Train loading carriage precise locating device and locating method

A technology for precise positioning and compartments, applied in the direction of railway vehicle traction devices, measuring devices, loading/unloading, etc., can solve problems such as inaccurate positioning of compartments, and achieve reliable detection, high precision, and easy access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

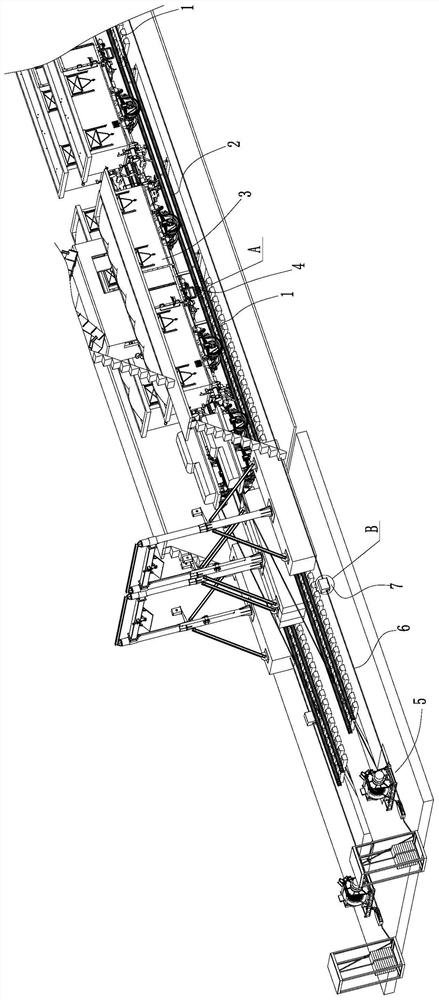

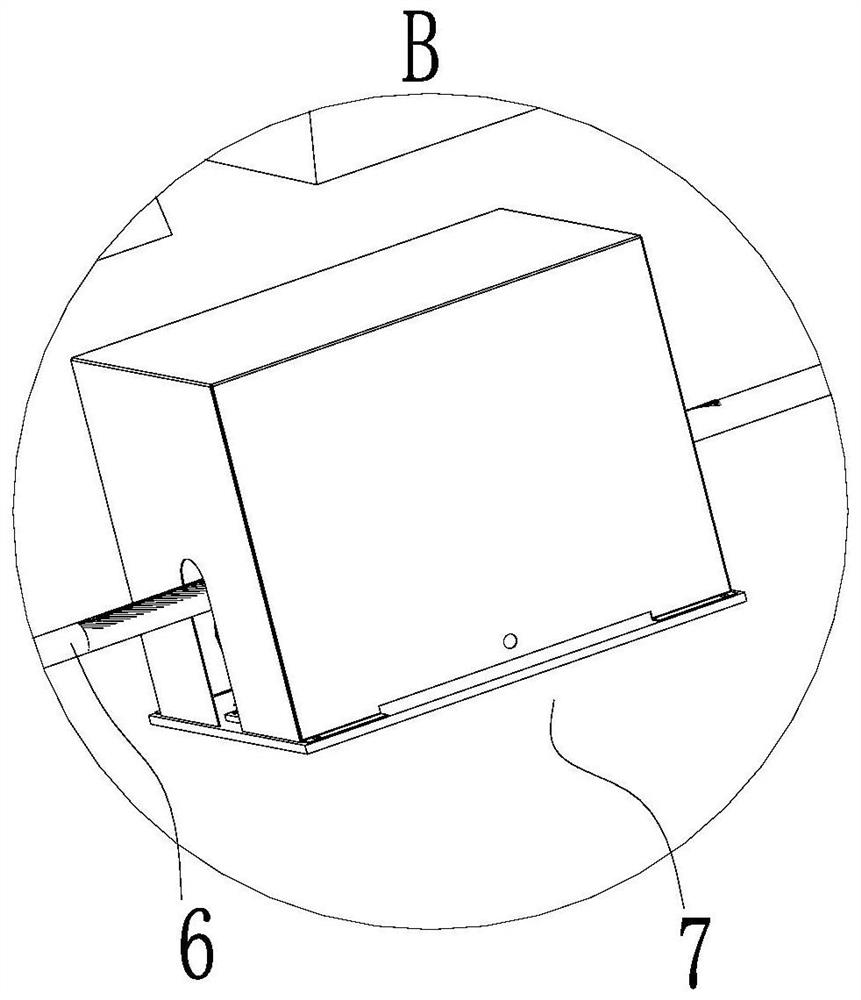

[0062] like Figure 1-3 As shown, a precise positioning device for a train loading compartment includes an anti-climbing rail 1, a track scale 2, a compartment 3, a train weighing and overweight detector 4, a winch 5, a steel cable 6, a train loading vehicle position detector 7, and a control unit.

