Reaction type crushing device for coal mine

An impact crushing and coal mine technology, applied in grain processing and other directions, can solve the problems that the distance between the blow hammer and the impact plate cannot be adjusted, and the relative distance and inclination cannot be adjusted at the same time, so as to improve the applicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

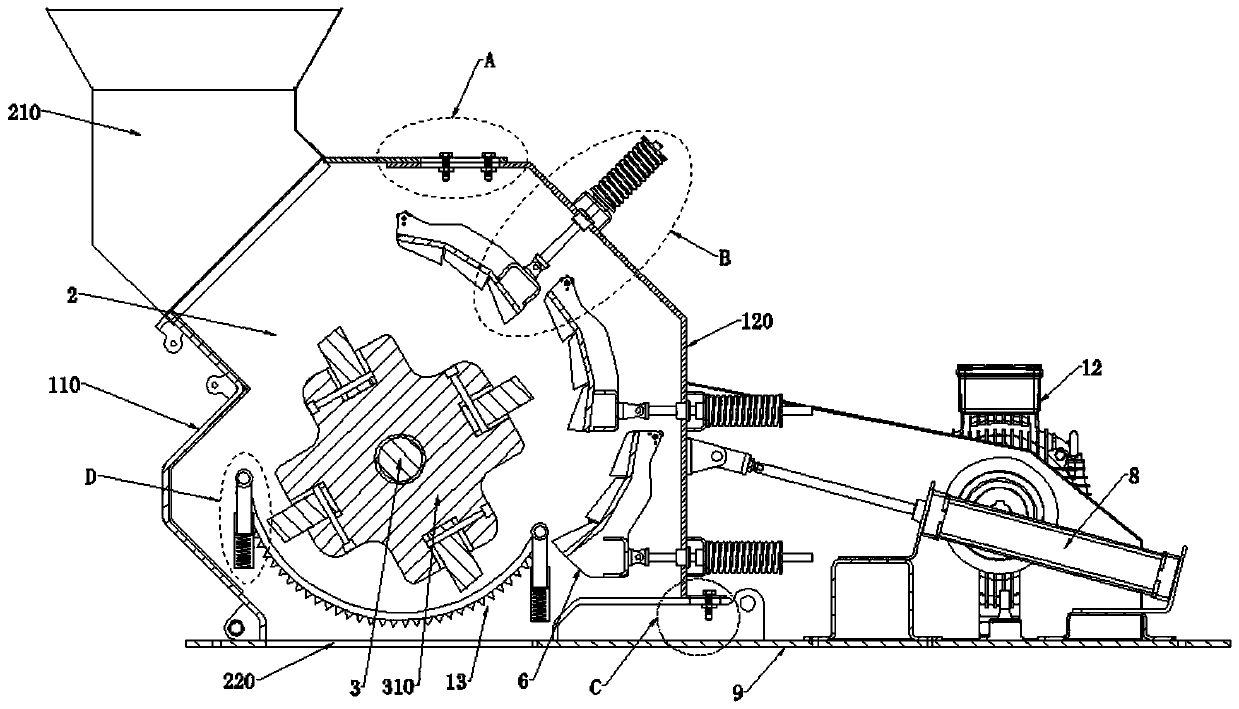

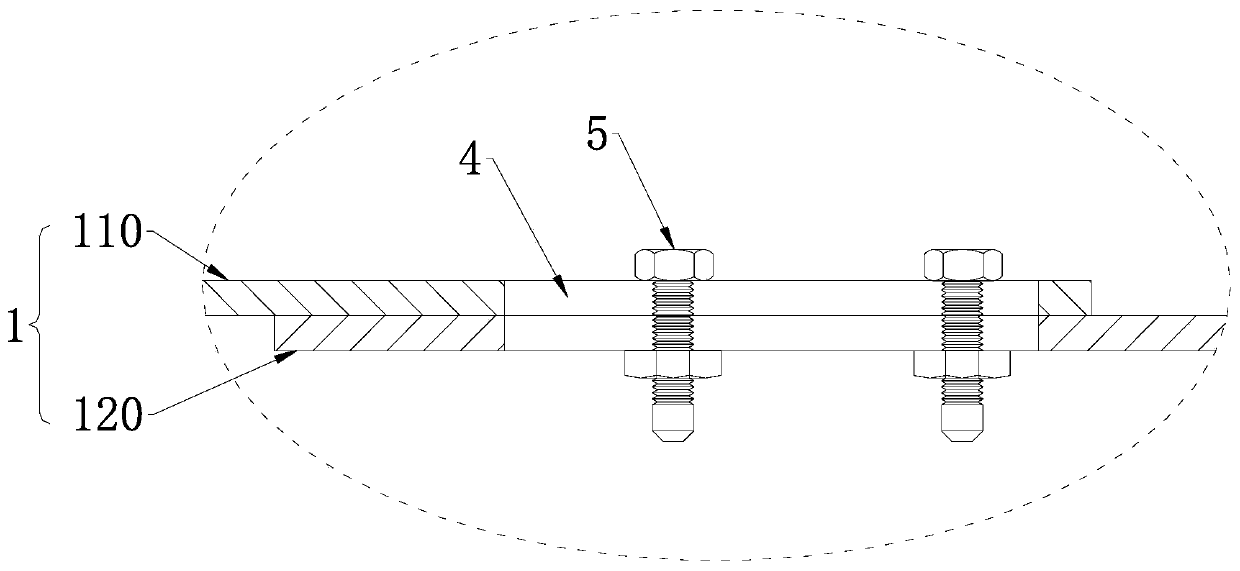

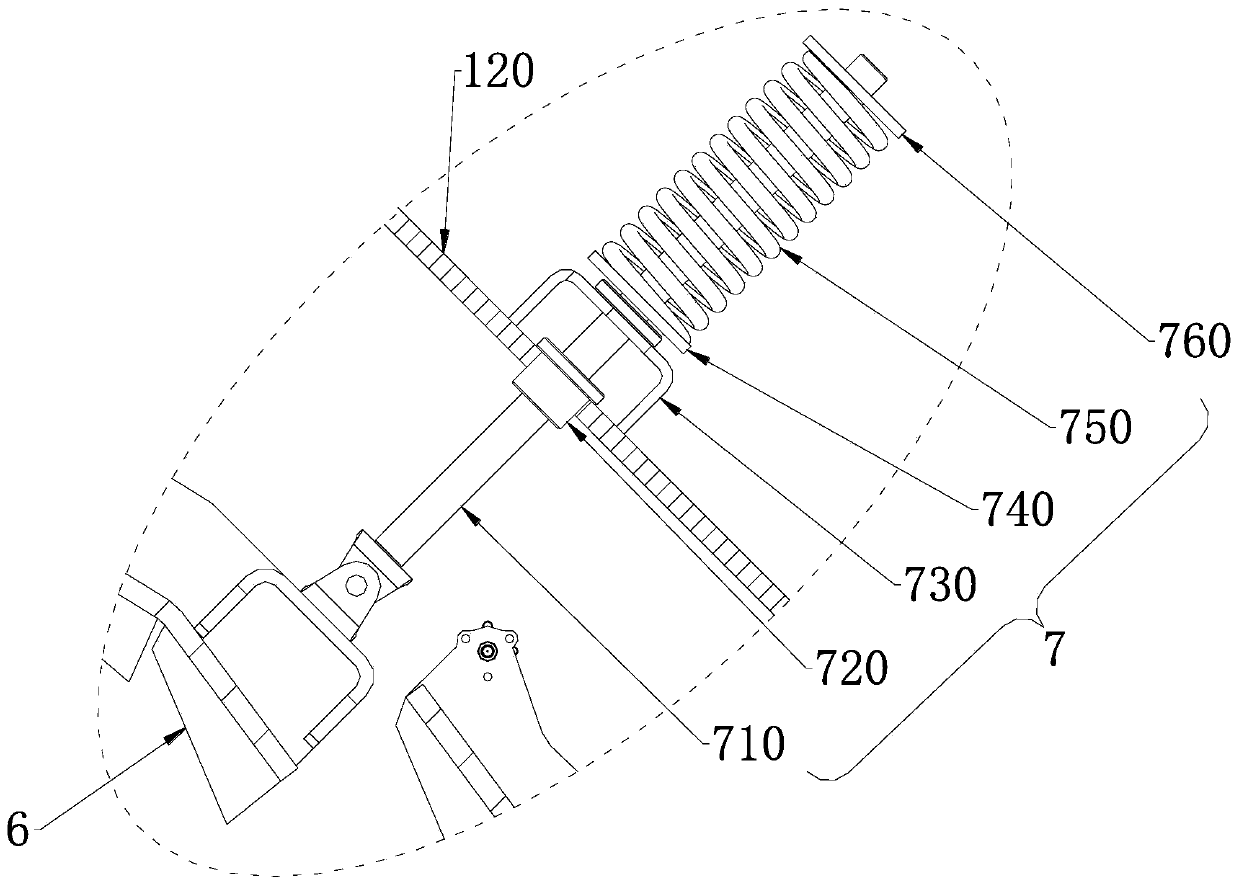

[0039] The impact crushing device for coal mines of the present invention includes a shell body 1, the upper end of the shell body 1 is provided with a feed port 210, the lower end of the shell body 1 is provided with a discharge port 220, and the shell body 1 includes a first shell Body 110 and second housing 120, one side of the first housing 110 is open, the second housing 120 blocks the opening of the first housing 110, the first housing 110 overlaps with the second housing 120, The first shell 110 and the second shell 120 are overlapped by a guide groove 4, and the guide groove 4 is equipped with a fixing assembly 5. The first shell 110 and the second