Patents

Literature

85results about How to "Adjust the degree of compression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

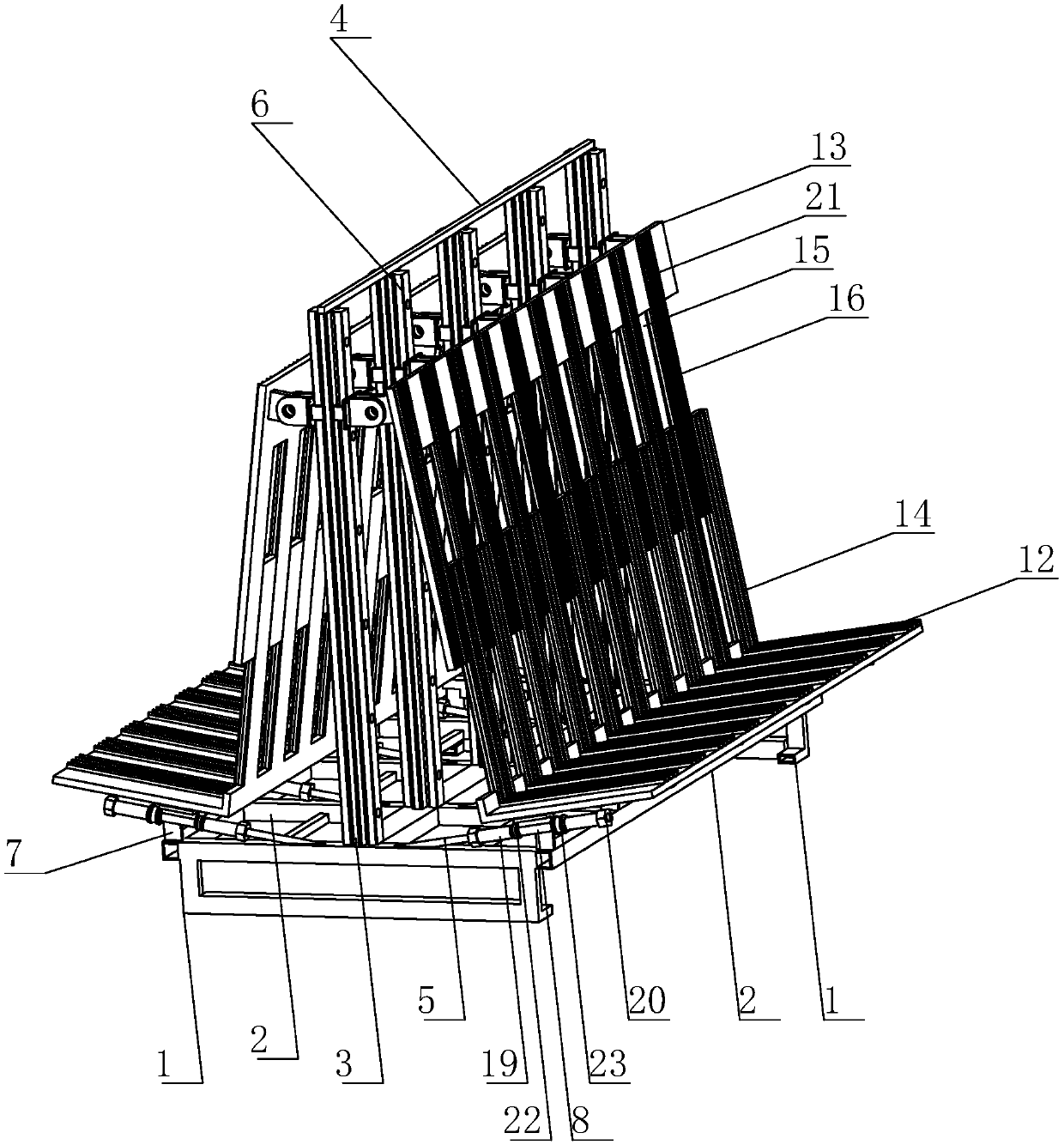

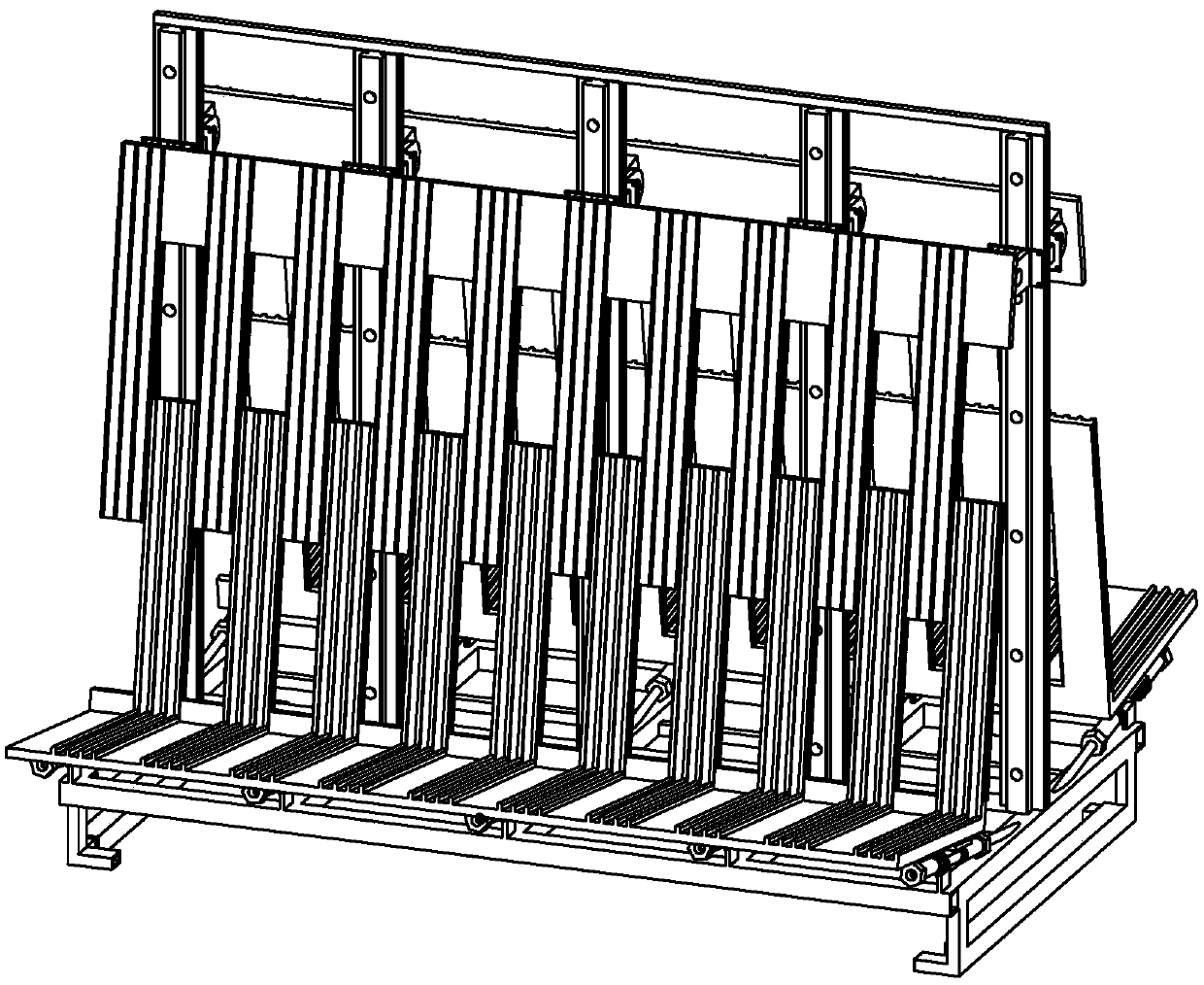

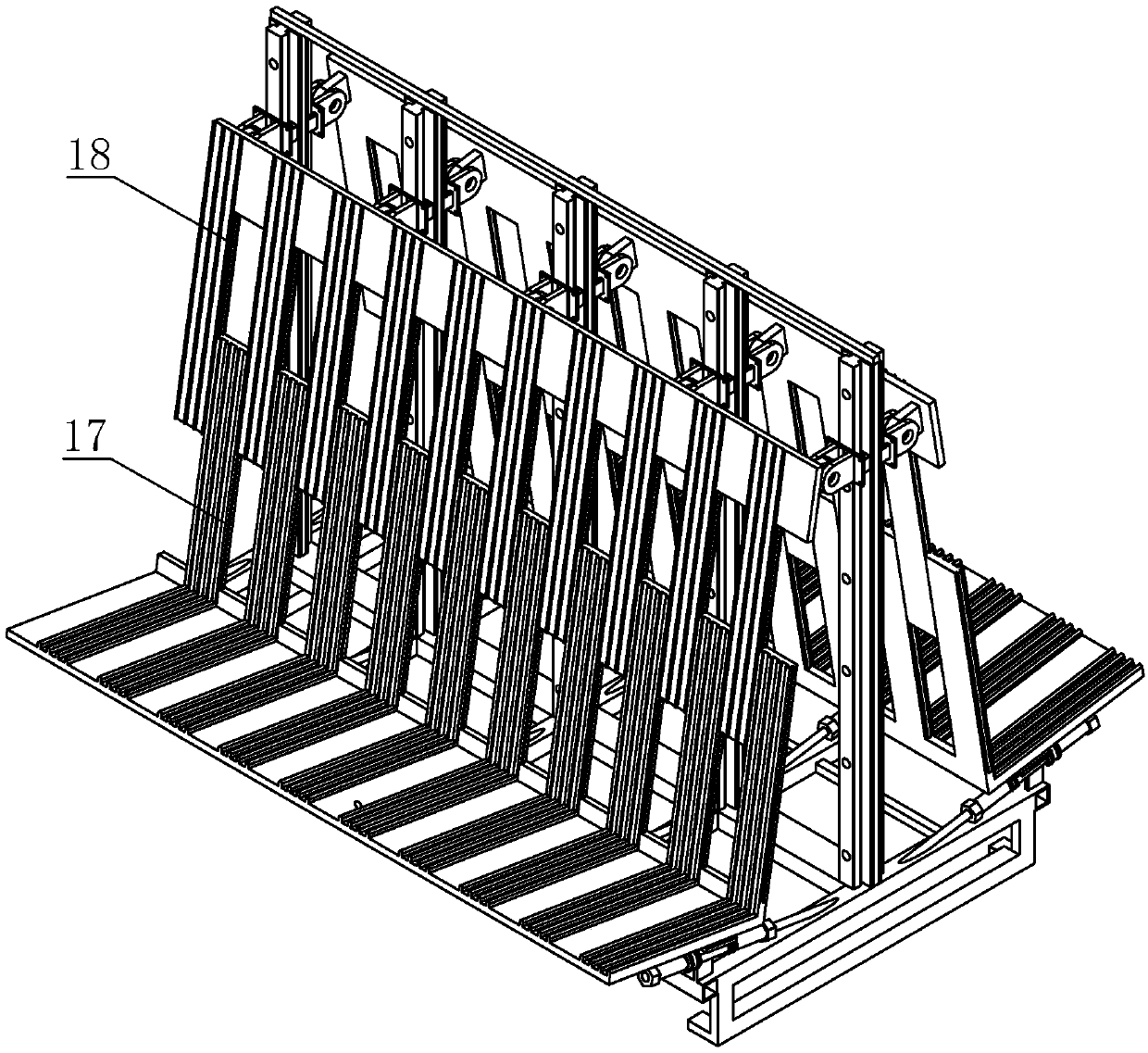

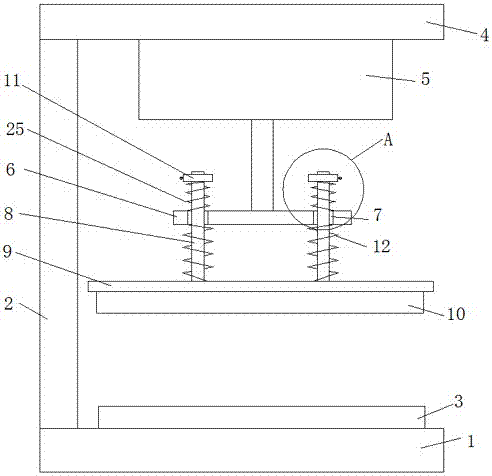

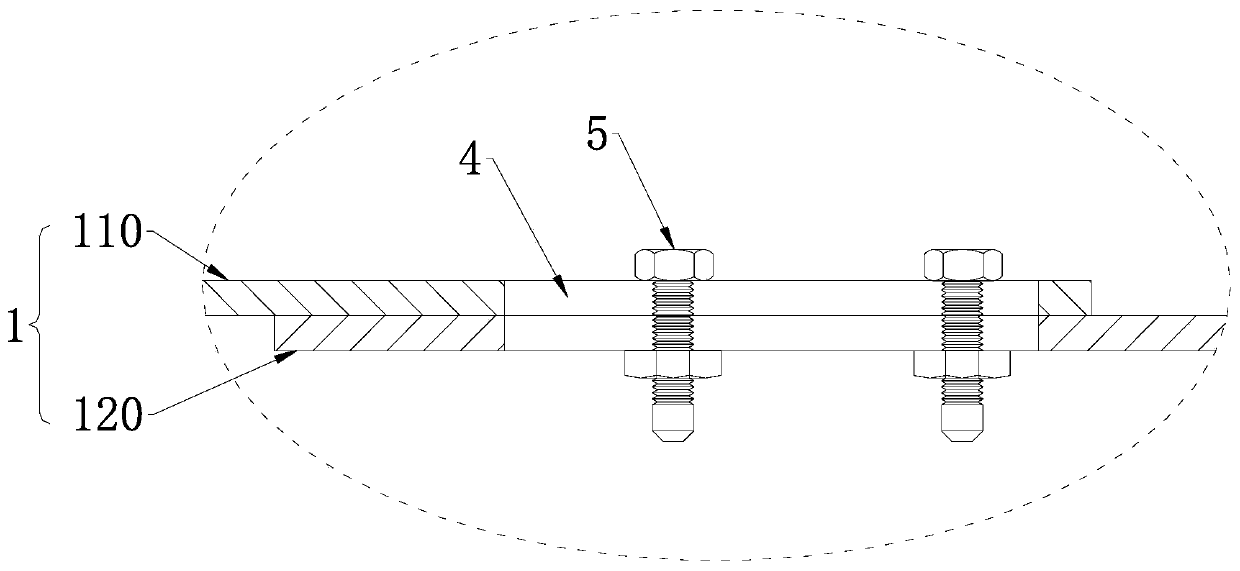

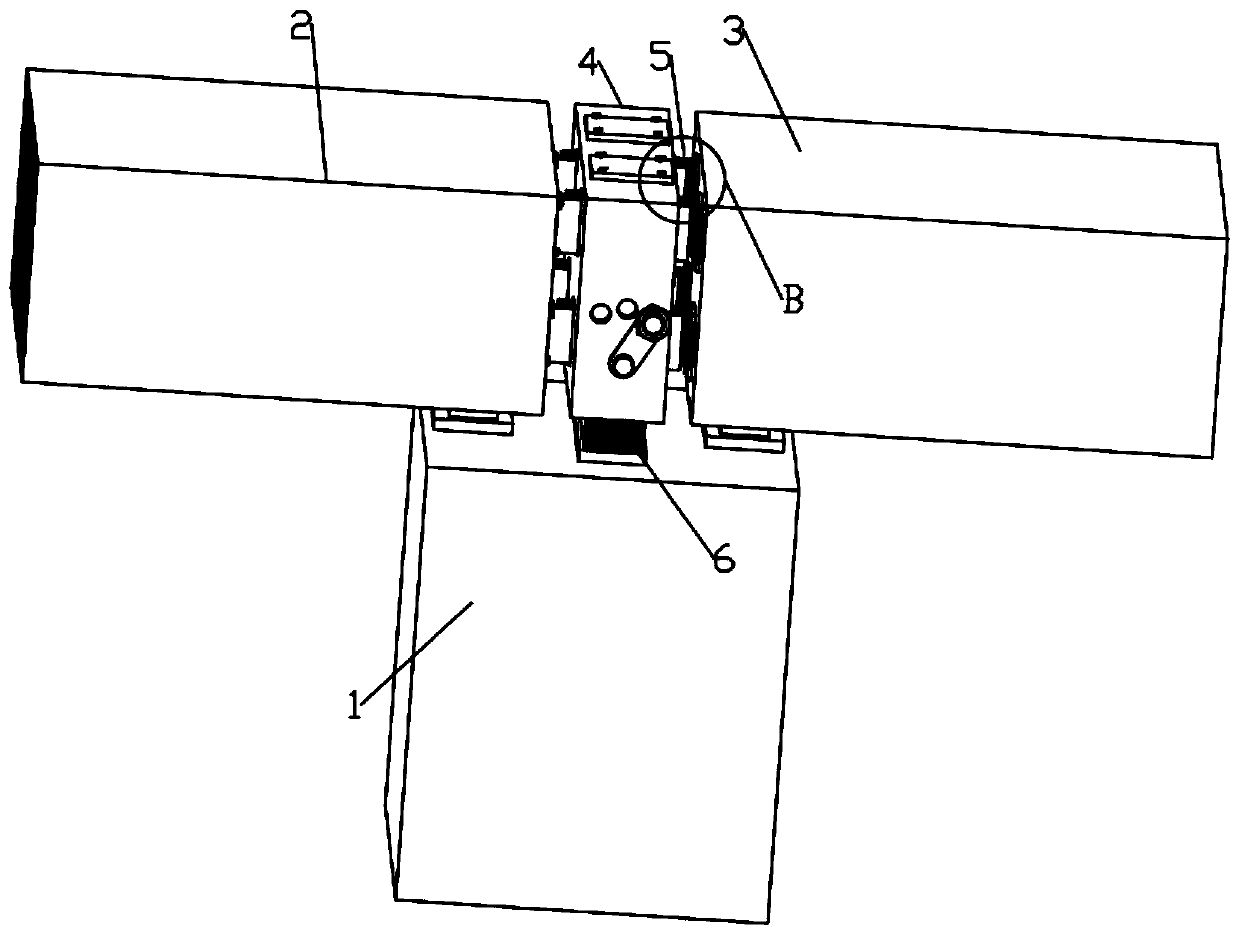

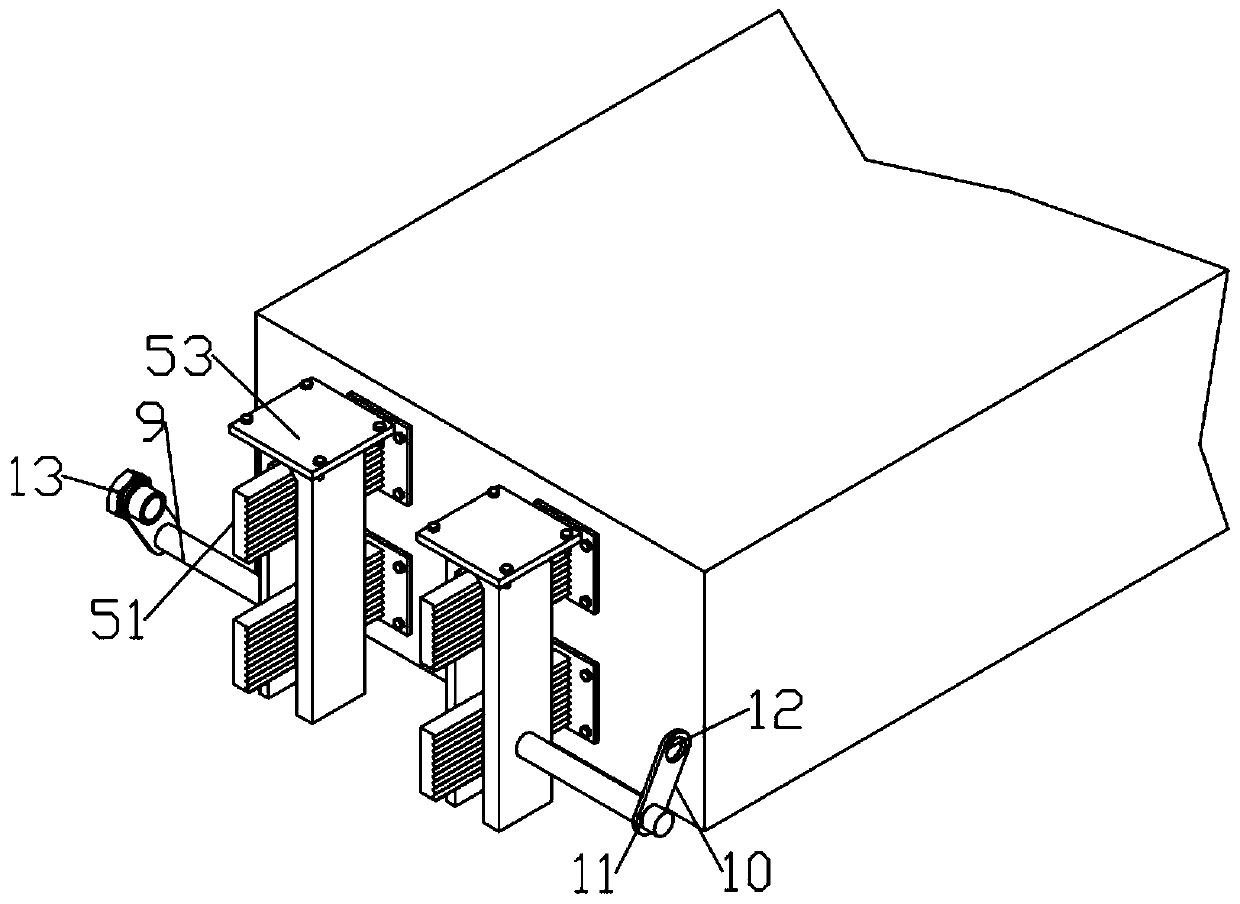

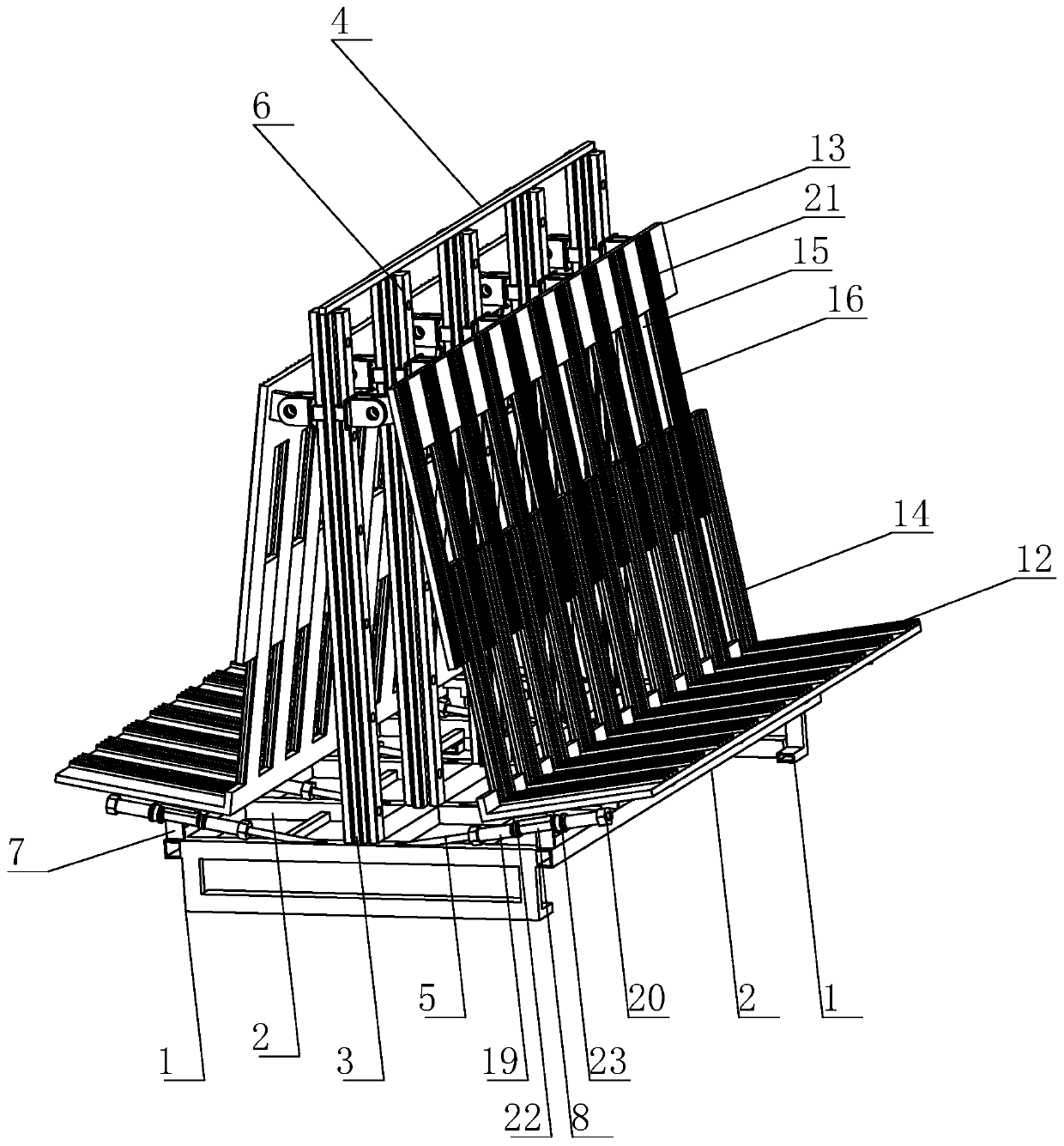

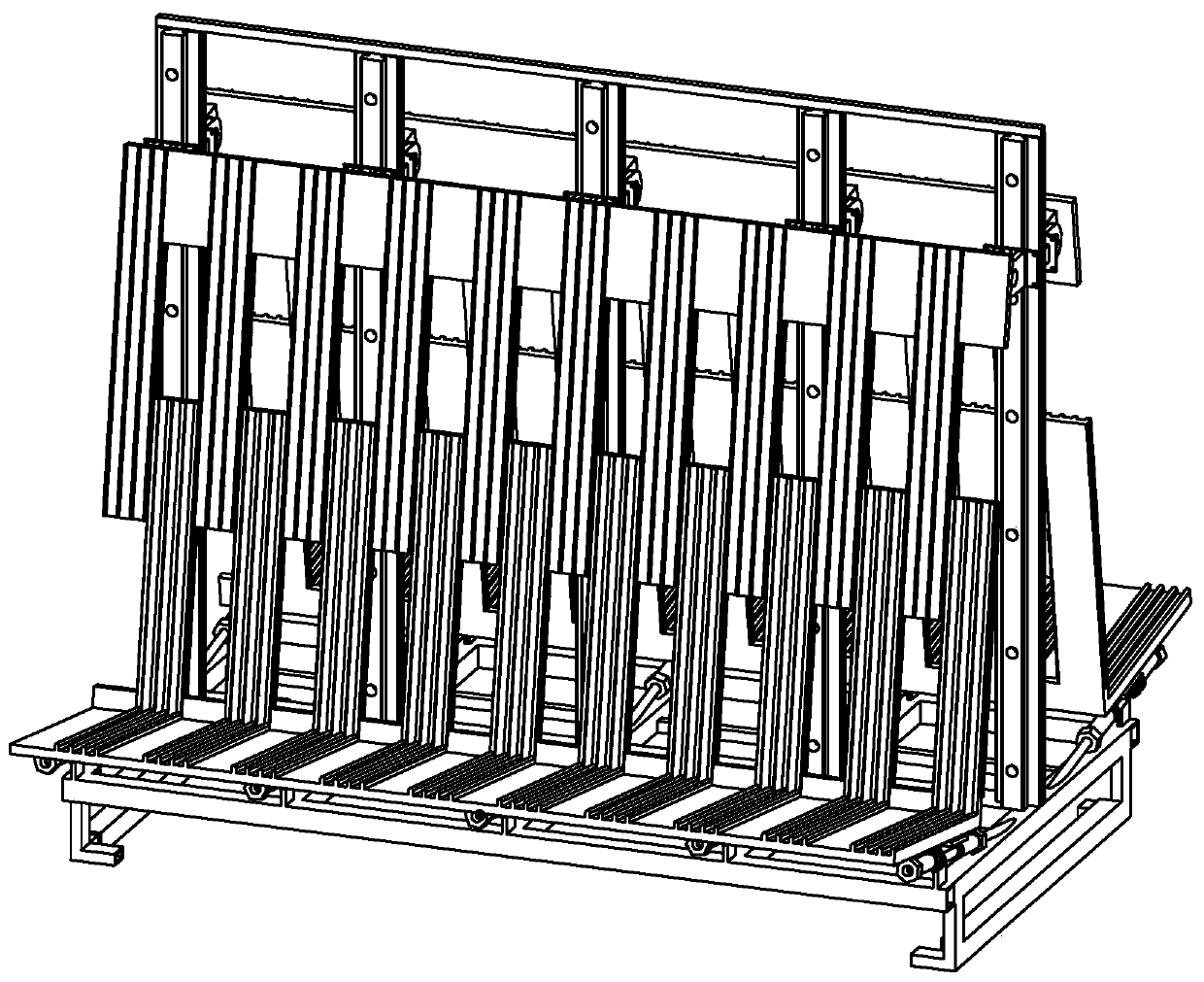

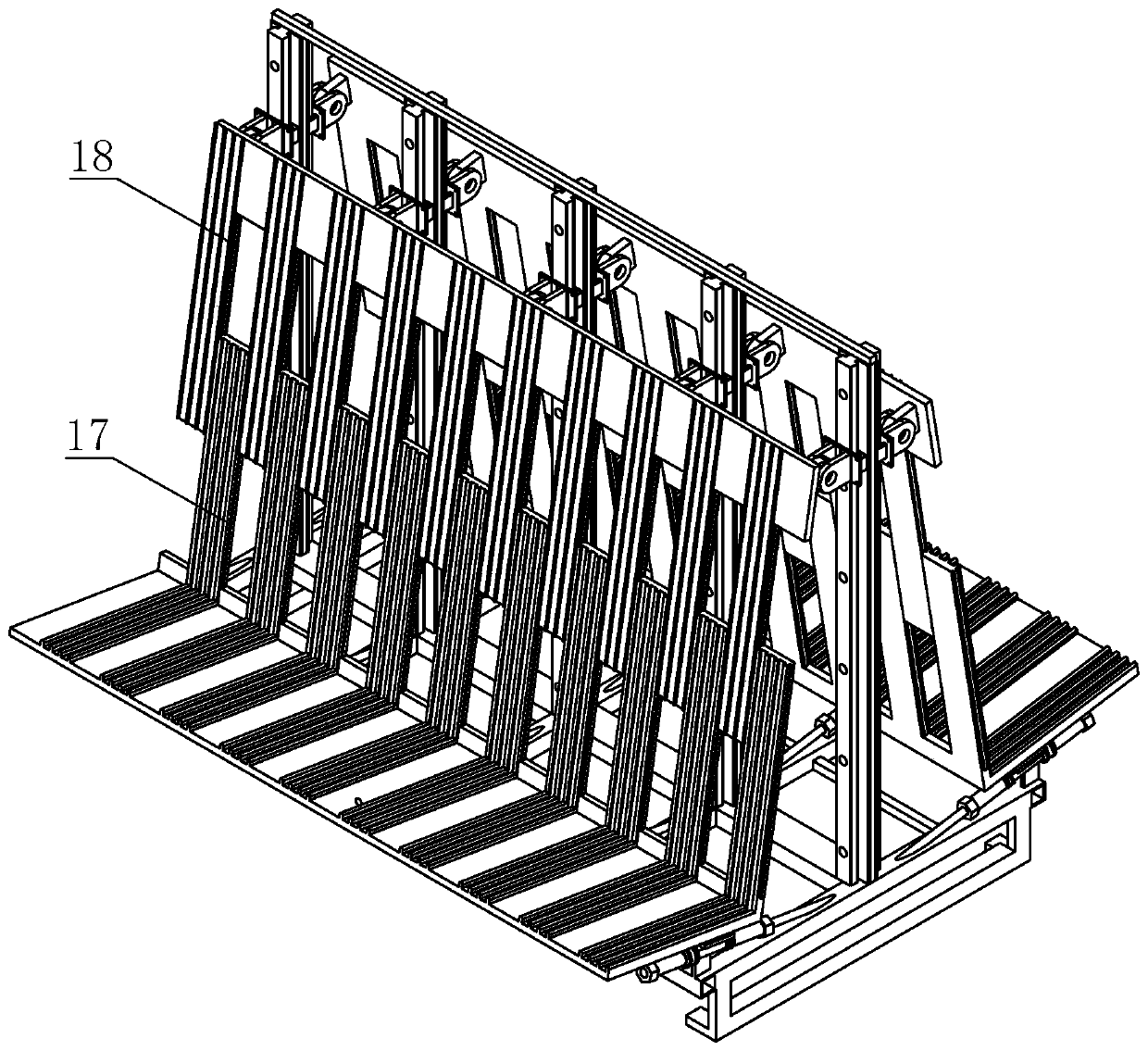

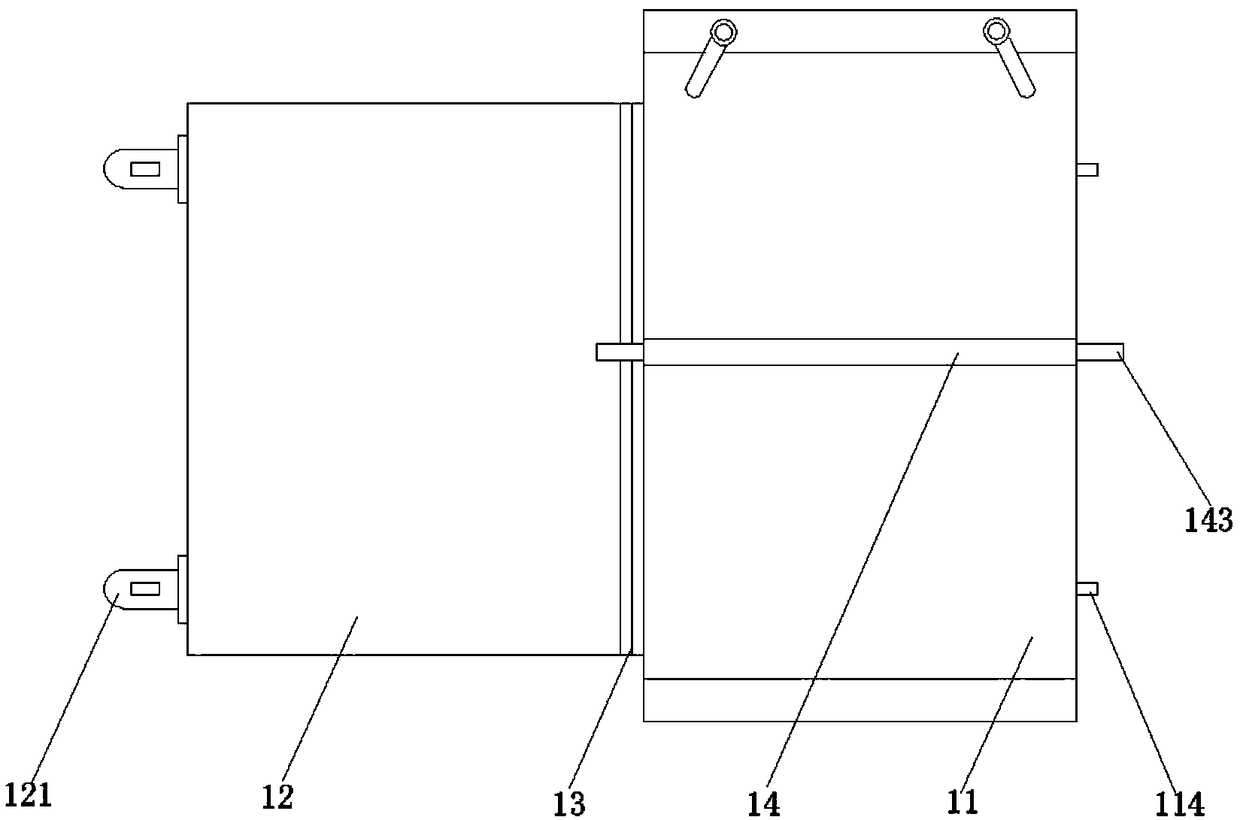

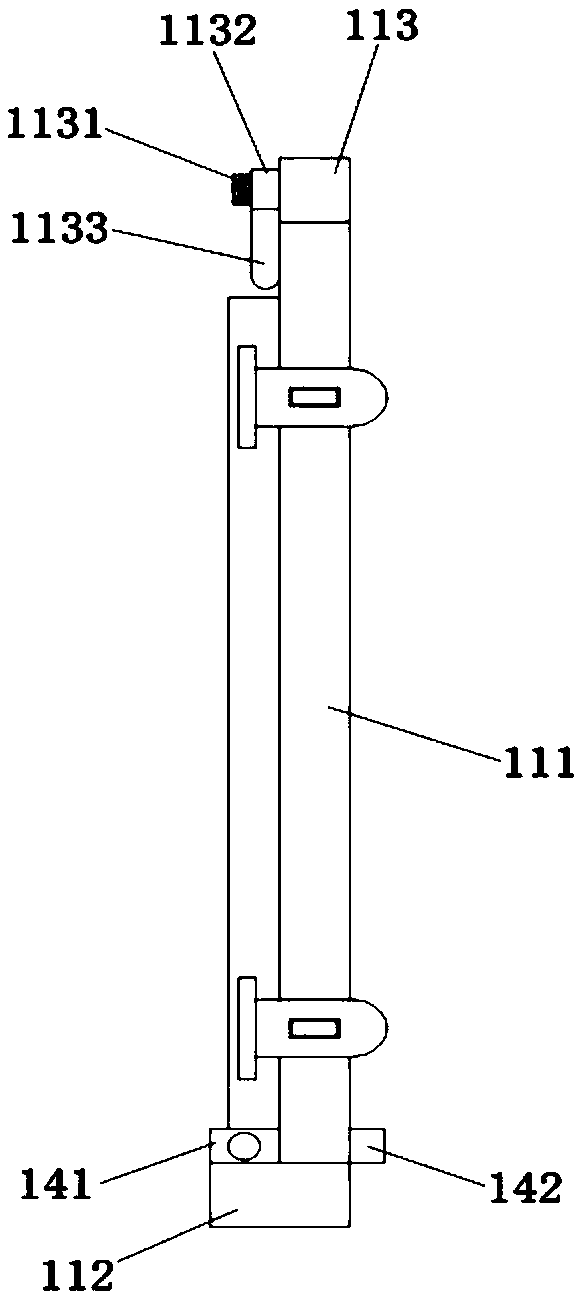

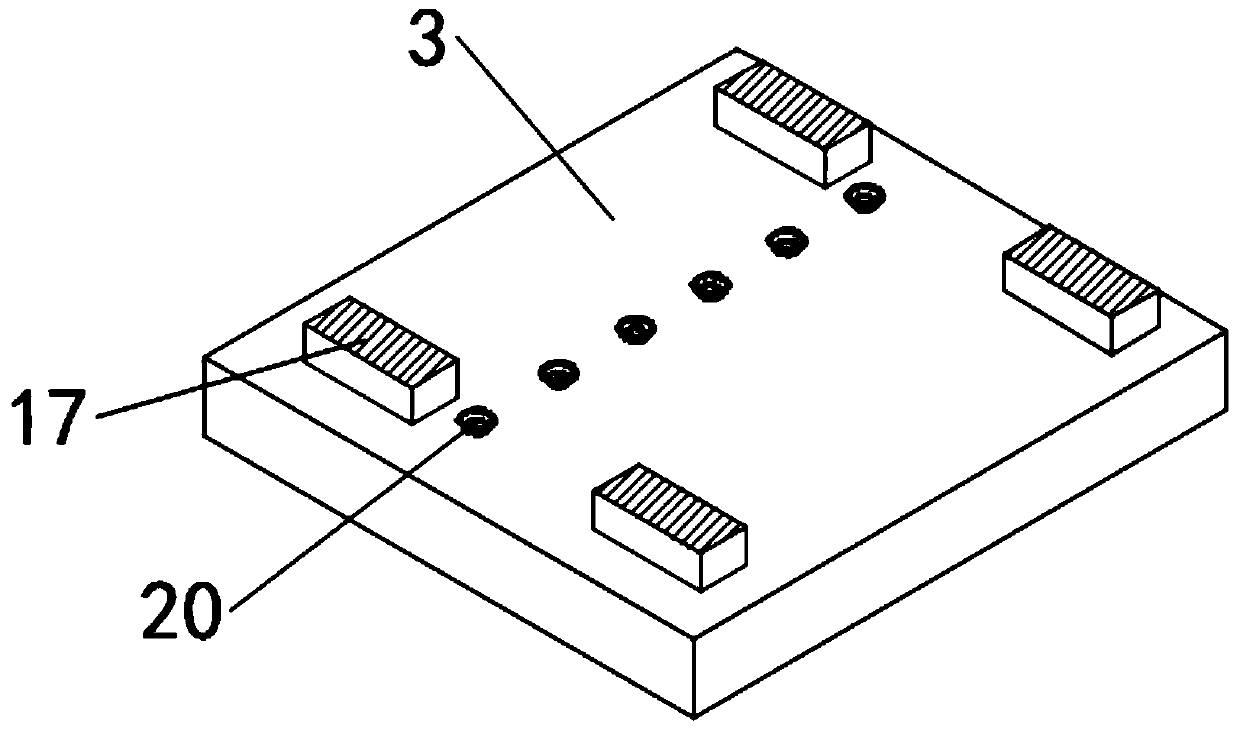

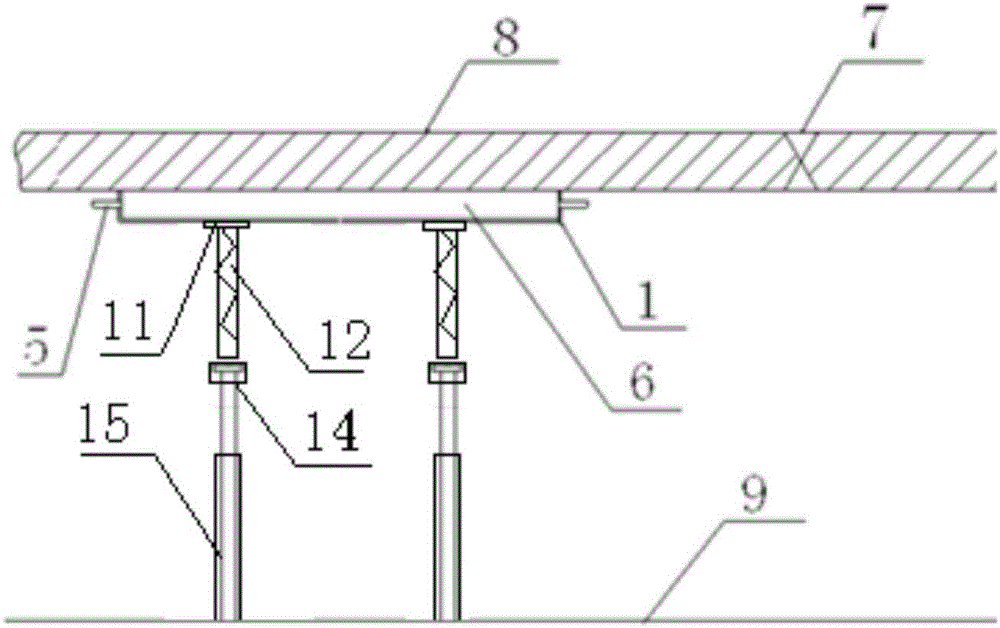

Fixing bracket for glass transportation

ActiveCN108674990AEliminate transportation lossDistribute the load evenlyCharge manipulationConveyor partsEngineeringResource utilization

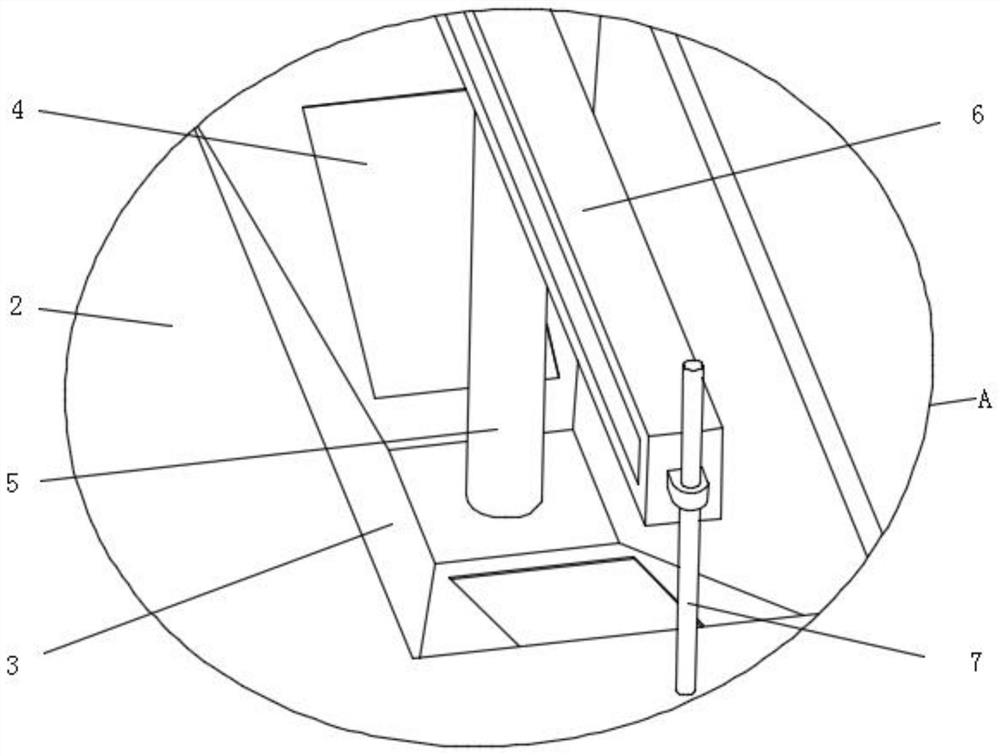

