Roller-crusher roller-distance automatic-adjustment device

An automatic adjustment device and roller crusher technology, which is applied in grain processing and other directions, can solve the problems of inconvenient adjustment, low adjustment accuracy, and small adjustment range, and achieves simple adjustment, high degree of intelligence, and meets the needs of adjustment accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

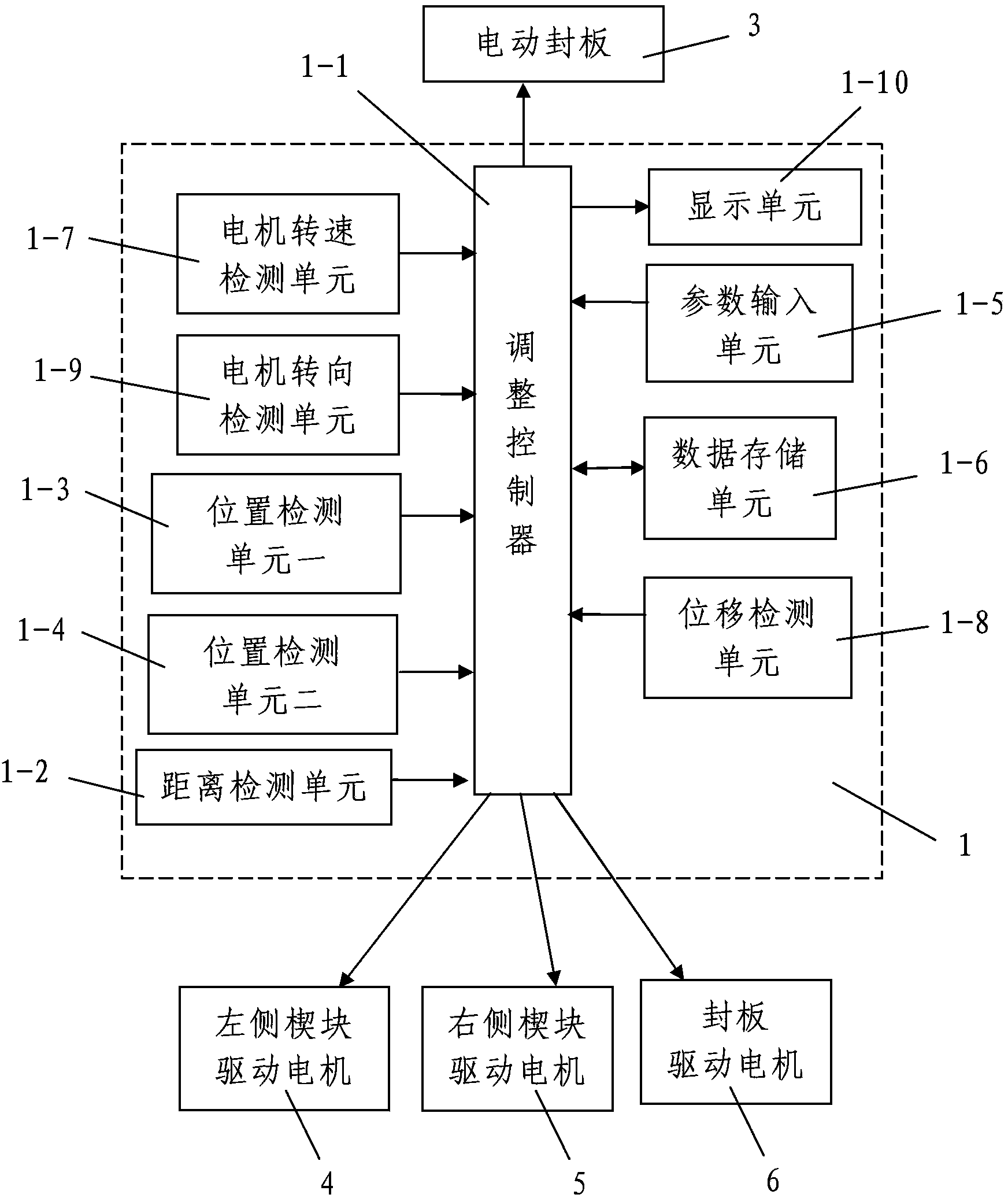

[0023] like figure 1 As shown, the present invention includes an adjustment control system 1, a coarse adjustment mechanism for roughly adjusting the distance between the adjusted pair of crushing rollers, and a fine adjustment mechanism for finely adjusting the distance between the adjusted pair of crushing rollers , the pair of crushing rollers are respectively a fixed-mounted crushing roller and a movable-mounted crushing roller. The left and right ends of the movable-mounted crushing roller are respectively installed on the casing of the adjusted roller crusher through bearings, and the left and right side walls of the casing are each provided with a shaft for the bearing to be installed. Bearing mounting seat, the bearing mounting seat is installed in the middle part of an electric sealing plate 3 that can move forward and backward along the inner side wall of the housing, and the middle part of the electric sealing plate 1 is correspondingly opened for installation of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com