shell 120 are buckled together to form a crushing chamber 2. A rotor 3 is installed in the cavity 2, and the rotor 3 is set with a blow bar 310. One end of the rotor 3 is connected to the first housing 110 in rotation, and the other end of the rotor 3 penetrates the outer wall of the first housing 110 and is connected with a ...

Embodiment 2

[0042] This embodiment is further optimized on the basis of Embodiment 1 as follows: the upper end and the front and rear ends of the second housing 120 are overlapped with the first housing 110, and the second housing 120 is overlapped with the first housing 110. A plurality of guide grooves 4 are arranged at the joints, and a fixing component 5 is arranged in any guide groove 4 .

[0043] After adopting the above technical solution: the upper end and the front and rear ends of the second housing 120 are provided with side plates, when the second housing 120 is installed with the first housing 110, the upper end and the front and rear ends of the second housing 120 are both It is overlapped with the first housing 110, and the overlapped part is quickly fixed and disassembled by the fixing assembly 5 and the guide groove 4, so as to realize stepless adjustment; as an idea, multiple guide grooves 4 can be arranged at intervals, and each guide groove 4 A plurality of fixing comp...

Embodiment 3

[0045] This embodiment is further optimized on the basis of Embodiment 1 as follows: the lower end of the housing body 1 is provided with a placement plate 9, the placement plate 9 is provided with an opening aligned with the discharge port 220, and the lower end of the second housing 120 Bending to the side away from the crushing chamber 2 to form a positioning plate 11, a support plate 10 is provided between the placement plate 9 and the positioning plate 11, and a guide groove 4 is also opened through the support plate 10 and the positioning plate 11, and the guide groove 4 is also provided There are fixed components 5. The guide groove 4 is a waist-shaped groove, and the fixing assembly 5 is a bolt assembly.

[0046] After adopting the above technical solution: the lower end of the second housing 120 is bent outward to form a positioning plate 11, and the positioning plate 11 and the support plate 10 are also fixed by the cooperation of the fixing assembly 5 and the guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com