Diamond drill bit for drilling fractured hard rock stratum

A diamond bit and diamond technology, applied in the direction of drill bits, drilling equipment, earthwork drilling, etc., can solve the problems of reducing the drilling efficiency and service life of the drill bit, aggravating the wear of the matrix and diamond, and affecting the drilling efficiency of the drill bit. Lightweight, effective rock breaking, ability-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

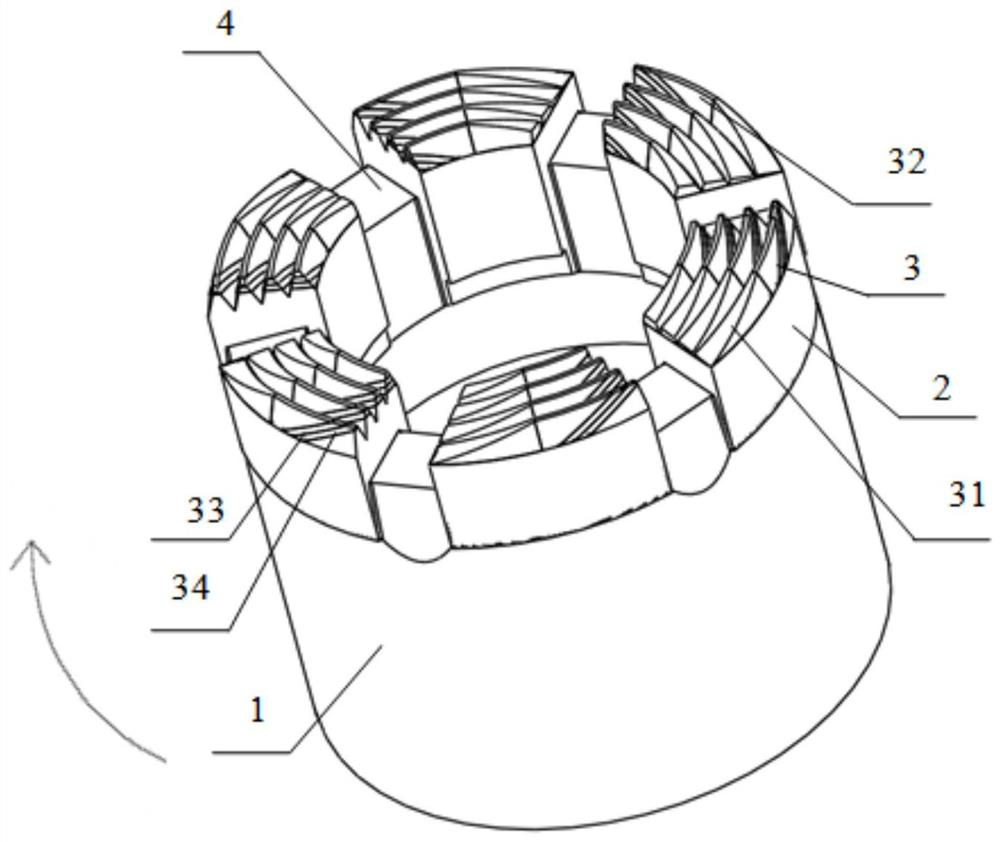

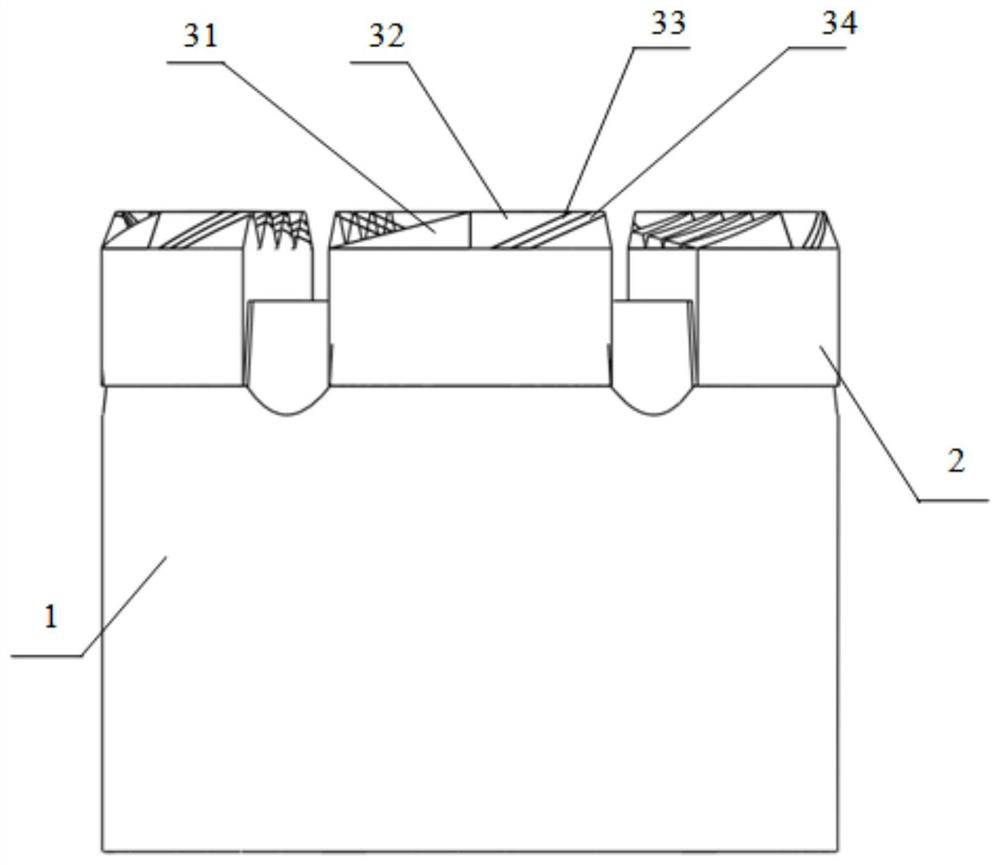

[0018] Please refer to Figure 1 to Figure 3 , a diamond drill bit for drilling into fissures in hard rock formations of the present invention