[0063] The control unit in this embodiment adopts PLC, which is an existing technology, and those skilled in the art can program it according to actual needs to realize the control function described in this embodiment.

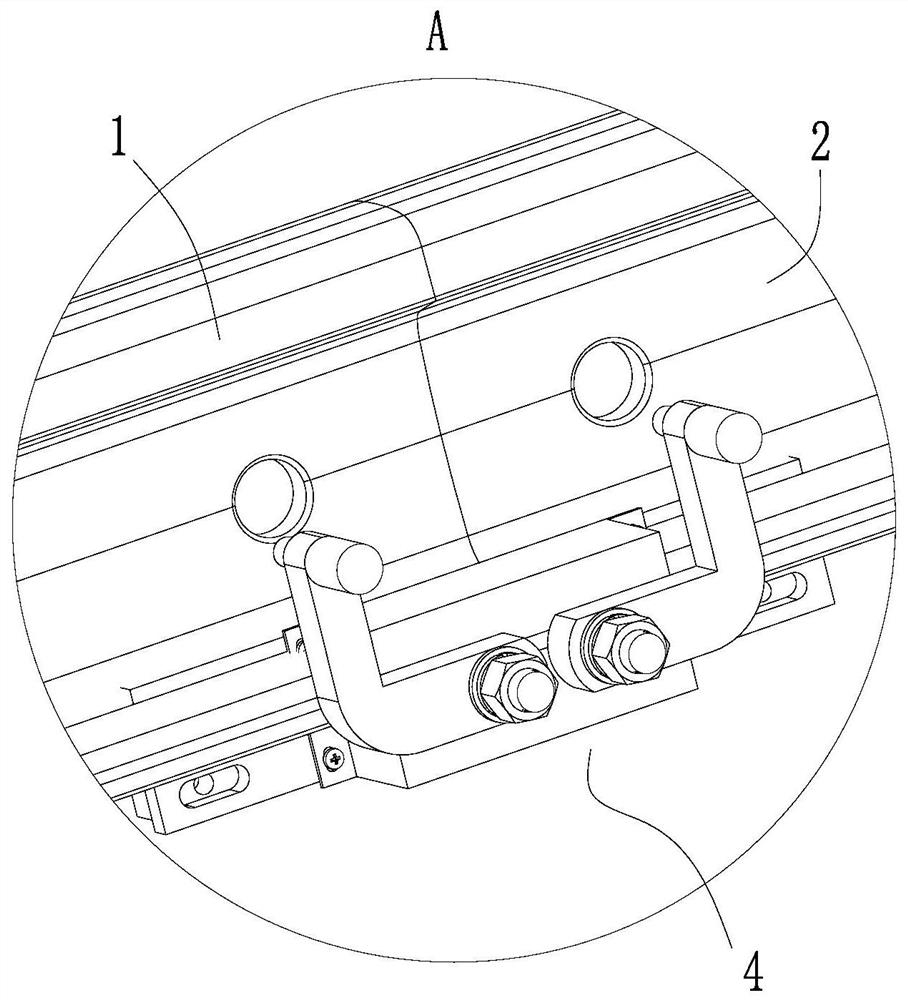

[0064] like figure 1 As shown, the track scale 2 is a static track scale, which is arranged between two sections of anti-climbing rails 1, with the moving direction of the compartment 3 as the front (moving direction during coal loading), and the rear end of the track scale 2 and the anti-climbing rail The inner side of the junction of 1 is provided with a train weighing and weighing detector 4, and the outer side of the junction of the track scale 2 and the an...

Embodiment 2

[0091] This embodiment discloses a positioning method using the above-mentioned precise positioning device for a train loading carriage, comprising the following steps:

[0092] s1. The control unit controls the operation of the winch 5, the winch 5 pulls the steel cable 6 to move, and the steel cable 6 pulls the entire carriage 3 to move;

[0093] s2. When the carriage 3 travels to the track scale 2, the inner flange of the wheel of the carriage 3 is pressed against the movable end of the swing arm 42 to make it swing, the detection sensor 45 detects the swing signal of the swing arm 42, and transmits the signal to the control unit, It means that the carriage 3 starts to travel to the track scale 2, or the signal is detected and fed back through the photoelectric switches on both sides of the carriage 3;

[0094] s3. When the carriage 3 starts to travel to the rail scale 2, the detection value of the train loading vehicle position detector 7 is defined as the zero position of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com