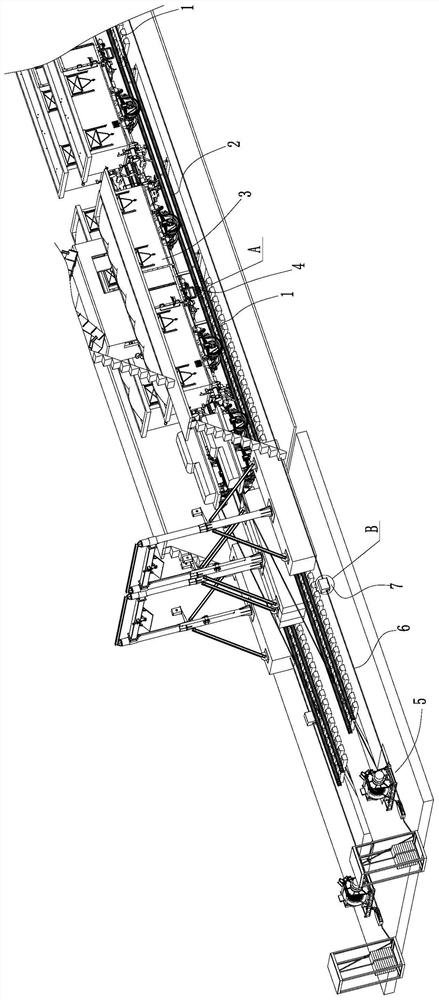

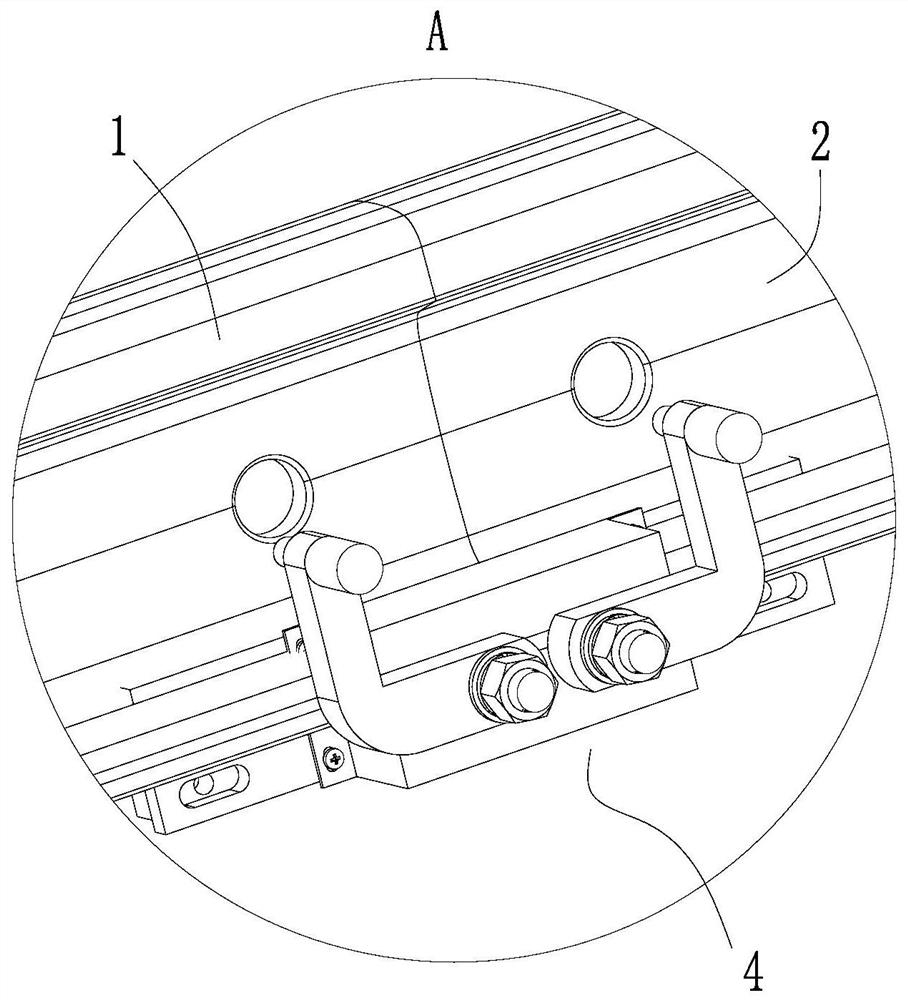

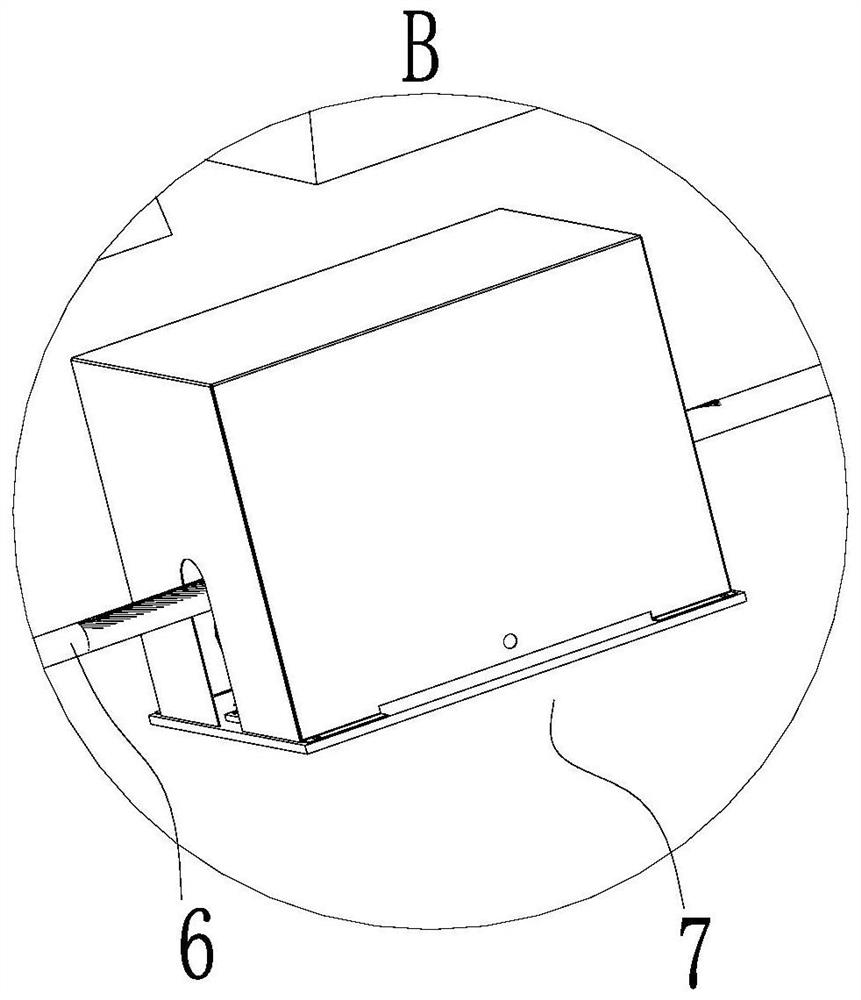

The invention discloses a fixing bracket for glass transportation, mainly relates to the field of construction equipment transportation. The fixing bracket for glass transportation comprises a main bracket body, a guide rail mechanism, a glass supporting mechanism, a limiting assembly and a buffering piece. The glass supporting mechanism achieves L-shaped extension adjustment by the bidirectionalguide rail mechanism, and achieves fixing and limiting by the limiting assembly; and the buffering piece achieves rigid shock absorption of glass. The fixing bracket has the beneficial effects of being capable of adapting to different conditions on site according to the glass with different sizes and characteristics to fix and transport the glass, significantly lowering transportation losses and improving resource utilization rate.

