Roller type crusher capable of automatically adjusting distance between rollers

A roll crusher, automatic adjustment technology, applied in the direction of grain processing, etc., can solve the problems of small adjustment range, low adjustment accuracy, and inconvenient adjustment, and achieve a large-scale adjustment, high degree of intelligence, and easy adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

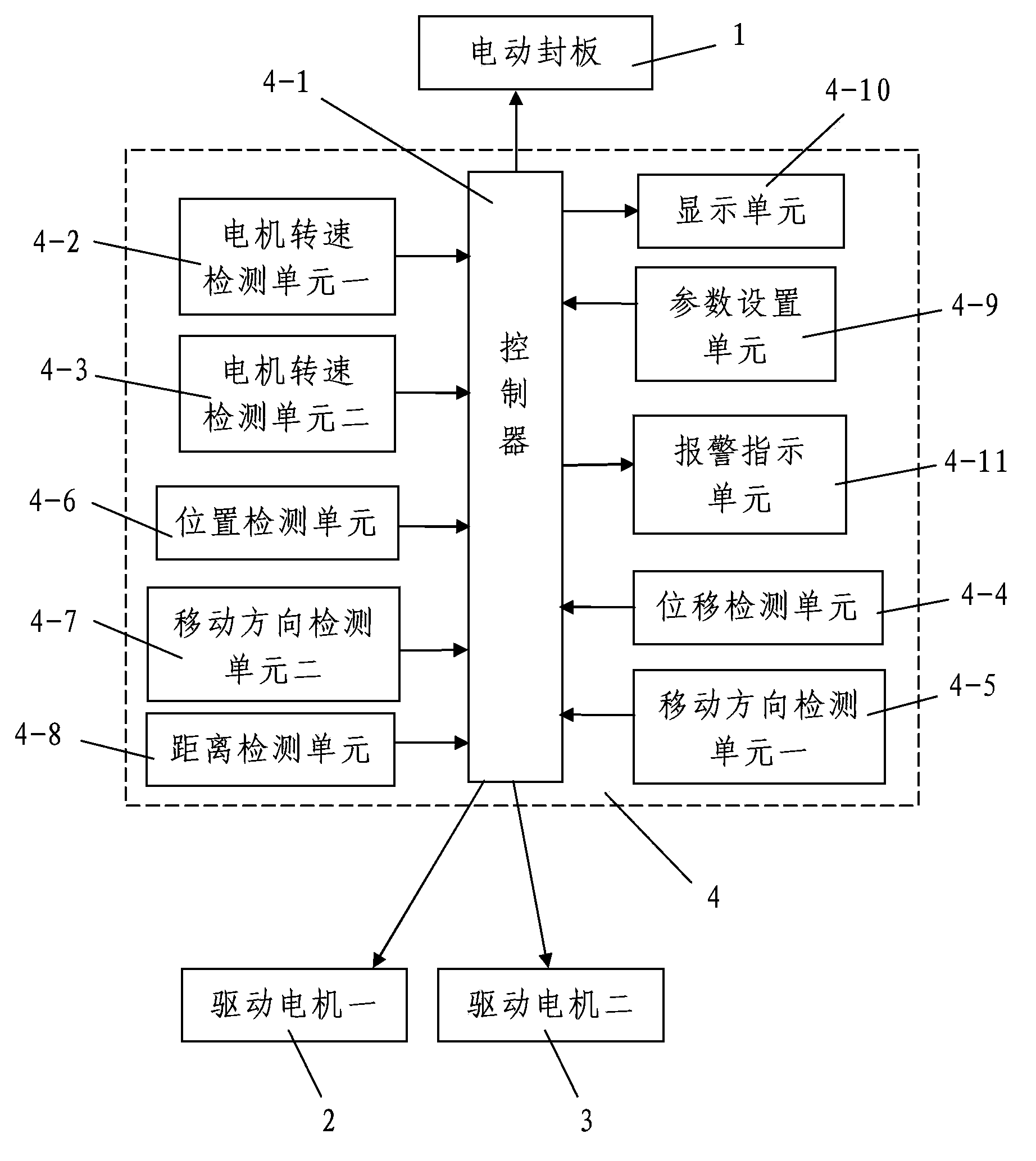

[0024] like figure 1 As shown, the present invention comprises a control system 4, a crusher housing and a pair of crushing rollers installed in said crusher housing. A pair of crushing rollers are crushing roller one and crushing roller two respectively, and the crushing roller one is driven by the drive motor one 2 and is connected to the power output shaft of the drive motor one 2 through a transmission mechanism. The second crushing roller is driven by the second driving motor 3 and is connected to the power output shaft of the second driving motor 3 through a transmission mechanism. The left and right ends of the crushing roller 1 are respectively installed on the inner side wall of the crusher shell through the bearing 1, and the inner side wall of the crusher shell is fixedly installed with a bearing mounting seat 1 for the bearing 1 to be installed. . The left and right ends of the crushing roller 2 are respectively installed on the bearing mounting seat 2 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com