Flame spraying method for high melting metal skin flexible ceramic wire

A technology of high melting point metal and flexible ceramics, applied in metal material coating process, melt spraying, coating and other directions, can solve the problems of complex manufacturing process, high import price and limited length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

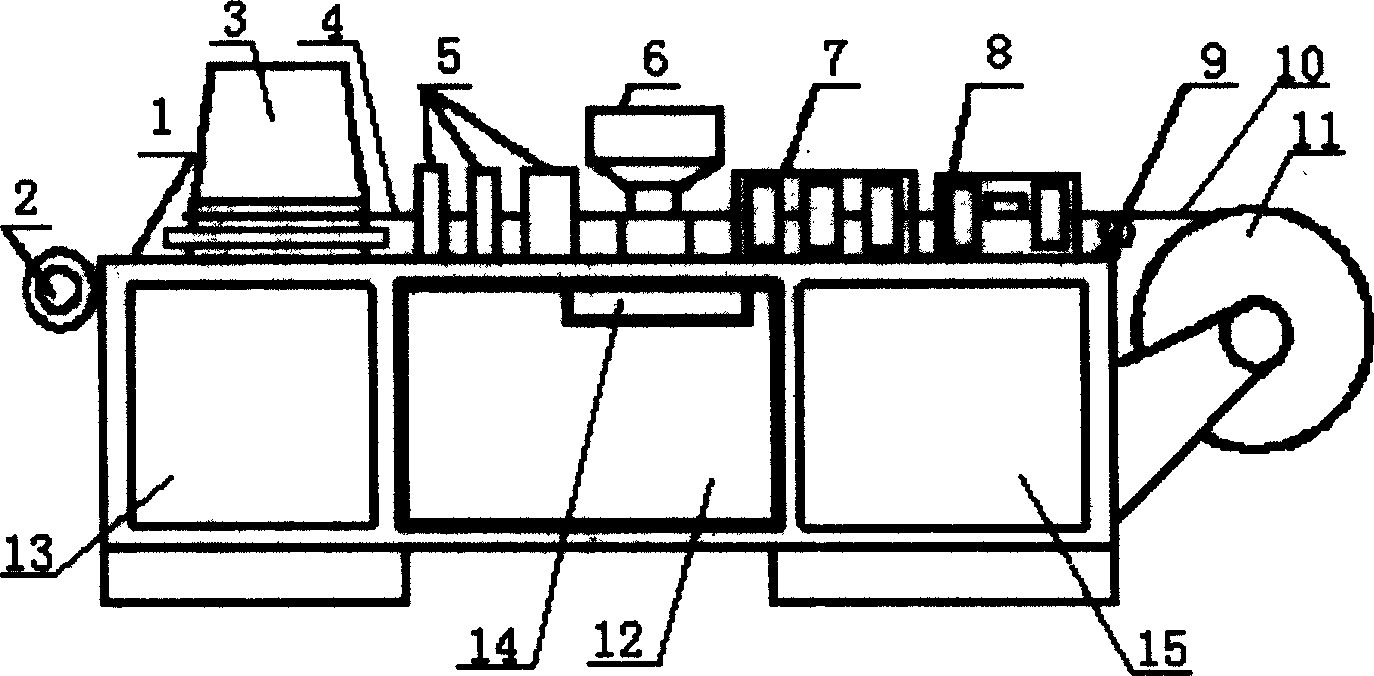

[0005] Specific Embodiment 1: This embodiment is achieved in the following way: a. Preparation of drug core: the drug core powder composed of a mixture of binder powder and additive powder and ceramic powder is fully mixed and stirred with a high-energy ball mill, wherein the ceramic powder accounts for the drug core. 55-90% of the total weight of the powder, and the mixture of binder powder and additive powder accounts for 10-45% of the total weight of the core powder; In the device of the functional system, put the uniformly stirred drug core into the drug core powder injection device of the wire making machine, start the machine to draw the wire, and make a tubular drug core wire. After the wire is drawn, the finished wire is guided from the wire drawing hub Put it on the finished wire reel for use; c. Surface treatment: use a sandblasting machine to roughen the shaft diameter of the sprayed part of the crankshaft; d. Assembly: install a flame spraying wire feed wheel with k...

specific Embodiment approach 2

[0006] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the ceramic powder accounts for 55-85% of the total weight of the drug core powder, and the mixture of binder powder and additive powder accounts for 15-45% of the total weight of the drug core powder. %, the material of the coating is Q235, and the ceramic powder is WC, Al 2 o 3 , ZrO 2 or Cr 2 o 3 , the mixture of the binder powder and the additive powder is Ni, Al, Co, TiO 2 , Y 2 o 3 and any mixture of Ti. Other process parameters and reaction steps are the same as in Embodiment 1. The technical data of the flexible ceramic wire in this embodiment is shown in Table 1.

specific Embodiment approach 3

[0007] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the ceramic powder accounts for 65-90% of the total weight of the drug core powder, and the mixture of binder powder and additive powder accounts for 10-35% of the total weight of the drug core powder. %, the material of the coating is Ni, and the ceramic powder is WC, Al 2 o 3 , ZrO 2 or Cr 2 o 3 , the mixture of the binder powder and the additive powder is Al, Co, TiO 2 , Y 2 o 3 One or any mixture of Ti and Ti. Other process parameters and reaction steps are the same as in Embodiment 1.

[0008] The technical data of the flexible ceramic wire in this embodiment is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com