Owner:王盼

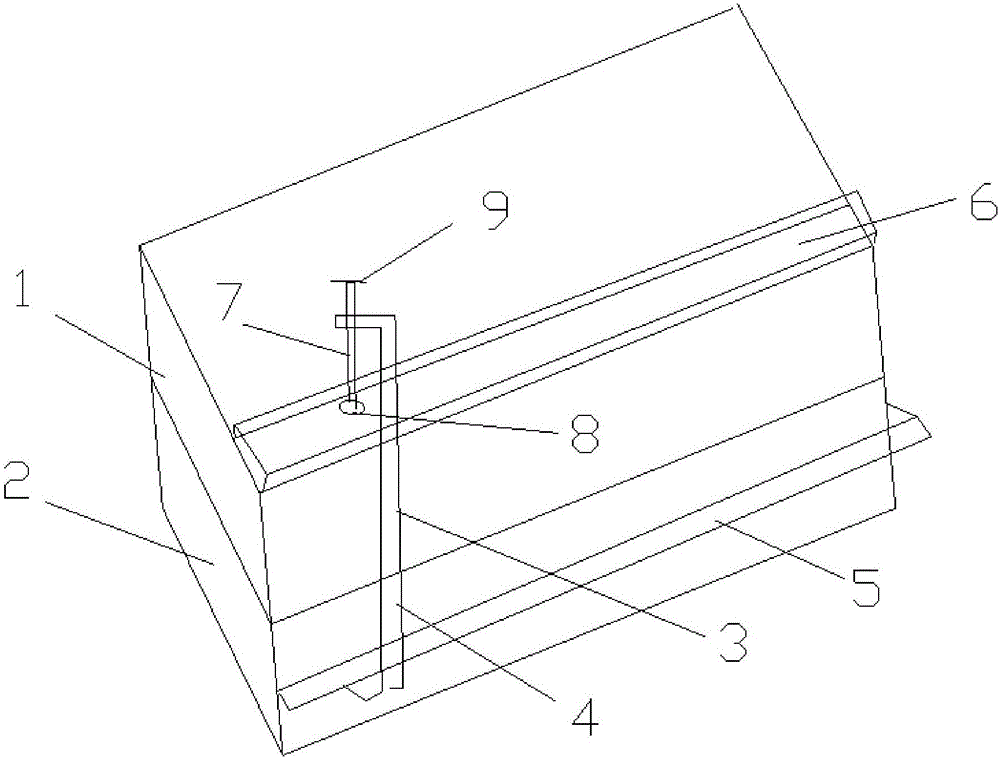

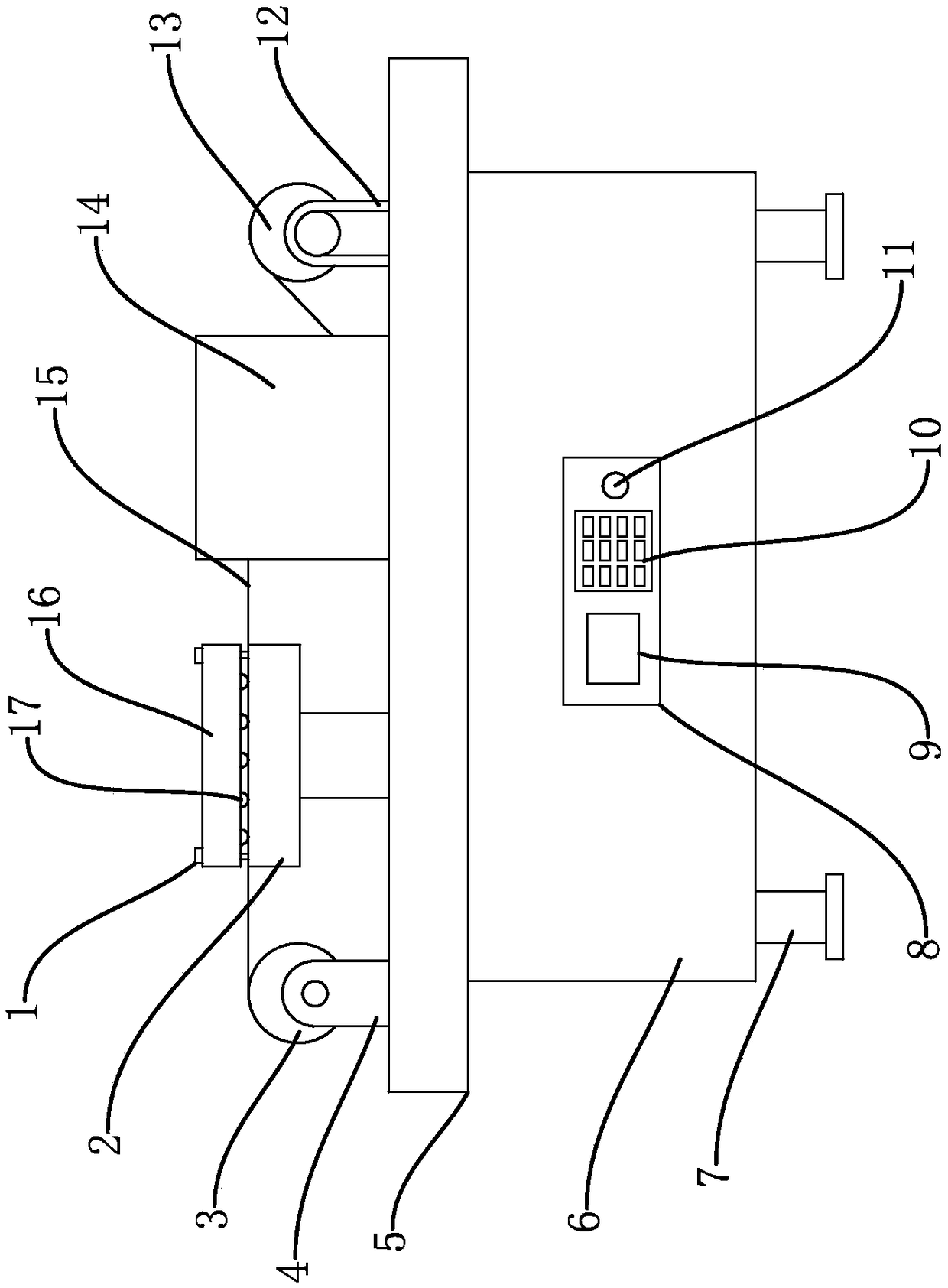

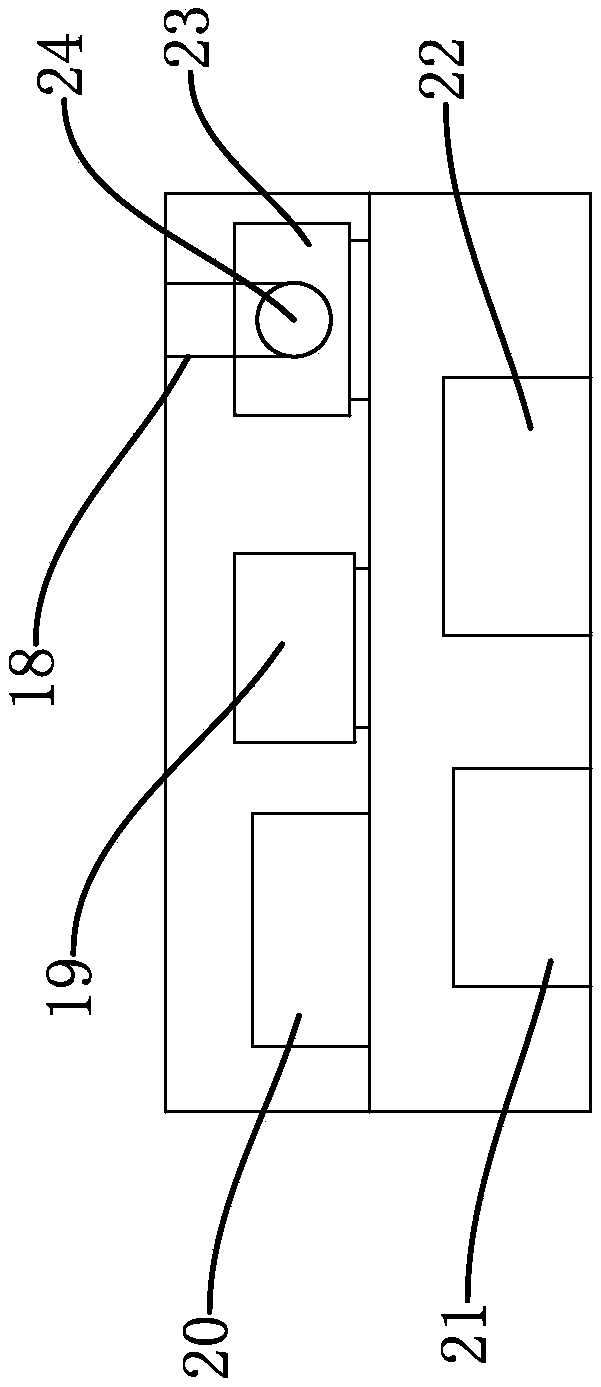

Textile printing device

InactiveCN107415504AConvenient printing workAvoid damageStampingTextile printerMechanical engineering

The invention discloses a printing device for fabric weaving, which comprises a base, a vertical bar is welded on one side of the top of the base, a horizontal bar is welded on the top of the vertical bar, and a printing table is also welded on the top of the base. A push rod motor is fixedly installed at the bottom of the cross bar, and a push plate is welded on the output shaft of the push rod motor, and two symmetrically arranged sliding holes are opened on the push plate, and a slide rod is slidably installed in the slide hole, The bottom ends of the two slide bars are welded with the same fixed plate, the fixed plate is located below the push plate, and the bottom of the fixed plate is fixedly equipped with a printing mold, and the printed mold is located above the printing table. The invention is simple in structure, easy to operate, easy to buffer the pressure between the printing mold and the fabric, prevents the printing mold and fabric from being damaged by excessive pressure, and is convenient to adjust the compression degree of the spring and the auxiliary spring, which is convenient for the printing mold. usage of.

Owner:浙江德清华丝纺织有限公司

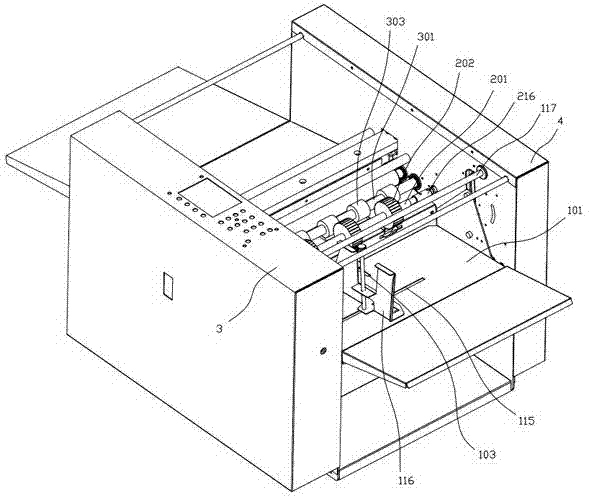

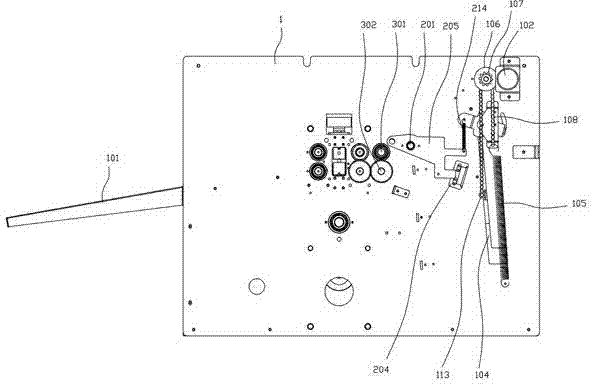

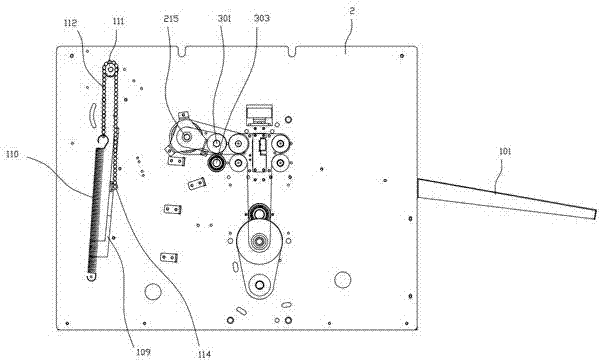

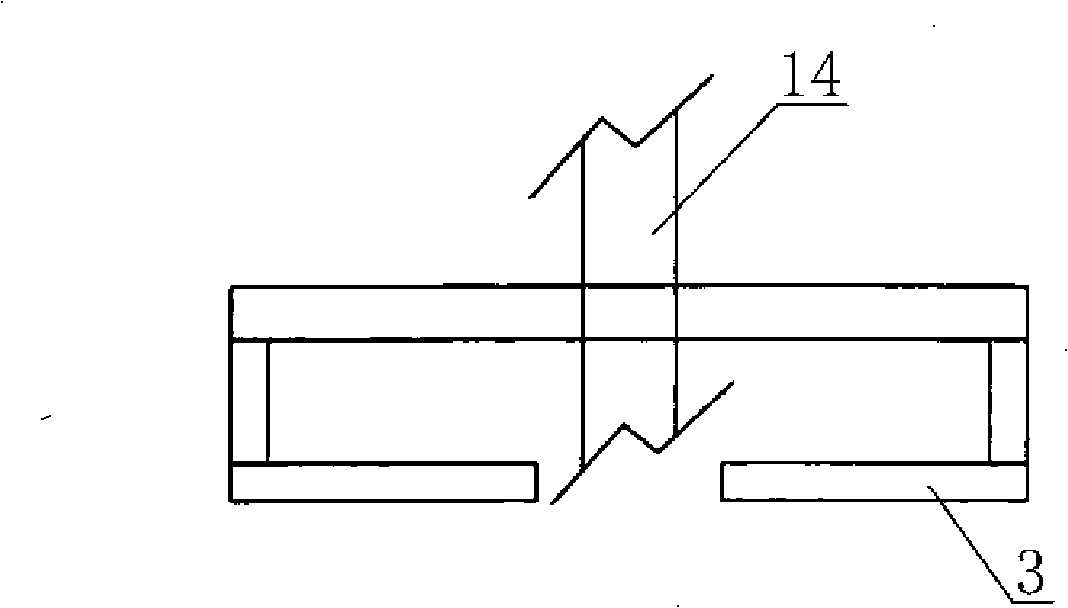

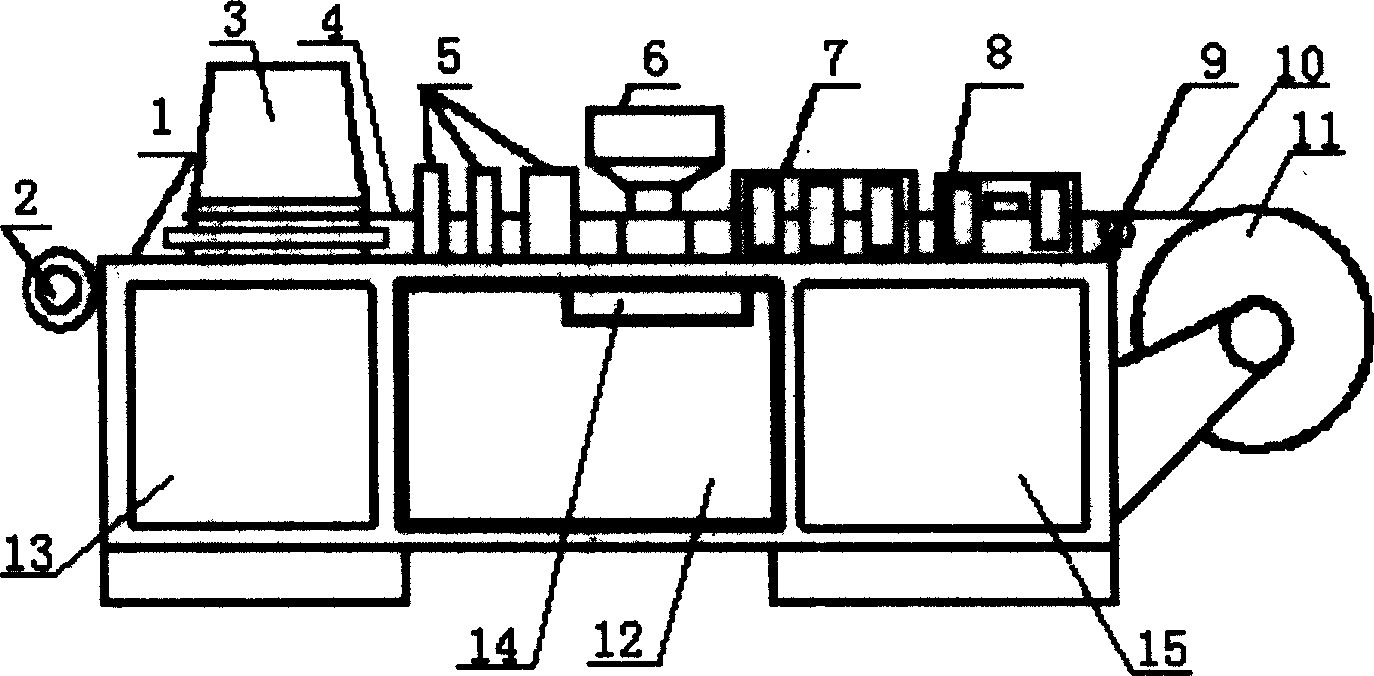

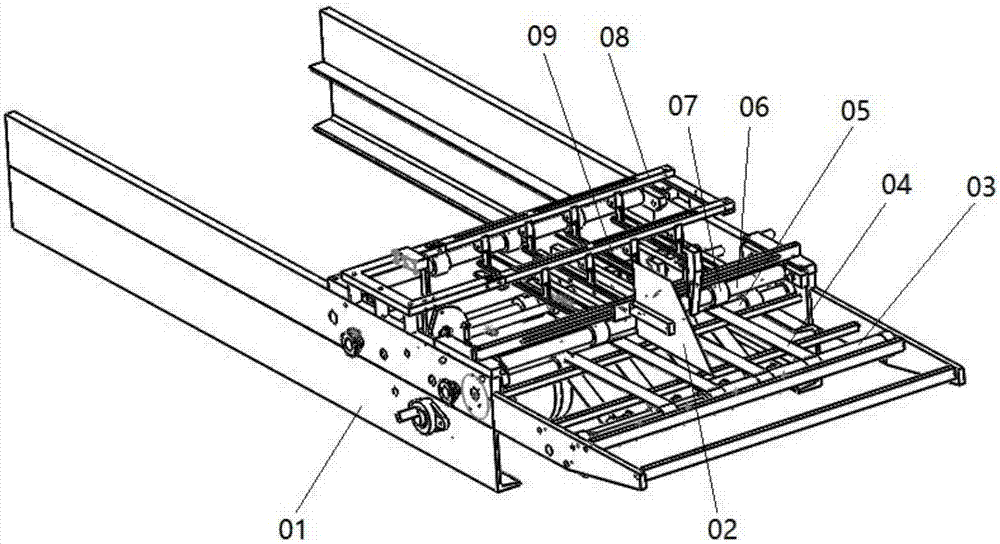

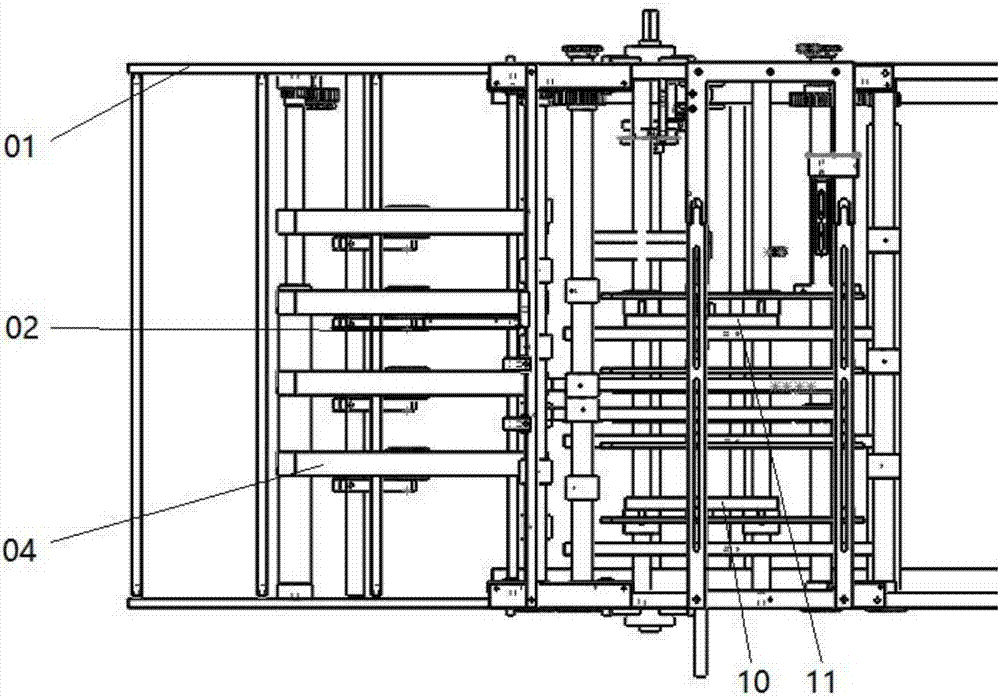

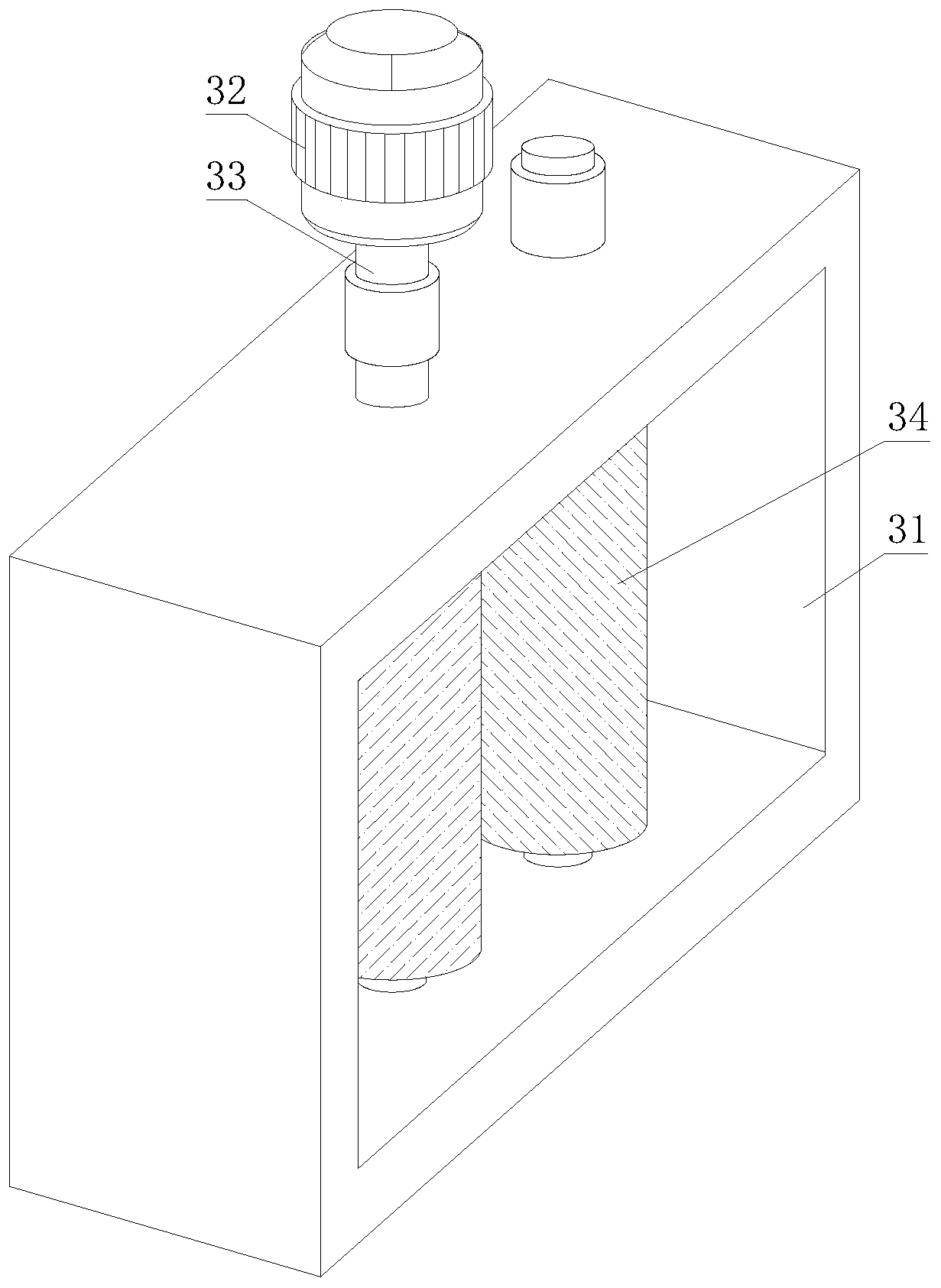

Automatic paper feeding mechanism of digital creasing machine

InactiveCN103612926AAvoid damageRealize automatic paper feeding operationArticle separationPulp and paper industry

The invention discloses an automatic paper feeding mechanism of a digital creasing machine. The automatic paper feeding mechanism of the digital creasing machine comprises a paper loading unit, a paper pickup unit and a double-paper feeding preventing unit, wherein the paper loading unit, the paper pickup unit and the double-paper feeding preventing unit are sequentially arranged between a left side plate and a right side plate; a paper feeding platform can automatically ascend or descend by using the paper loading unit; the paper pickup unit can automatically pick up paper when the paper feeding platform rises and the paper is conveyed in place; and the double-paper feeding preventing unit can guarantee that a single piece of paper is fed at a time. By the automatic paper feeding mechanism of the digital creasing machine, automatic paper feeding operation can be realized, the paper feeding efficiency is high, and the problem that a creasing component is failed due to double pieces of paper are fed at a time can be solved.

Owner:NINGBO RONGHUA OFFICE EQUIP

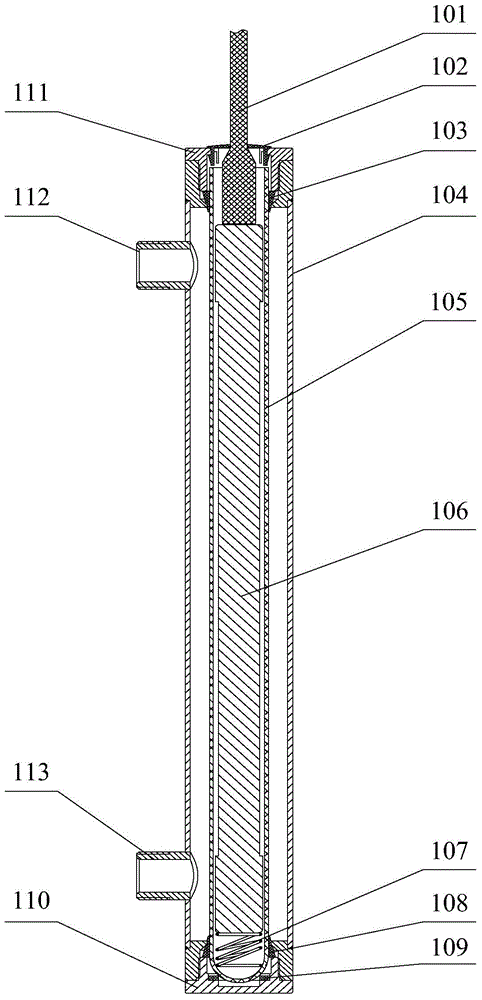

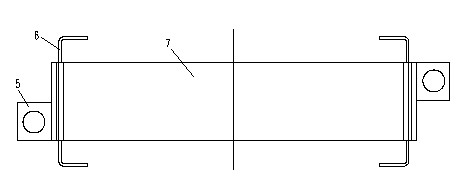

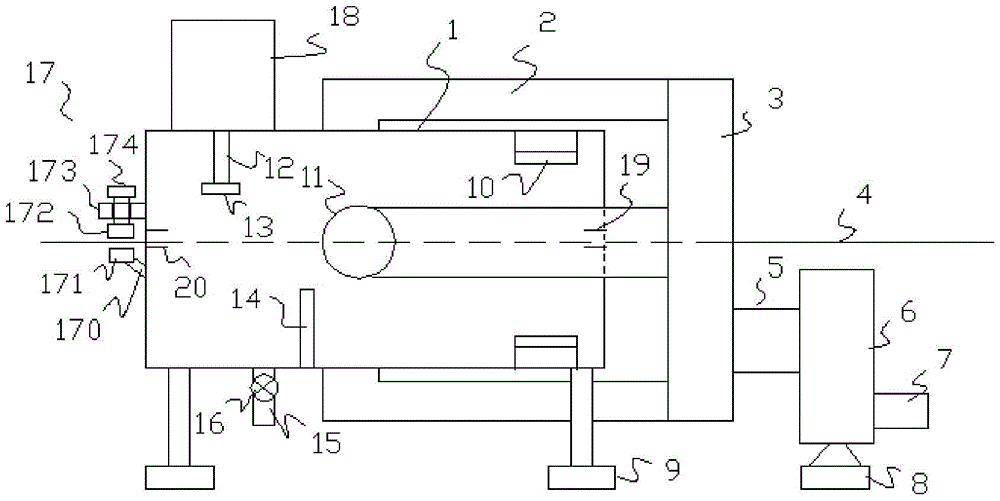

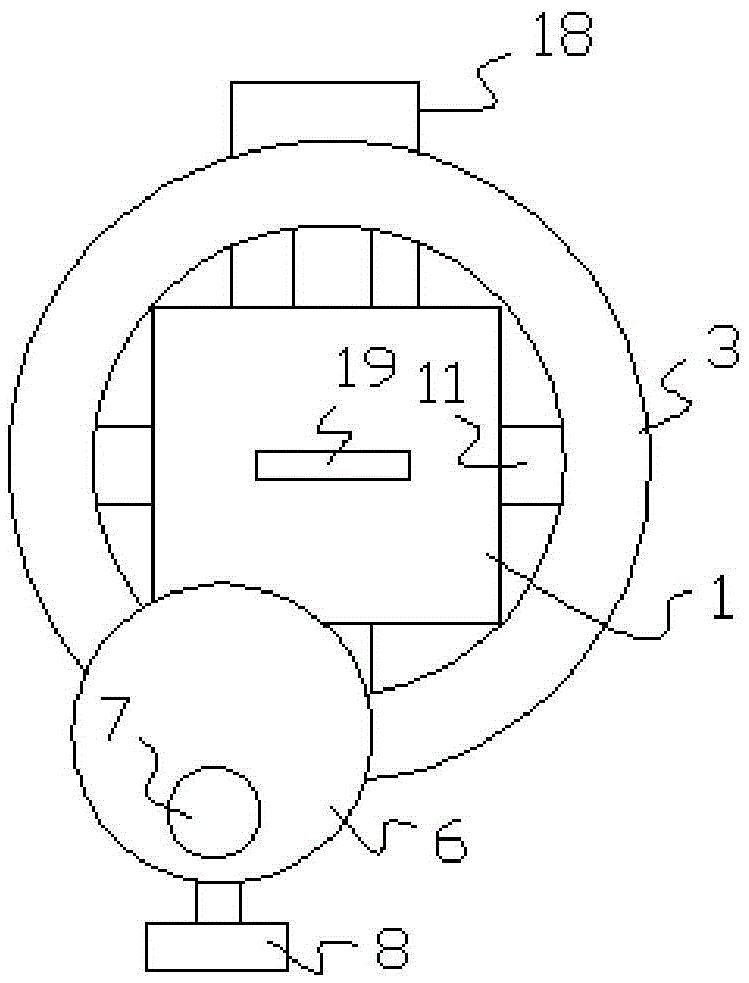

Ultraviolet sterilizer

InactiveCN104828901APrevent leakageAvoid deformationWater/sewage treatment by irradiationWater leakageUltraviolet lights

The invention discloses an ultraviolet sterilizer comprising: (1) an ultraviolet light; (2) a quartz tubular sleeve sleeving the outer side of the ultraviolet light; and (3) an outer tubular sleeve sleeving the outer side of the quartz tubular sleeve, wherein the outer tubular sleeve is provided with a water inlet and a water outlet. One end of the outer tubular sleeve is sealed by a first sealing ring and the other end of the outer tubular sleeve is sealed by a second sealing ring. In the ultraviolet sterilizer, by means of the first sealing ring and the second sealing ring, the upper end and the lower end of the quartz tubular sleeve are respectively sealed and clamped with the outer tubular sleeve, so that not only is water leakage prevented but also the quartz tubular sleeve is prevented from being contacted with the outer tubular sleeve, so that a problem of shape deformation of a spring can be prevented. The ultraviolet sterilizer can prevent a damage hidden danger due to loose fixation of the bottom of the quartz tubular sleeve and impact of the quartz tubular sleeve with tube wall.

