinder 6, a movable wing assembly 9 and an adjustment component 10;

[0031] Further, there are three groups of fixed wings 2, three groups of fixed wings 2 are coated on the outer wall and top of the drill body 1, a cavity is arranged inside the drill body 1, and three groups of nozzles 3 are provided, and the three groups of nozzles 3 are all threaded on the drill body 1 top and communicates with the cavity of the drill body 1, the fixed cylinder 4 is fixedly connected in the cavity of the drill body 1, the connecting cylinder 5 is fixedly connected at the bottom of the drill body 1, the tapered pipe thread cylinder 6 is fixedly connected at the bottom of the connecting cylinder 5, and the drill body 1 The o...

Embodiment 2

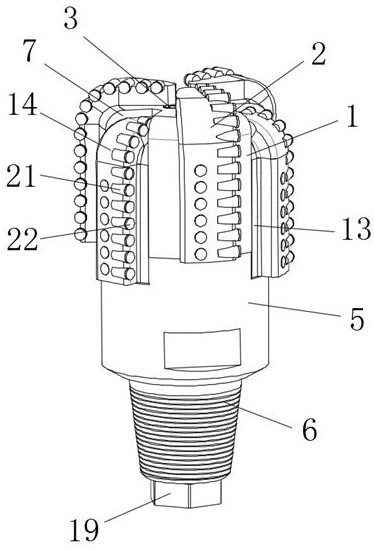

[0042] Embodiment 2, a retractable crushing PDC drill bit for oil drilling mentioned in the present invention, including a drill body 1, a fixed wing 2, a nozzle 3, a fixed cylinder 4, a connecting cylinder 5, a tapered pipe threaded cylinder 6, and a movable wing assembly 9 and adjustment assembly 10;

[0043] The difference from Example 1 is:

[0044] There are four groups of fixed wings 2, and the four groups of fixed wings 2 are covered on the outer wall and top of the drill body 1. There is a cavity inside the drill body 1. There are four groups of nozzles 3, and the four groups of nozzles 3 are all threaded on the drill body 1. The top is also in communication with the cavity of the drill body 1, the fixed cylinder 4 is fixedly connected in the cavity of the drill body 1, the connecting cylinder 5 is fixedly connected at the bottom of the drill body 1, the tapered pipe thread cylinder 6 is fixedly connected at the bottom of the connecting cylinder 5, and the drill body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com