Textile equipment facilitating thread residue cleaning

A technology for textile equipment and thread ends, which is applied in the field of textile equipment for easy cleaning of thread ends, and can solve problems such as unqualified fabrics, leakage holes, interweaving and winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

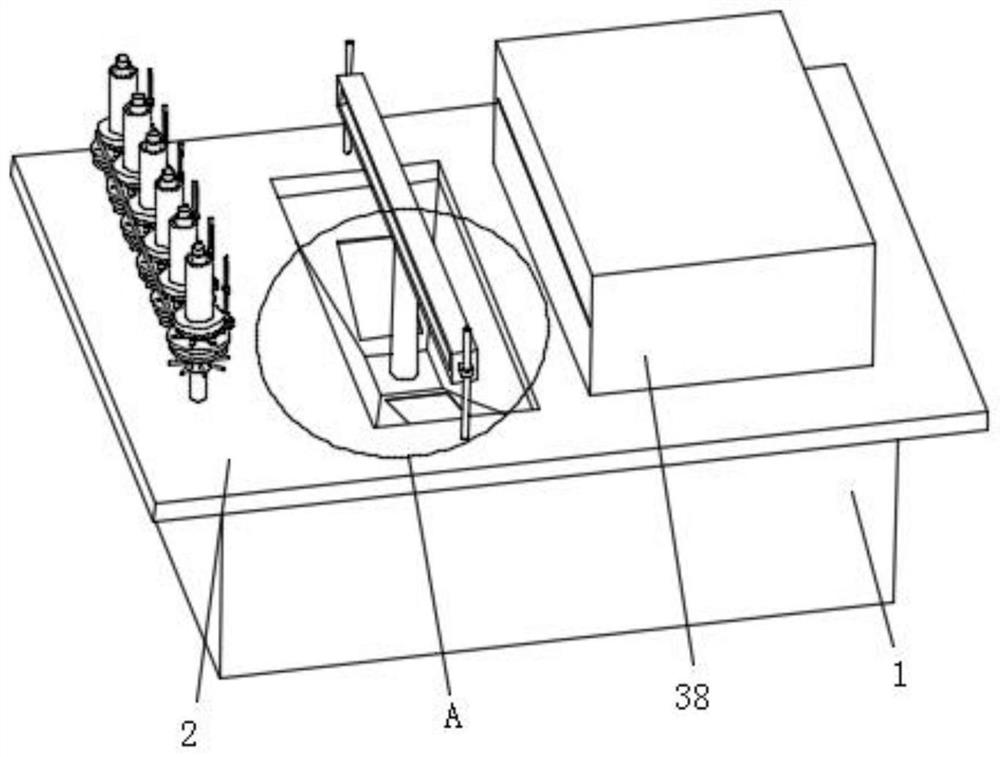

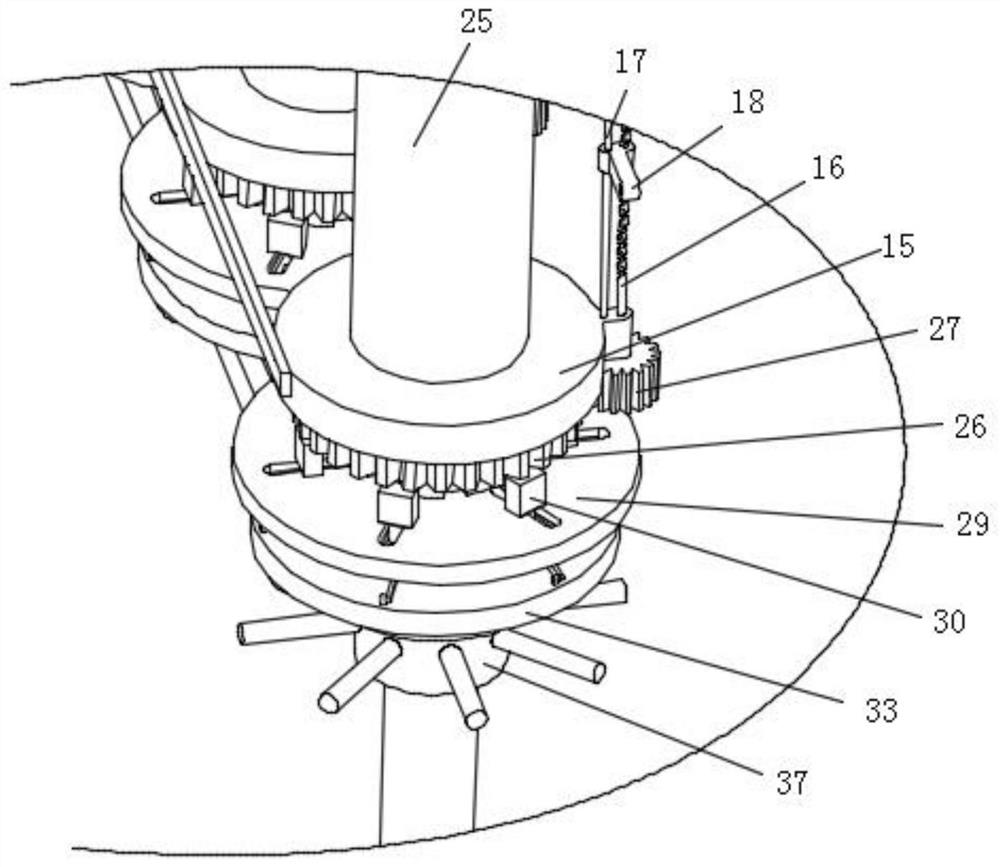

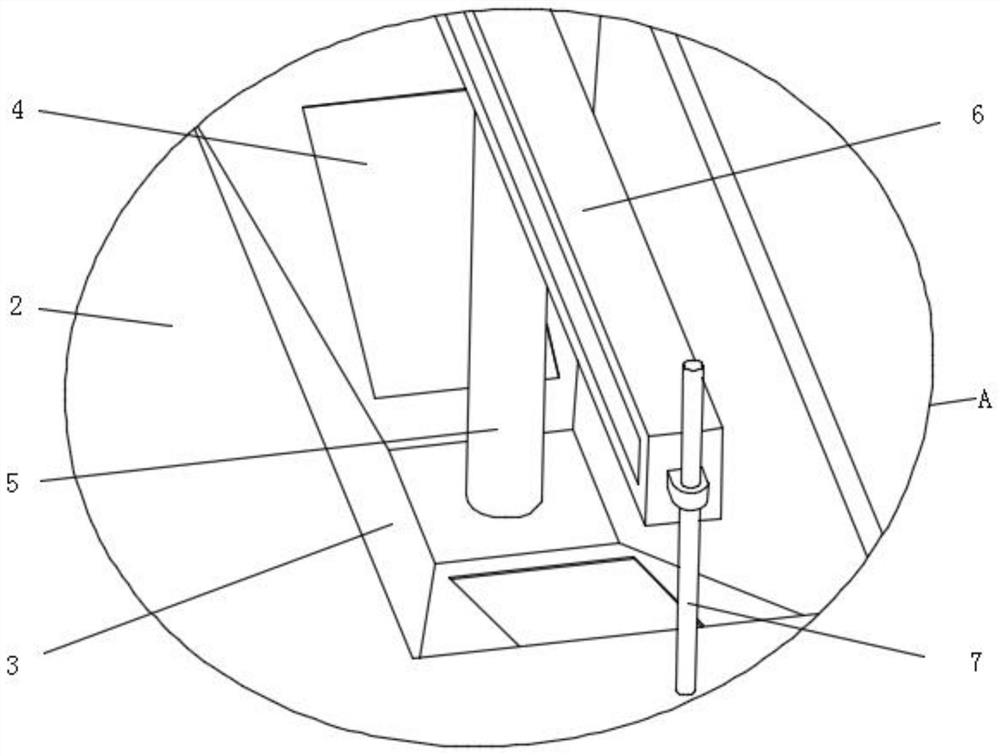

[0042] Example: Reference Figure 1-8 A kind of textile equipment that is convenient for cleaning thread ends is shown, including a bottom box 1, a working plate 2 is fixedly installed on the top side of the bottom box 1, and the working plate 2 is fixed by welding with the top side of the bottom box 1, and the top side of the working plate 2 Offer absorption hole, the top side of work plate 2 is fixedly installed with textile machine 38, and the bottom side of work plate 2 is fixedly installed with storage box 3, and the position and the size of storage box 3 and absorption hole are adapted, and the top side of work plate 2 Two sliding rods 7 are fixedly installed on the side, and the sliding rods 7 are fixed by welding with the top side of the working plate 2. The same vibration rod 6 is movably socketed on the two sliding rods 7, and a vibration groove is opened on one side of the vibration rod 6. , the vibrating groove top side inner wall and the bottom side inner wall are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com