Owner:GREE ELECTRIC APPLIANCES INC

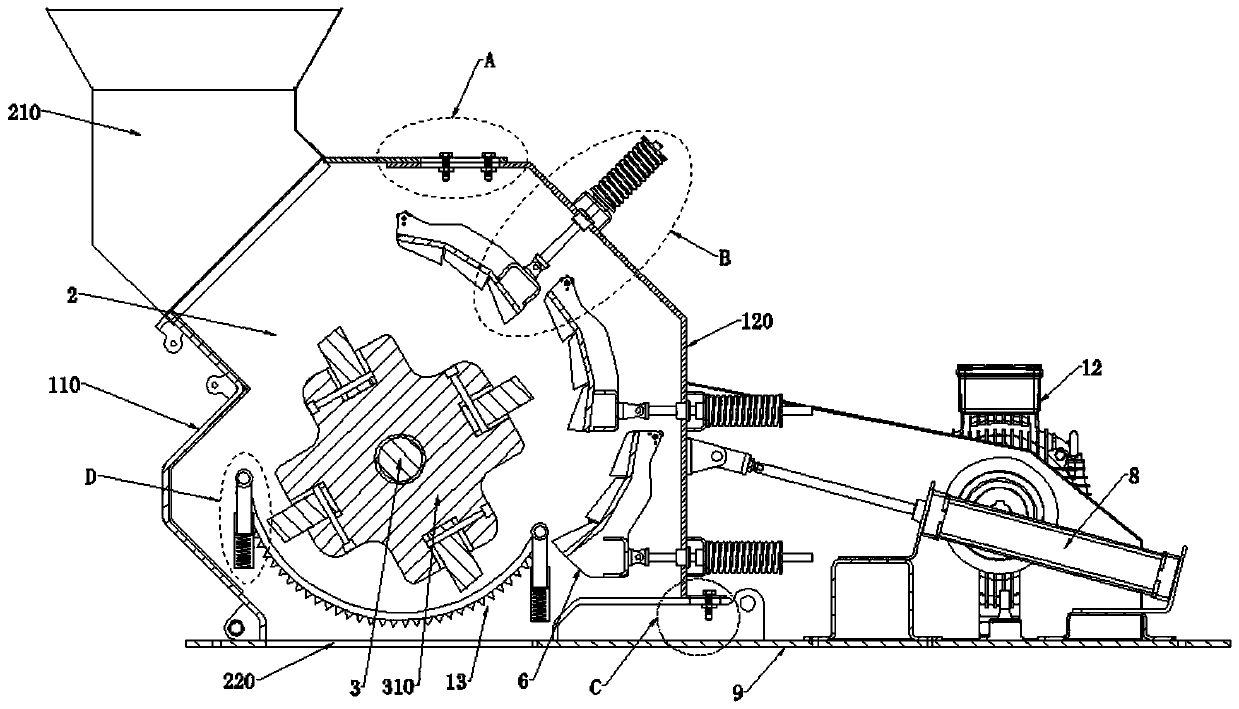

Reaction type crushing device for coal mine

The invention discloses a reaction type crushing device for coal mine, and relates to the technical field of coal mine crushing devices. The reaction type crushing device can regulate spacing betweena reaction plate and a plate hammer according to a practical use condition while regulating a relative distance and relative inclination degree between the plate hammer and a reaction plate of a reaction device, and guarantees that coal mines discharged from a position between the plate hammer and the reaction plate can meet required particle diameters. A first housing is in lap joint to a secondhousing; the first housing and the second housing are locked to form a crushing cavity; a rotor is arranged in the crushing cavity; the rotor is sleeved by the plate hammer; one end of the rotor is rotatably connected to the first housing, and the other end of the rotor penetrates through the outer wall of the first housing, and then is connected to a drive device; the reaction plate at the outerside of the plate hammer is further arranged in the crushing cavity; the reaction plate is connected to a regulating device which penetrates through the outer wall of the second housing; and a supporting device is further arranged on the outer wall of the second housing.

Owner:张其朋

Slicing device suitable for leatherleaf mahonia

The invention discloses a slicing device suitable for leatherleaf mahonia. The slicing device comprises a slicing box, wherein a pushing-pressing channel which is in communication in the horizontal direction is arranged on the center of a front panel of the slicing box and the center of a rear panel of the slicing box; left and right sides of the pushing-pressing channel are equipped with inclinedpressing conveyor belts; the inclined pressing conveyor belts are mounted on the inner side wall of a mounting slide plate; the mounting slide plate is blocked between two supporting slide tables ina sliding mode; an elastic pressing device is arranged between the outer side wall of the mounting slide plate and the inner side wall of the slicing box; the supporting slide tables are fixedly arranged on left and right inner side walls of the slicing box; the slicing box is fixedly mounted at the periphery of the rear-end opening of the pushing-pressing channel; and a cutting device is arrangedin the slicing box. The inclined pressing conveyor belts of the slicing device can continuously increase clamping force to the sides of the raw materials while conveying the raw materials, so that the raw materials can keep a relatively stable state to perform slicing action, and therefore, the conditions that a cutting surface is uneven, raw materials shake in a cutting process, the cutting thickness is uneven, and a cutter disc is possibly damaged are avoided.

Owner:赵学明

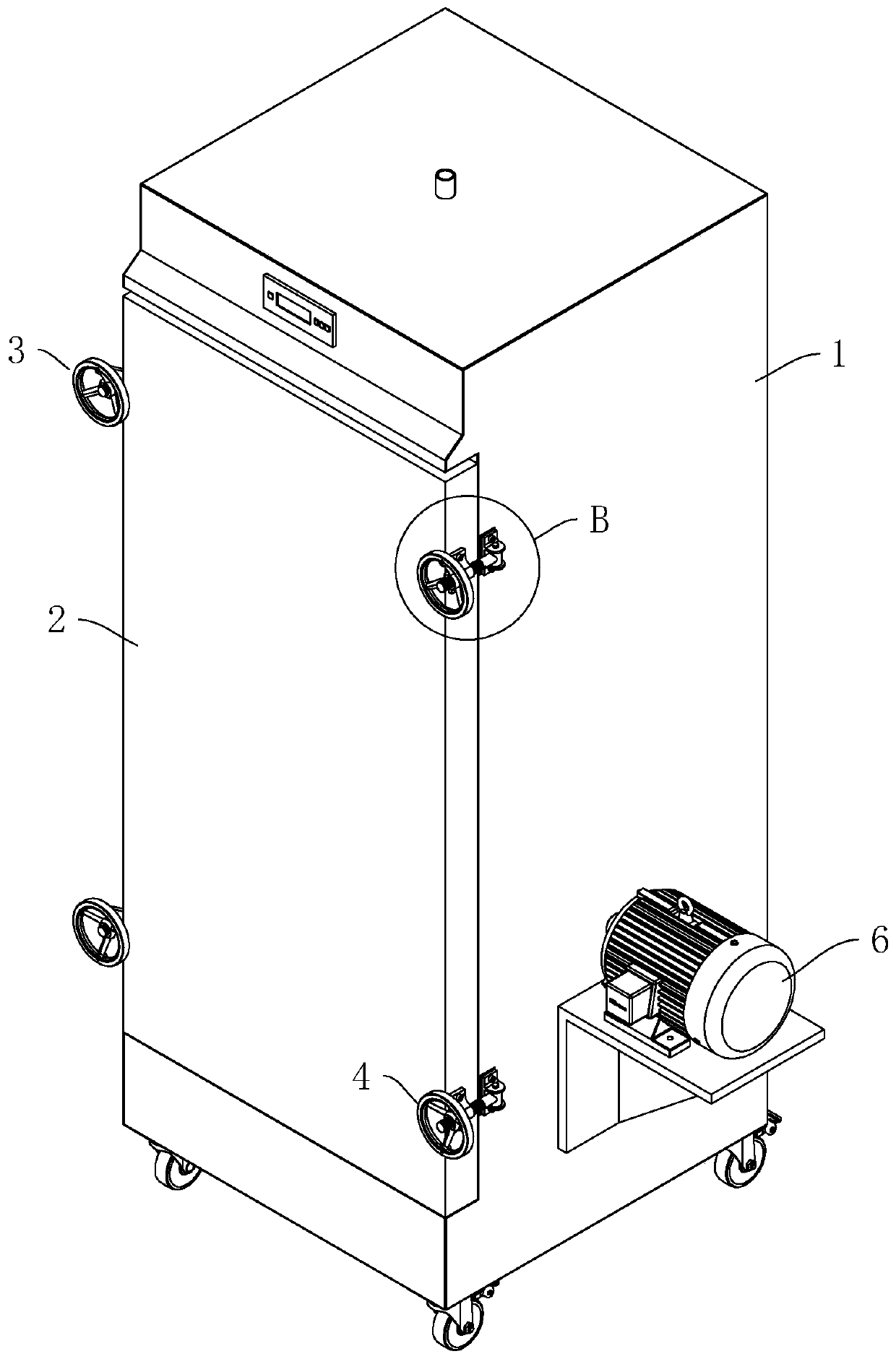

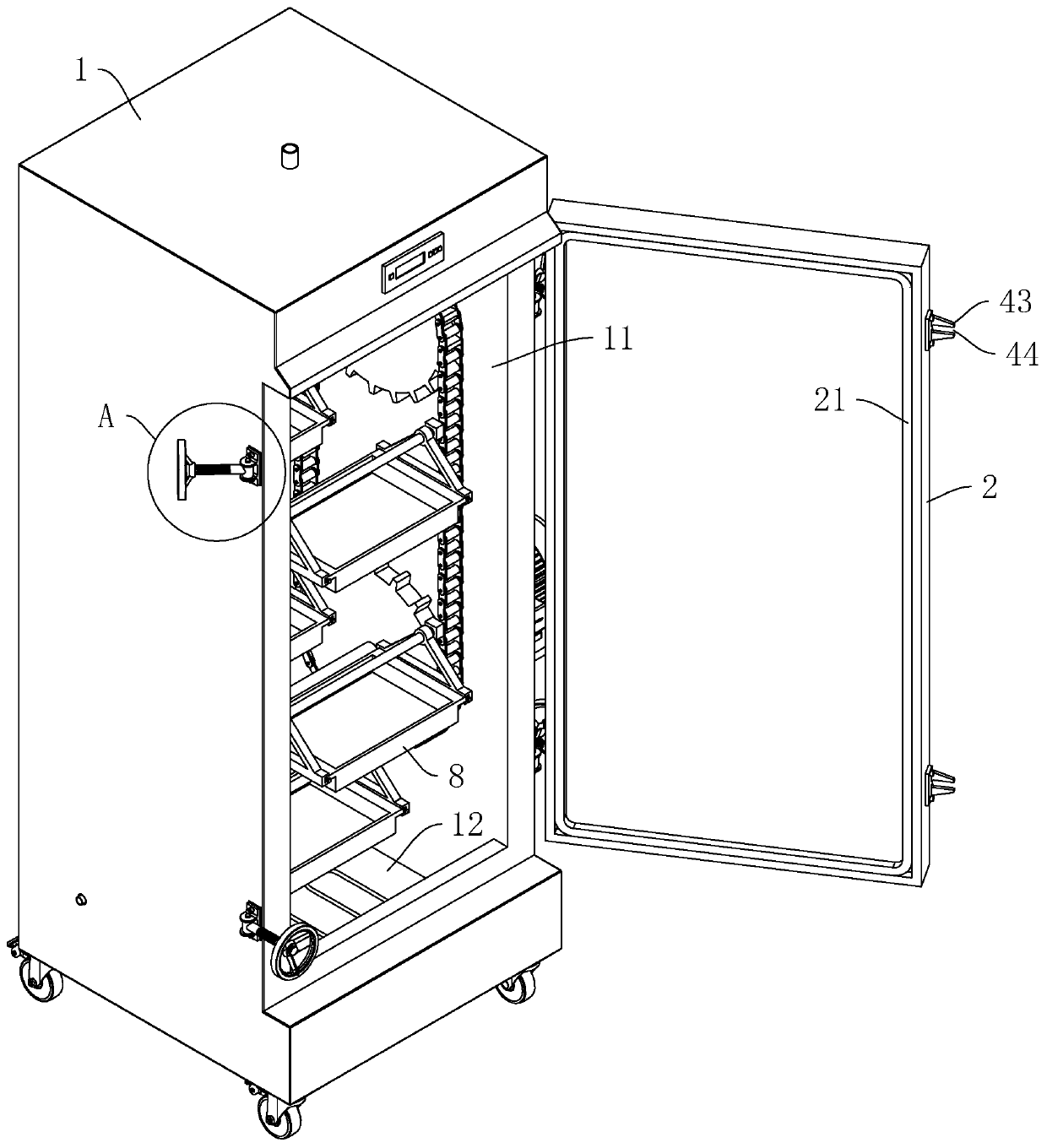

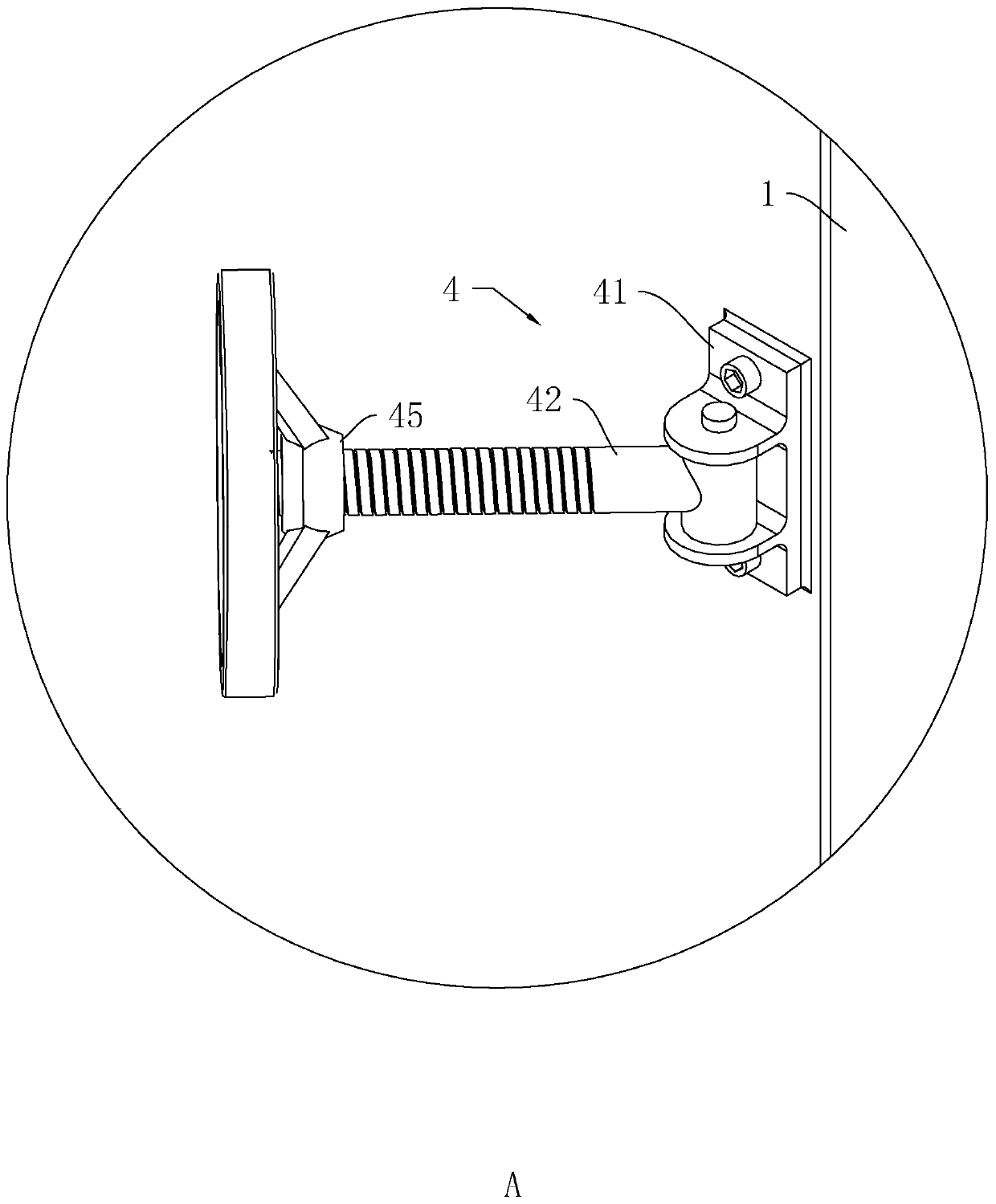

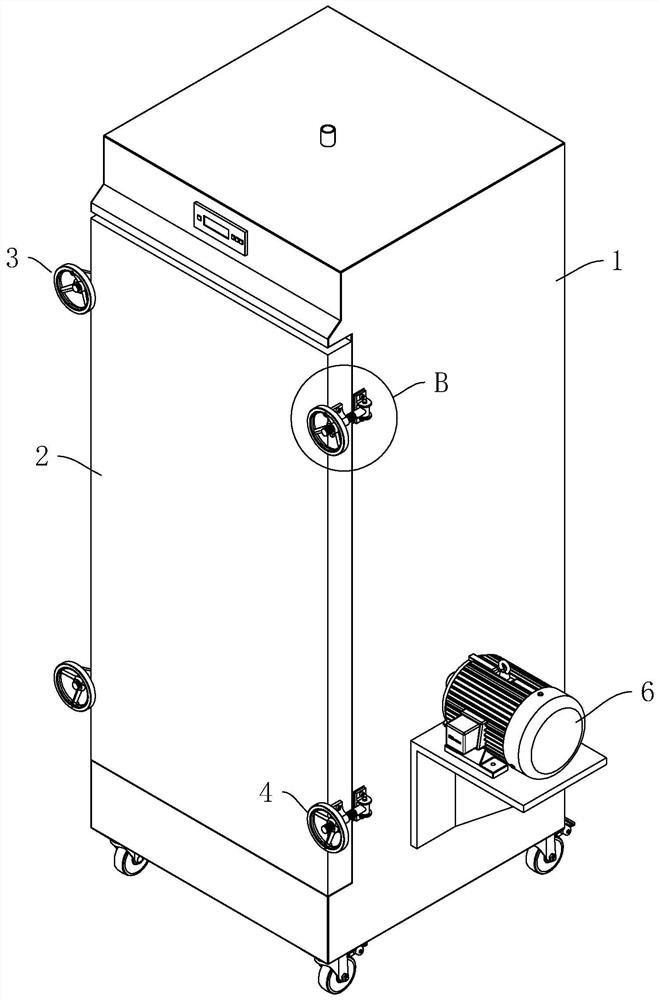

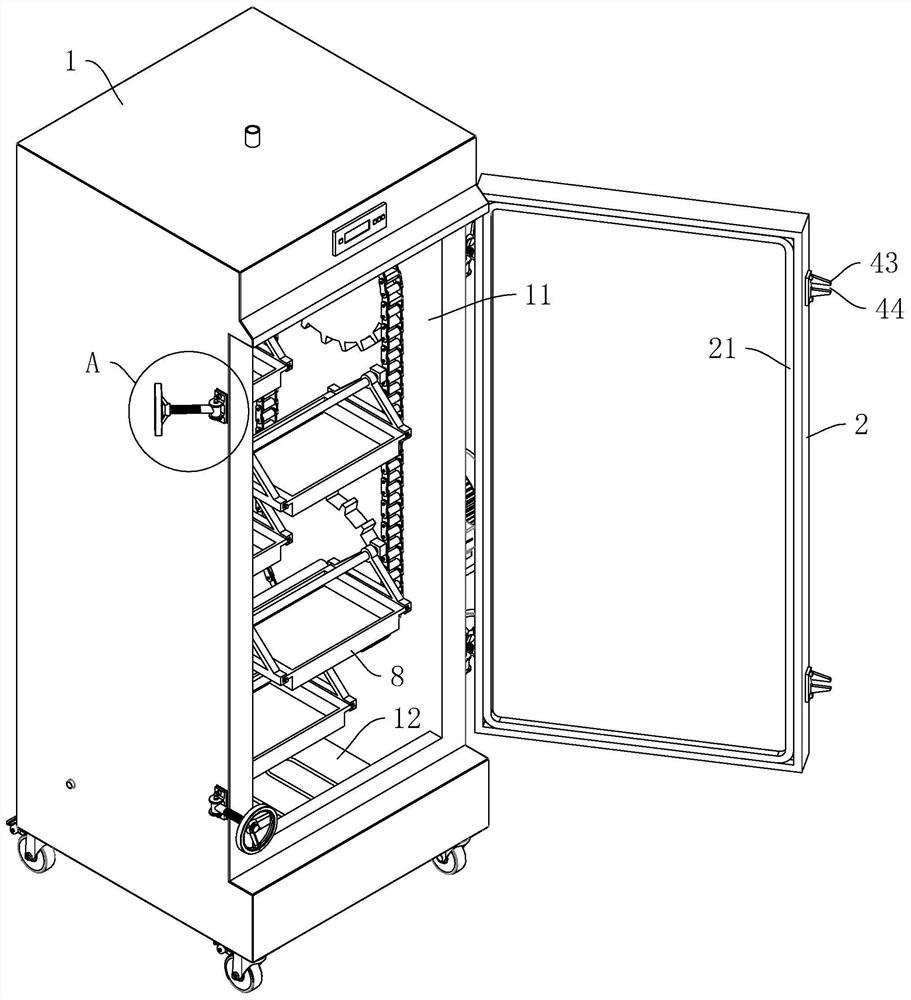

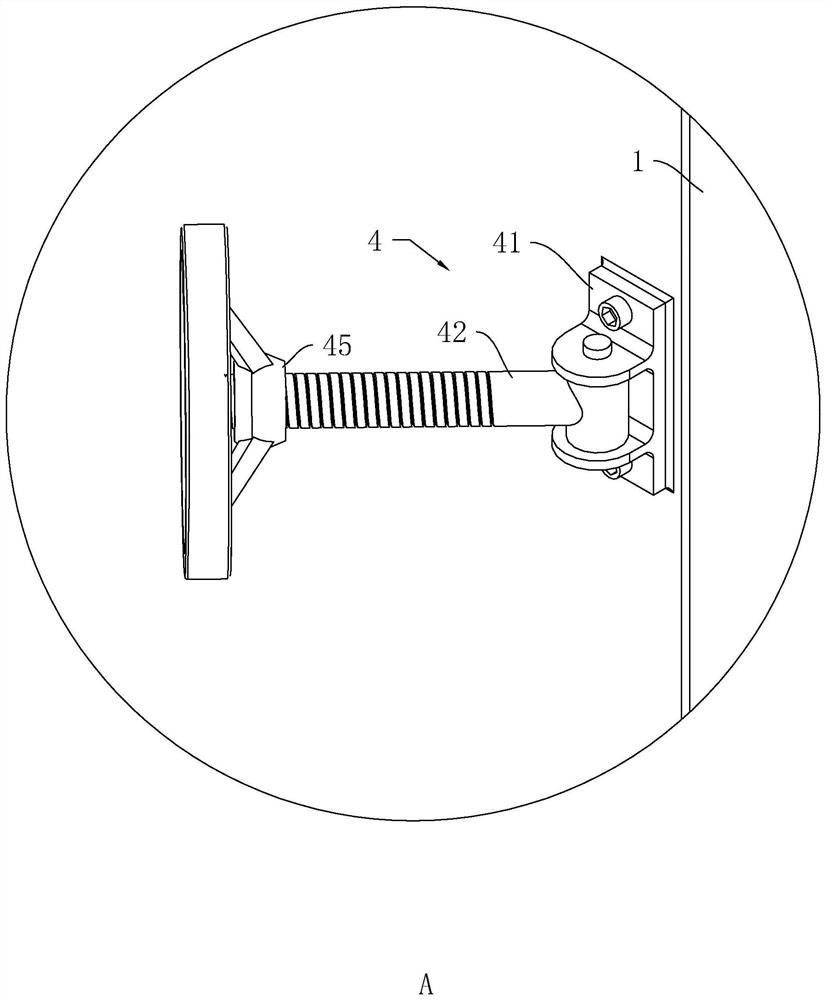

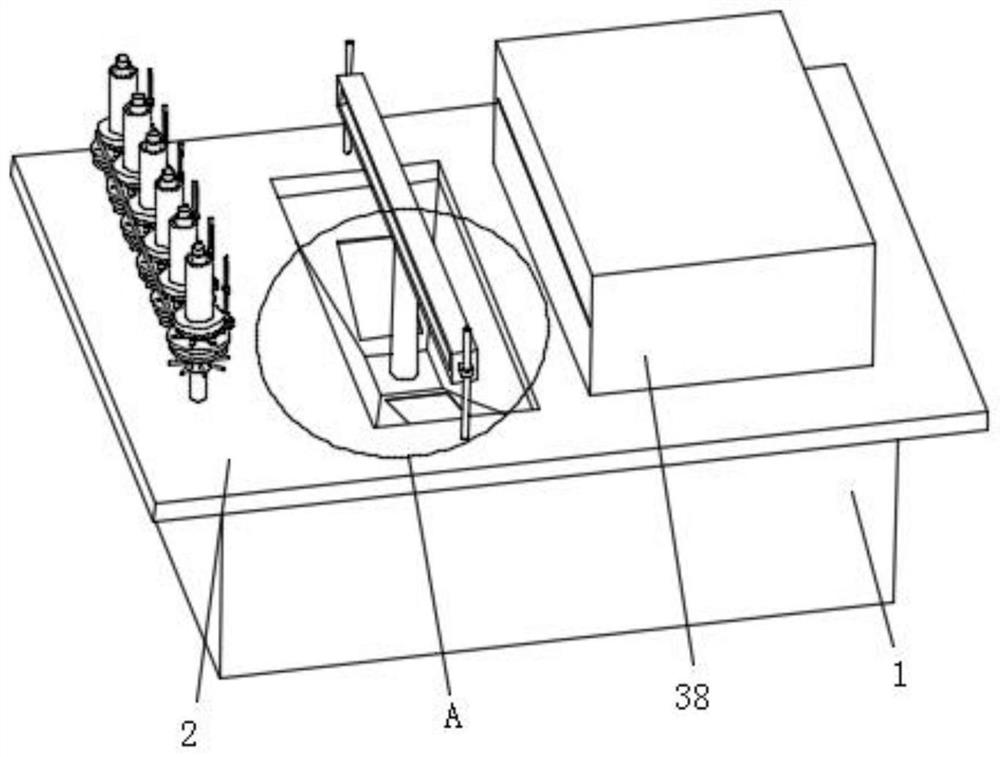

Rice steaming cabinet

InactiveCN109864575AEvenly heatedEasy removal and installationCooking vesselsElectric heatingMotor drive

The invention discloses a rice steaming cabinet. The rice steaming cabinet comprises a cabinet body and a cabinet door. A hollow steam chamber is arranged inside the cabinet body. A sink is arranged at the bottom wall of the steam chamber, and an electric heating pipe is arranged inside the sink; a pair of rotating shafts are rotationally and horizontally connected to the interior of the cabinet body, and the rotating shafts are distributed at the upper and lower ends of the cabinet body, and a servo motor driving the rotating shafts to rotate is arranged at the outer wall of the cabinet body;the two ends of the rotating shafts are each provided with a gear, the two gears located at the same ends of the rotating shafts is wound by a chain, a plurality of uniformly-distributed supporting rods are horizontally arranged between the pair of chains, a hanging bracket is rotationally connected to each of the two ends of the supporting rods, and trays are arranged between the pair of hangingbrackets. The rice steaming cabinet has the advantages that by arranging the trays capable of rotating inside the steam chamber, each tray can make contact with high heat at the bottom of the steam chamber, and therefore each tray is heated more uniformly, and it is ensured that rice inside each tray can be cooked at the same time. Meanwhile, the rice cooking time is shortened, energy dissipationis saved, and the effect of saving energy is achieved.

