Application of welding preheating device

A technology of preheating device and heating sheet, which is applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of poor control of preheating time or temperature, and achieve convenient operation, stable adjustment and positioning, and fruitful results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

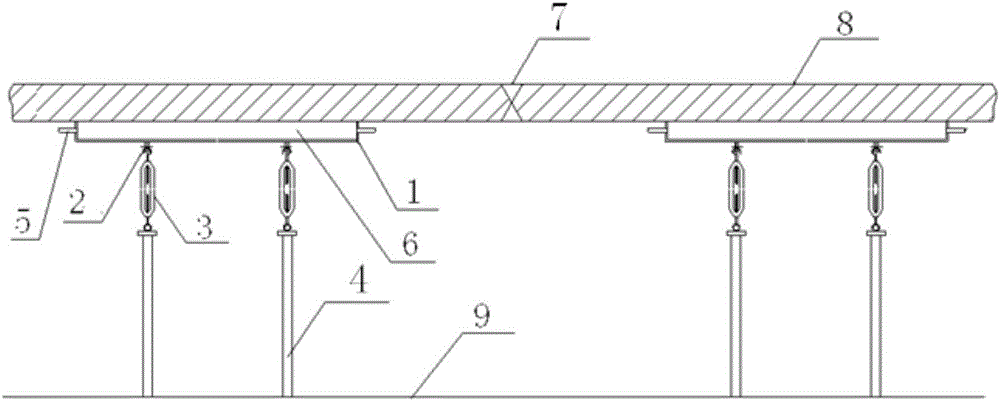

[0032] The application of a welding preheating device in this example includes a body, the body includes a positioning mechanism and a preheating mechanism, and an adjustment mechanism, the positioning mechanism is arranged under the side of the weld 7, and the preheating mechanism is arranged at the bottom near the weld 7 On the end face, the adjustment mechanism is connected between the positioning mechanism and the preheating mechanism to adjust the compression degree of the preheating mechanism and the bottom end surface of the weld 7; figure 1 As shown, in this embodiment, there are two sets of bodies, and each set of bodies has two adjustment mechanisms and positioning mechanisms. The adjustment mechanism is a turnbuckle 3, and the positioning mechanism is a support seat 4 with a T-shaped cross section, which is welded by steel plates and steel pipes. (welding foot size 5mm), the steel plate is a circular plate with a diameter of 100mm, the steel pipe diameter is 89mm, an...

Embodiment 2

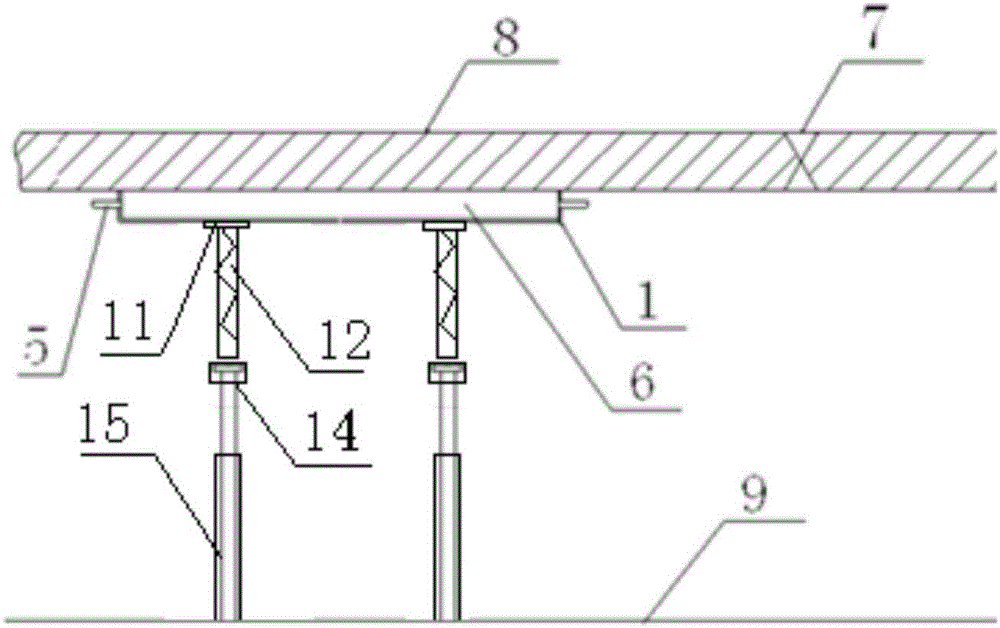

[0039] The application of a welding preheating device in this example includes a body, the body includes a positioning mechanism and a preheating mechanism, and an adjustment mechanism, the positioning mechanism is arranged under the side of the weld 7, and the preheating mechanism is arranged at the bottom near the weld 7 On the end face, the adjustment mechanism is connected between the positioning mechanism and the preheating mechanism to adjust the compression degree of the preheating mechanism and the bottom end surface of the weld 7; figure 2 As shown, in this embodiment, the adjustment mechanism is a spring 12, the positioning mechanism is a nut barrel 15 fixed on the assembly platform 9 at the bottom end and a bolt 14 that is connected with the nut barrel 15, and the top end of the spring 12 is supported on the preset position by the top piece 11. The bottom surface of the thermal mechanism; the hexagonal head of the bolt 14 is fixedly connected with the bottom end of ...

Embodiment 3

[0042] A flatness measuring device in this example has the same basic structure as that in Embodiment 2. In order to prevent the risk of electric shock when the operator operates, a layer of insulation and heat preservation is laid on the bottom of the heating sheet mold 1, one is to reduce the risk of electric shock It can also play a role in preventing waste of heat source.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com