comprises a bit body 1 and a bit matrix arranged at the end of the bit body 1, the bit body 1 is in the shape of a circular tube, and the bit body 1 is away from the bit tire The inner wall at the end of the body is provided with a connecting thread for connecting a core pipe or a drill pipe.

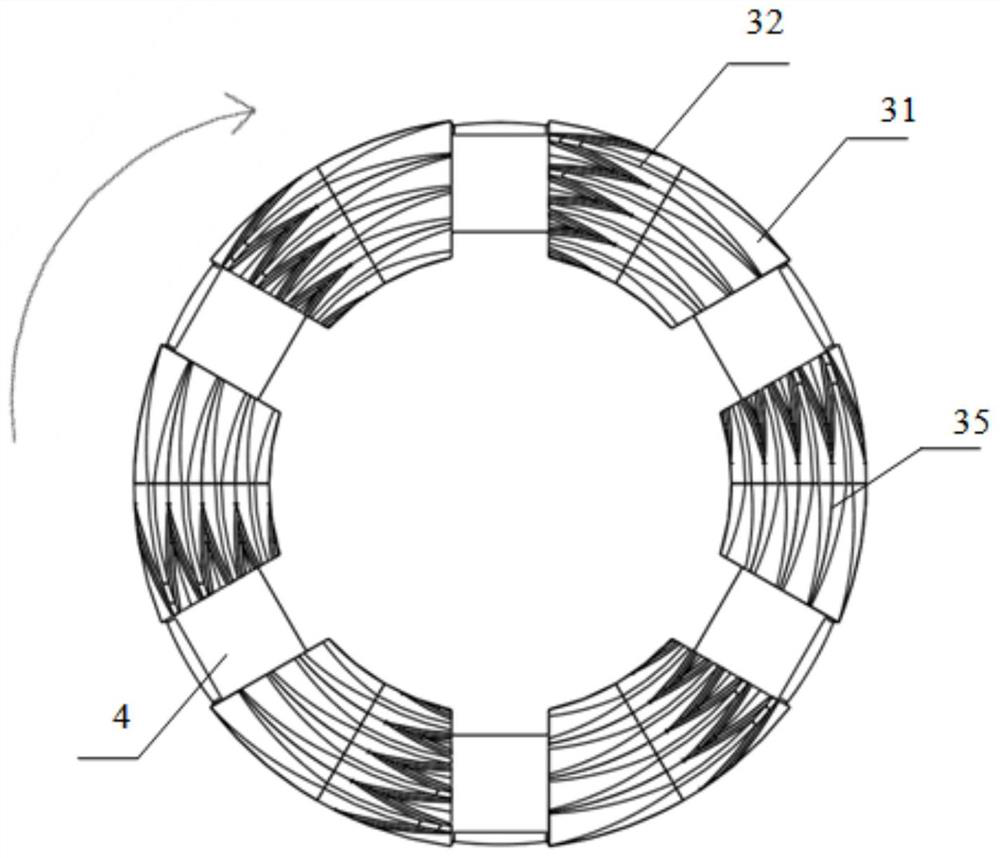

[0019] The drill bit matrix includes a plurality of sectors, all sectors are equal in size, and all sectors are uniformly and fixedly connected to the end of the drill body 1 in the circumferential direction, all sectors are arranged at intervals, and the gap between adjacent sectors is The nozzles 4, all nozzles 4 have th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com