Owner:浙江广博厨房设备有限公司

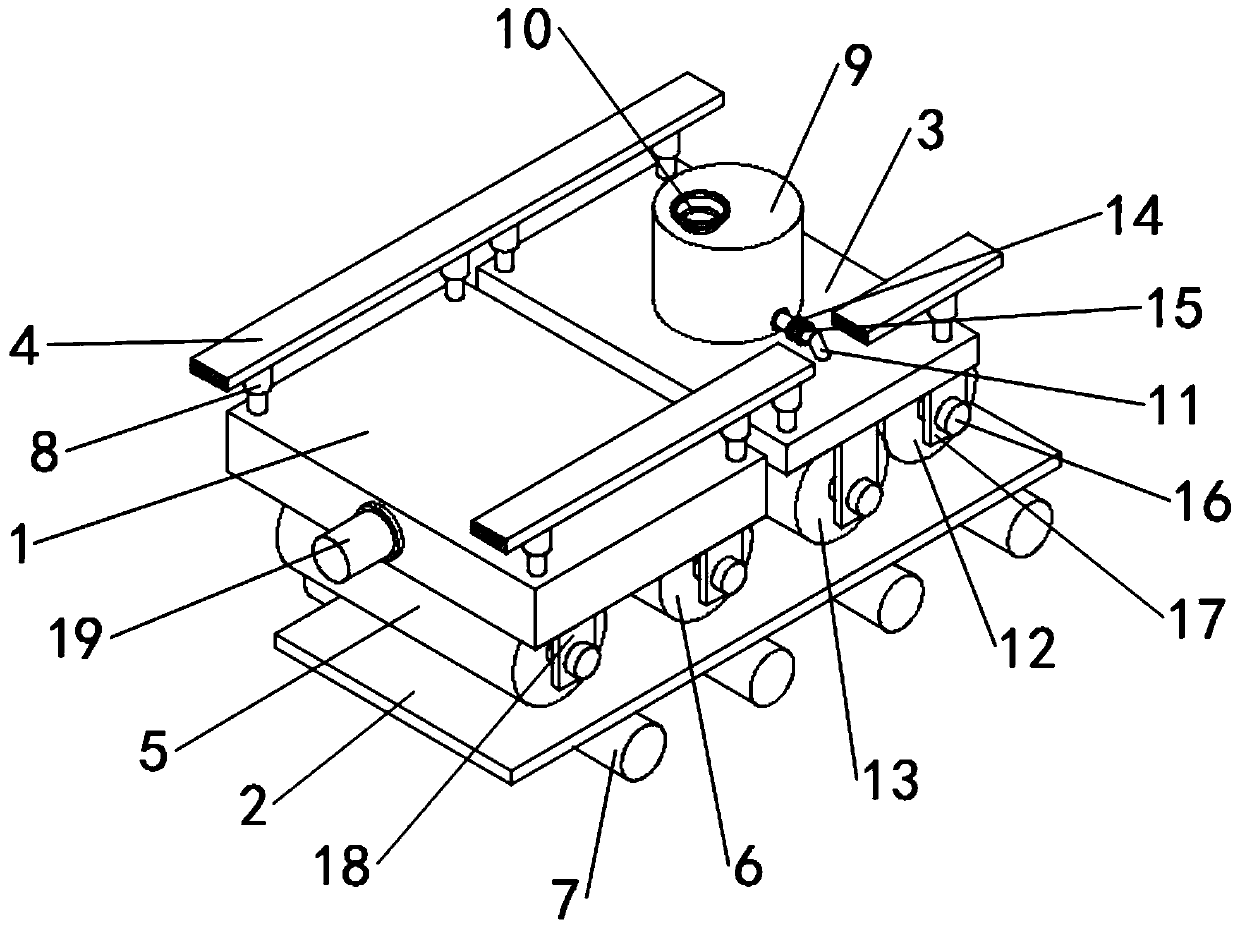

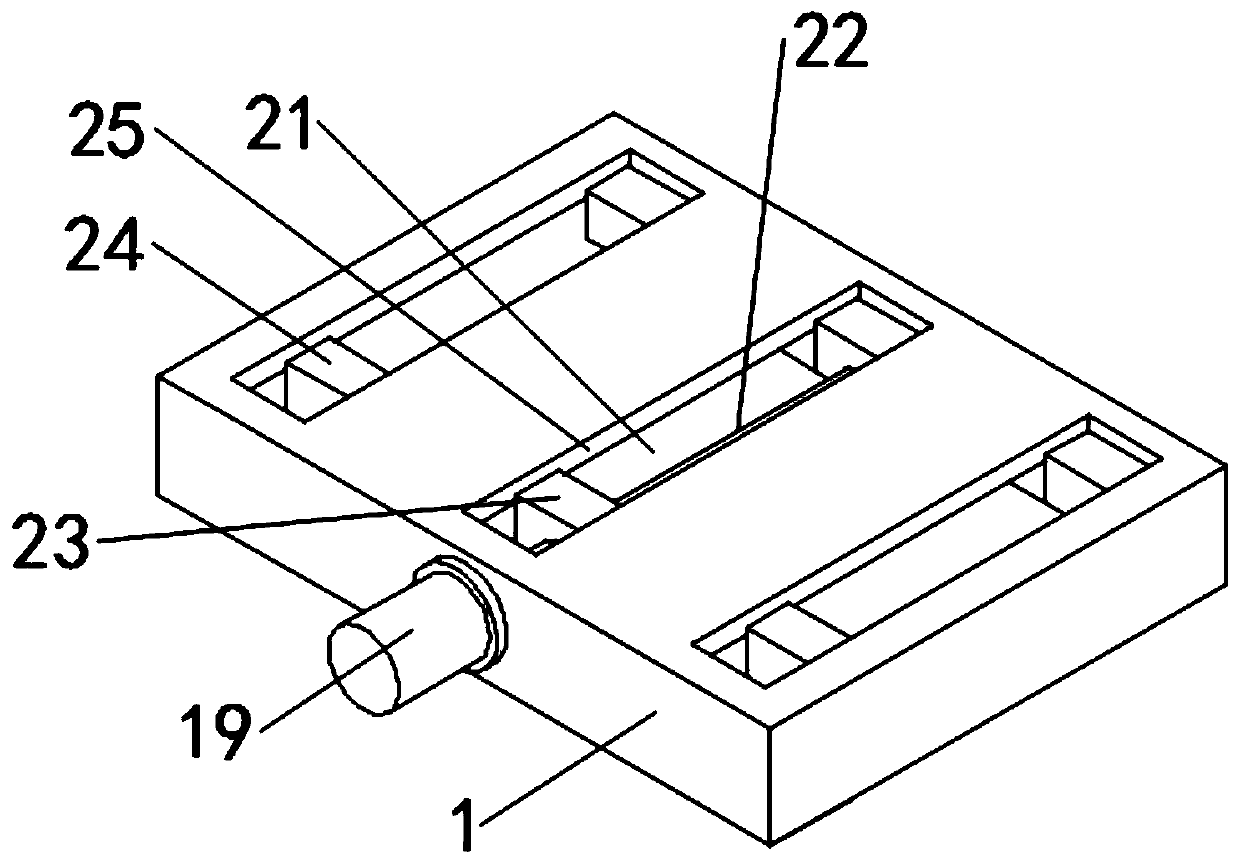

Transfer mechanism for adjusting product positions

ActiveCN105947611AAchieve horizontal inflowSimple structureConveyor partsProduction lineArchitectural engineering

The invention relates to a transfer mechanism for adjusting product positions. A first horizontal fixed plate is mounted between a left side baffle plate and a middle baffle plate; a second horizontal fixed plate is mounted on the right side of the upper end of the left side baffle plate; a horizontal production line is arranged between the middle baffle plate and the right side baffle plate; a horizontal driving device is mounted on the right side of the right side baffle plate; a stop mechanism capable of stopping products is arranged on a support plate at an output end of the horizontal production line; a vertical production line is mounted between the first and second horizontal fixed plates; a vertical driving device is mounted at the lower part of the first horizontal fixed plate; a pressing device capable of pressing the products on the horizontal production line is mounted on the second horizontal fixed plate; a rotating shaft is mounted at the bottom of the support plate through a rotating bracket; and a turnover driving device capable of driving the support plate to rotate around the rotating shaft is mounted at the bottom of the support plate. The horizontal and vertical production lines alternatively act to realize an overturning action of the products by 90 degrees to operate two side surfaces of the products so as to realize automatic input and output of the products.

Owner:BOZHON PRECISION IND TECH CO LTD

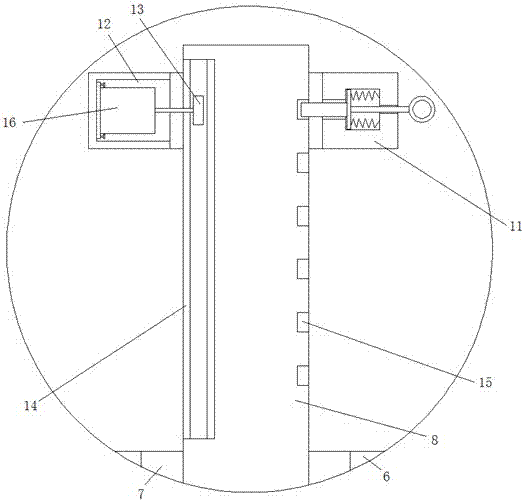

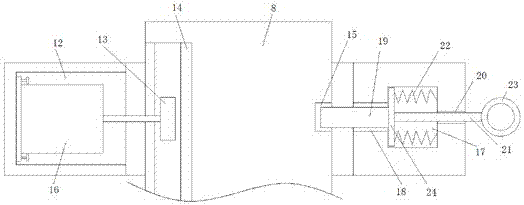

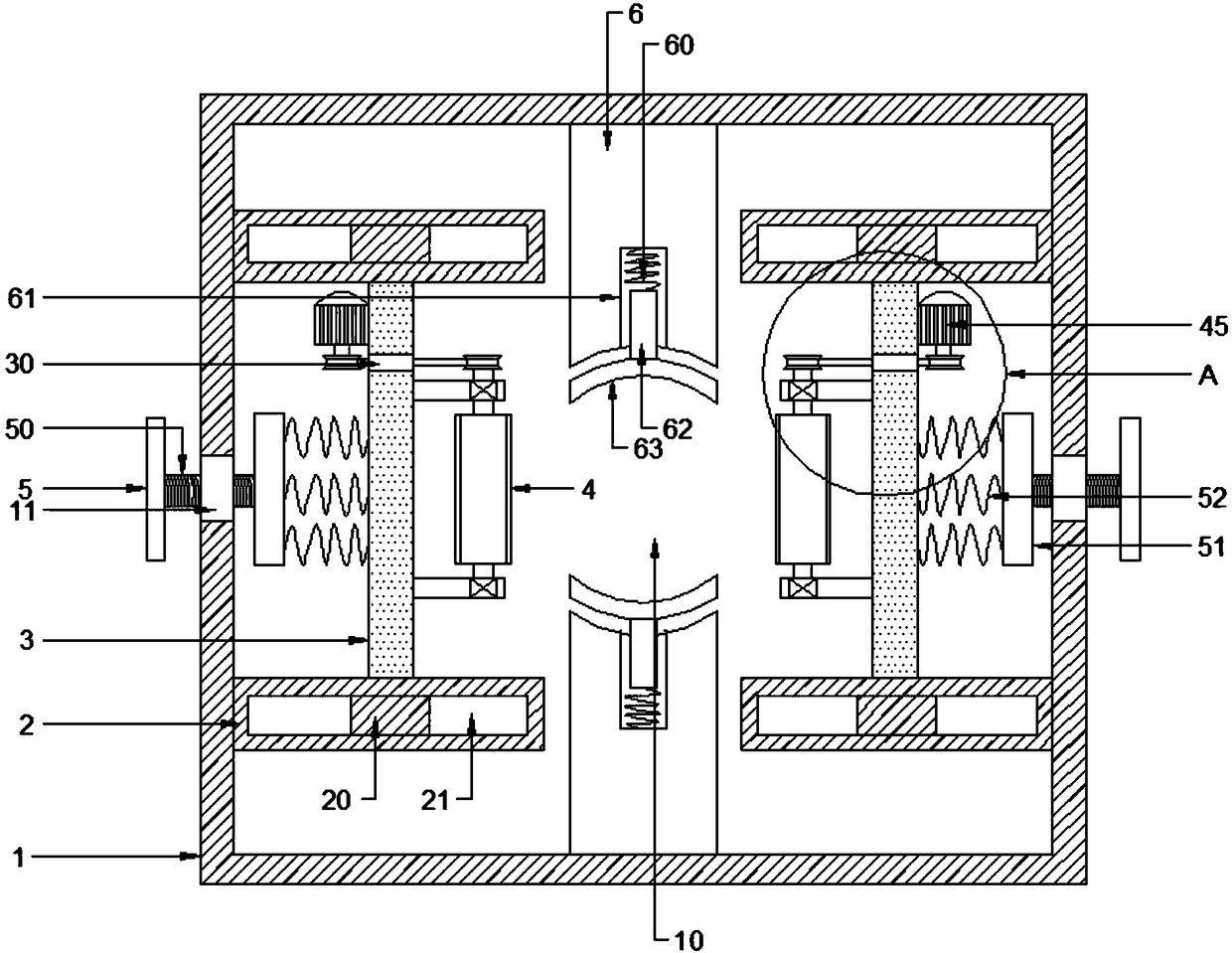

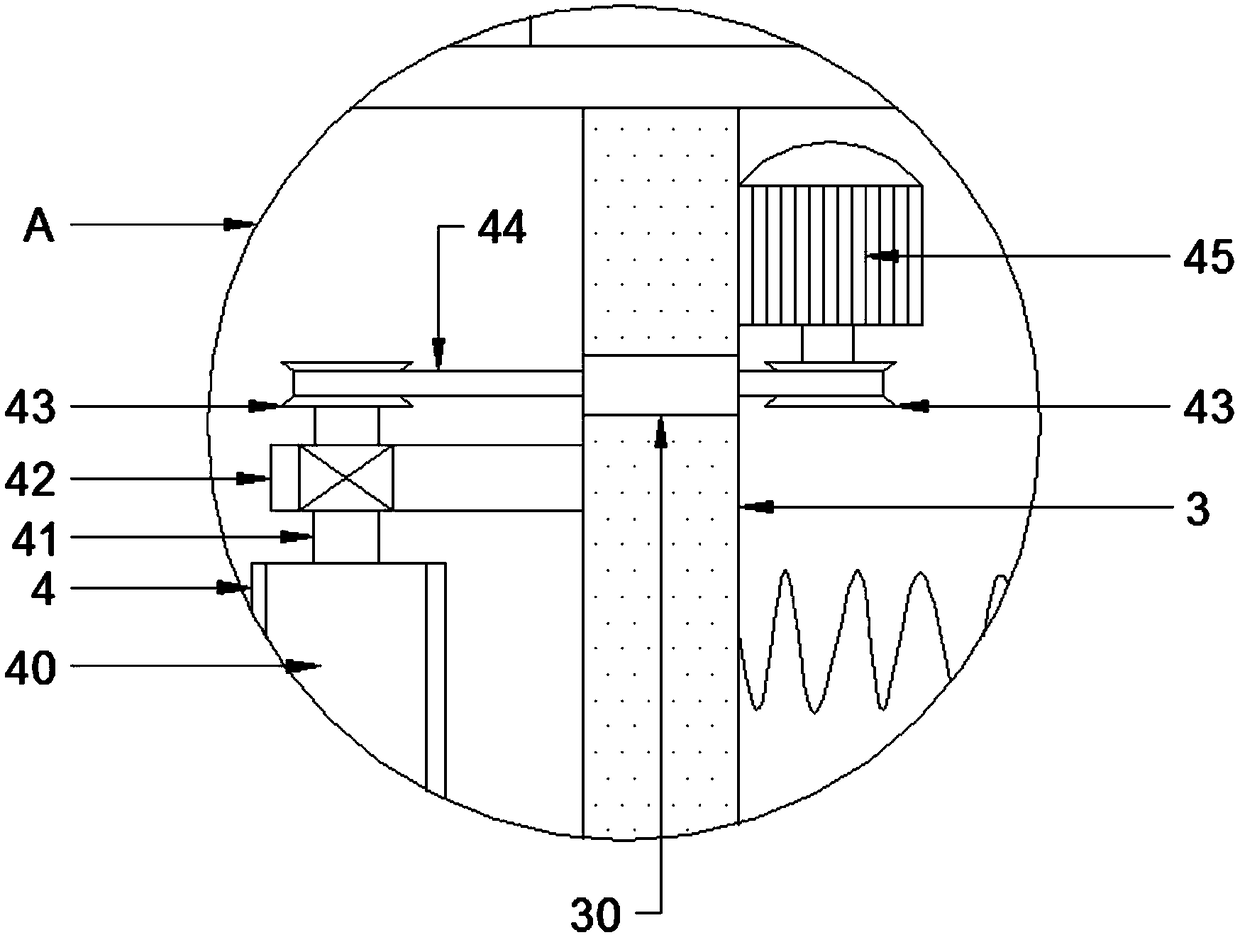

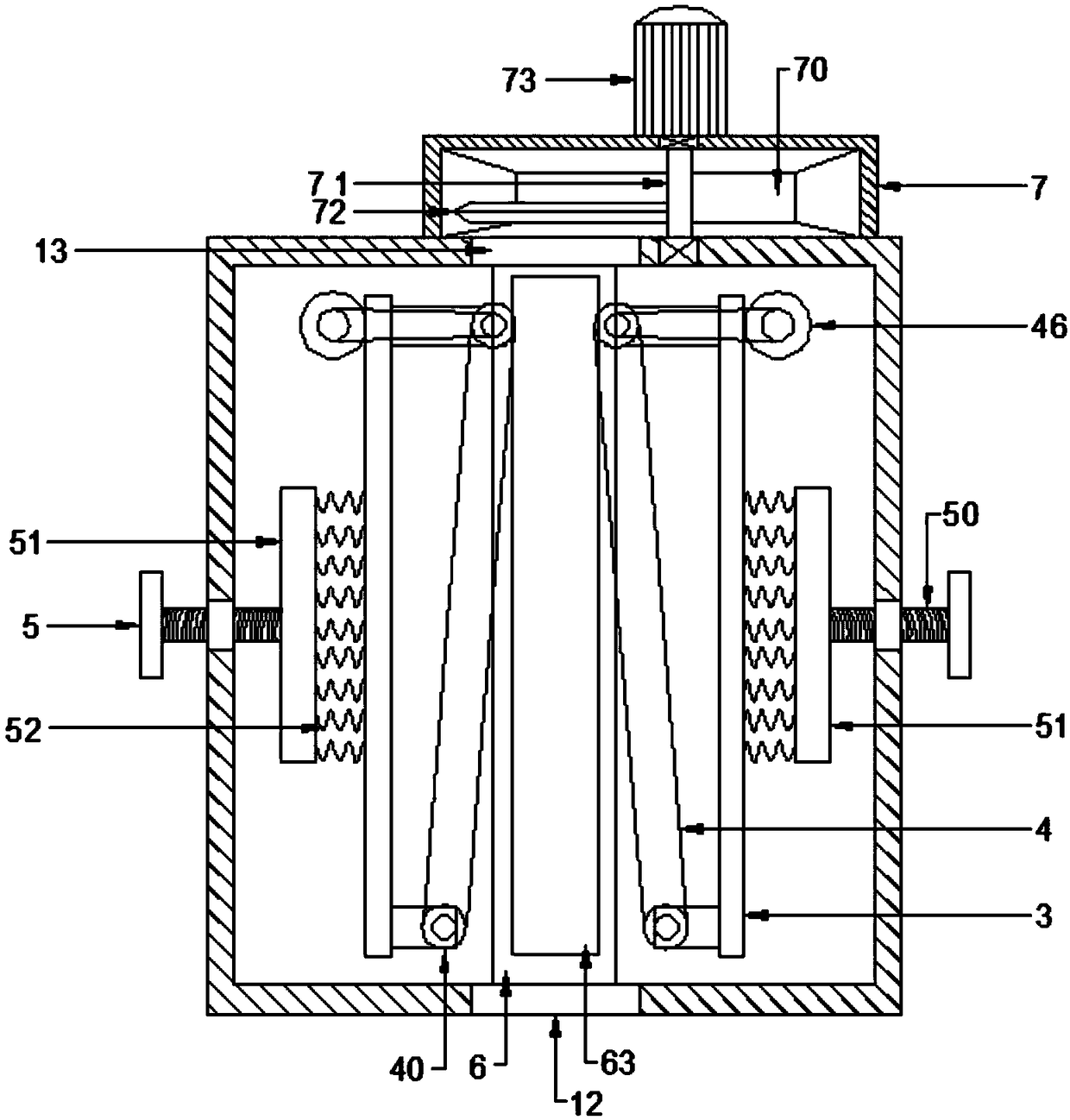

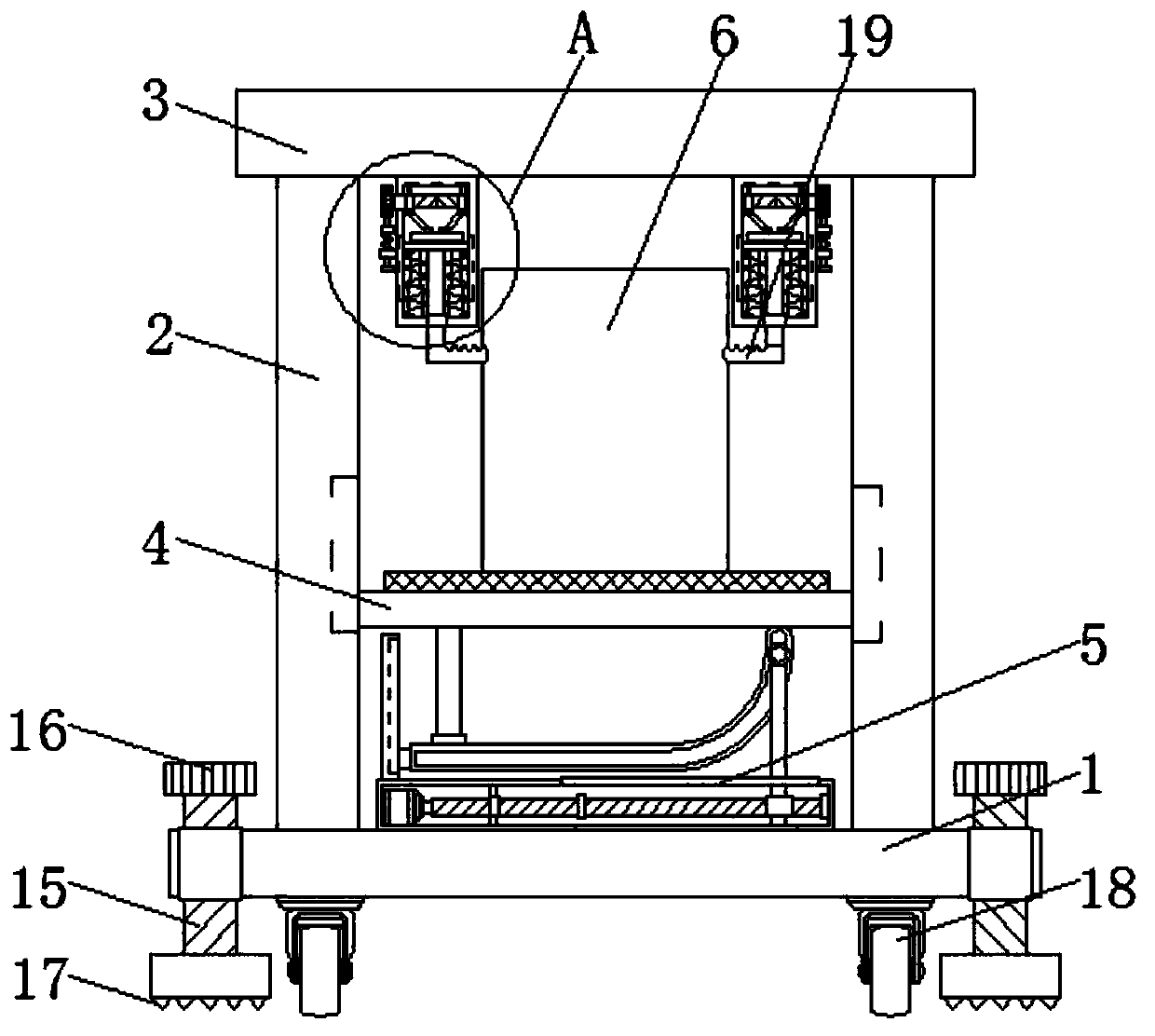

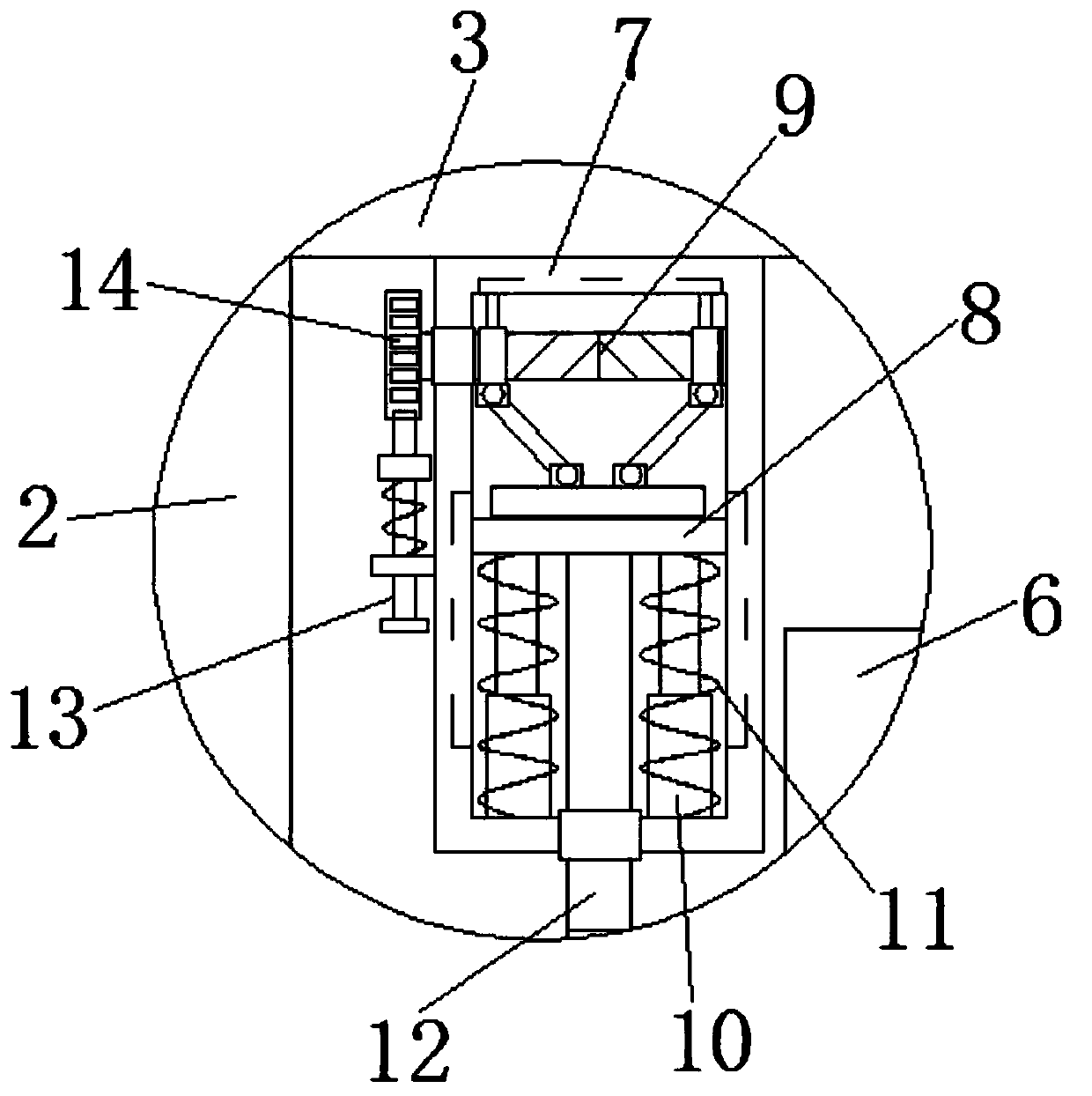

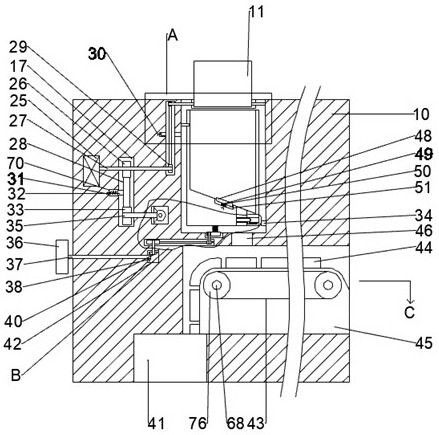

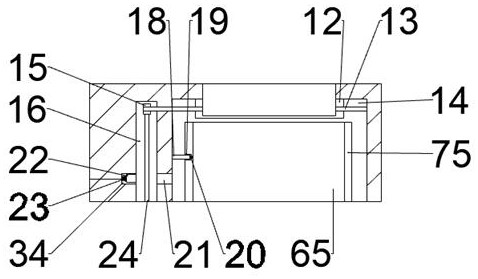

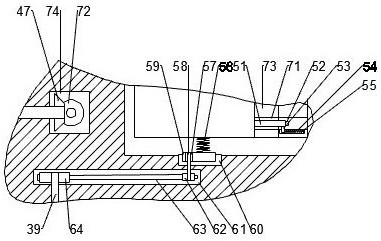

Arm exercising device for neurology department nursing and exercising method thereof

InactiveCN111001131AAchieve the purpose of exerciseAdjust the degree of compressionMuscle exercising devicesPhysical medicine and rehabilitationNeurology department

The invention discloses an arm exercising device for neurology department nursing. The arm exercising device comprises a bottom plate, and supporting plates are fixedly connected to the two sides of the top of the bottom plate. A top plate is fixedly connected over the supporting plates; a straight plate is slidably connected between the opposite sides of the two supporting plates. A lifting device is fixedly connected between the bottom of the straight plate and the top of the bottom plate; and a backrest is fixedly connected to the top of the straight plate, outer frames are fixedly connected to the positions, between the opposite sides of the two supporting plates, of the two sides of the bottom of the top plate, and a sliding plate is fixedly connected between the two sides of the inner wall of each outer frame. The invention relates to the technical field of neurology department nursing equipment. According to the arm exercising device for neurology department nursing, the compression degree of springs can be adjusted according to the rehabilitation condition of a user, so that the purpose of exercising the arms of the user is achieved, the use height of the straight plate canbe adjusted, the device is suitable for people with different heights, and the practicability of the device is improved.

Owner:刘梅

Semi-direct drive megawatt-level permanent-magnet windmill generator

ActiveCN102005841AEfficiency and Reliability GuaranteedIncrease the length of the wind pathMagnetic circuit rotating partsMagnetic circuit stationary partsWind forceDynamo

The invention discloses a semi-direct drive megawatt-level permanent-magnet windmill generator which relates to the technical field of windmill generators. The semi-direct drive megawatt-level permanent-magnet windmill generator comprises a permanent magnet fixing structure, a cooling ventilation structured bearing insulating structure and a stator core compaction structure, wherein the permanent magnet fixing structure comprises a magnetic steel fixed mount and a stainless steel bolt, and the magnetic steel fixed mount is used for installing the permanent magnet; the bottom of the magnetic steel fixed mount is closely laminated with the permanent magnet; joint lugs on both ends of the bottom of the magnetic steel fixed mount are provided with through holes which are matched with the stainless steel bolt; and the magnetic steel fixed mount is connected with a rotor cylinder through the stainless steel bolt. In the invention, the defect of unfirm fixation of the prior high-power surface type permanent-magnet rotor permanent magnet on the rotor is overcome, thereby ensuring the reliability and efficiency of the generator, and the defects in the prior ventilation structure is also overcome, thereby increasing the length of the wind path, enhancing the heat elimination efficiency and further effectively lowering the operation temperature rise of the motor.

Owner:DONGFANG ELECTRIC MACHINERY

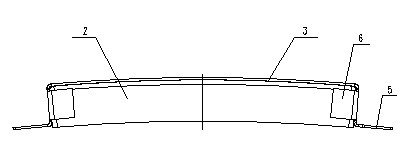

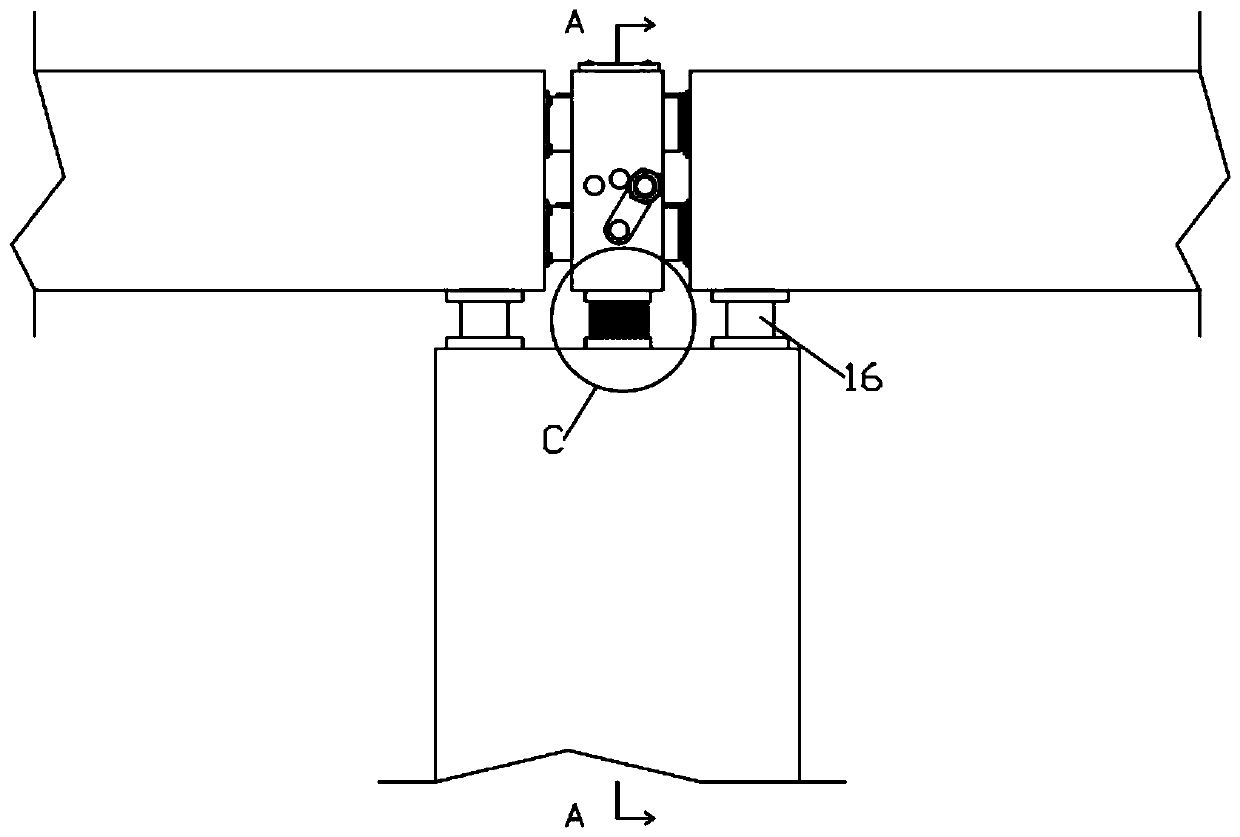

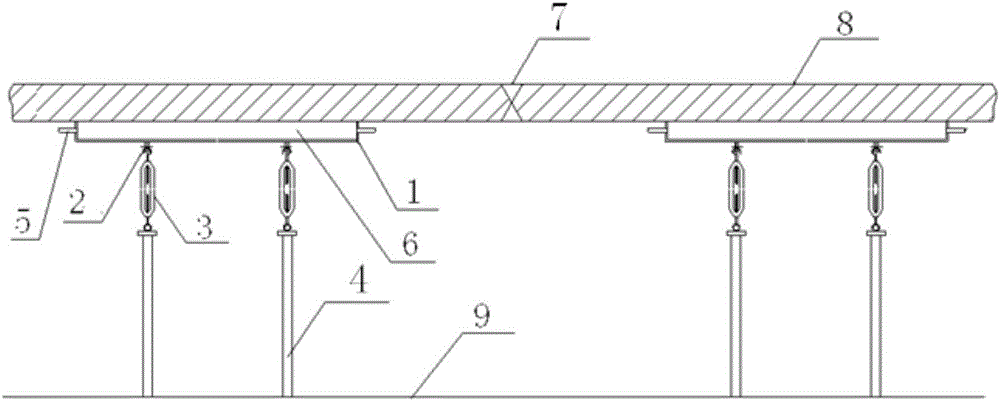

Variable-damping anti-falling beam structure

ActiveCN111549651ARegulating pressureTo achieve the purpose of energy consumption and shock absorptionBridge structural detailsProtective buildings/sheltersEngineeringStructural engineering

The invention relates to the technical field of bridges, and particularly discloses a variable-damping anti-falling beam structure. The variable-damping anti-falling beam structure comprises a bridgepier, a first main beam and a second main beam, a partition plate support is arranged between the first main beam and the second main beam. A first damping structure is arranged between the first mainbeam and the second main beam; the partition plate support is connected with the pier through a second damping structure. The first damping structure comprises a first energy consumption strip-shapedplate, a second energy consumption strip-shaped plate and a pressing mechanism. The first energy dissipation strip-shaped plate is fixedly arranged on the end face of the first main beam. According to the variable-damping anti-falling beam structure, the damping rigidity of energy consumption of the device can be adjusted according to season requirements, so that the device can be kept in a goodworking state all the time, and bridge falling is prevented.

Owner:创辉达设计股份有限公司

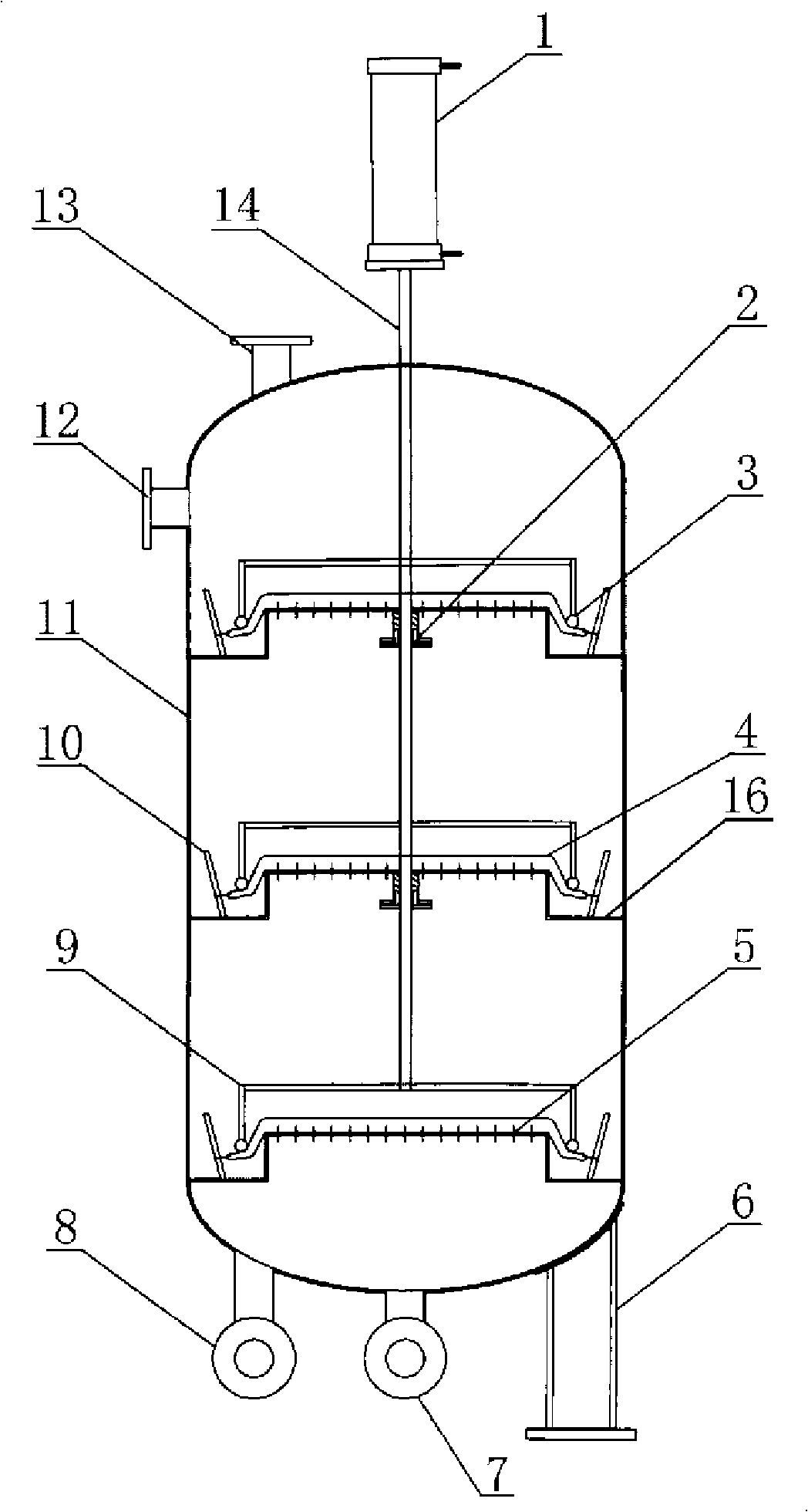

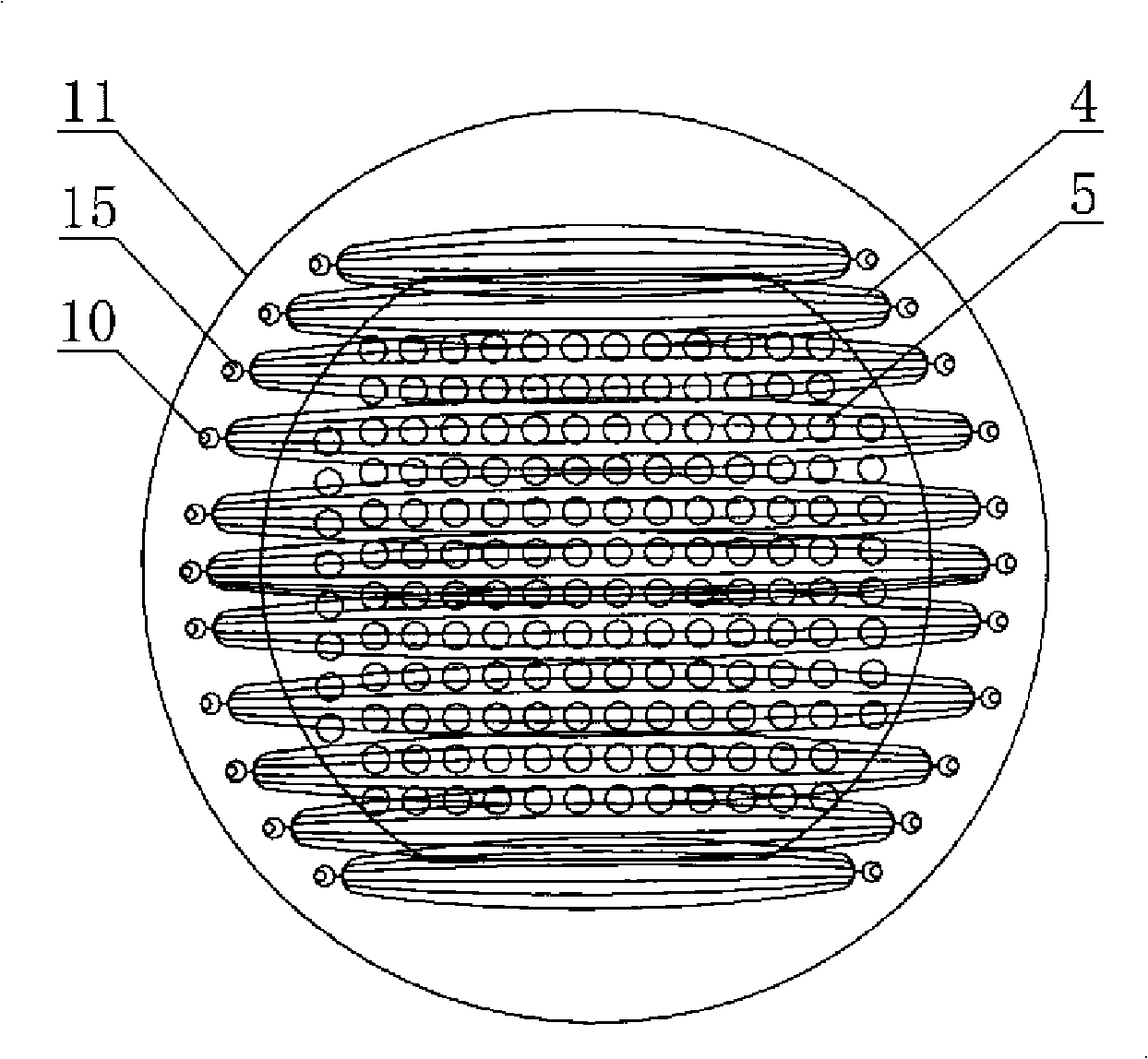

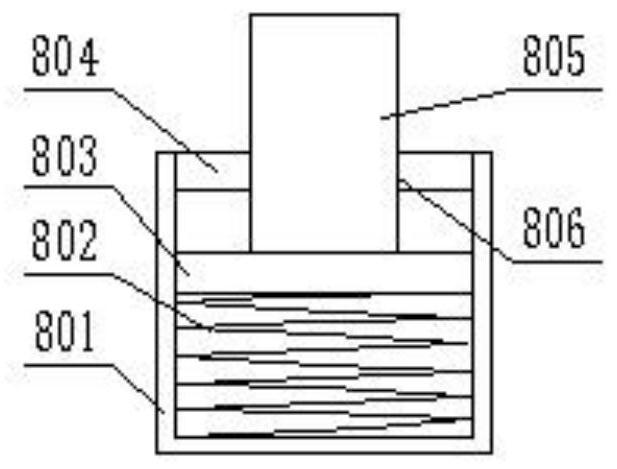

High precision fiber filter

InactiveCN101249319AEasy to separateSimple structureLoose filtering material filtersGravity filtersFiberDrive shaft

A high-precision fiber filter includes a shell body, fiber beams in the shell body and a wire hanging rod, a water inlet pipe and a water outlet pipe are opened on the shell body, the inner wall of the shell body is provided with at least one layer of placing ring with an L-shaped cross-section, a transverse plate of the L-shaped placing ring is connected with the side wall of the shell body, porous plates are covered on a vertical plate of the L-shaped placing ring, at least one layer of fiber beam is covered on each layer of the porous plate, all the fiber beams are hung on the wire hanging rod which is arranged on the L-shaped placing ring, the upper surface of each layer of the fiber beam is pressed with a fiber tightening pressing frame with the diameter which is larger than the porous plate, all the fiber tightening pressing frames are connected with a transmission shaft at the center of the shell body, the transmission shaft penetrates out of the shell body to be connected with a drive device; the shell body is provided with a back wash air inlet pipe on one end of the water outlet pipe, and one end of the water inlet pipe is provided with a back wash water discharge pipe. The high-precision fiber filter has simple structure, low cost, easy back-wash, high filtration precision and small area coverage, which can greatly improve the water quality of the discharged water, solve the technical difficult problems of unstable water quality of the discharge water, accelerate the filtration speed and improve the effect of the solid-liquid separation.

Owner:北京东方纪元水务工程有限公司 +2

Sand box with pressing device

InactiveCN106825451AAdjust the degree of compressionAvoid deformationMoulding flasksEngineering managementCircular segment

Owner:句容市有色金属铸造厂

Glass Transport Fixtures

ActiveCN108674990BDistribute the load evenlyImprove adaptabilityCharge manipulationConveyor partsEngineeringMechanical engineering

Owner:王盼

Flame spraying method for high melting metal skin flexible ceramic wire

InactiveCN1594641AAdjust the degree of compressionSimple production equipmentMolten spray coatingBobbinHigh energy

Flame spraying method for high melting metal skin flexible ceramic strip belongs to a hot spraying process. The invention is accomplished as follows : a. mixing and stirring powder core using high energy ball milling b. placing strip electrode coating in bobbin disk, placing powder core into refiller to make tube type powder core strip, c. surface coarsening of shank diameter of crank axle spray painting part d. mounting flame spraying strip delivery reel on strip making machine, encasing tube type powder core strip in reel and penetrating into spray gun nozzle, connecting spray gun with compressed air valve, acetylene and oxygen pipeline, e. adjusting strip delivery speed, pressure and flux of compressed air , acetylene and oxygen f. assembling crank axle at special rotary workbench, crank axle rotating while spray painting, spraying adopting manual manipulation, coating contour machining using crankshaft grinder. The invention has advantages of simple production apparatus, low cost.

Owner:HARBIN INST OF TECH

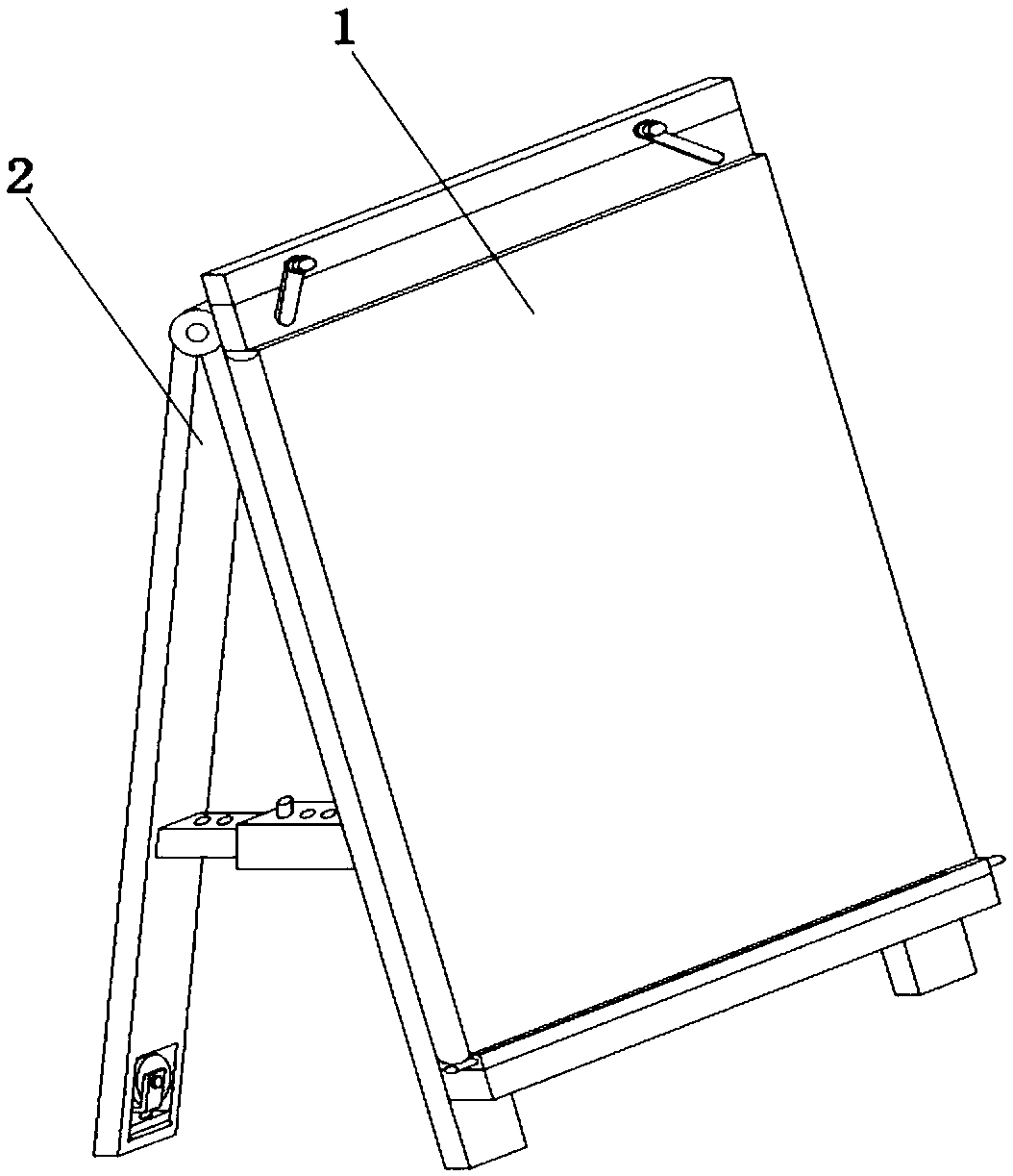

Culture communication advertisement display rack

The invention provides a culture communication advertisement display rack, which comprises a display portion and a supporting portion, wherein the supporting portion is connected to the back of the display portion; the display portion comprises a display plate, a transparent cover, a first hinge and an adhesion device; one end of the first hinge is connected to one side of the display plate, and the other end of the first hinge is connected to one side of the transparent cover; the transparent cover can turn along the plane of the display plate around the first hinge; the transparent cover isas wide as the display plate; the adhesion device adheres to the upper surface of the display plate; a pair of locking plates are arranged at the other side of the transparent cover; and plate eyeletsare formed in the locking plates. The display rack provided by the invention can replace advertising pages conveniently, without destructive demolition, so that the advertising pages can be repeatedly used; therefore, resource waste and property loss as well as the generation of a great amount of waste can be prevented, and environmental pollution can be relieved; and the display rack is quite convenient to move and transport, so that efficiency is improved.

Owner:HUZHOU HUIXIN CULTURE COMM CO LTD

Vacuum glass coating equipment

ActiveCN110551976AEasy to useGood coating qualityVacuum evaporation coatingSputtering coatingEngineeringMechanical engineering

The invention relates to the technical field of glass processing, in particular to vacuum glass coating equipment which comprises a supporting box, a supporting plate, a first compressing rotary drum,a second compressing rotary drum, conveying rollers, electric push rods and a hydraulic cylinder; the multiple conveying rollers, exerting the conveying and supporting effects to glass, are installedat the bottom of the rack; and the supporting box is installed on the upper part of the left side of a rack in a lifting manner through the electric push rods arranged at four corners of the supporting box and is internally provided with an adjusting mechanism used for adjusting the relative position between the first compressing rotary drum and the second compressing rotary drum. For the vacuumglass coating equipment provided by the invention, excessive deformation of the glass during coating can be avoided; and in addition, by adjusting the relative position between the two compressing rotary drums through the adjusting mechanism, the two compressing rotary drums can be adjusted to a proper distance position according to different glass toughness, and thus the effect of preventing deformation during compression of the glass is the best.

Owner:咸阳镭瑟奥普光电科技有限公司

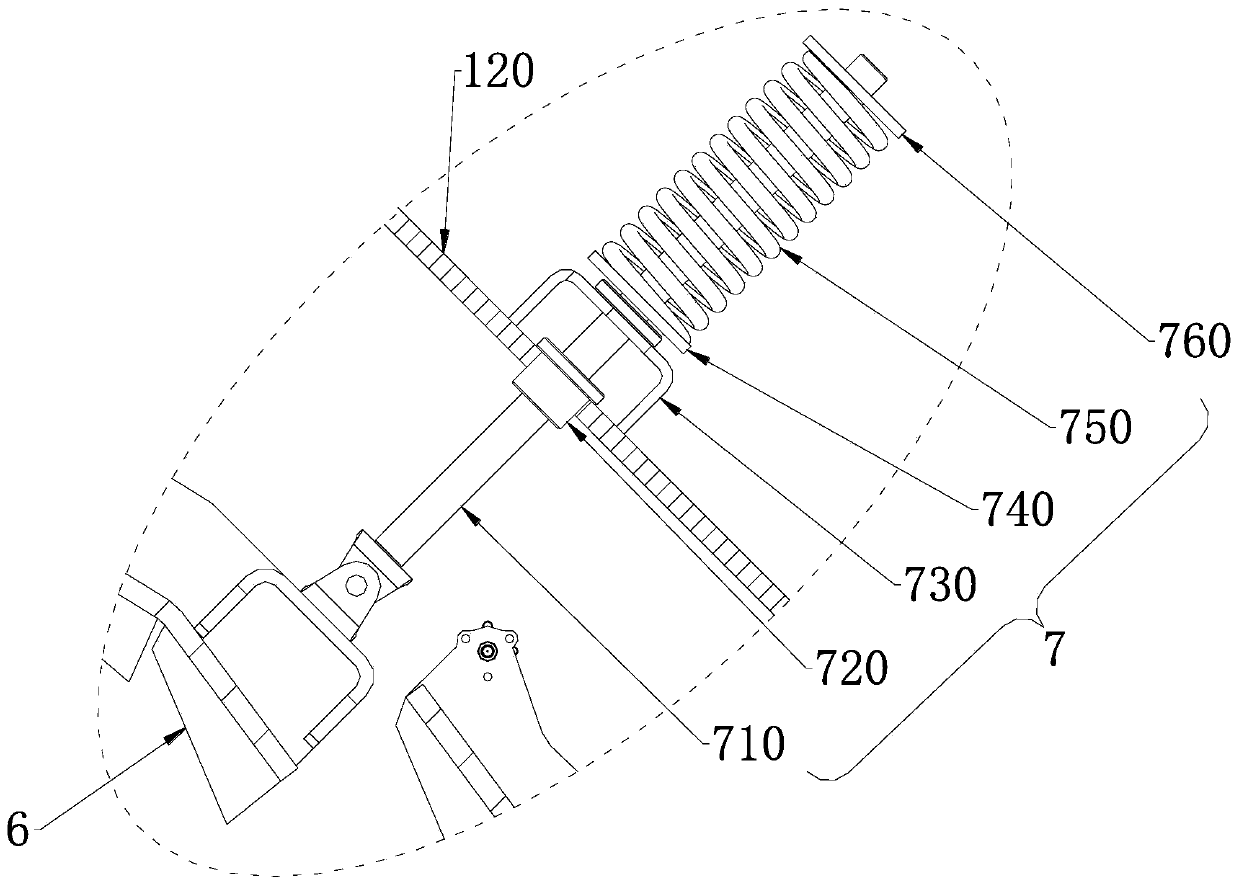

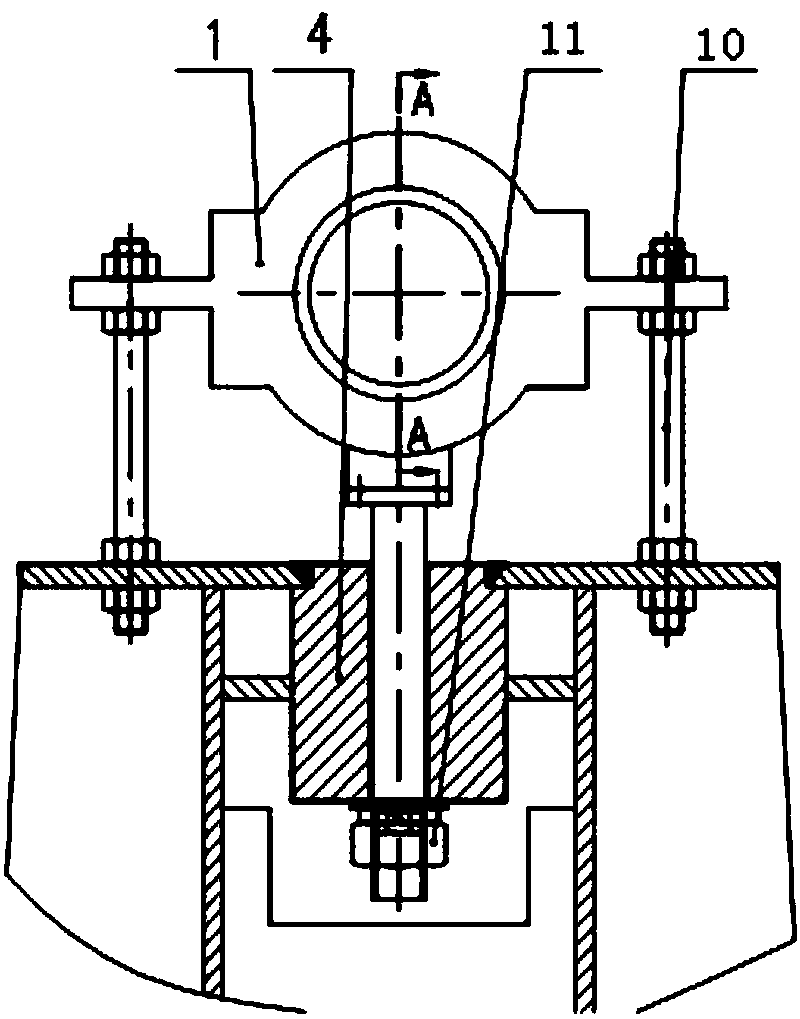

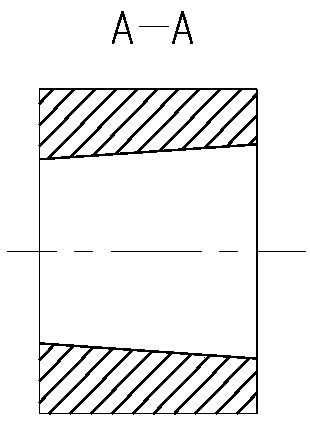

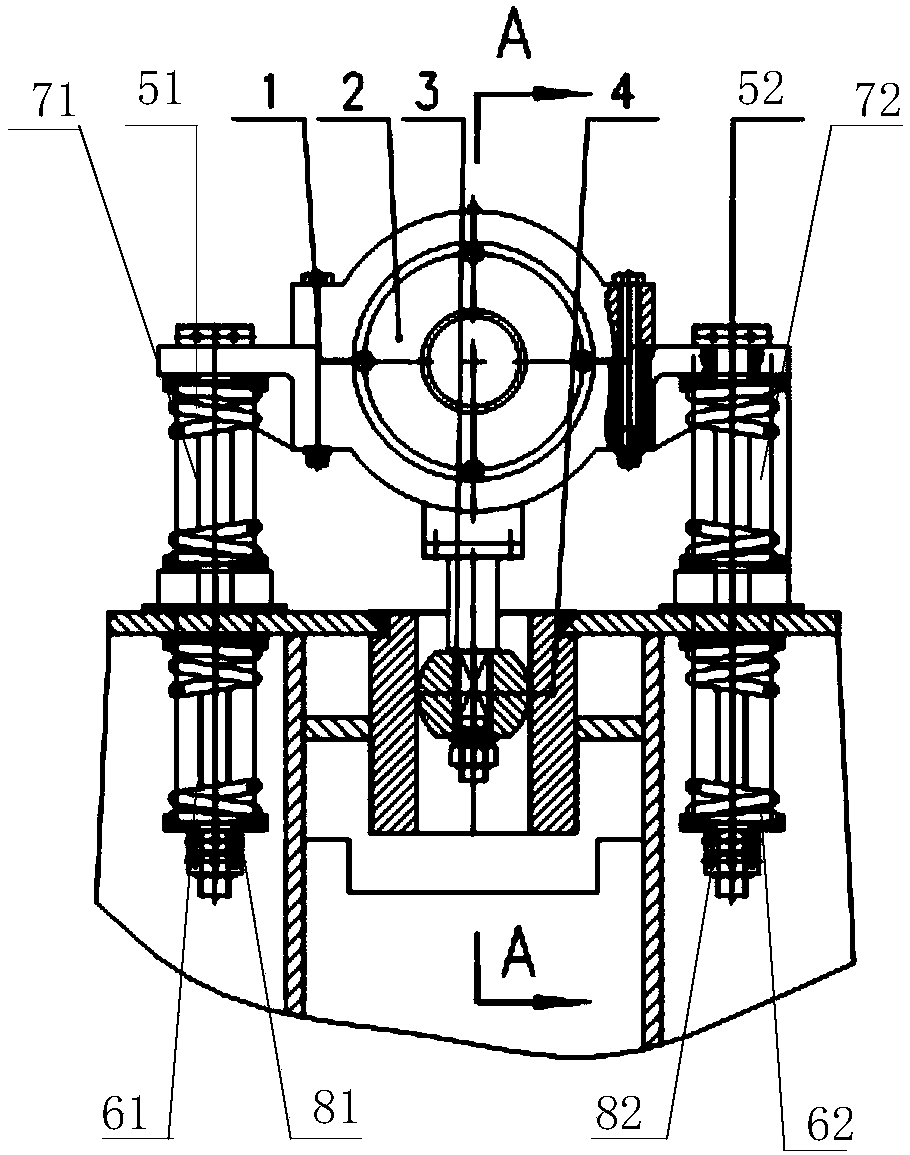

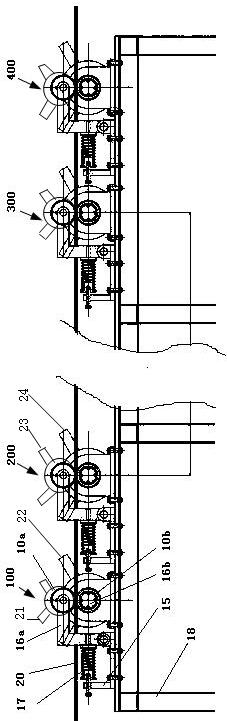

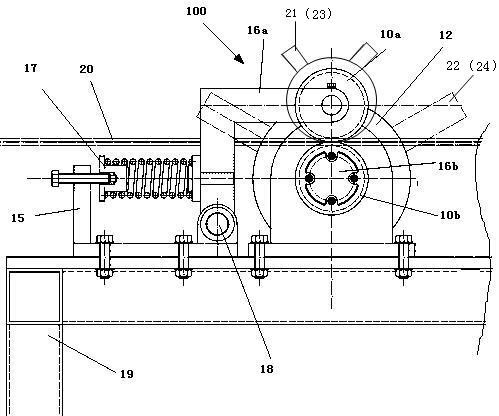

Flexible outlet-inlet guide and guard unit as well as guiding and guarding method

ActiveCN107931467APlay a buffer roleAvoid bumpingMetal-working feeding devicesPositioning devicesMarine engineeringStructural engineering

The invention provides a flexible outlet-inlet guide and guard unit as well as a guiding and guarding method. The device comprises a guide and guard mechanism, a guide and guard support, a spherical swing device, a first floating supporting piece and a second floating supporting piece, wherein the two sides of the guide and guard mechanism are supported on the guide and guard support in a floatingmode through the first floating supporting piece and the second floating supporting piece respectively, and the bottom of the guide and guard mechanism is coaxially and fixedly connected with the spherical swing device through a connecting piece; a cylindrical hole matched with the spherical swing device is formed in the guide and guard support, and the spherical swing device is located in the cylindrical hole and is in rolling contact with the inner wall of the cylindrical hole; and the spherical swing device is used for limiting the guide and guard mechanism to swing in the rolling range. According to the outlet-inlet guide and guard unit, a rigid guide and guard mechanism is replaced by the flexible guide and guard mechanism; when rolled materials enters the guide and guard unit, the guide and guard mechanism can be automatically adjusted in all directions according to the impact force of the rolled materials and a certain buffer effect can be realized, and therefore the roller materials can be prevented from colliding with the rigid guide and guard mechanism, and the surface smoothness of the rolled materials is improved.

Owner:SINOSTEEL XIAN MACHINERY

Drying device for spinning

InactiveCN105603653AImprove drying efficiencyImprove drying qualityTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsEngineeringMechanical engineering

The invention relates to the field of spinning, in particular to a drying device for spinning. The drying device can be used for drying and sterilizing textiles. The drying device structurally comprises a sealed working bin. A feed inlet and a discharge outlet are respectively formed in the left and right sides of the working bin. A blowing opening is formed in each of the four lateral walls of the working bin. The blowing openings are connected with an annular connecting pipe through blowing pipes. The annular connecting pipe is connected with the air outlet of a blower. The outer side of the blower is provided with an air inlet. A shower head is arranged above the right side of the feed inlet. The shower head is connected with a disinfectant storage tank fixed on the upper surface of the working bin through a liquid spraying pipe. The drying device has the advantages that the textiles can be dried and sterilized by the blowing of the lateral walls and the sterilizing of a secondary sterilizing device, and the device is simple to operate, convenient to use and applicable to various textiles.

Owner:SUZHOU HUIZHI TEXTILE CO LTD

Ribbed steel bar short-circuit heat treatment equipment and heating power supply thereof

PendingCN114774668AGood grain structureHigh tensile strengthConversion with intermediate conversion to dcFurnace typesBrushRebar

Ribbed steel bar short-circuit heat treatment equipment and a heating power supply thereof belong to the field of steel bar manufacturing. The reinforcing steel bar short-circuit heat treatment equipment comprises a plurality of modules, each module comprises two sets of reinforcing steel bar guide rollers, the two sets of reinforcing steel bar guide rollers are connected with a positive electrode and a negative electrode of a heating power source respectively, each set of reinforcing steel bar guide rollers comprises an upper roller and a lower roller, and carbon brush drums are fixedly arranged on the peripheries of rotating shafts of the upper roller and the lower roller respectively. The heating power supply is respectively communicated with the upper roller and the lower roller through the carbon brushes, and the positive electrode of the heating power supply and the negative electrode of the heating power supply are short-circuited through the reinforcing steel bars and simultaneously heat the reinforcing steel bars. The method can reduce heat loss, reduce production energy consumption, shorten production process length, reduce production cost, improve product performance indexes and improve product market competitiveness.

Owner:河南省鼎鼎实业有限公司

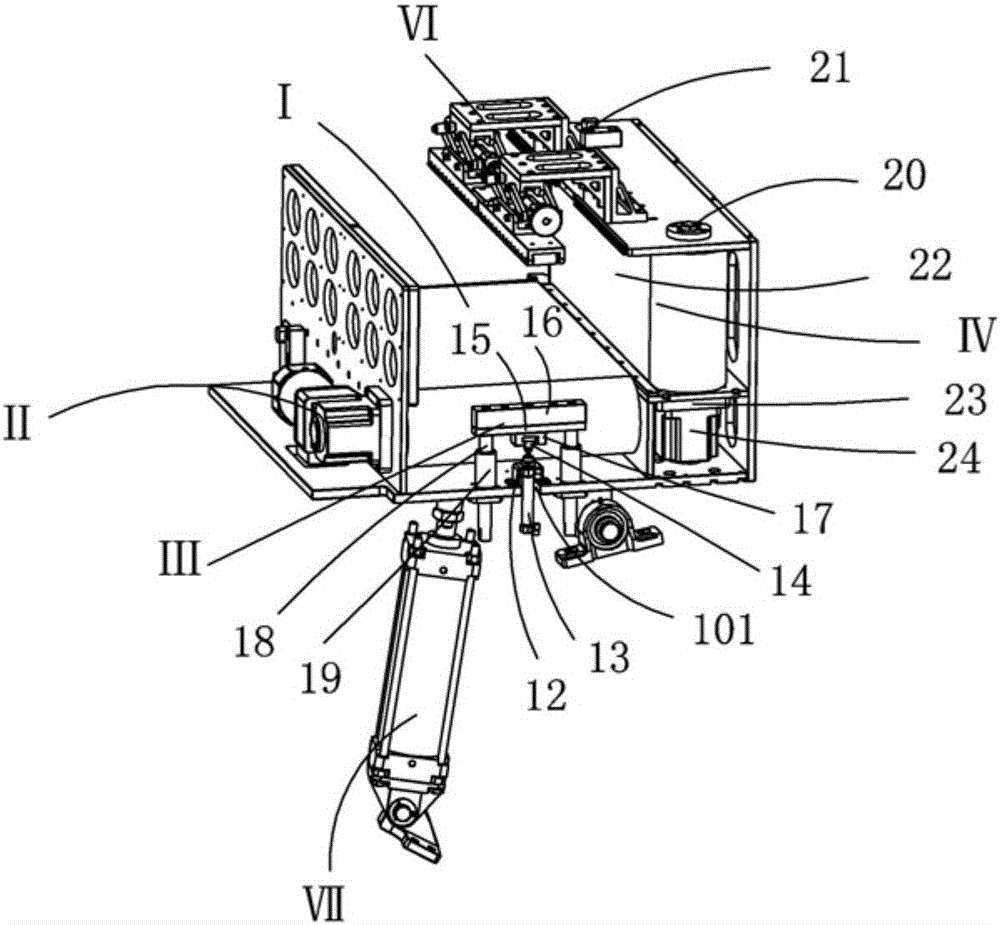

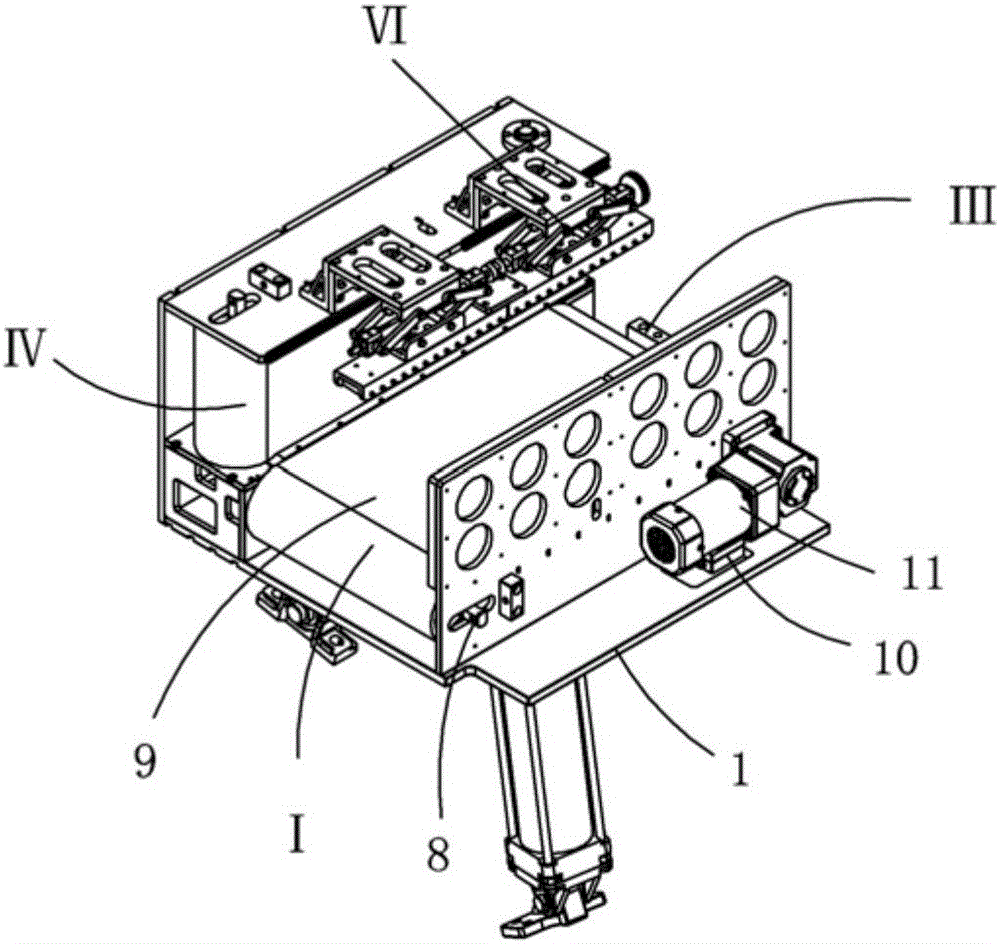

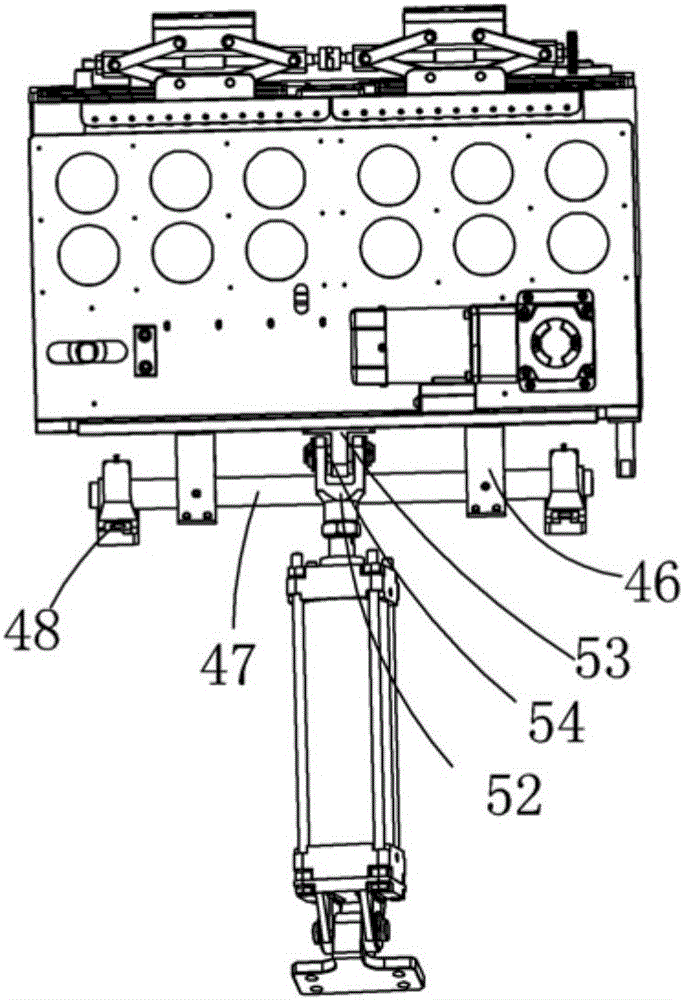

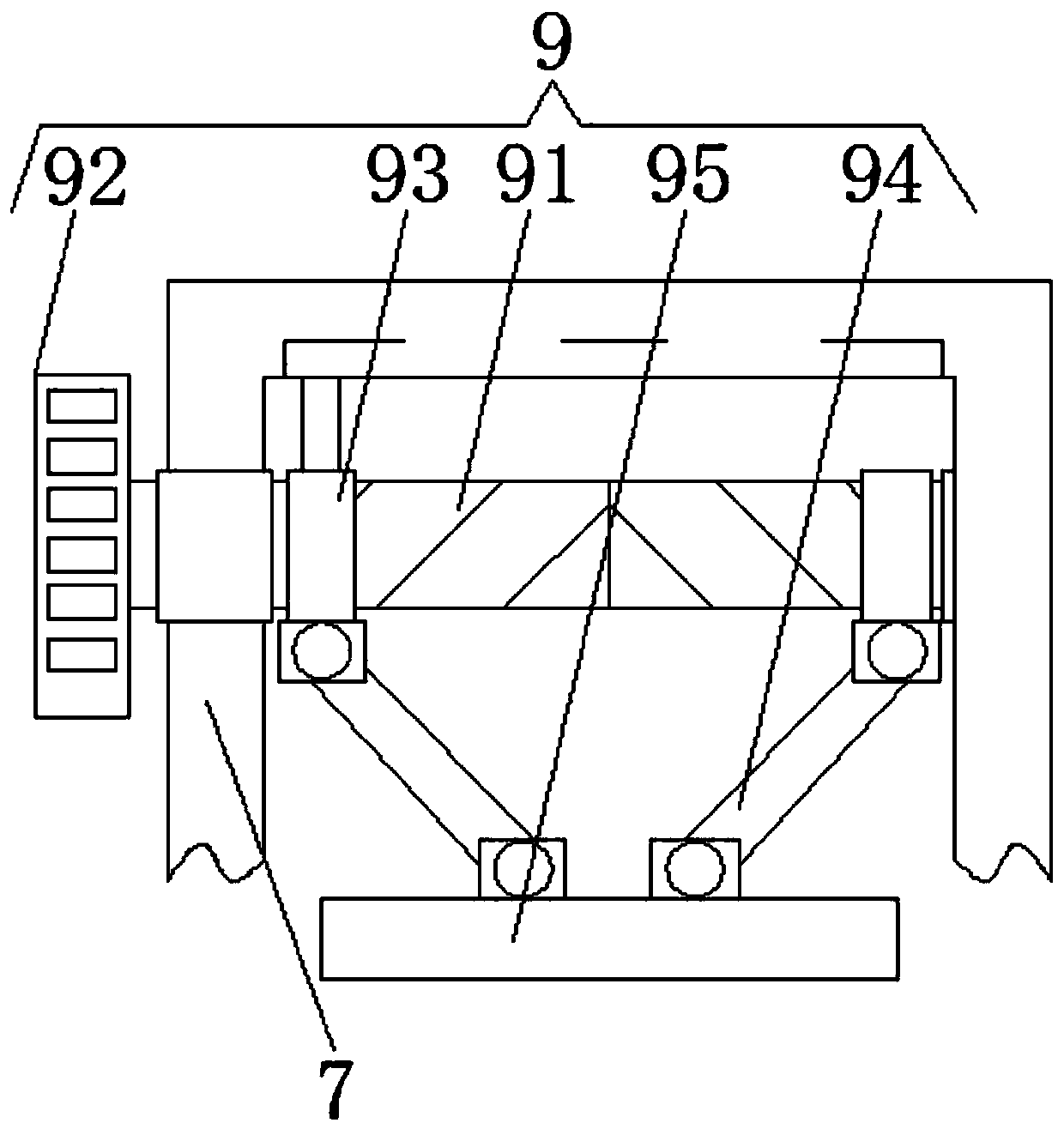

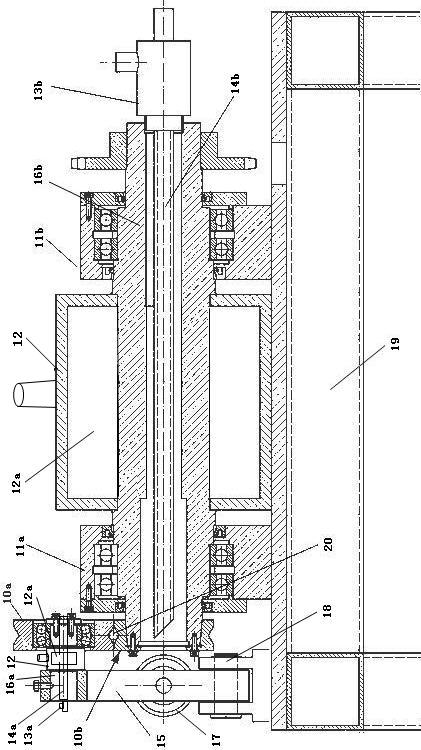

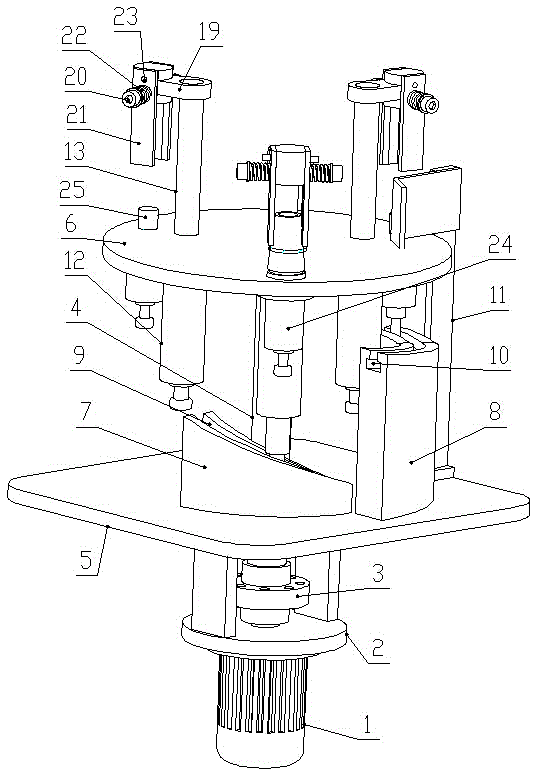

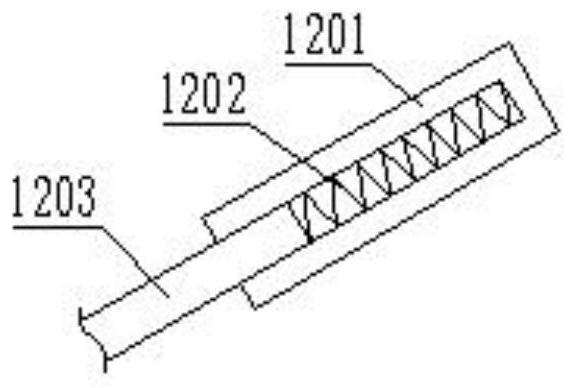

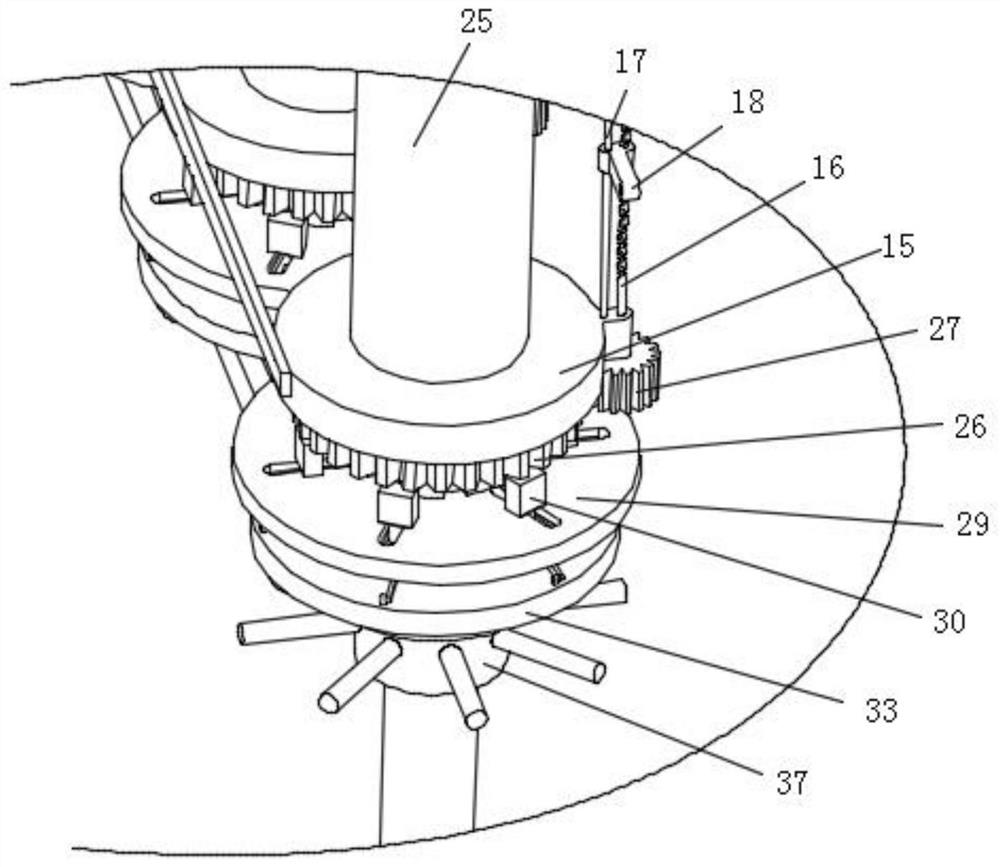

Automatic double-slide installing machine for installing clamping piece sleeves of anchor cables and anchorage devices

InactiveCN104816149AAdjust the degree of compressionPrevent rotationMetal working apparatusEngineeringManipulator

An automatic double-slide installing machine for installing clamping piece sleeves of anchor cables and anchorage devices comprises a servo motor, a motor base, a coupler, a transmission shaft, a fixing plate and a rotary table; an internal elastic guiding mechanism and an external elastic guiding mechanism are arranged on the rotary disc; the internal elastic guiding mechanism and an internal slide which are vertically corresponding are in slide fit; the elastic guiding mechanism and an external slide which are vertically corresponding are in slide fit; the upper end of the internal elastic guiding mechanism is provided with a manipulator mechanism; the manipulator mechanism is arranged above the internal elastic guiding mechanism. The automatic double-slide installing machine for installing the clamping piece sleeves of the anchor cables and the anchorage devices is simple in operation, stable in operation, simple and convenient to maintain, automatically achieves installation of the clamping pieces and greatly reduces the labor intensity.

Owner:HENAN POLYTECHNIC UNIV

A rice steamer

The invention discloses a rice steaming cabinet. The rice steaming cabinet comprises a cabinet body and a cabinet door. A hollow steam chamber is arranged inside the cabinet body. A sink is arranged at the bottom wall of the steam chamber, and an electric heating pipe is arranged inside the sink; a pair of rotating shafts are rotationally and horizontally connected to the interior of the cabinet body, and the rotating shafts are distributed at the upper and lower ends of the cabinet body, and a servo motor driving the rotating shafts to rotate is arranged at the outer wall of the cabinet body;the two ends of the rotating shafts are each provided with a gear, the two gears located at the same ends of the rotating shafts is wound by a chain, a plurality of uniformly-distributed supporting rods are horizontally arranged between the pair of chains, a hanging bracket is rotationally connected to each of the two ends of the supporting rods, and trays are arranged between the pair of hangingbrackets. The rice steaming cabinet has the advantages that by arranging the trays capable of rotating inside the steam chamber, each tray can make contact with high heat at the bottom of the steam chamber, and therefore each tray is heated more uniformly, and it is ensured that rice inside each tray can be cooked at the same time. Meanwhile, the rice cooking time is shortened, energy dissipationis saved, and the effect of saving energy is achieved.

Owner:浙江广博厨房设备有限公司

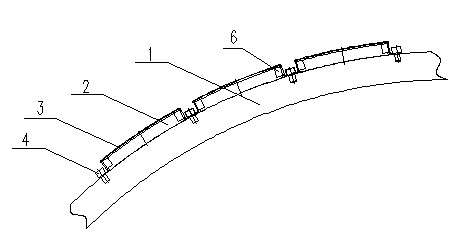

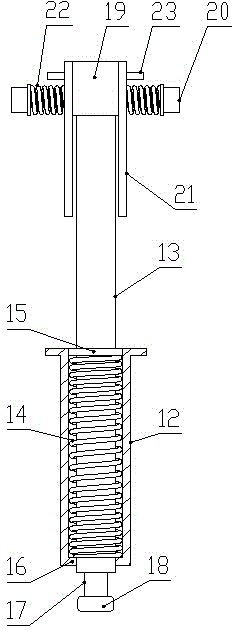

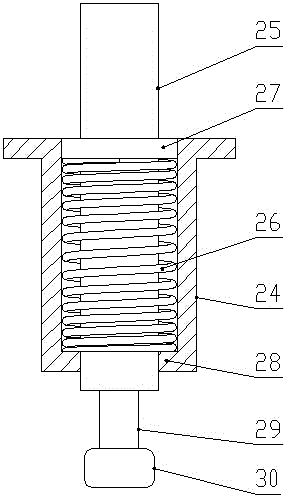

Application of welding preheating device

ActiveCN106514075AAdjust the degree of compressionEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineeringWelding joint

The invention discloses application of a welding preheating device, and belongs to the technical field of welding preheating. According to the application of the welding preheating device, the welding preheating device comprises a body, wherein the body comprises a positioning mechanism, a preheating mechanism and an adjustment mechanism, the positioning mechanism is arranged below the weld joint side, the preheating mechanism is arranged on the bottom end face close to a weld joint, and the adjustment mechanism is connected between the positioning mechanism and the preheating mechanism and used for adjusting the pressing degree of the preheating mechanism and the bottom end face of the weld joint; and the application of the welding preheating device comprises the step of assembling, the step of mounting and adjustment, and the step of dismounting. According to the application of the welding preheating device, the preheating mechanism is positioned in the position close to a preheated object through the positioning mechanism, the adjustment mechanism is used for adjusting the preheating mechanism and the pressing degree of the preheated object and the preheating mechanism, and thus the technical problem that the preheating time or temperature cannot be controlled easily is effectively solved.

Owner:ANHUI MASTEEL ENG & TECH GRP

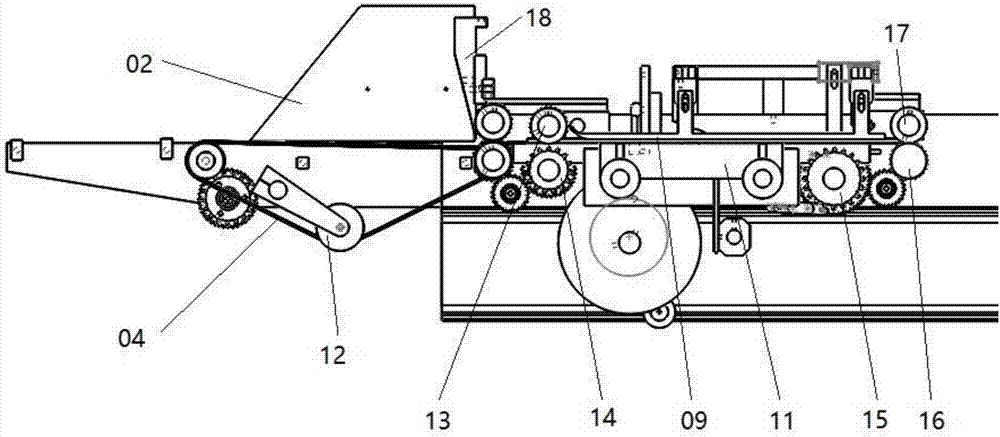

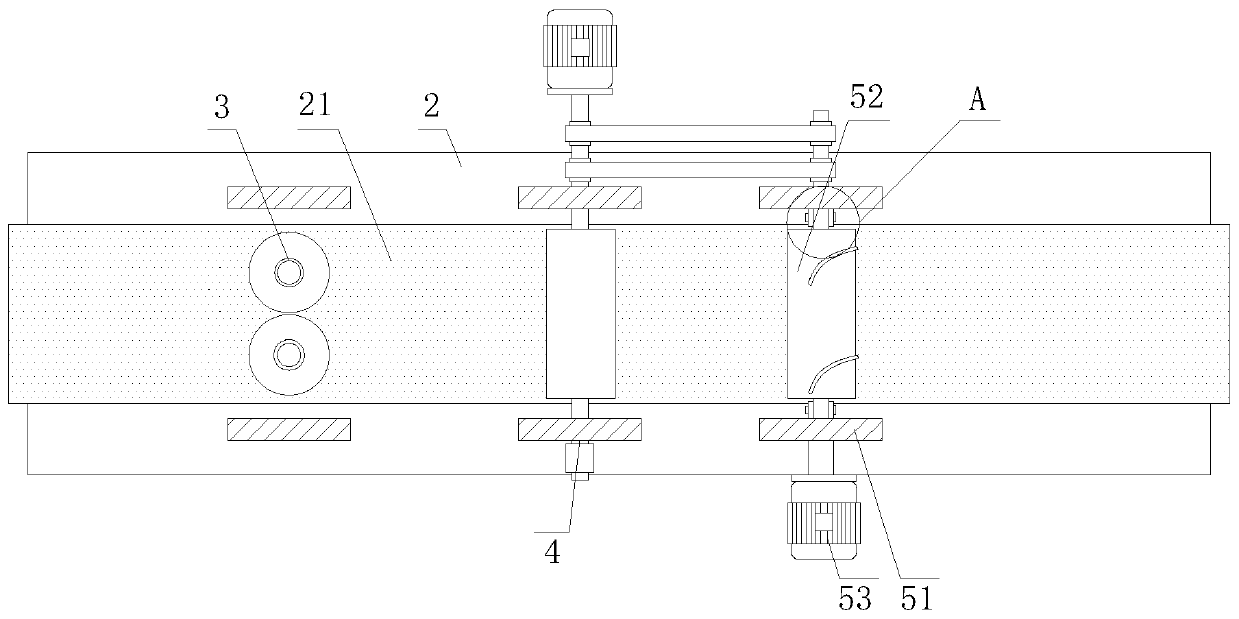

Automatic alignment paper feeding mechanism of die cutting machine

InactiveCN106985207ASimple structureGuaranteed to proceed normallyMetal working apparatusCardboardEngineering

The invention provides an automatic alignment paper feeding mechanism of a die cutting machine. The automatic alignment paper feeding mechanism comprises a support. The front end of the support is provided with feeding belts. An alignment plate is arranged in the position, located above the feeding belts, of the support. A feeding stop block is arranged in the position, located above the tail ends of the feeding belts, of the support. A conveyor belt is arranged in the position, located behind the feeding belts, of the support. Fixed alignment blocks and movable alignment blocks are arranged above the conveyor belt. The movable alignment blocks are fixedly connected to a sliding block. The sliding block is slidably connected to the support. The support is provided with a crank. The sliding block is in transmission connection with the crank through a connecting rod. A pressing rod is arranged above the conveyor belt. The automatic alignment paper feeding mechanism is simple in structure. A stack of paperboards leans against the alignment plate to be positioned and is fed onto the conveyor belt through the feeding belts. The feeding stop block is arranged in the position, located above the tail ends of the feeding belts, of the support so as to guarantee that only a piece of paperboard is fed in. The movable alignment blocks enable the paperboards to be aligned and then to be input to a rolling and cutting device, and normal operation of rolling and cutting is guaranteed.

Owner:东台世恒机械科技有限公司

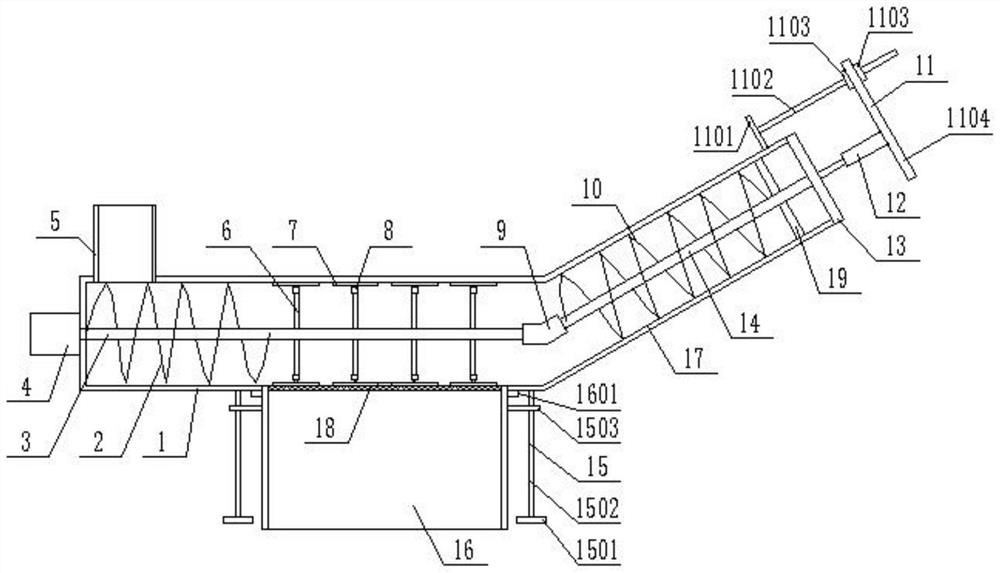

Roxburgh rose beverage processing equipment and use method thereof

InactiveCN112046053AAdjust the degree of compressionMeet crushing needsPressesSpiral bladeStructural engineering

The invention discloses roxburgh rose beverage processing equipment and a using method thereof. The roxburgh rose beverage processing equipment comprises a conveying barrel, wherein the end part of the conveying barrel is connected with a squeezing barrel inclining upwards, a conveying shaft is rotationally arranged inside the conveying barrel, and a conveying spiral blade and cutters are sequentially arranged on the outer side of the conveying shaft; a driving motor is connected to the end part, far away from the squeezing barrel, of the conveying barrel, a filter box and a lifting assembly are arranged at the bottom, close to the squeezing barrel, of the conveying barrel, and a filter screen is arranged at the upper end of the filter box; and a squeezing shaft is arranged inside the squeezing barrel, the squeezing shaft is connected with the conveying shaft through a universal coupling, and the outer side of the squeezing shaft is connected with an squeezing spiral blade. The roxburgh rose beverage processing equipment and the using method thereof have the beneficial effects that the distance between an elastic supporting and ejecting rod and the squeezing barrel is adjusted through a distance adjusting assembly, so that the squeezing degree is adjusted, and the non-passing squeezing requirement is met; and lifting of the filter box is conveniently achieved through the lifting assembly, so that the filter screen is conveniently cleaned, operation is easy and convenient, and the using effect is good.

Owner:贵州天刺力生物科技有限责任公司

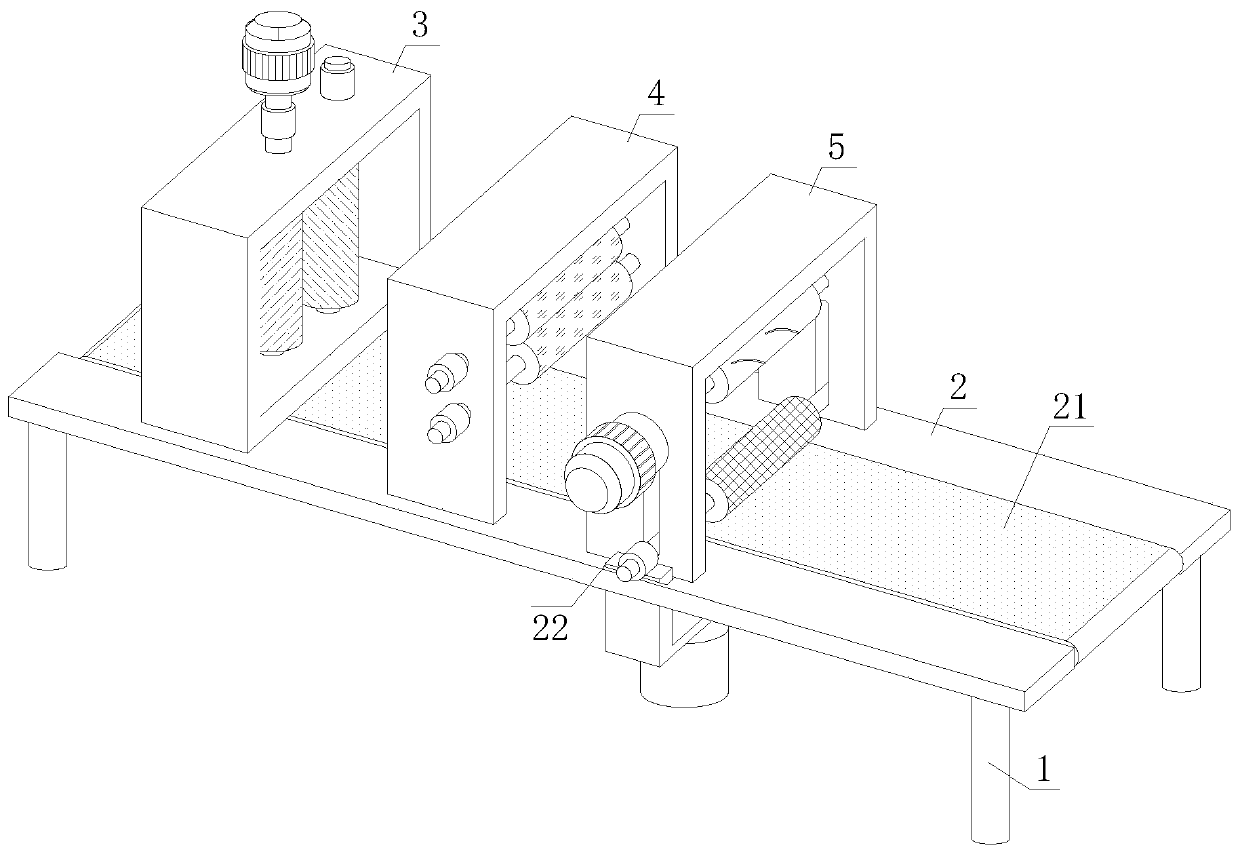

Roller-type cutting tool and method of medical folding mask

InactiveCN111409257AImprove flatnessAvoid wrinklesDomestic articlesMetal working apparatusEngineeringConveyor belt

The invention discloses a roller-type cutting tool and method of a medical folding mask, belonging to the technical field of medical folding mask cutting. The roller-type cutting tool of the medical folding mask comprises a support frame; a worktable is fixed on the support frame; a conveyor belt is arranged in the middle of the worktable; a guide device, a horizontal pressing fixing device and acutting device are arranged above the worktable; the horizontal pressing fixing device is arranged at the lateral end of the guide device; and the cutting device is arranged at the lateral end of thehorizontal pressing fixing device. The roller-type cutting tool and method of the medical folding mask disclosed by the invention shapes the material, which is convenient for subsequent cutting; two sets of cutting blades are arranged to cut two sets of materials at the same time, which improves the cutting efficiency, increases the production speed, and reduces the production costs; and the degree of compression between a butt roller and a cutting roller can be adjusted according to requirements, which increases the schedulability in production, reduces the wear of the blade while ensuring the quality of the produced product, increases the service life of the blade, facilitates replacement and maintenance, and avoids the occurrence of bad products produced due to blade aging and wear.

Owner:MAANSHAN HENGLIDA MACHINE BLADE

Textile equipment facilitating thread residue cleaning

InactiveCN112831898AAvoid unqualifiedAvoid thread ends entering the textile machine and cause unqualifiedLoomsAuxillary apparatusElectric machineryEngineering

The invention discloses textile equipment facilitating thread residue cleaning, and relates to the field of textiles. The textile equipment comprises a bottom box; a working plate is fixedly mounted on the top side of the bottom box; an absorption hole is formed in the top side of the working plate; a textile machine is fixedly mounted on the top side of the working plate; a storage box is fixedly mounted on the bottom side of the working plate; and the storage box is matched with the absorption hole in position and size. According to the textile equipment, a motor is started to drive a telescopic rod to reciprocate at a high speed, the telescopic rod moves to drive a vibration rod to vibrate at a high speed, so that doubling threads can be driven to swing at a high frequency, thread ends attached to the doubling threads are shaken off, and the thread ends can be further brushed off under the action of a hair removal soft brush; and an exhaust fan adsorbs the fallen thread residues into the storage box through the air bellow to complete cleaning, and the situation that the thread residues enter the textile machine, consequently, the finished cloth has the thread residues or leaks, and the cloth is unqualified can be avoided.

Owner:广州同畅装饰业有限公司

Train loading carriage precise locating device and locating method

ActiveCN111776786ASimple structureThe principle is simpleTrain hauling devicesLoading/unloadingControl cellCarriage

The invention discloses a train loading carriage precise locating device and locating method. The device includes a track scale, and a train weighing detector, and further includes a train loading vehicle location detector, and a control unit. Carriages are pulled through a winch and a wire rope, and the railroad track scale, the train weighing detector, the winch, and the train loading vehicle location detector are connected with the control unit separately. The method includes the steps that the carriages move, the train weighing detector detects that the carriages get on the track scale, adetection numerical value of the train loading vehicle location detector is defined as an on-scale zero location, the moving length of the wire rope detected by the train loading vehicle location detector from the on-scale zero location is a moving distance of the whole carriages, and the locations of the carriages can be controlled through the winch. The locating device has the advantages that the precise locating of the carriages can be achieved, the statement of error accumulation in the prior art is prevented, and the precise locating of the locations of the carriages during loading can beguaranteed.

Owner:HUAIBEI MINING IND +1

Particle quantitative packing device

InactiveCN111846304AAdjust the degree of compressionProduction packaging quantity standard is fixedSolid materialGear wheelEngineering

The invention discloses a particle quantitative packing device. The particle quantitative packing device comprises a main body box; a material barrel working cavity is disposed in the main body box; acommunicating cavity is disposed on the lower side of the material barrel working cavity in a communicating mode; a material conveying cavity is disposed on the lower side of the communicating cavityin a communicating mode; a packaging bag storing cavity is disposed on the lower side of the material conveying cavity in a communicating mode; a gear moving cavity which communicates with the material barrel working cavity is disposed on the lower side of the material barrel working cavity and on the left side of the communicating cavity; a conveying power cavity which extends leftwards is disposed on the lower side of the gear moving cavity; and a pressure-regulating direction-change cavity is disposed on the lower side of the conveying power cavity. The weight of a particle product can besensed through a pressure-bearing spring, thus quantitative discharging is achieved, the quantitative packaging effect is achieved, the production packaging quantity of the particle product is more standard and fixed, and meanwhile the packaging labor amount is reduced; and on the other hand, the compression degree of the pressure-bearing spring can be adjusted through a rotating handle, thus theset sensed weight can be adjusted, the weighing and packaging weight can be adjusted, and the effect of improving the universality is achieved.

Owner:ZHUJI TAIHE PACKING MATERIAL CO LTD

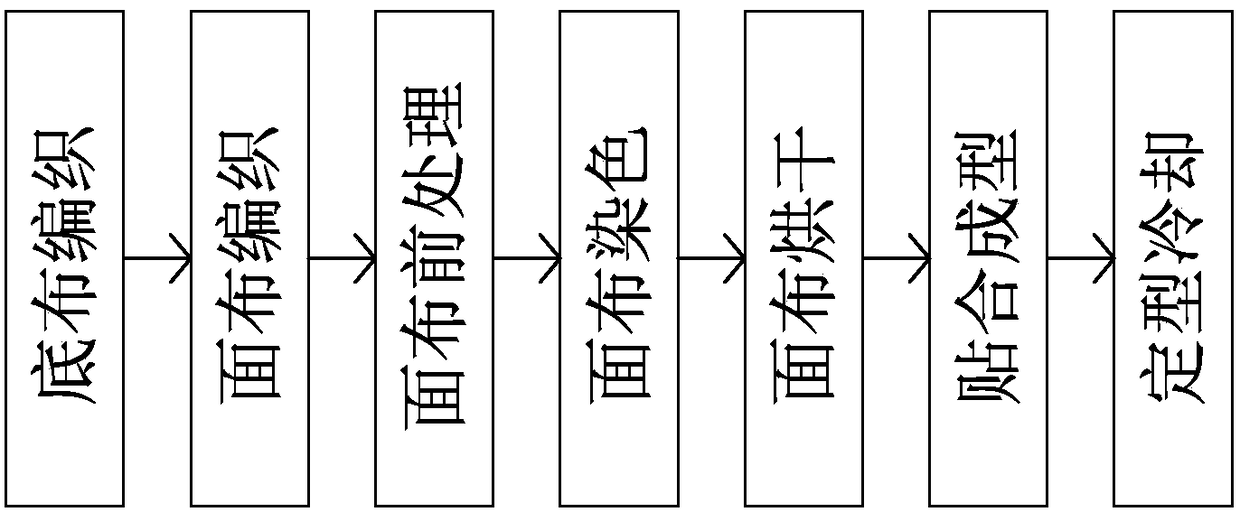

Manufacturing process of antibacterial linen composite fabric

InactiveCN108442126AManufacturing process advantagesAntibacterial hasSingeingLiquid/gas/vapor removalYarnPolyester

The invention provides a manufacturing process of an antibacterial linen composite fabric, belongs to the technical field of fabrics, and solves the problem of low production quality in the prior art.The manufacturing process of the antibacterial linen composite fabric comprises the following steps: a, base fabric weaving, to be more specific, weaving polyester yarns into a base fabric, and applying an antibacterial coating to the base fabric through a coating machine; b, surface fabric weaving, to be more specific, weaving wool and linen into a surface fabric; c, surface fabric pretreatmentincluding singeing and biological enzyme treatment; d, surface fabric dyeing, to be more specific, putting the surface fabric of the step c into a dyeing tank for dyeing; e, surface fabric drying , tobe more specific, putting the surface fabric of the step d into a drying device for drying; f, bonding and forming, to be more specific, bonding the base fabric of the step a with the surface fabricof the step e into a semi-finished fabric; and g, stetting and cooling, to be more specific, setting the semi-finished fabric by a fabric setting machine to form the finished antibacterial linen composite fabric. The manufacturing process has the advantages of good manufacturing quality.

Owner:海宁星皓进出口有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com